Low-corrosivity soldering flux

A flux and corrosive technology, applied in the field of low corrosive flux, can solve the problems of affecting the welding quality and the high corrosiveness of the welded material, and achieve the effect of improving the welding effect, reducing the corrosiveness and reducing the acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

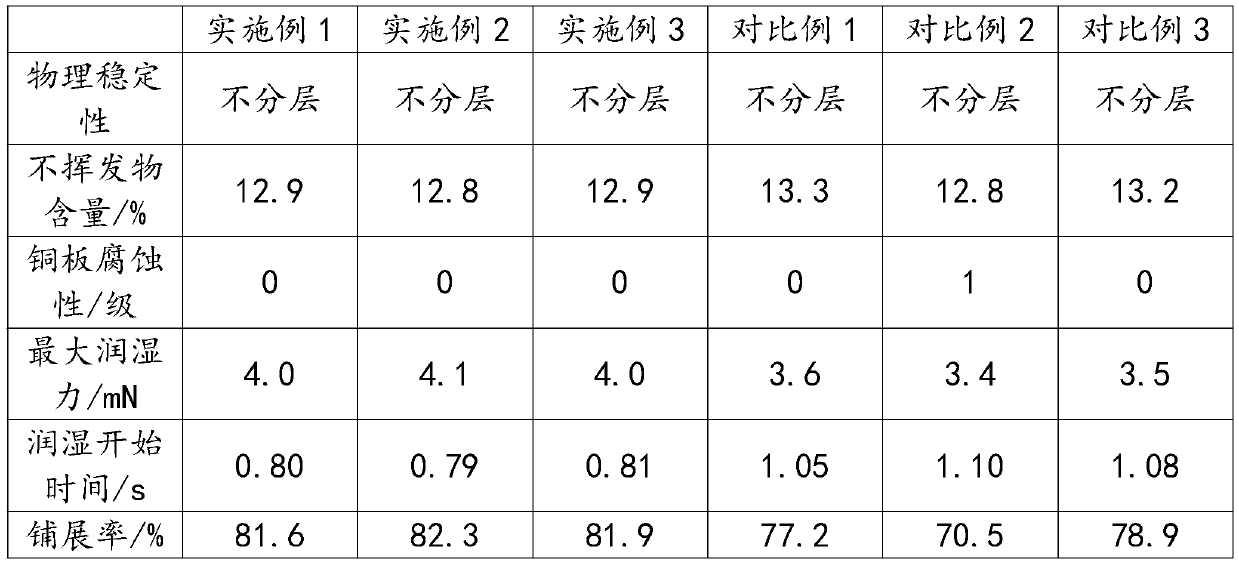

Examples

Embodiment 1

[0043] A low-corrosion soldering flux, made of the following raw materials by weight: 35 parts of modified rosin, 7 parts of activator, 4 parts of thixotropic agent, 0.8 part of surfactant, 1.2 parts of other additives, 30 parts of solvent;

[0044] The flux is made by the following steps:

[0045] Step S1, adding modified rosin to the solvent, heating to 100°C and stirring evenly to fully dissolve the modified rosin to obtain a premix;

[0046] Step S2, keep the temperature constant, add the activator to the premix under constant stirring at 150r / min, and continue stirring for 15min after the addition;

[0047] Step S3, cooling the above mixture to 65°C, stirring at a constant speed of 150r / min, adding thixotropic agent, surfactant and other additives in turn, and continuing to stir for 15min after adding;

[0048] Step S4, stop heating, after the product is cooled down to room temperature, grind twice to prepare flux.

Embodiment 2

[0050] A low-corrosion soldering flux, made of the following raw materials by weight: 40 parts of modified rosin, 8 parts of activator, 4.5 parts of thixotropic agent, 0.9 part of surfactant, 1.3 parts of other additives, 35 parts of solvent;

[0051] The flux is made by the following steps:

[0052] Step S1, adding modified rosin to the solvent, heating to 100°C and stirring evenly to fully dissolve the modified rosin to obtain a premix;

[0053] Step S2, keep the temperature constant, add the activator to the premix under constant stirring at 150r / min, and continue stirring for 18min after the addition;

[0054] Step S3, cooling the above mixture to 65°C, stirring at a constant speed of 150r / min, adding thixotropic agent, surfactant and other additives in turn, and continuing to stir for 18min after the addition;

[0055] Step S4, stop heating, after the product is cooled down to room temperature, grind 3 times to prepare flux.

Embodiment 3

[0057] A low-corrosion soldering flux, made of the following raw materials in parts by weight: 45 parts of modified rosin, 9 parts of activator, 5 parts of thixotropic agent, 1 part of surfactant, 1.4 parts of other additives, 40 parts of solvent;

[0058] The flux is made by the following steps:

[0059] Step S1, adding modified rosin to the solvent, heating to 100°C and stirring evenly to fully dissolve the modified rosin to obtain a premix;

[0060] Step S2, keep the temperature constant, add the activator to the premix under constant stirring at 150r / min, and continue stirring for 20min after the addition;

[0061] Step S3, cooling the above mixture to 65°C, stirring at a constant speed of 150r / min, adding thixotropic agent, surfactant and other additives in turn, and continuing to stir for 20min after adding;

[0062] Step S4, stop heating, after the product is cooled down to room temperature, grind 3 times to prepare flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com