Diffusion welding method of copper target material and back plate

A technology of diffusion welding and back plate, which is applied in the welding of target components and the diffusion welding of copper target and back plate, which can solve the problems of porosity, weld seam and coarse grains on the edge of copper target , poor welding effect and other problems, to avoid abnormal grain growth, good thermal conductivity, and ensure the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

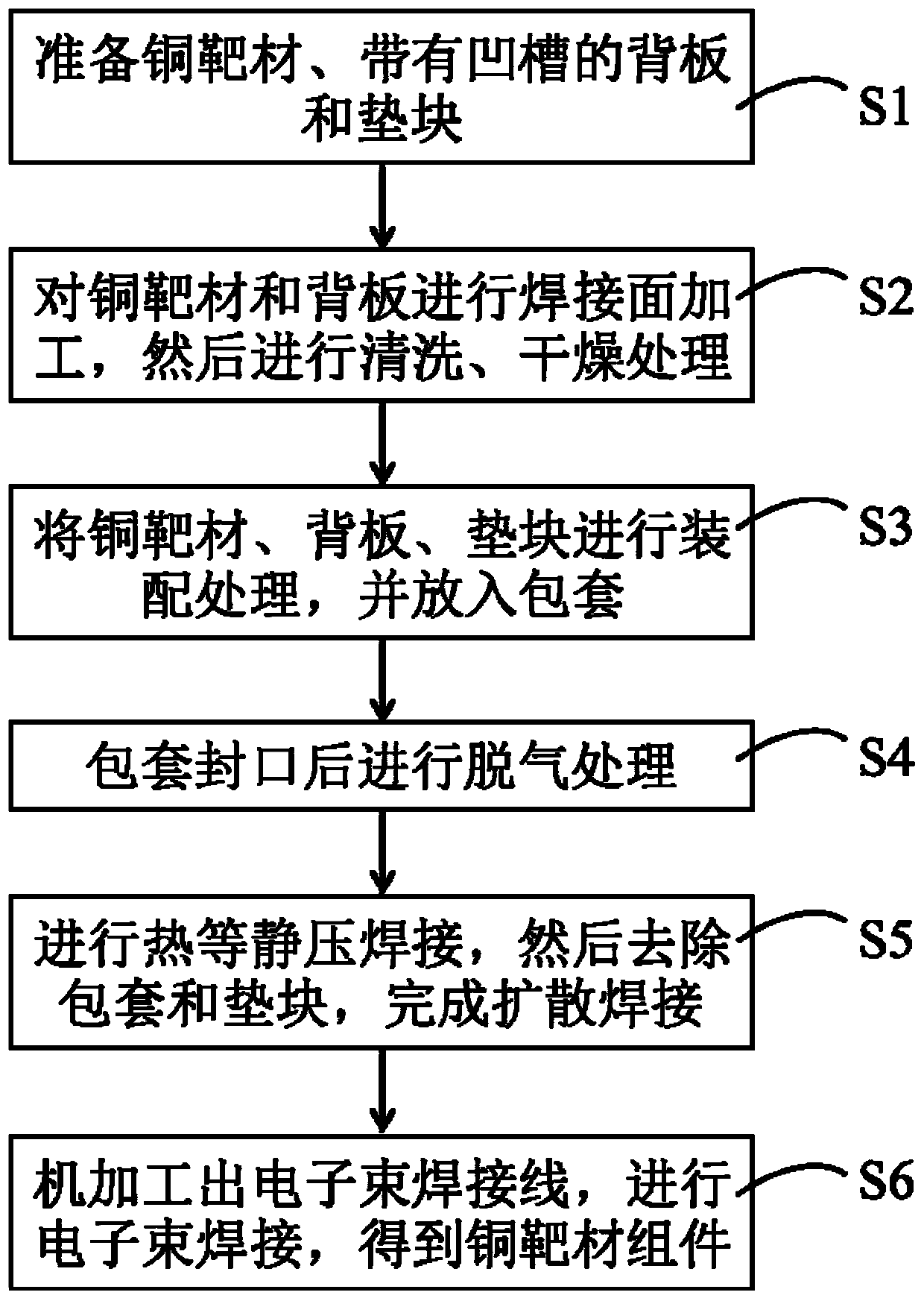

[0101] This embodiment provides a diffusion welding method of a copper target and a back plate, the diffusion welding method comprising the following steps:

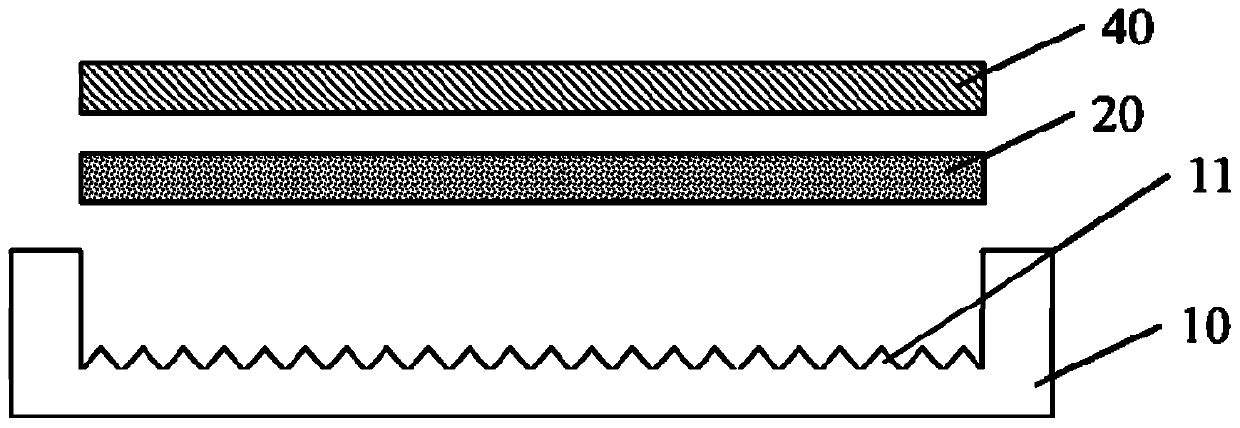

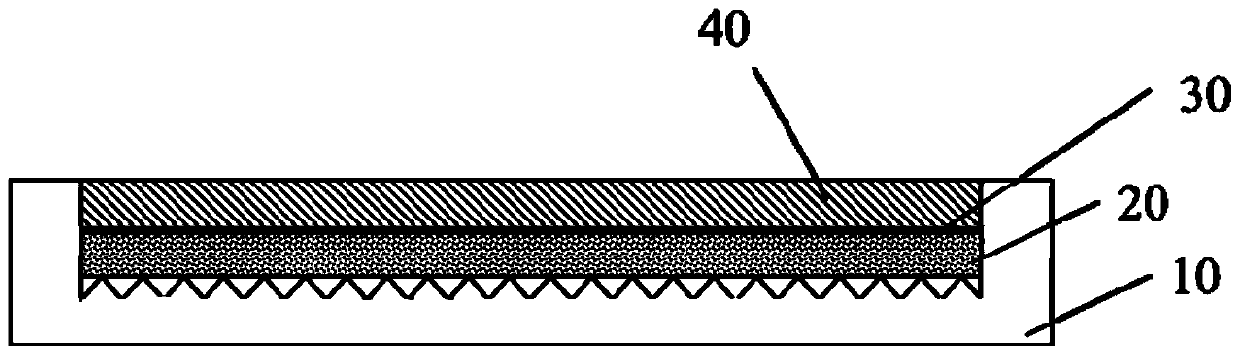

[0102] (1) Prepare copper target material 20, C18000 back plate 10 and stainless steel pad 40 with grooves, wherein the area of the copper target material 20 and stainless steel pad 40 is equal to the bottom area of the back plate groove; The welding surface of the copper target is turned and smoothed with a diamond blade, and the welding surface of the back plate is turned and threaded. The protrusion of the thread is called a thread, and the distance between adjacent threads in the thread is 0.45mm , the height of the thread is 0.15mm;

[0103] (2) Clean and dry the copper target 20 obtained in step (1) and the C18000 back plate 10 with grooves, wherein the IPA cleaning solution is used for ultrasonic cleaning for 10 minutes, and then vacuumed at a vacuum degree of 0.005 Pa. Dry for 50 minutes, and then put the co...

Embodiment 2

[0111] This embodiment provides a method for diffusion welding of a copper target and a back plate, changing the thread size in step (1) to "wherein the distance between adjacent threads in the thread is 0.3mm, the height of the thread Be 0.05mm ", other conditions and embodiment 1 are exactly the same.

[0112] The copper target assembly obtained by the diffusion welding method of this embodiment has a high degree of bonding between the copper target and the back plate, and there is no abnormal grain growth. The enlarged view of the edge of the copper target is similar to that of Example 1; In addition, the obtained copper target assembly can ensure the uniformity of the coated film during the sputtering process.

Embodiment 3

[0114] This embodiment provides a method for diffusion welding of a copper target and a back plate, changing the thread size in step (1) to "wherein the distance between adjacent threads in the thread is 0.6mm, the height of the thread Be 0.25mm ", other conditions and embodiment 1 are identical.

[0115] The copper target assembly obtained by the diffusion welding method of this embodiment has a high degree of bonding between the copper target and the back plate, and there is no abnormal grain growth. The enlarged view of the edge of the copper target is similar to that of Example 1; In addition, the obtained copper target assembly can ensure the uniformity of the coated film during the sputtering process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com