Atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace and working method thereof

A sintering furnace and dual temperature control technology, applied in the field of ceramsite sintering, can solve the problems of complex structure and inability to effectively control the atmosphere in the furnace, and achieve the effect of avoiding re-oxidation and avoiding sudden temperature drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

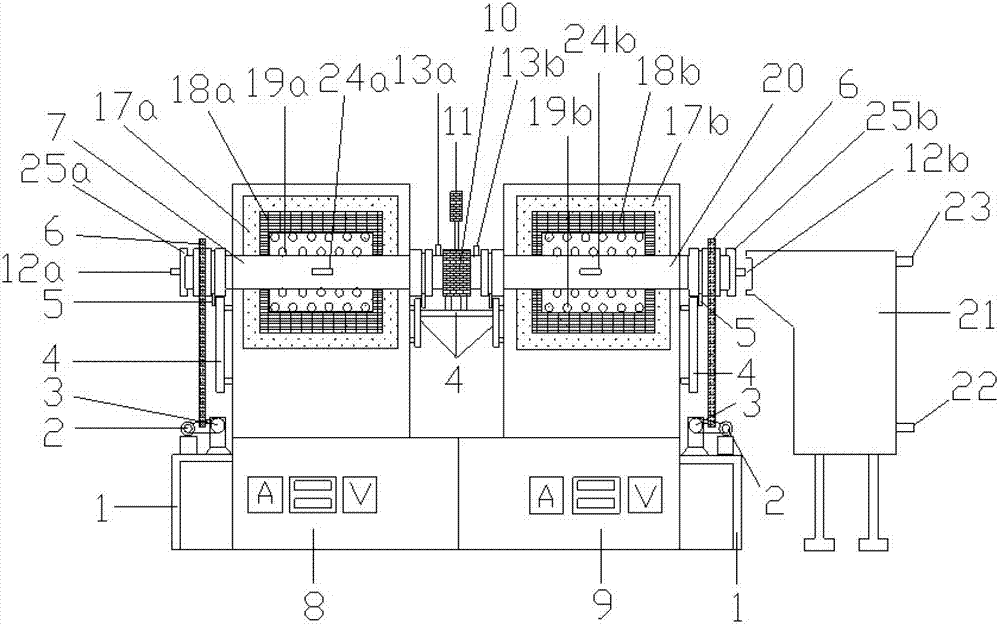

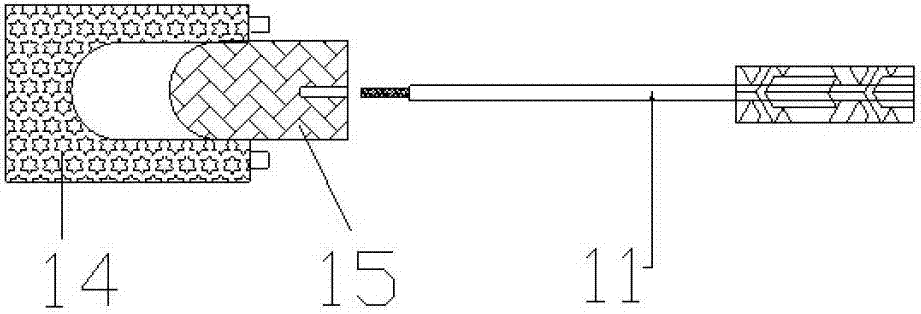

[0040]An atmosphere-adjustable double-temperature-control composite ceramsite sintering rotary furnace, comprising a preheating furnace tube 7, a reducer 2, a bottom bracket 1, a segmented partition 10 and a sintering furnace tube 20, the preheating furnace tube 7 Heaters are respectively provided on the outer layer of the sintering furnace tube 20 ; thermocouples are provided inside the preheating furnace tube 7 and the sintering furnace tube 20 .

[0041] The heater 19a arranged on the outer layer of the preheating furnace tube 7 and the thermocouple 24a arranged in the preheating furnace tube are respectively connected to the automatic temperature controller 8 of the preheating furnace tube; the heater 19b arranged on the outer layer of the sintering furnace tube 20 and the thermocouple 24b set in the sintering furnace tube are respectively connected to the automatic temperature controller of the sintering furnace 9; a total of two reducers are provided corresponding to the ...

Embodiment 2

[0046] Example 2: The working method of the atmosphere adjustable double temperature control composite ceramsite sintering rotary kiln

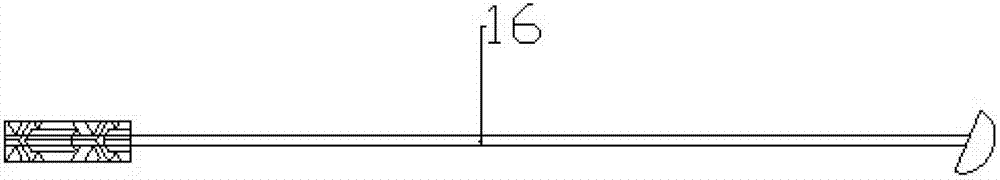

[0047] Using the atmosphere adjustable double temperature control composite ceramsite sintering rotary kiln of embodiment 1, the raw ceramsite (such as Figure 4 the left picture of Figure 5 ) and sintered according to the following steps.

[0048] 1) Set the preheating temperature of the preheating furnace tube to 350°C-450°C and the sintering temperature of the sintering furnace tube to 950°C-1050°C respectively through the preheating automatic temperature controller and the sintering automatic temperature controller;

[0049] 2) Turn on the chain linkage control switch to make the preheating furnace tube and sintering furnace tube rotate at the same time;

[0050] 3) Open the air inlets of the preheating furnace tube and the sintering furnace tube, and feed N 2 Gas, to maintain an oxygen-poor environment in the furnace;

[0051] 4) Op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com