Melting treatment system for waste incineration fly ash

A waste incineration fly ash and processing system technology, which is applied in the field of waste incineration fly ash fusion processing system, can solve the problems of secondary fly ash pollution, weakening of combustion intensity, and slagging at the slag mouth, so as to avoid secondary pollution and save energy. Water resources, the effect of preventing slagging and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further elaborated below in conjunction with the accompanying drawings.

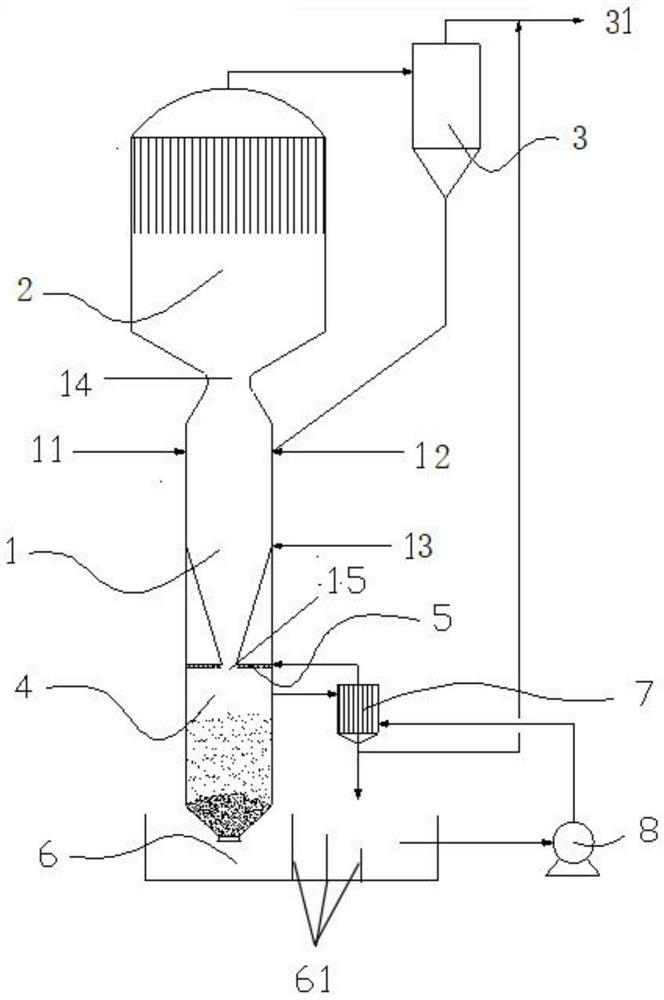

[0030] In this example, if figure 1 As shown, the waste incineration fly ash melting treatment system includes a circulating swirling combustion melting system and a slag quenching water circulation system.

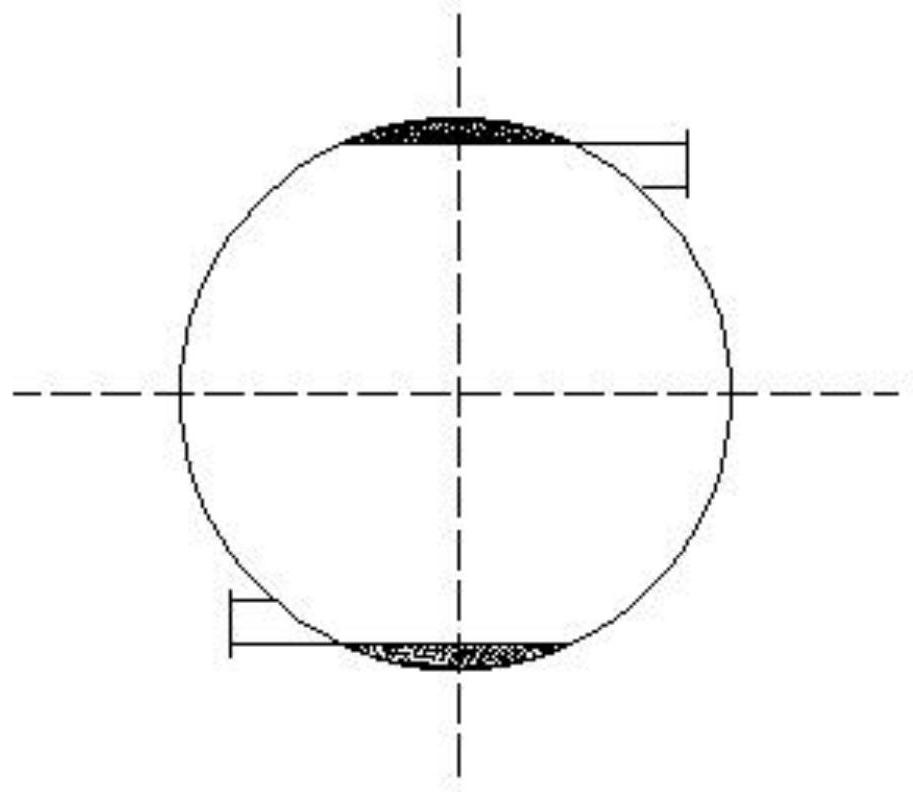

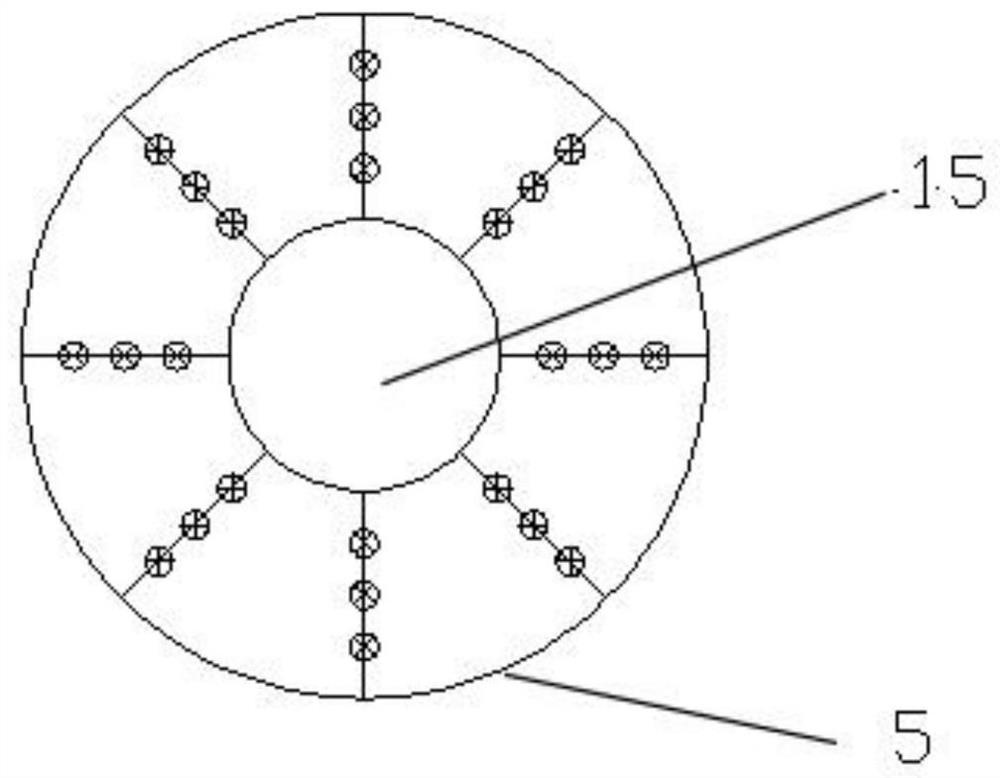

[0031] The circulating swirling combustion melting system includes a combustion melting chamber 1, a flue gas cooling chamber 2, and an ash trapping chamber 3. The top of the ash trapping chamber 3 is provided with a gas outlet 31; the combustion melting chamber 1 is a swirling combustion melting chamber, and the combustion dust particles Outward swirling flow, flue gas forms internal swirling flow, the upper part of the combustion melting chamber 1 is a hollow cylinder, the upper part of the cylindrical cylinder is tangentially provided with a primary auxiliary fuel inlet 11, fly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com