Low-temperature-resistant compound fertilizer absorbed by stages and preparation method of low-temperature-resistant compound fertilizer

A compound fertilizer and low-temperature-resistant technology, which is applied in the cross field of chemicals and agricultural fertilizers, can solve the problems of affecting the absorption of fertilizers by plants, the occurrence of frozen soil, and volatilization loss, so as to reduce the freezing point, prevent sudden temperature drops, and promote absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

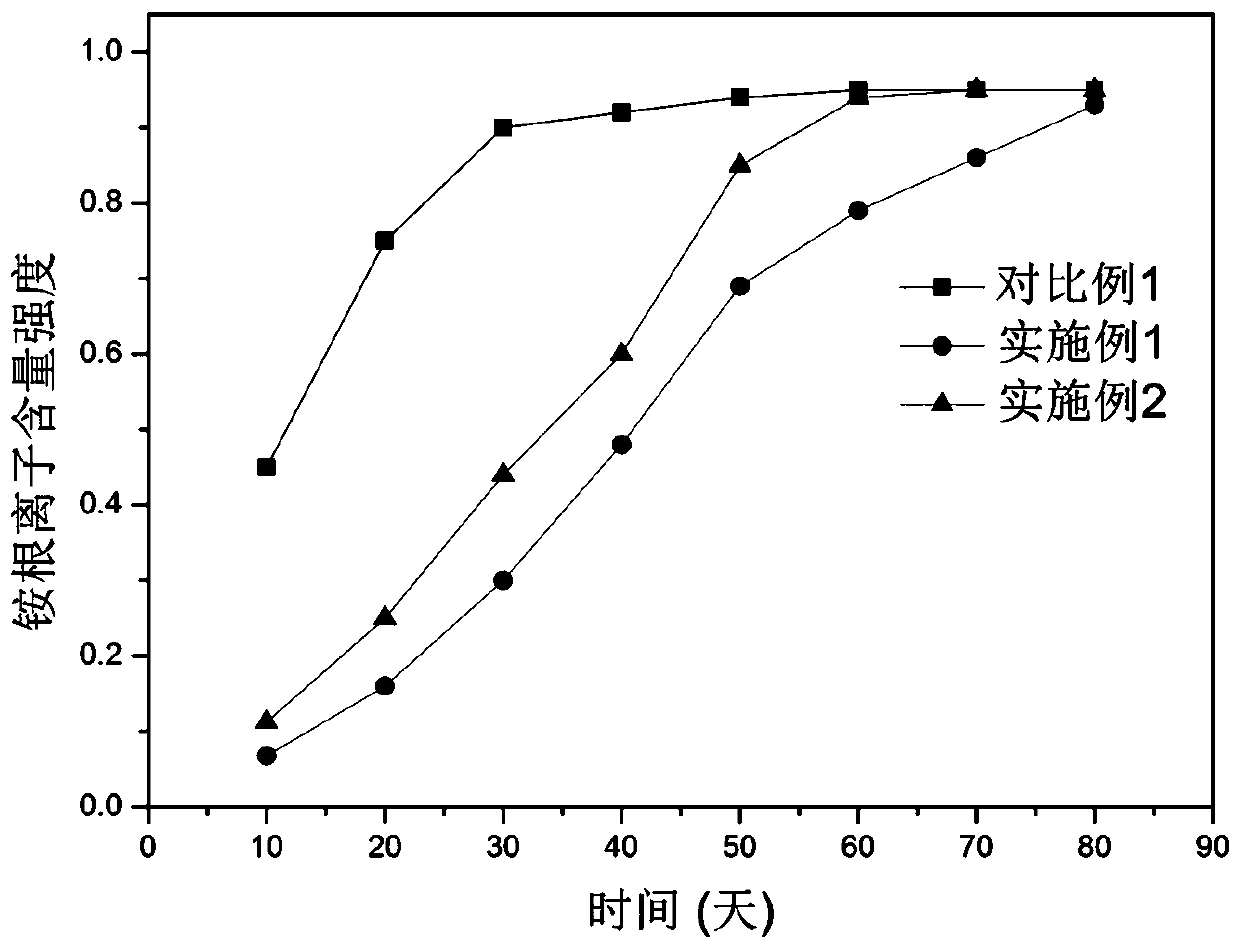

Embodiment 1

[0042] This embodiment provides a low temperature-resistant and segmented absorption compound fertilizer and its preparation method, specifically:

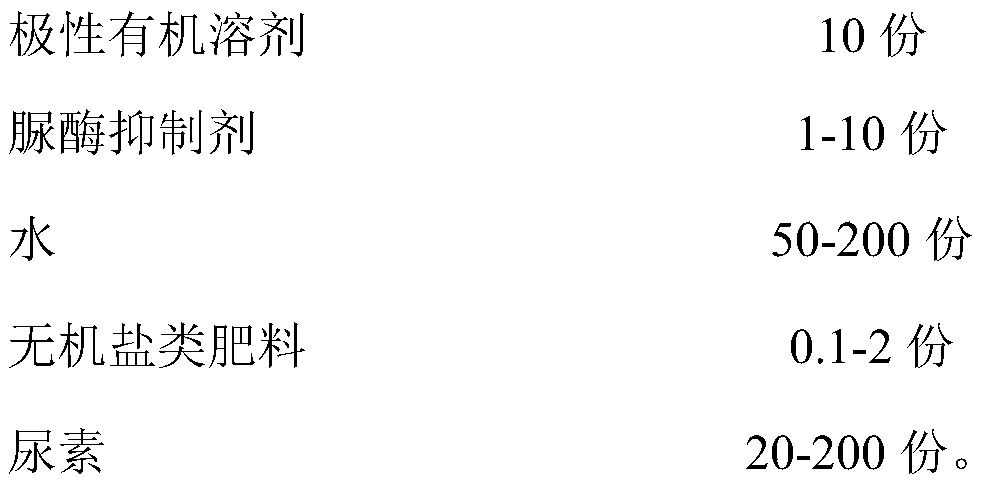

[0043] Described compound fertilizer is made up of polar organic solvent, urease inhibitor, water, inorganic salt fertilizer and urea,

[0044] Wherein, the polar organic solvent in the compound fertilizer is dimethylsulfoxide (DMSO), and the number of additions is 10kg;

[0045] The urease inhibitor is n-butylthiophosphoric triamide (NBPT) in the phosphate amine compound, and the number of added parts is 5kg;

[0046] The inorganic salt fertilizers are zinc sulfate, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate, and borax, and the added parts are 0.2kg respectively;

[0047] The amount of water added is 100kg

[0048] The number of additions of the urea is 100kg.

[0049] The preparation method comprises the following specific steps:

[0050] (1) Step 1: according to the above parts by weight, take resp...

Embodiment 2

[0057] This embodiment provides a low temperature-resistant and segmented absorption compound fertilizer and its preparation method, specifically:

[0058] Described compound fertilizer is made up of polar organic solvent, urease inhibitor, water, inorganic salt fertilizer and urea,

[0059] Wherein, the polar organic solvent in the compound fertilizer is dimethylsulfoxide (DMSO), and the number of additions is 10kg;

[0060] The urease inhibitor is phenylphosphoric diamide (PPD) in the phosphate amine compound, and the number of added parts is 5kg;

[0061] The inorganic salt fertilizers are zinc sulfate, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate, and borax, and the added parts are 0.2kg respectively;

[0062] The amount of water added is 100kg

[0063] The number of additions of the urea is 100kg.

[0064] The preparation method comprises the following specific steps:

[0065] (1) Step 1: according to the above-mentioned parts by weight, take...

Embodiment 3

[0072] This embodiment provides a low temperature-resistant and segmented absorption compound fertilizer and its preparation method, specifically:

[0073] Described compound fertilizer is made up of polar organic solvent, urease inhibitor, water, inorganic salt fertilizer and urea,

[0074] Wherein, the polar organic solvent in the compound fertilizer is trifluoroacetic acid, and the number of additions is 10kg;

[0075] The urease inhibitor is n-butylthiophosphoric triamide (NBPT) in the phosphate amine compound, and the number of added parts is 5kg;

[0076] The inorganic salt fertilizers are zinc sulfate, ammonium molybdate, manganese sulfate, ferrous sulfate, copper sulfate, and borax, and the added parts are 0.2kg respectively;

[0077] The amount of water added is 100kg

[0078] The number of additions of the urea is 100kg.

[0079] The preparation method comprises the following specific steps:

[0080] (1) Step 1: according to the above-mentioned parts by weight, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com