Base rubber material of a shock-isolation bearing and preparation method thereof

A vibration isolation bearing and rubber material technology, applied in the field of rubber materials, can solve the problems of mechanical properties change, reducing the safety and stability of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

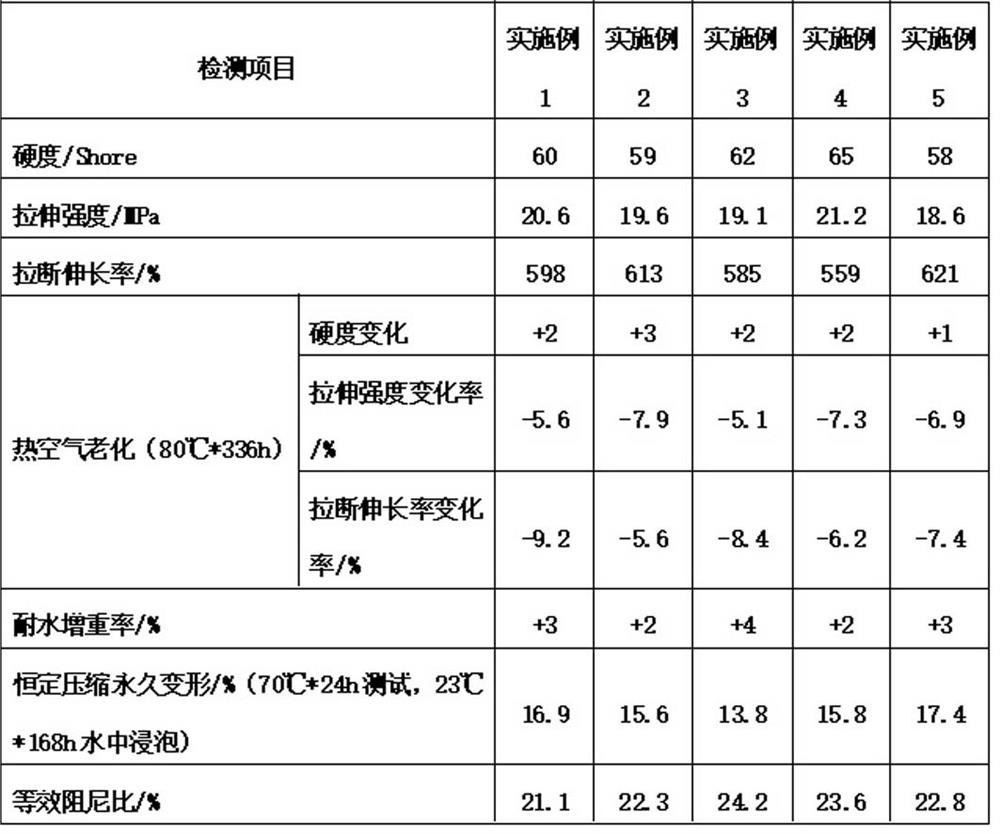

Examples

Embodiment 1

[0041] In the first step, 50 parts by weight of natural rubber, 25 parts by weight of chlorinated polyethylene rubber, and 25 parts by weight of acrylate rubber are added to the internal mixer at a speed of 30 r / min, and mixed for 5 seconds;

[0042] Add 4 parts by weight of active agent, 1 part by weight of antioxidant, 20 parts by weight of carbon black, 20 parts by weight of carbon fiber powder, 10 parts by weight of petroleum resin, and 25 parts by weight of softening agent;

[0043] When the temperature rises to 120°C, add 10 parts by weight of maleic anhydride and 8 parts by weight of initiator, and continue mixing for 30 seconds to debinding;

[0044] The compounded rubber is discharged into the twin-screw extruder through a completely sealed pipeline, and is formed into a sheet by a twin-roller calender. The screw speed of the extruder is 1.5r / min, the sheet output speed of the double-roller calender is 2r / min, the distance between the rollers is 20mm, and the film tem...

Embodiment 2

[0054] In the first step, 90 parts by weight of natural rubber, 5 parts by weight of chlorinated polyethylene rubber, and 5 parts by weight of acrylate rubber are added to the internal mixer at a speed of 70 r / min, and mixed for 120 s;

[0055] Add 8 parts by weight of active agent, 3 parts by weight of antioxidant, 70 parts by weight of carbon black, 5 parts by weight of carbon fiber powder, 30 parts by weight of petroleum resin, and 5 parts by weight of softening agent;

[0056] When the temperature rises to 150°C, add parts by weight of maleic anhydride and 2 parts by weight of initiator, and continue mixing for 90s to debinding;

[0057] The compounded rubber is discharged into the twin-screw extruder through a completely sealed pipeline, and is formed into a sheet by a twin-roller calender. The screw speed of the extruder is 40r / min, the sheet output speed of the double-roller calender is 40r / min, the distance between the rollers is 2mm, and the temperature of the film is...

Embodiment 3

[0067] In the first step, 70 parts by weight of natural rubber, 15 parts by weight of chlorinated polyethylene rubber, and 15 parts by weight of acrylic ester rubber are added to the internal mixer at a speed of 50 r / min, and mixed for 60 seconds;

[0068] Add 6 parts by weight of active agent, 2 parts by weight of antioxidant, 50 parts by weight of carbon black, 10 parts by weight of carbon fiber powder, 20 parts by weight of petroleum resin, and 15 parts by weight of softener. When the temperature rises to 140 ° C, add 6 parts by weight of Malay Anhydride and 5 parts by weight initiator, continue mixing 60s debinding;

[0069] The compounded rubber is discharged into the twin-screw extruder through a completely sealed pipeline, and is formed into a sheet by a twin-roller calender. The screw speed of the extruder is 10r / min, the sheet output speed of the double-roller calender is 10r / min, the distance between the rollers is 15mm, and the temperature of the film is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com