Patents

Literature

187results about How to "Guaranteed assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

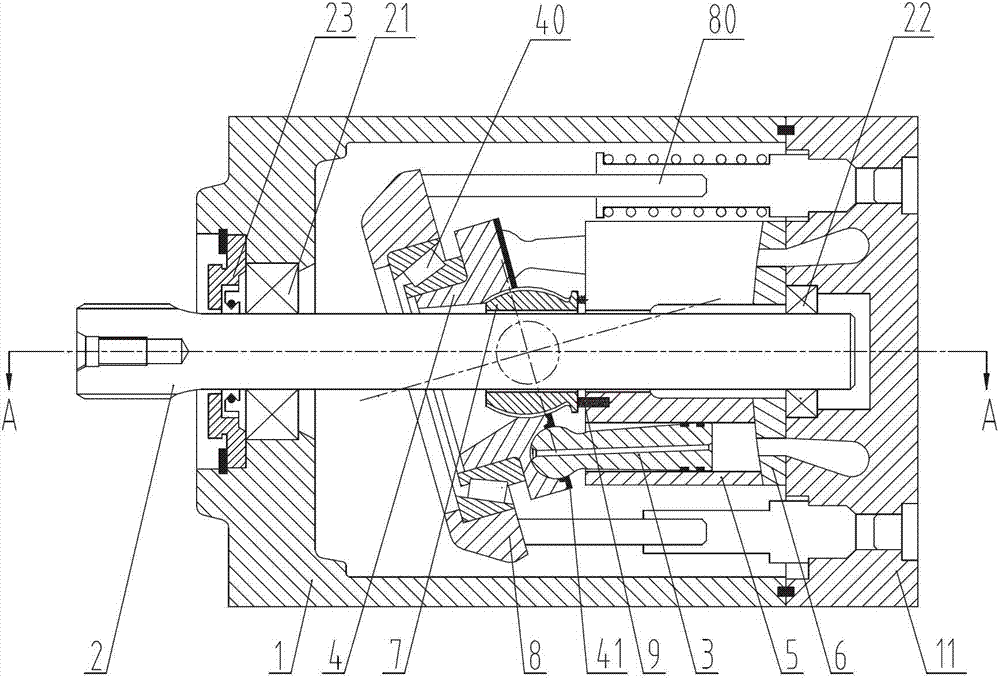

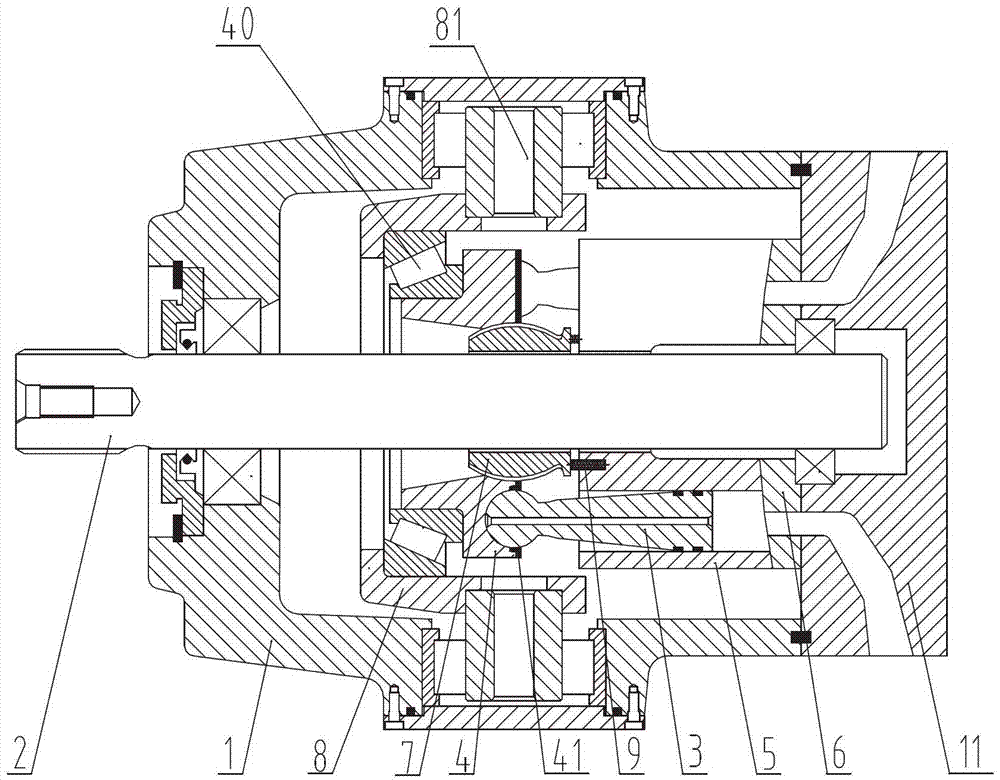

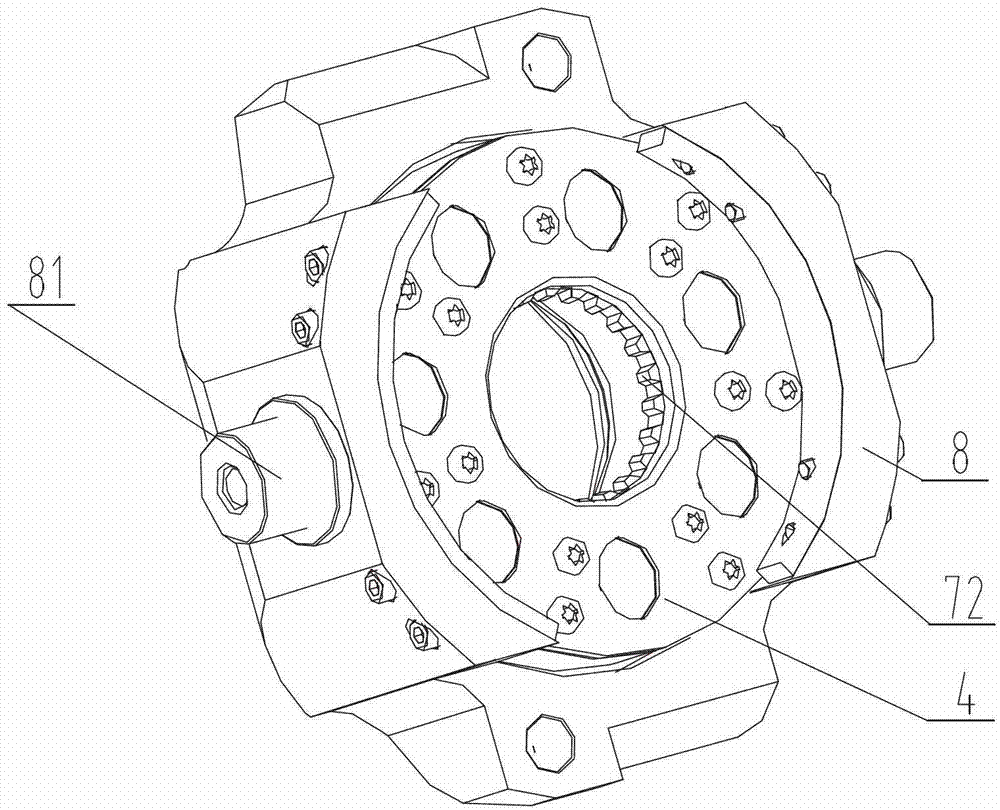

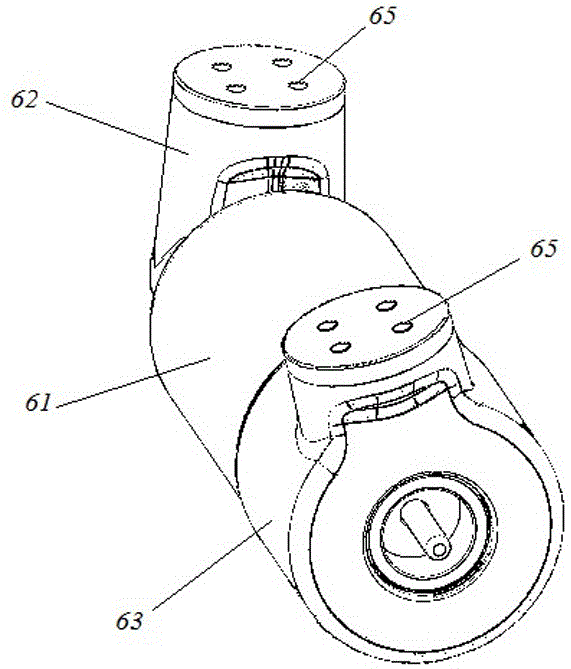

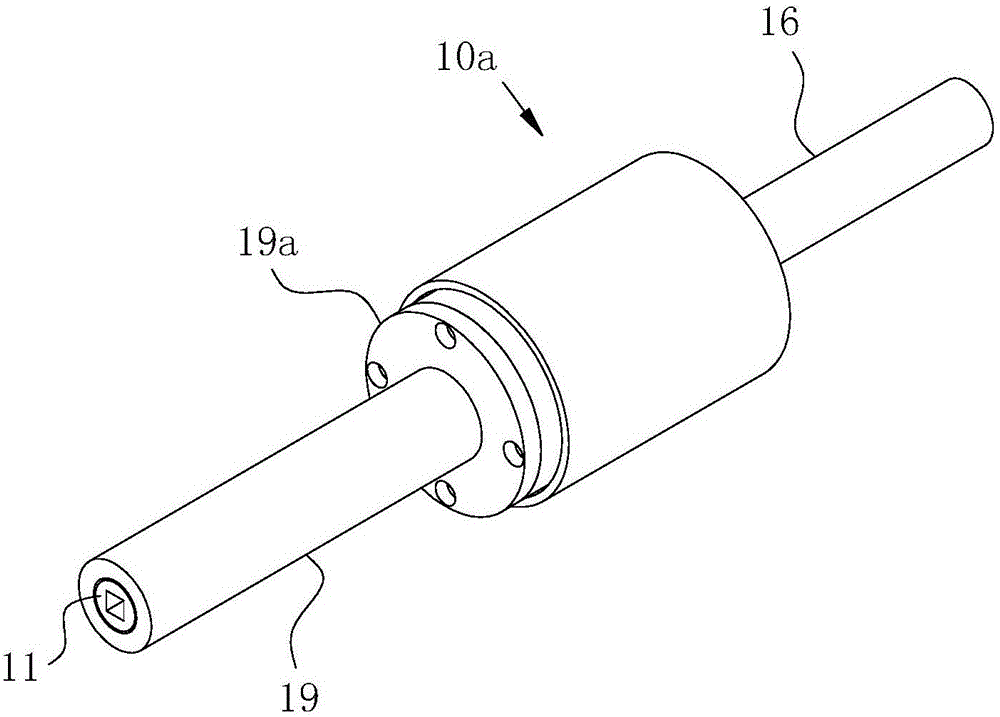

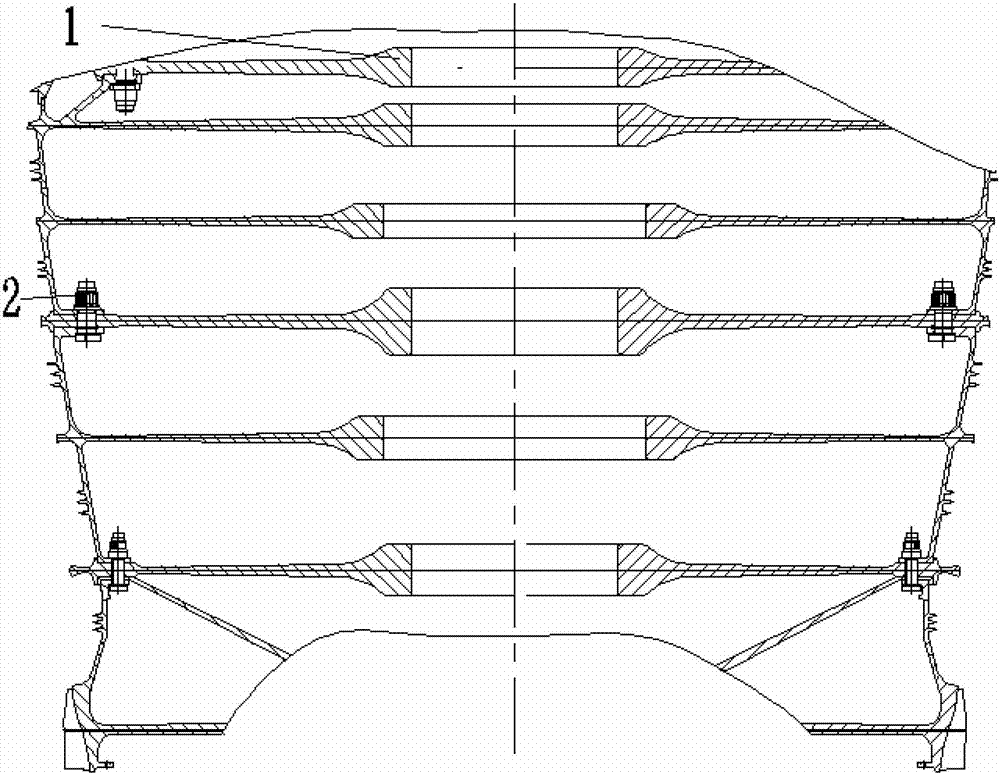

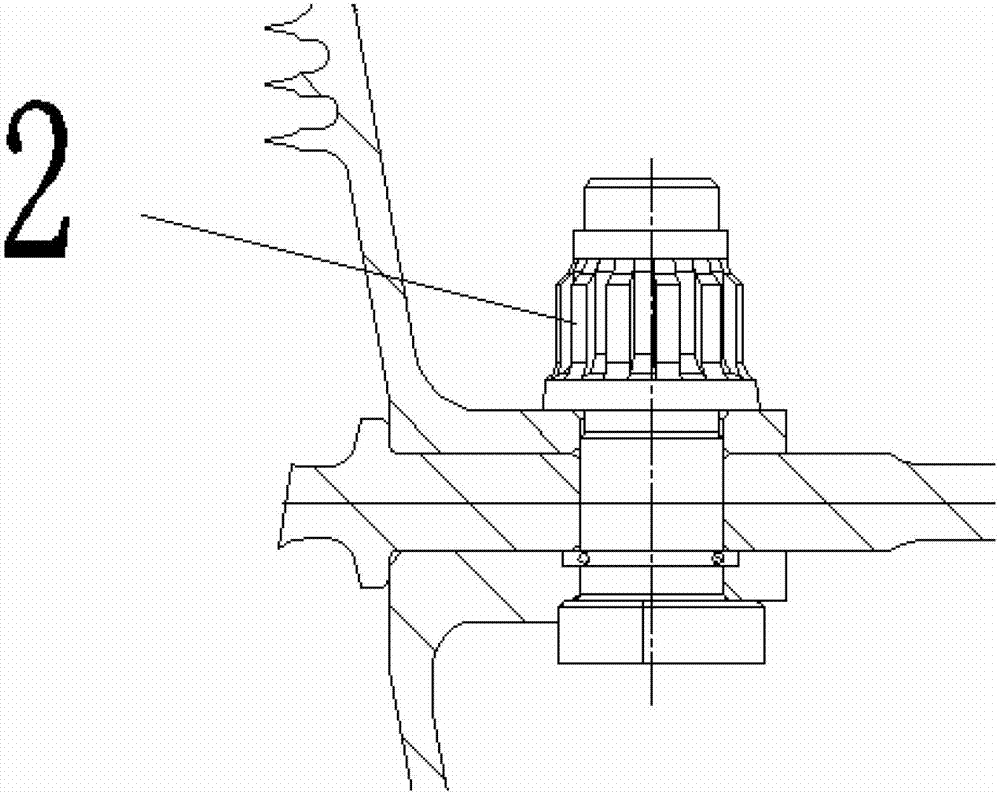

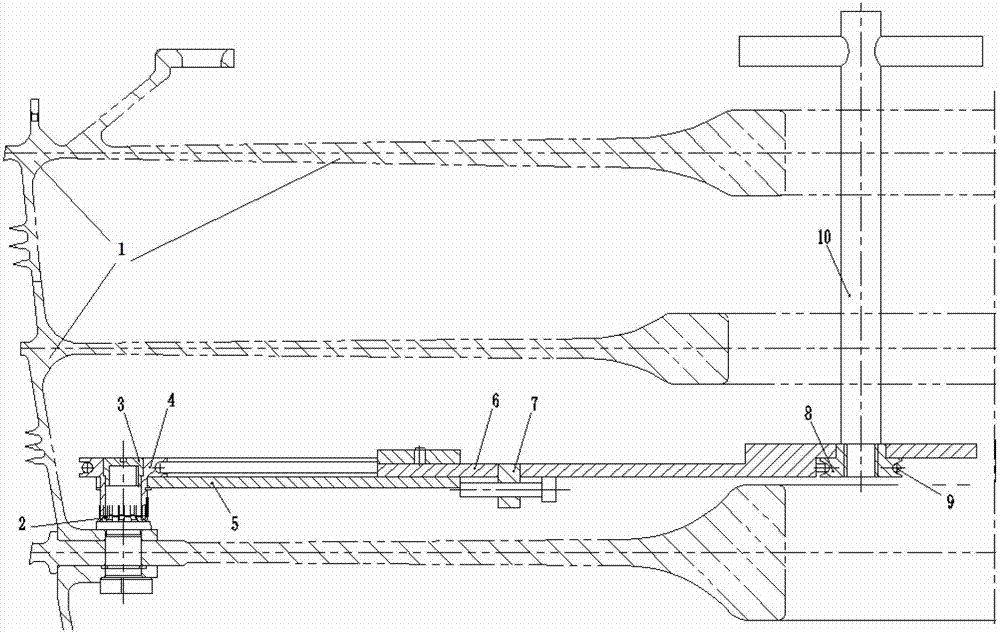

Swash plate type axial piston pump or motor

ActiveCN102926959AReduce Assembly MatesRequirements for lower machining accuracyPositive-displacement liquid enginesMulti-cylinder pumpsPlunger pumpTransmission line

The invention provides a swash plate type axial piston pump or a motor, which comprises a shell, a main shaft, a plurality of piston components, a swash plate, a cylinder, a distributive flow disk and a connecting part, wherein the connecting part comprises a first part and a second part which relatively swing, the first part is combined with the main shaft and synchronously rotates with the main shat, the swash plate is combined with the second part and synchronously rotates with the second part, a cylindrical inner hole is arranged on the center of the cylinder, the main shaft stretches into the cylindrical inner hole, the main shaft and the cylindrical inner hole are matched, and when the main shat rotates, the cylinder is driven by the piston components to rotate. The main shaft and the cylinder of the swash plate type axial piston pump can form clearance fit, the transmission line of the swash plate type axial piston pump is the main shaft, the connecting part, the swash plate, the piston components and the cylinder, and the swash plate type axial piston pump has the advantages of excellent assembly, high total efficiency and small lateral force, and can achieve the advantages of coaxial or through-shaft connection and the like.

Owner:SANY HEAVY IND CO LTD (CN)

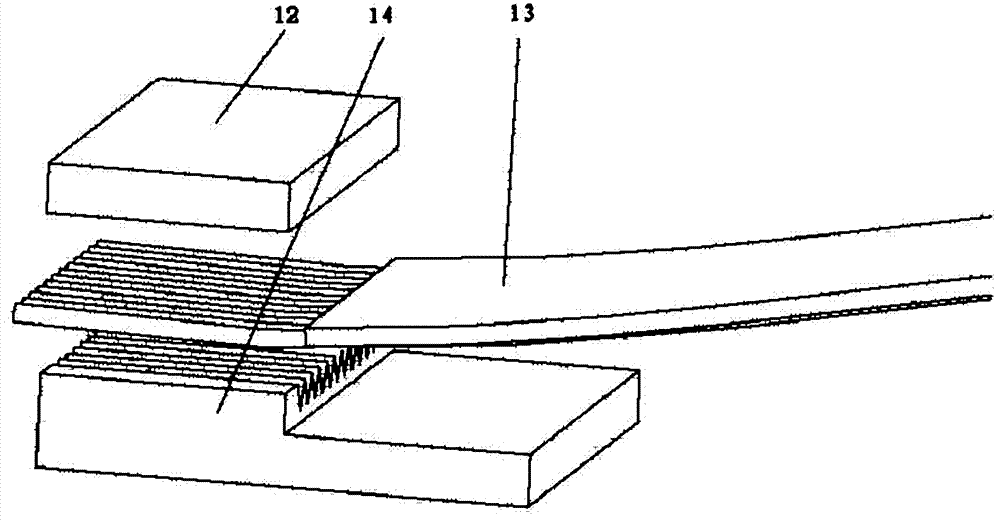

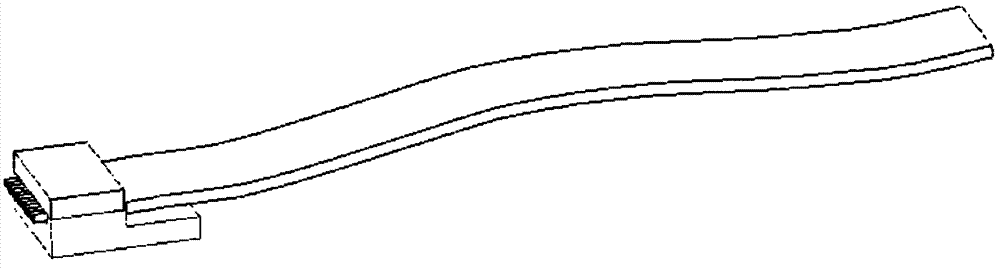

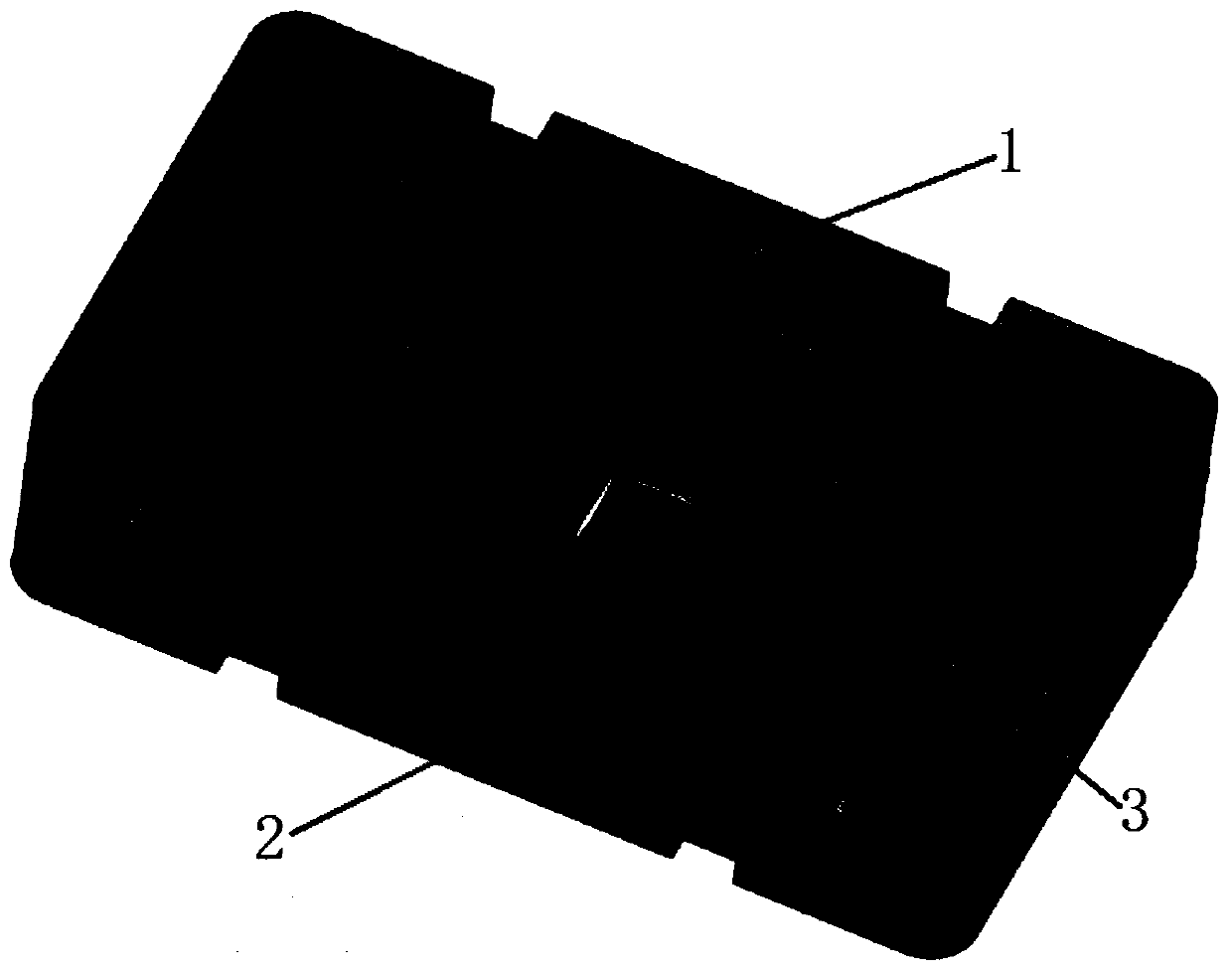

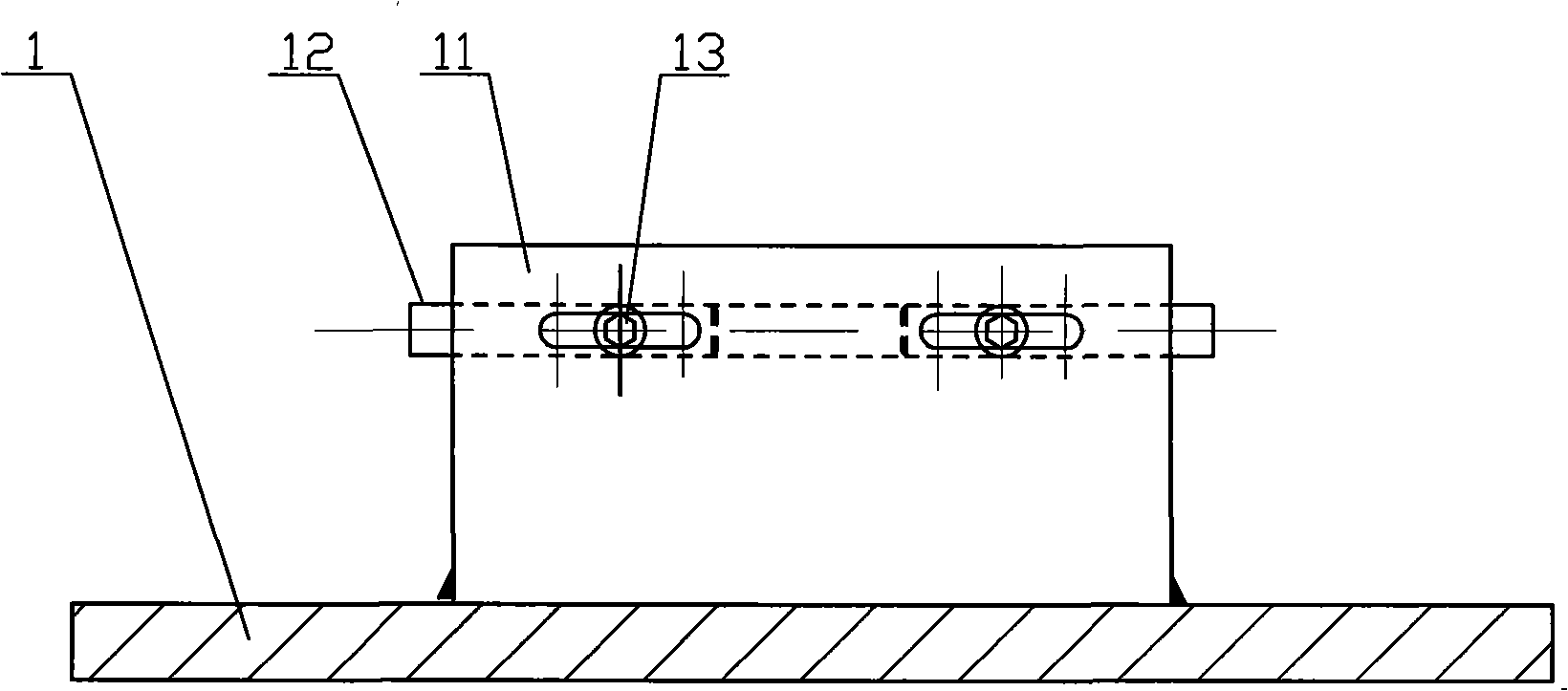

Fiber array board assembly device and fiber array board assembly platform using same

ActiveCN103358249AImprove assembly qualityIncrease profitWork holdersFastening meansFiber arrayMechanical engineering

The invention relates to a fiber array board assembly device and a fiber array board assembly platform using the same. The fiber array board assembly device comprises an L-shaped positioning base and a clamp component. The L-shaped positioning base comprises a side wall and a base. A positioning block is fixedly connected to the inner side of the side wall. A pressure block parallel to the positioning block is also movably connected to the inner side of the side wall. The pressure block can horizontally move along the inner side of the side wall. The inner side of the side wall is further provided with a clamp groove. The base is provided with a through hole. A lifting member and a support member are disposed in the through hole. A U-shaped support is disposed on two side walls of the clamp component. An elastic member is arranged between the bottom of the U-shaped support and the bottom of the clamp component. A glass pressure block is arranged between two ends of the U-shaped support. One end of the clamp component is provided with a protrusion which is clamped in the clamp groove. The lifting member controls the U-shaped support to ascend and descend through the support member.

Owner:广东安捷康光通科技有限公司

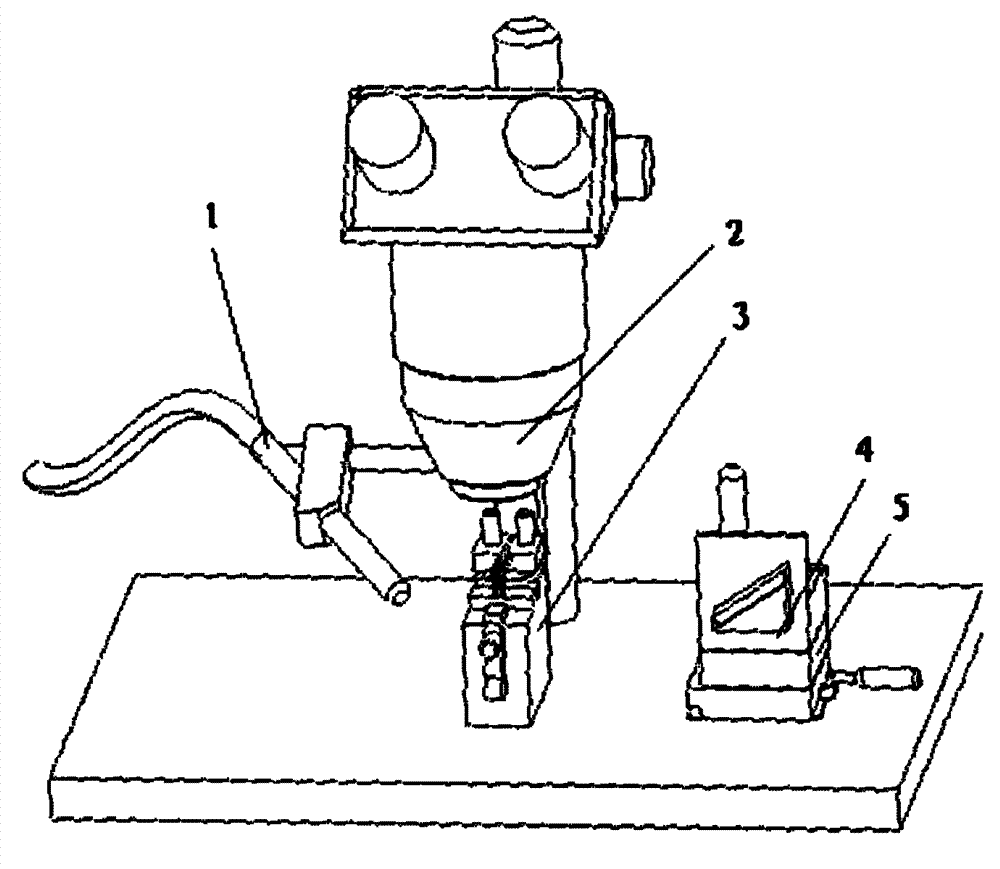

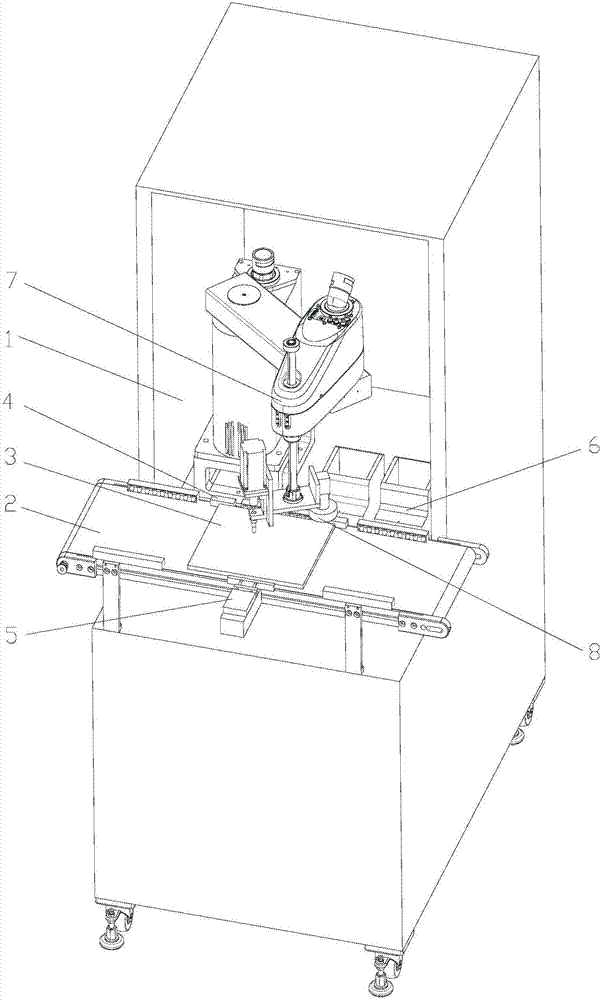

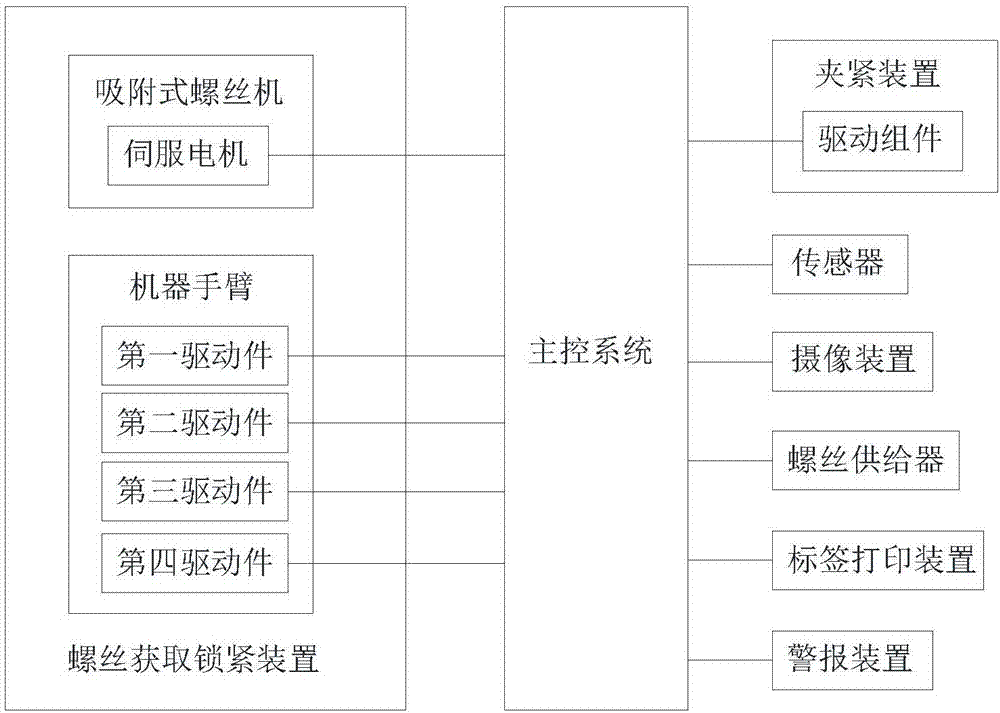

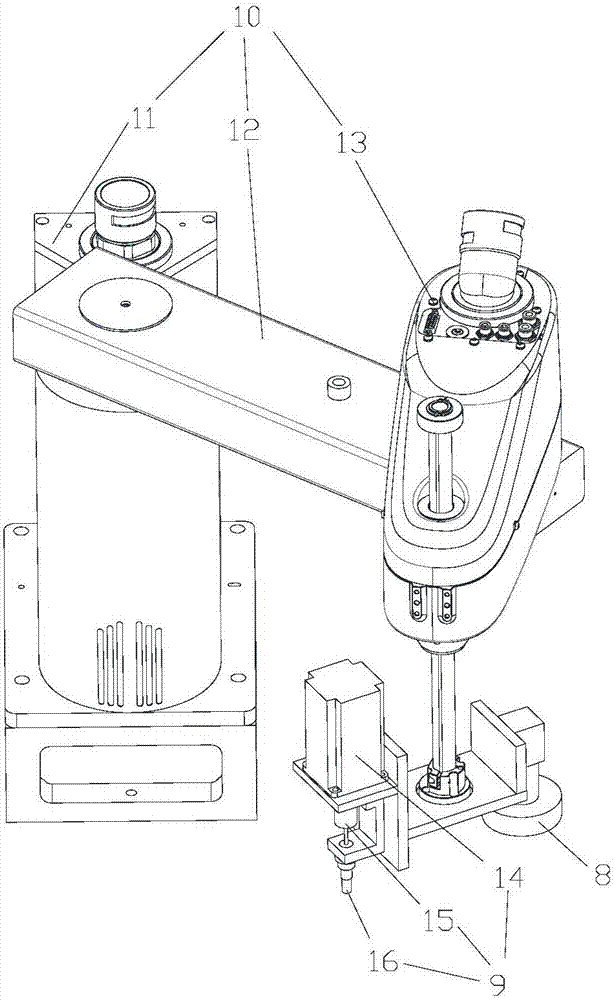

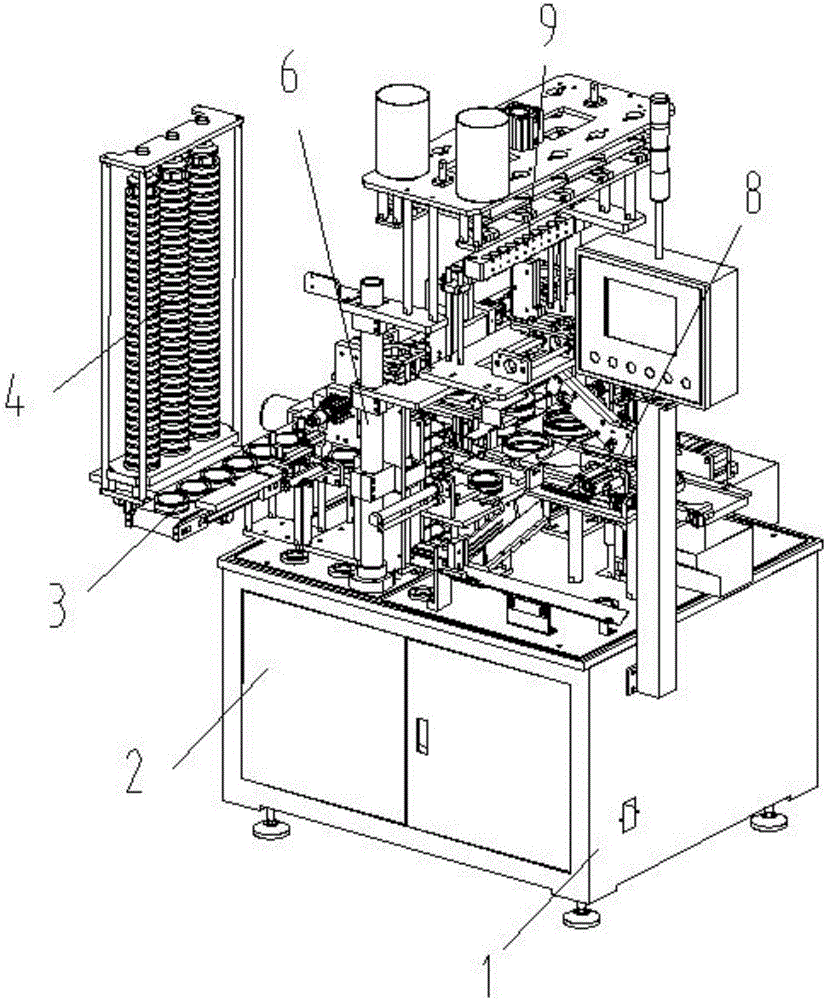

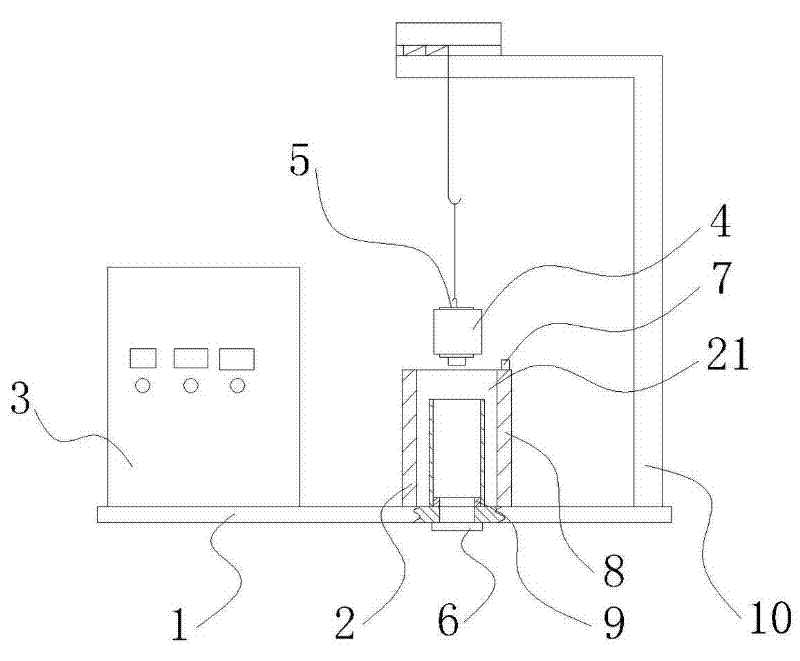

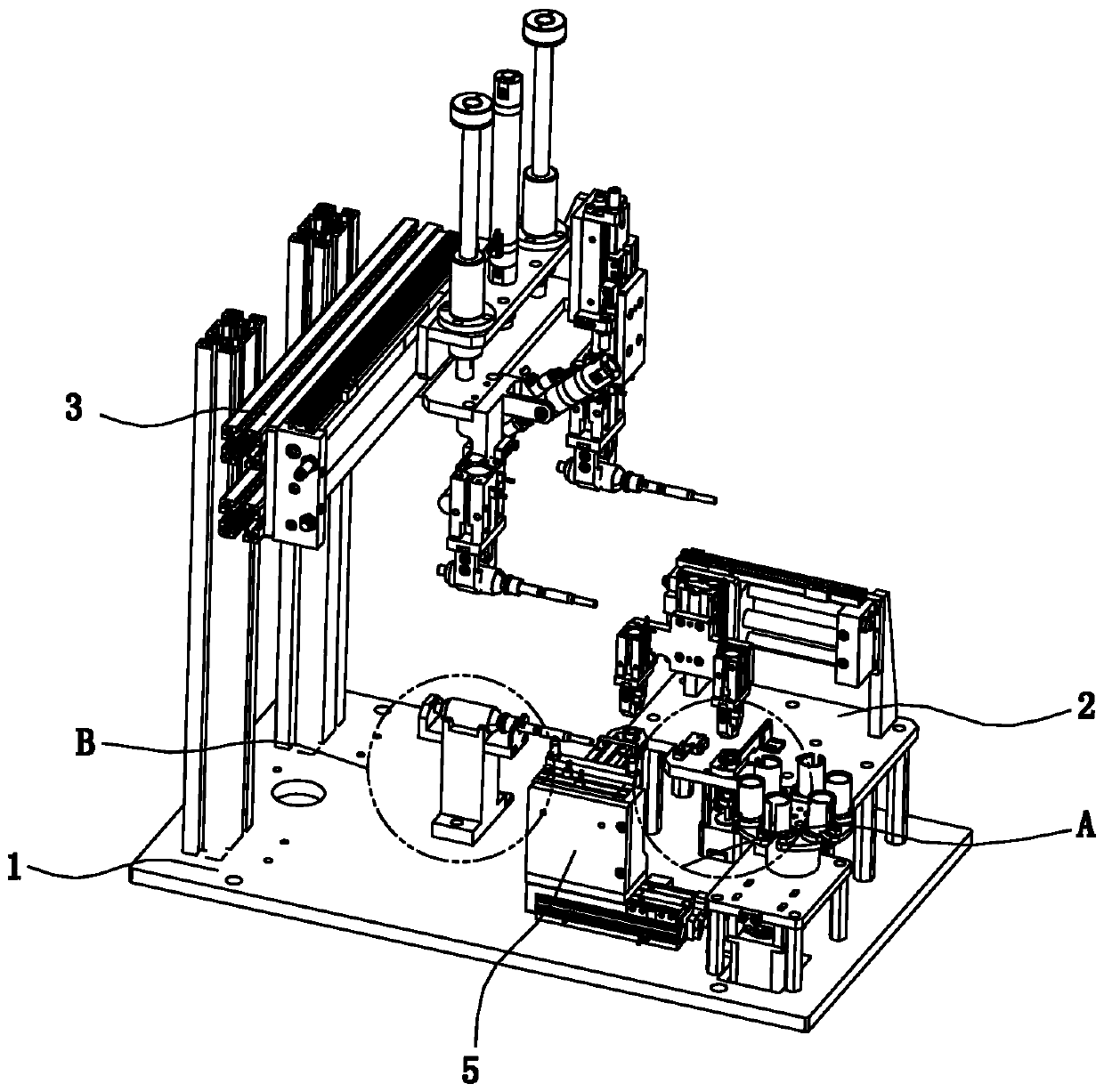

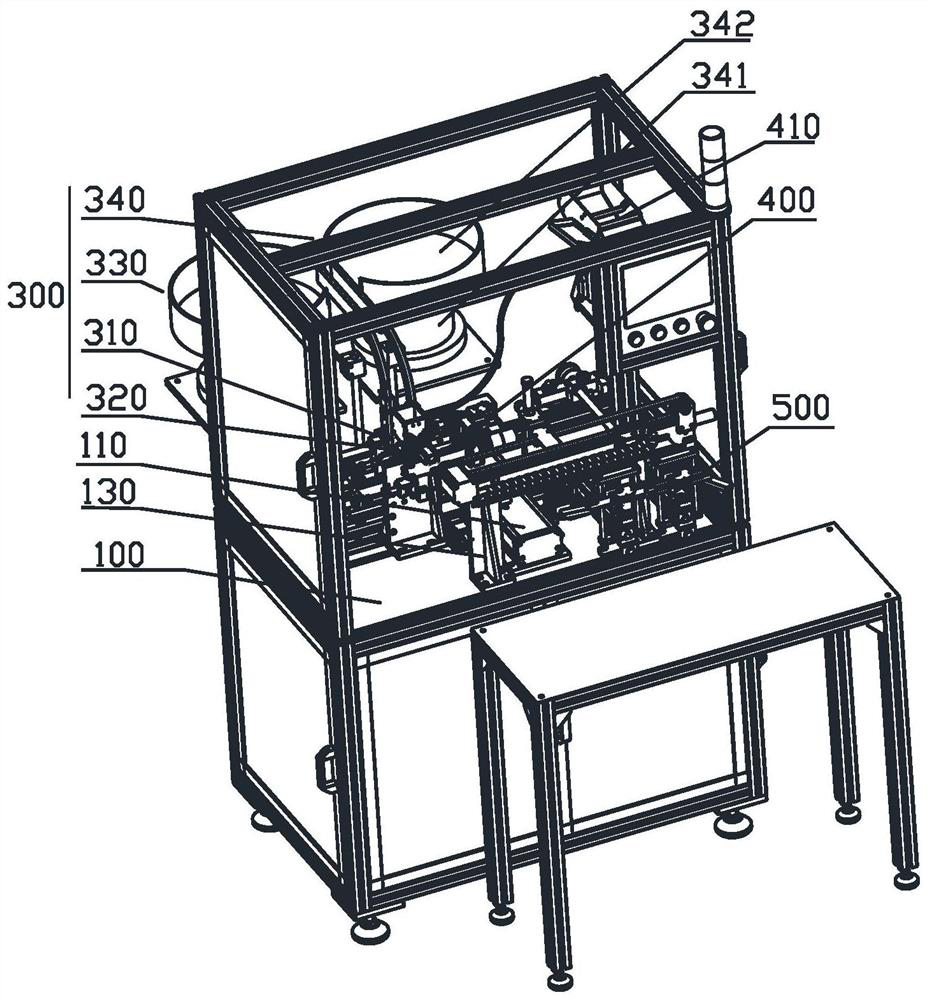

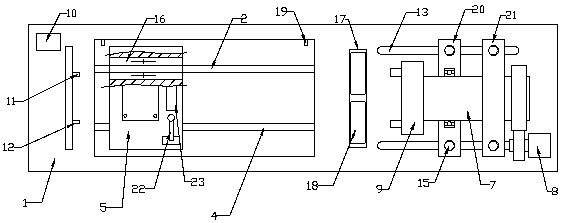

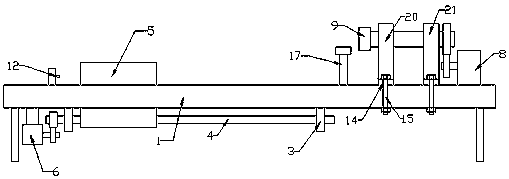

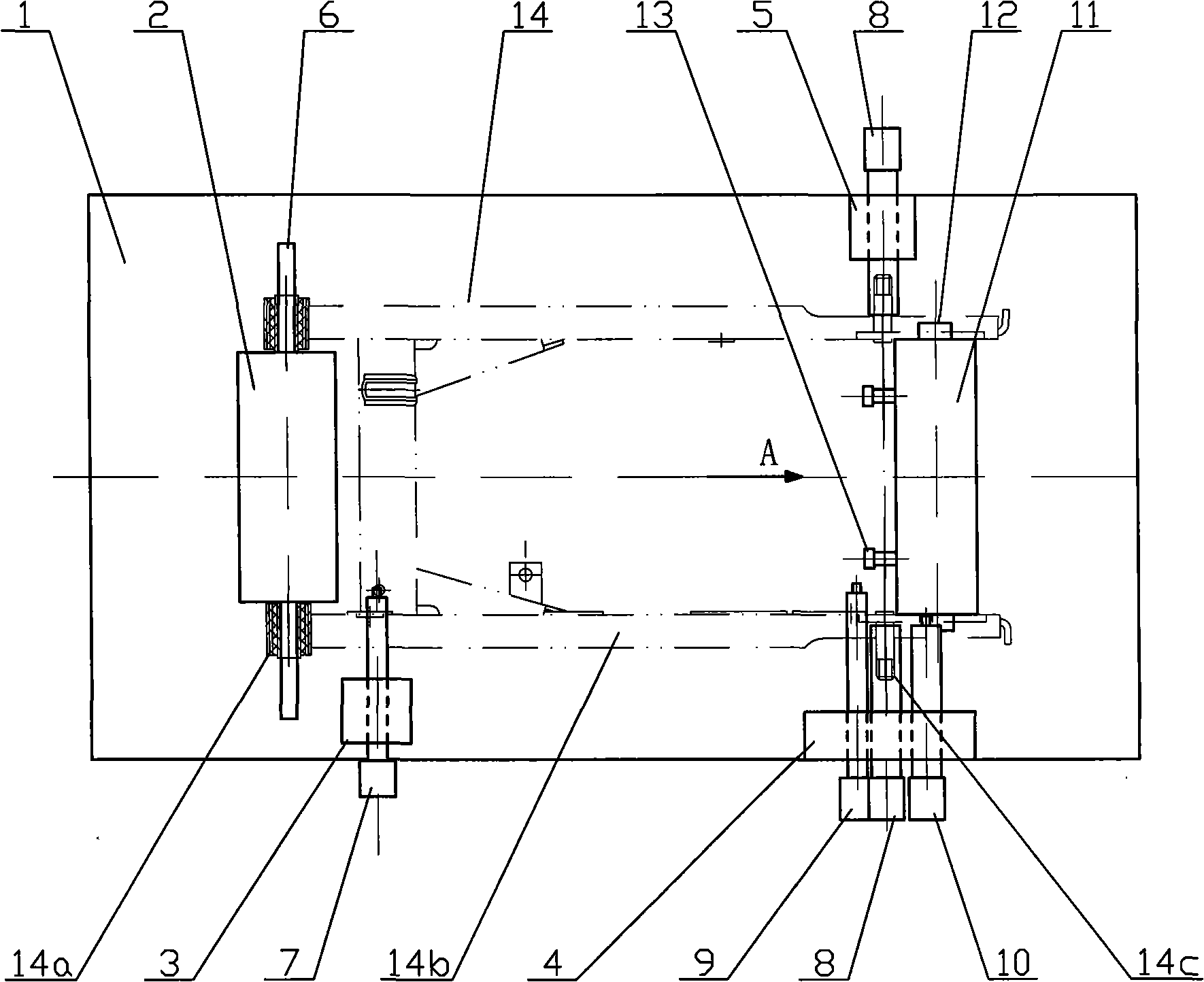

Screw assembly equipment

InactiveCN107322278AQuality assuranceAccurate captureMetal working apparatusControl systemEngineering

The embodiment of the present invention relates to assembly equipment, and discloses an assembly screw equipment, which includes a frame and a conveying line arranged on one side of the frame. The frame is equipped with a main control system, a screw feeder, a screw acquiring and tightening device, and a camera device ; Each component is connected to the main control system respectively; the conveying line is electrically connected to the main control system for conveying the product, and the conveying line is provided with a sensor and a clamping device. When the sensor detects the product, the main control system closes the conveying line, drives the clamping device to clamp the product, and turns on the camera to capture the image of the product, and obtains the screw hole position of the product in the image according to the captured image. The main control system is still After obtaining the screw hole positions, drive the screw obtaining and tightening device to obtain screws from the screw feeder, and control the screw obtaining and tightening device to screw the screws into the screw holes of the product. The screw assembling equipment in the present invention can not only ensure the quality of assembling but also the efficiency of assembling when assembling screws, and can reduce the cost of assembling at the same time.

Owner:DONGGUAN HUABEL ELECTRONICS TECH

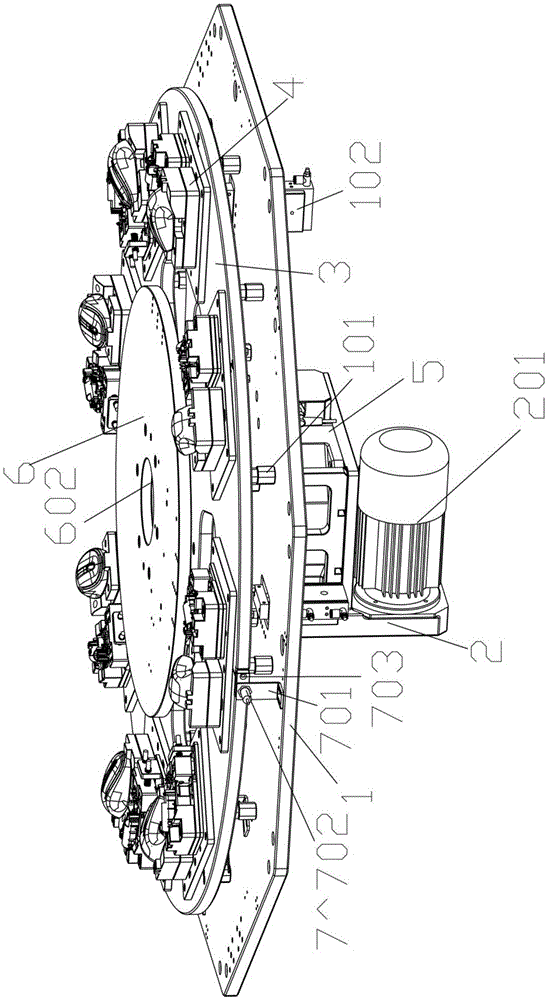

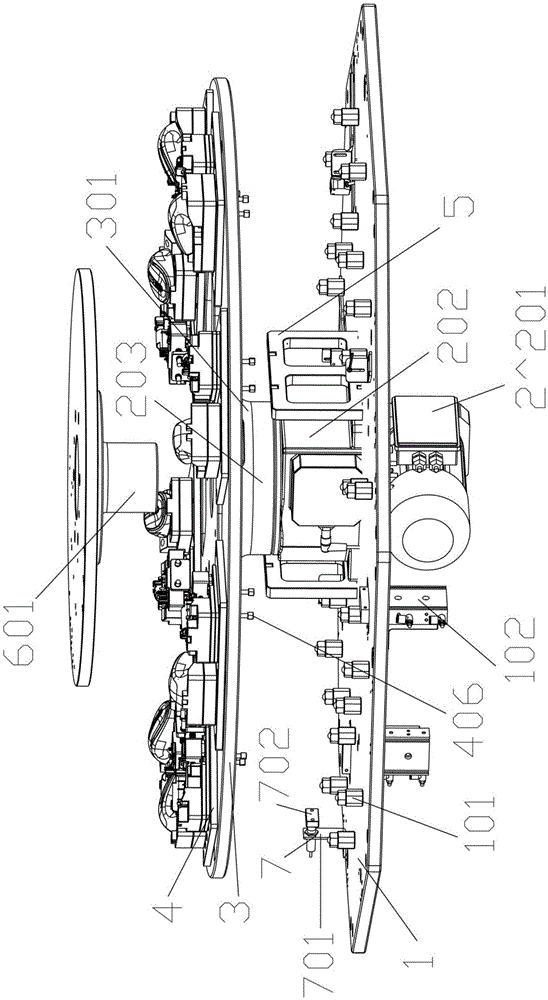

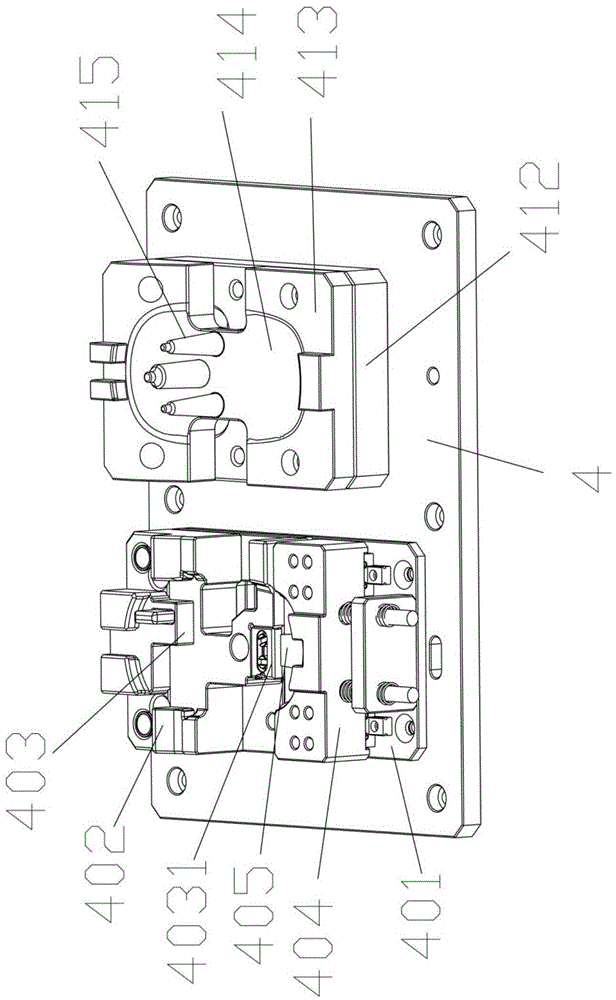

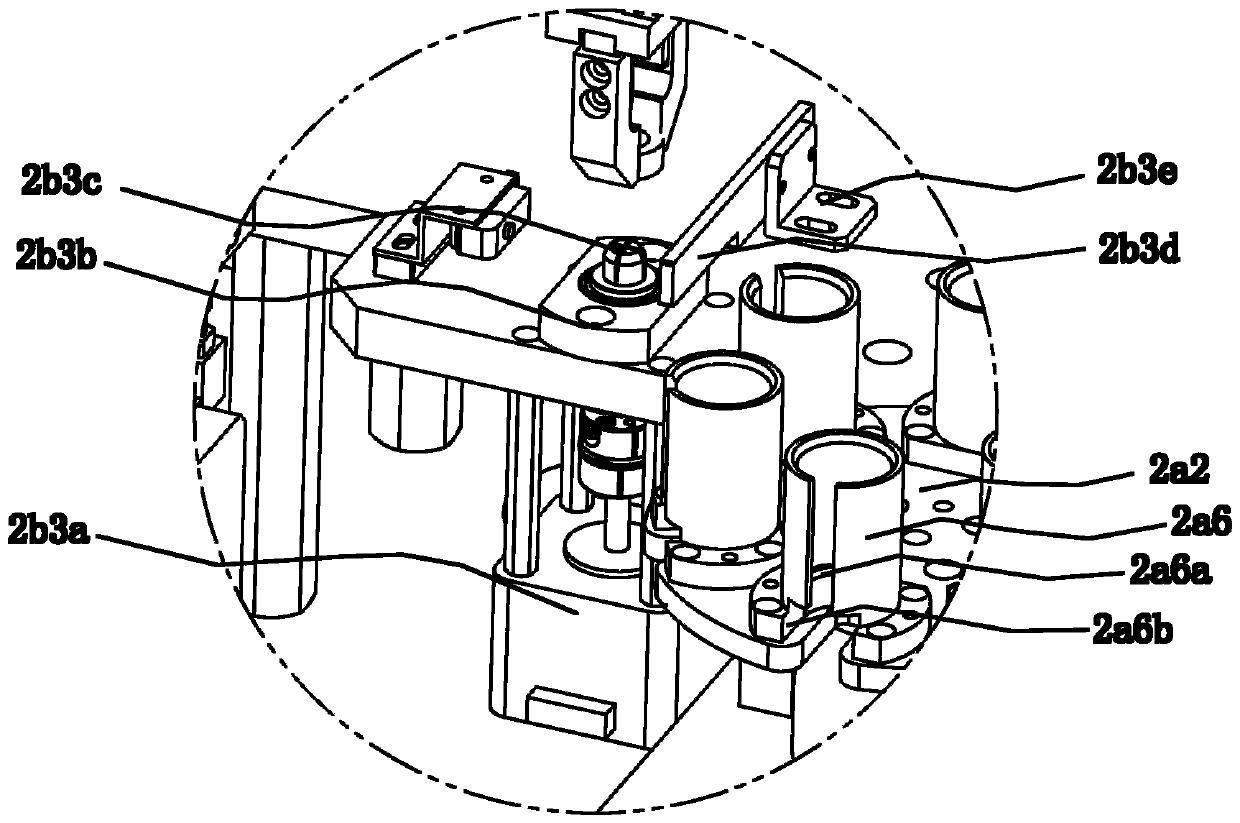

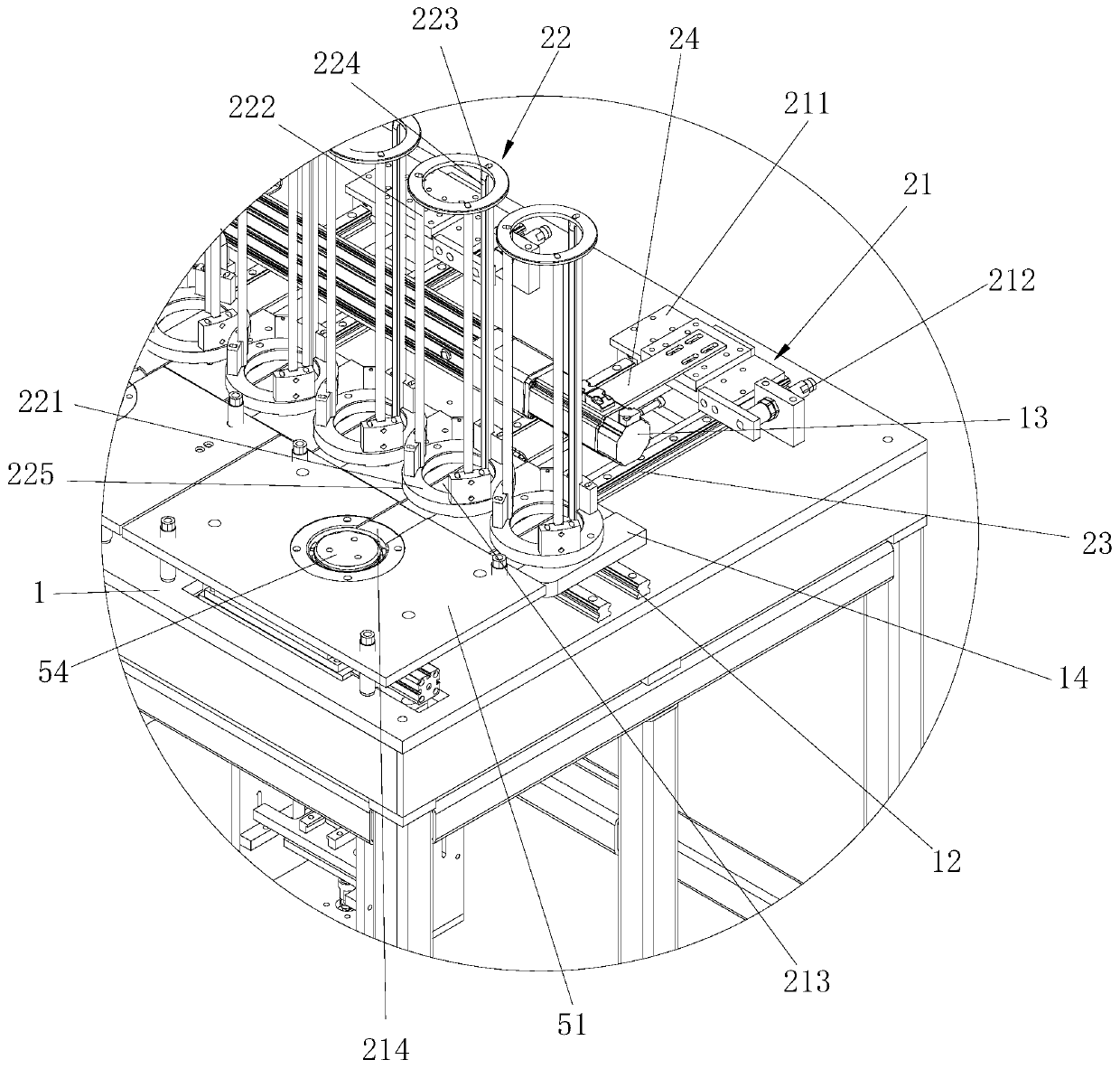

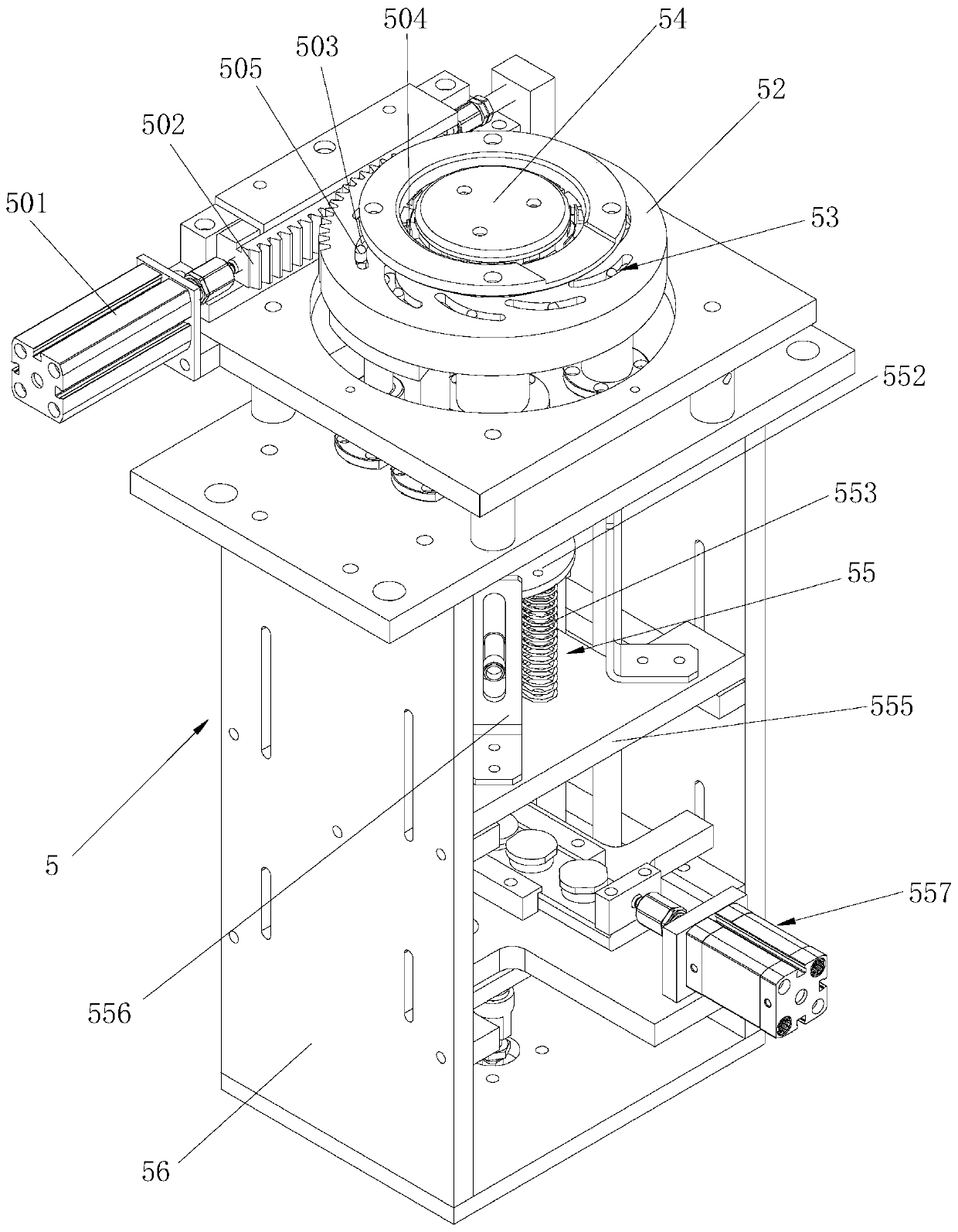

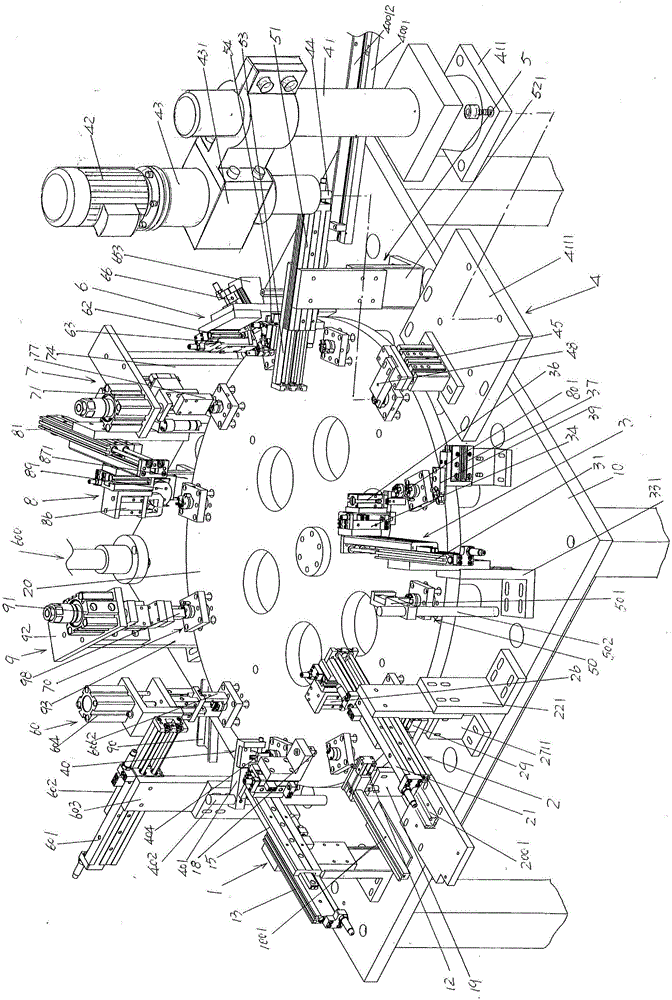

Magnetic steel assembling equipment and magnetic steel assembling method therefor

ActiveCN106374696AEffect of position errorQuick changeManufacturing stator/rotor bodiesExecution unitEngineering

The invention relates to magnetic steel assembling equipment. The magnetic steel assembling equipment comprises an execution unit, a tool unit, an assembling unit and a detecting-positioning unit, wherein the detecting-positioning unit comprises a magnetic steel detecting-positioning mechanism for detecting position information of the magnetic steel and an iron core detecting-positioning mechanism for detecting position information of an iron core. By adoption of the equipment, quick and high-precision assembling of the magnetic steel can be realized; and in addition, detecting-positioning is performed in assembling of the magnetic steel in each time, so that positioning accuracy is ensured.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD

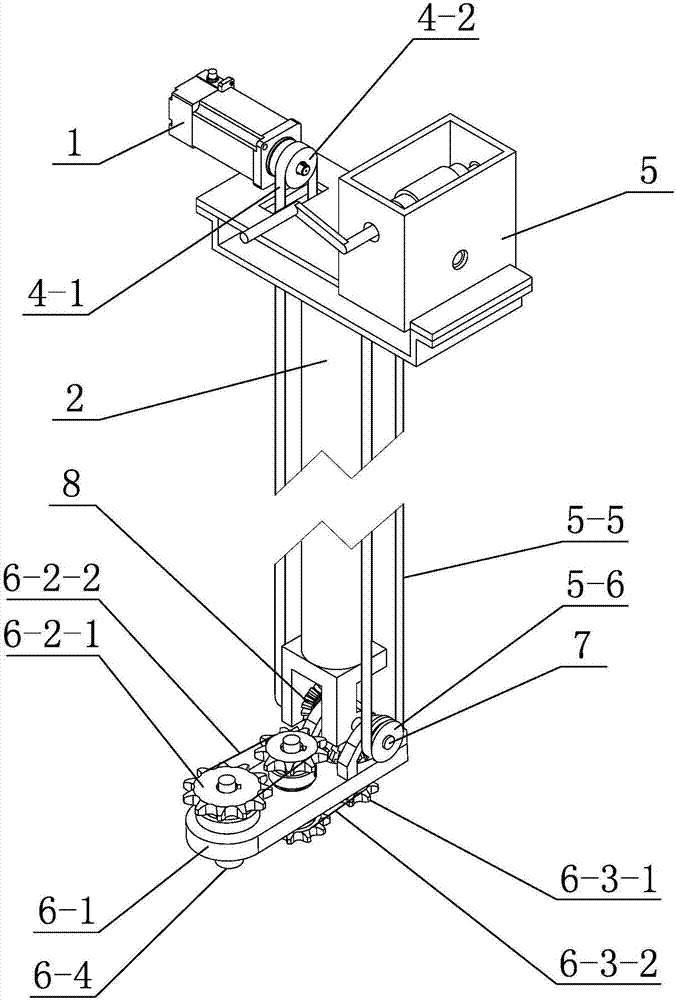

Mechanical arm tool mechanism used for nut assembling in narrow space

ActiveCN106964971ARealize the preload workEffectively realize the preload workMetal working apparatusAttitude controlMechanical engineering

The invention relates to a mechanical arm tool mechanism, in particular to a mechanical arm tool mechanism used for nut assembling in a narrow space. The problems that during nut assembling in the narrow space, manual assembling is needed, the time and labor are consumed, working efficiency is low, and the assembling quality is difficult to guarantee are solved. The mechanical arm tool mechanism used for nut assembling in the narrow space comprises a motor, a supporting assembly, a lifting mechanism, a transmission mechanism, a posture control mechanism and an executing mechanism; the lifting mechanism is arranged at an entrance of the narrow space, the supporting assembly is arranged on the lifting mechanism and makes up-down reciprocating movement in the height direction of the lifting mechanism under control of the lifting mechanism, and the executing mechanism is hinged to the bottom of the supporting assembly; and the motor is arranged on the supporting assembly and connected with the executing mechanism through the transmission mechanism, the executing mechanism is driven by the posture control mechanism to make rotating action, and the executing mechanism is driven by the transmission mechanism to make nut assembling action. The mechanical arm tool mechanism used for nut assembling in the narrow space is used for assisting nut assembling in the narrow space.

Owner:HARBIN INST OF TECH

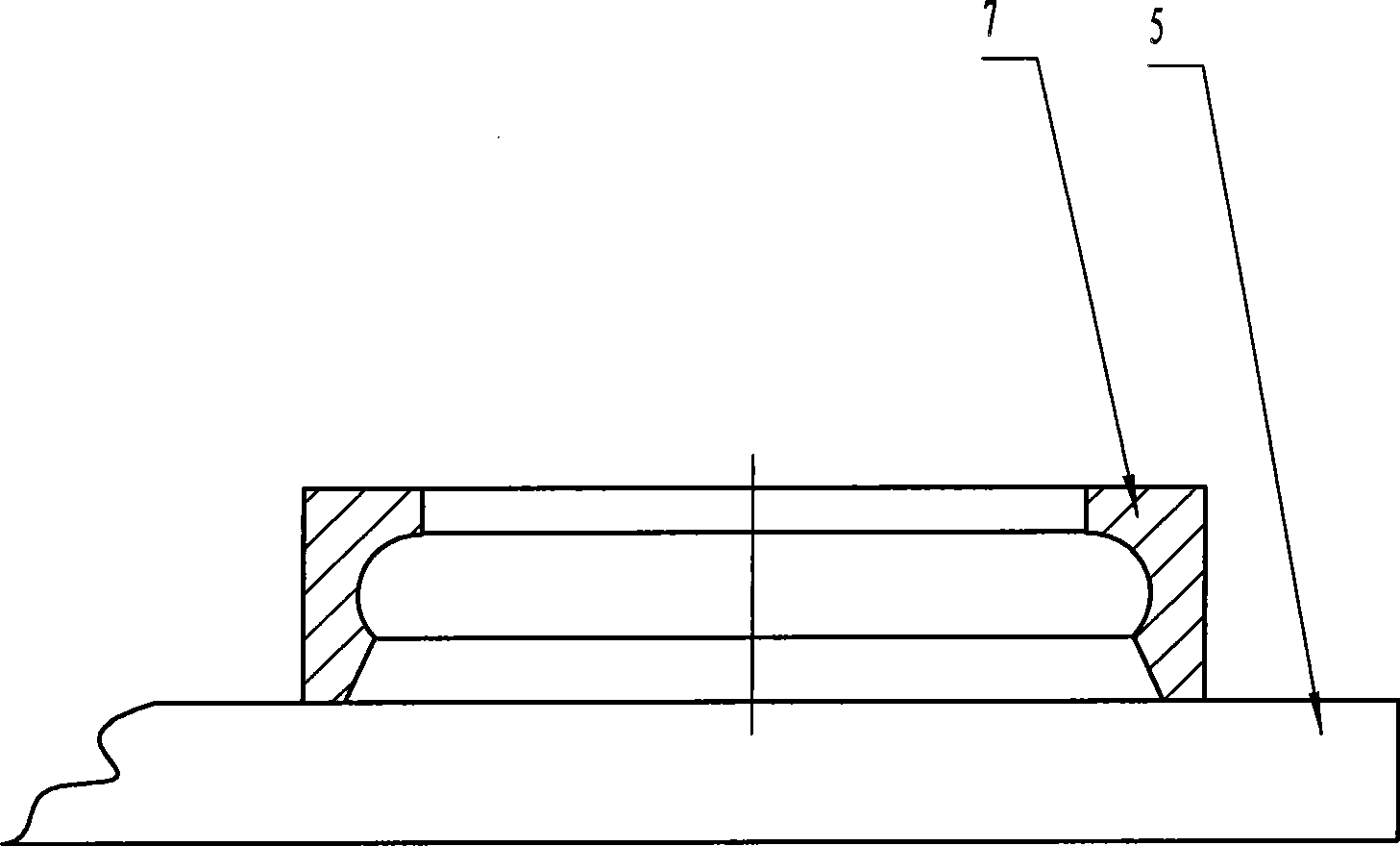

Thermal assembling method for angular contact ball bearing and heating apparatus

InactiveCN101457795AGuarantee quality and efficiencyGuaranteed assembly efficiencyTemperatue controlBearing componentsTemperature controlElectricity

The invention discloses a method for thermally assembling an angular contact ball bearing and a heating device. The heating device comprises a temperature controller and an electric heating device; the temperature controller is connected with the heating element of the electric heating device by a power supply circuit; the top part of the electric heating device is provided with an electric hot plate table-board used for holding and heating the outer sleeve ring of the bearing; a thermoelectric couple capable of feeding back the actual temperature signal of the electric hot plate table-board inserted into the electric hot plate table-board is connected with the outside of the temperature controller; during the thermal assembling, the outer sleeve ring of the bearing or the outer sleeve ring of the bearing internally provided with a retainer is arranged on the electric hot plate table-board; then the temperature controller controls the electric heating device to be electrified for heating and controls the heating temperature of the electric hot plate table-board until the outer sleeve ring of the bearing, or the outer sleeve ring of the bearing internally provided with a retainer is heated and thermally expanded to a required caliber; then the outer sleeve ring of the bearing, or the outer sleeve ring of the bearing internally provided with a retainer is combined and sheathed with the other parts of the bearing. The invention overcomes the defects of oil boiling heating of the thermal assembling of the bearing, can reduce oil smoke pollution and can improve the production safety.

Owner:LUOYANG BEARING SCI & TECH CO LTD

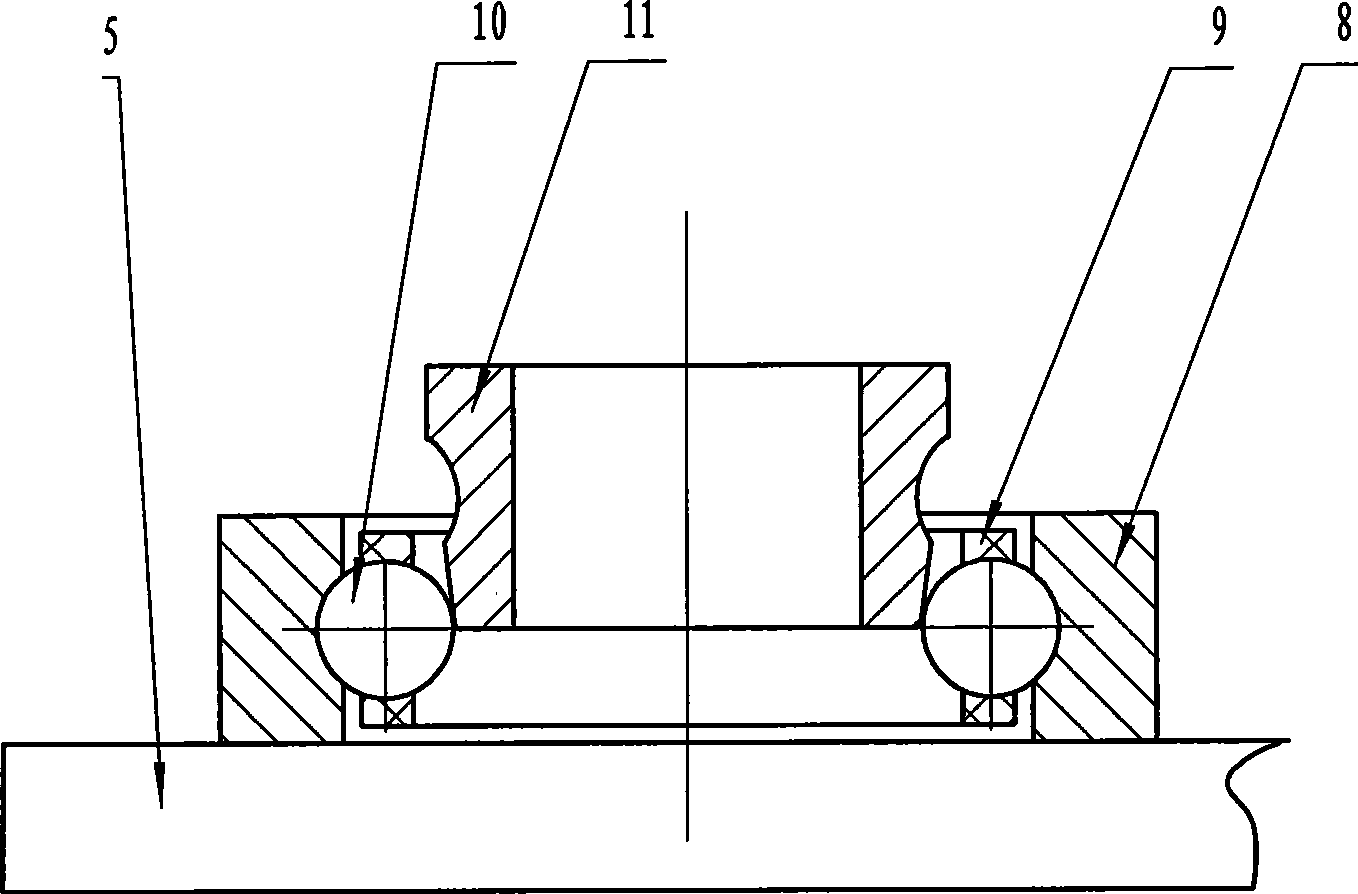

Automatic bearing assembly machine

ActiveCN106584102AFully automatedRealize automated assemblyAssembly machinesDistribution controlCoupling

The invention relates to an automatic bearing assembly machine which comprises a machine frame and a power distribution control cabinet. The machine frame is provided with a muff-coupling device which is matched with an upper ball conveyor channel through a feeding device. A ball pressing limiting hole is formed in the middle of the upper ball conveyor channel. A ball pressing limiting device is arranged below the ball pressing limiting hole, and a ball pressing device is arranged above the ball pressing limiting hole. The ball pressing limiting device comprises a limiting base, and the limiting base is provided with a movable limiting air cylinder and a movable limiting base. The movable limiting base is provided with a limiting lifting air cylinder and a limiting ball-jacking block. The limiting ball-jacking block is annular and is in clearance fit with an inner sleeve and an outer sleeve. An inner sleeve clamping block matched with the inner side of the inner sleeve is further arranged in the middle of the limiting ball-jacking block. The muff-coupling device is arranged and matched with a ball pressing conveyor channel through the feeding device, the locations of the inner sleeve and the outer sleeve are controlled through the specific ball pressing limiting device, then the good ball pressing effect is achieved through the ball pressing device, automatic assembly is achieved, and the assembly efficiency is improved.

Owner:恩施市长源轴承制造有限公司

Bearing assembling machine facilitating sleeved connection of inner and outer sleeves

InactiveCN108544231AFully automatedRealize automated assemblyAssembly machinesDistribution controlEngineering

The invention relates to a bearing assembling machine facilitating sleeved connection of inner and outer sleeves. The bearing assembling machine facilitating sleeved connection of the inner and outersleeves comprises a rack and a power distribution control cabinet; the rack is provided with a sleeved connection device which is matched with a bead feeding conveying groove through a feeding device;the middle portion of the bead feeding conveying groove is provided with a bead pressing limiting hole; a bead pressing limiting device is arranged below the bead pressing limiting hole, and a bead pressing device is arranged above the bead pressing limiting hole; the bead pressing limiting device comprises a limiting base which is provided with a limiting movable cylinder and a limiting movablebase; the limiting movable base is provided with a limiting lifting cylinder and a limiting bead ejecting block which is annular, and is matched with a gap between the inner sleeve and the outer sleeve; and an inner sleeve position clamping block matched with the inner side of the inner sleeve is further arranged on the middle portion of the limiting bead ejecting block. The bearing assembling machine facilitating sleeved connection of the inner and outer sleeves is provided with the sleeved connection device, and due to the feeding device, the sleeved connection device is matched with a beadpressing conveying groove; and the positions of the inner sleeve and the outer sleeve are controlled through the specific bead pressing limiting device, and then a good bead pressing effect is achieved through the bead pressing device, automatic assembling is achieved, and the assembling efficiency is improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

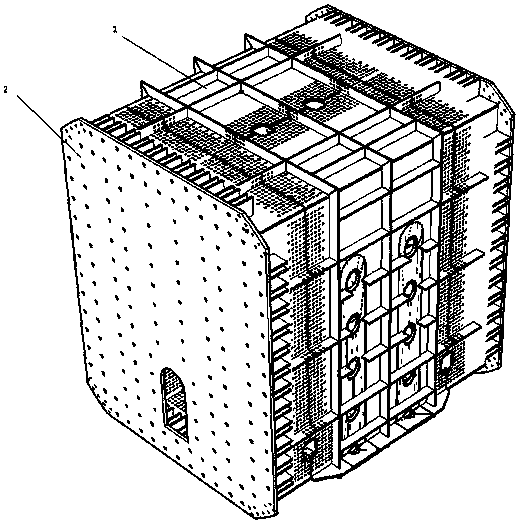

Manufacturing method for multi-module multi-layer bolted anchoring beam

ActiveCN108098264AGuaranteed installation accuracyGuaranteed assembly accuracyBridge structural detailsBridge materialsButt jointEngineering

The invention relates to a manufacturing method for a multi-module multi-layer bolted anchoring beam. The anchoring beam comprises a pair of cable tower anchoring blocks and a pair of transverse blockbodies; and the cable tower anchoring blocks and the transverse block bodies are connected end to end in a staggered mode to form a cuboid structure. The manufacturing method for the anchoring beam is characterized by comprising the processes of 1, the construction method of the cable tower anchoring blocks, 2, the construction method of the transverse block bodies, and 3, processing of splicingplates. According to the method, the cable tower anchoring blocks and the transverse block bodies of the anchoring beam are constructed in a modularized mode, all components after being accurately machined undergo high-precision butt-joint splicing on a specially-arranged assembling jig frame, so that the splicing precision and the splicing efficiency are guaranteed; and processing of the semi-finished parts adopts a standardized level, so that the accumulated error is reduced, and the overall mounting precision of steel balls is guaranteed.

Owner:中铁山桥(南通)有限公司

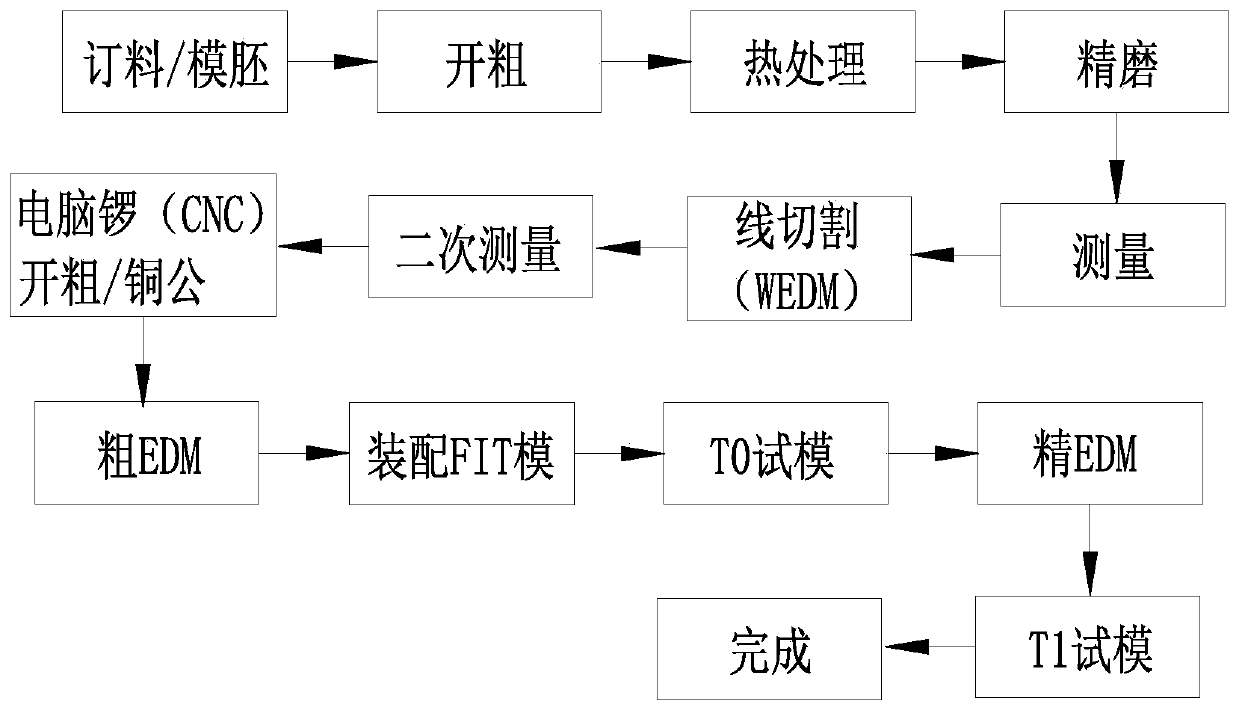

High-precision mold production process

The invention relates to the technical field of mold production and manufacturing, and discloses a high-precision mold production process. The production process specifically comprises the following steps that S1 material / mold base ordering is conducted, specifically, a mold base material is preliminarily screened out, and is preliminary machined, so that a mold base material internally with largeparticles is removed; and S2, roughing is conducted, specifically, the mold base material is machined through a machine tool, the approximate shape of the mold is machined out, and a margin is reserved on the periphery of the mold. According to the production process, procedures are simple and convenient, used equipment is mostly a numerical control lathe, the machining process is controllable, wire cutting treatment and computerized numerical control machine treatment in the treatment procedures are gathered on the same equipment for treatment, when the numerical control milling machine is used for machining, high-precision machining is conducted by utilizing primary electric spark and intermediate electric spark, technical personnel conduct detection by utilizing 3D scanning detection and 2D detection, so that the size errors of an insert hole and a slide tunnel are minimized.

Owner:苏州尖腾精密技术有限公司

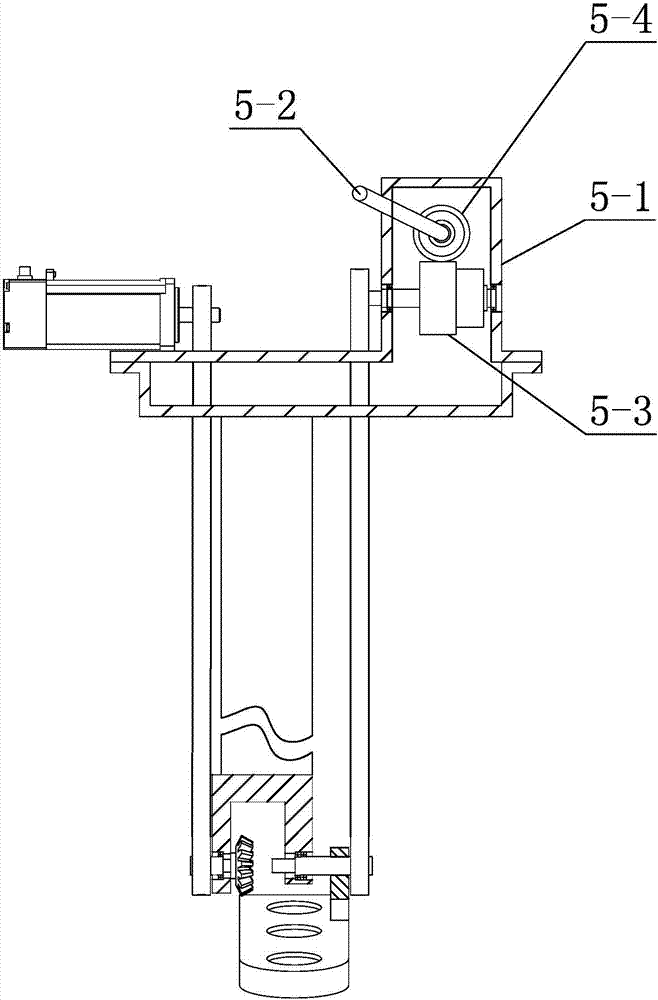

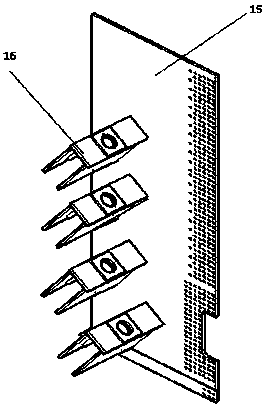

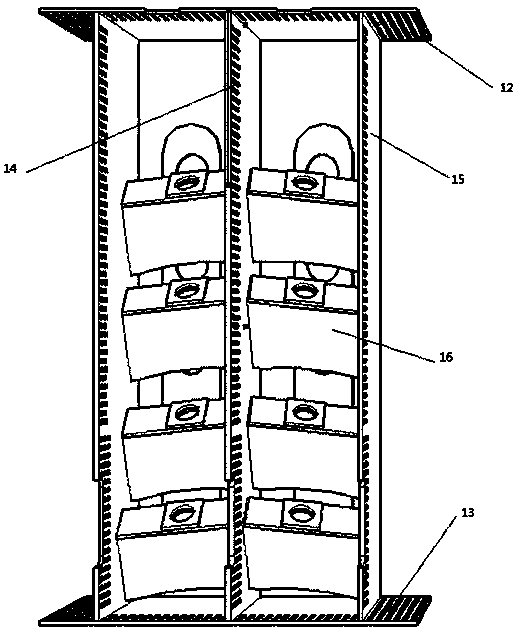

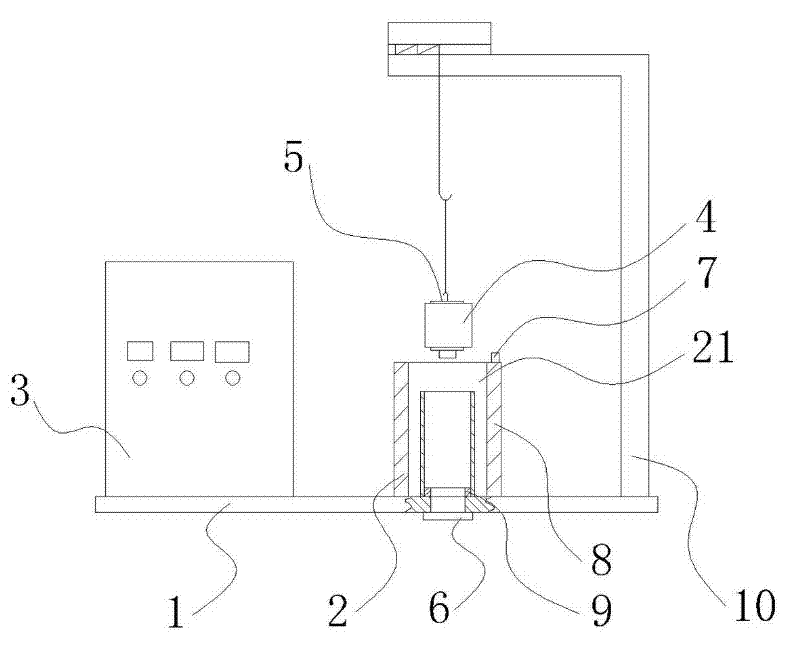

Medium-frequency heating and shrinking equipment of servo motor stator and using method thereof

ActiveCN102412670AGuaranteed assembly qualityGuaranteed assembly efficiencyManufacturing stator/rotor bodiesElectric machineMedium frequency

The invention discloses heating and shrinking equipment of a motor stator and a using method thereof. The principle of expansion with heat and contraction with cold is adopted, namely before installation, after a motor shell is heated at medium frequency, a middle hole is expanded; and after the motor stator is installed in the motor shell, the motor shell is cooled to be shrunk and positioned. The invention provides the medium-frequency heating and shrinking equipment of a servo motor stator and a using method thereof. The medium-frequency heating and shrinking equipment is simple in structure, time-saving and labor-saving in operation, low in energy consumption and high in production efficiency. The technical problems of complex process of installing the motor stator in the motor shell, easy damage of the motor stator and the motor shell, unguaranteed quality of the motor and the like in the prior art are solved. The medium-frequency heating and shrinking equipment comprises a platform, wherein a sensing coil is vertically arranged on the platform and is connected with a main power supply through a medium-frequency power supply controller; a heating cavity capable of accommodating the motor shell is arranged on the middle part of the sensing coil; a lifting device is arranged above the heating cavity; a fixture body used for clamping the motor stator is arranged on the lifting device; and a fan is arranged below the heating cavity.

Owner:菲仕绿能科技(北京)有限公司

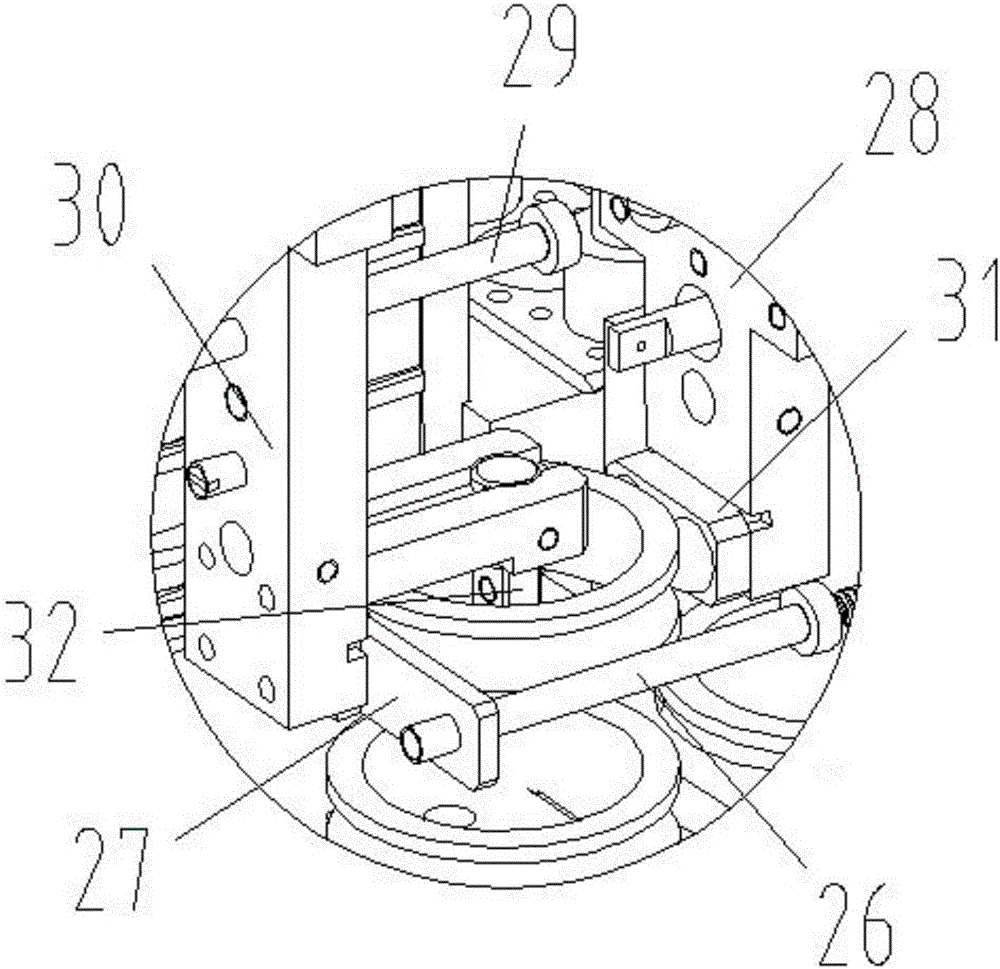

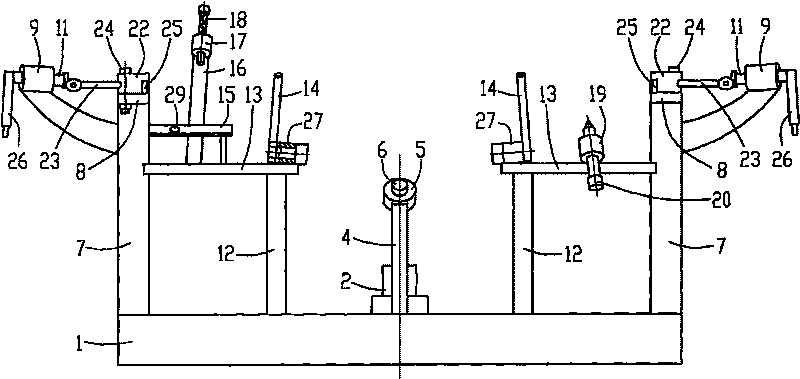

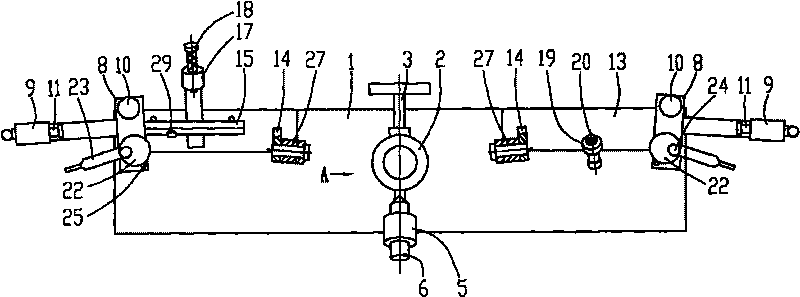

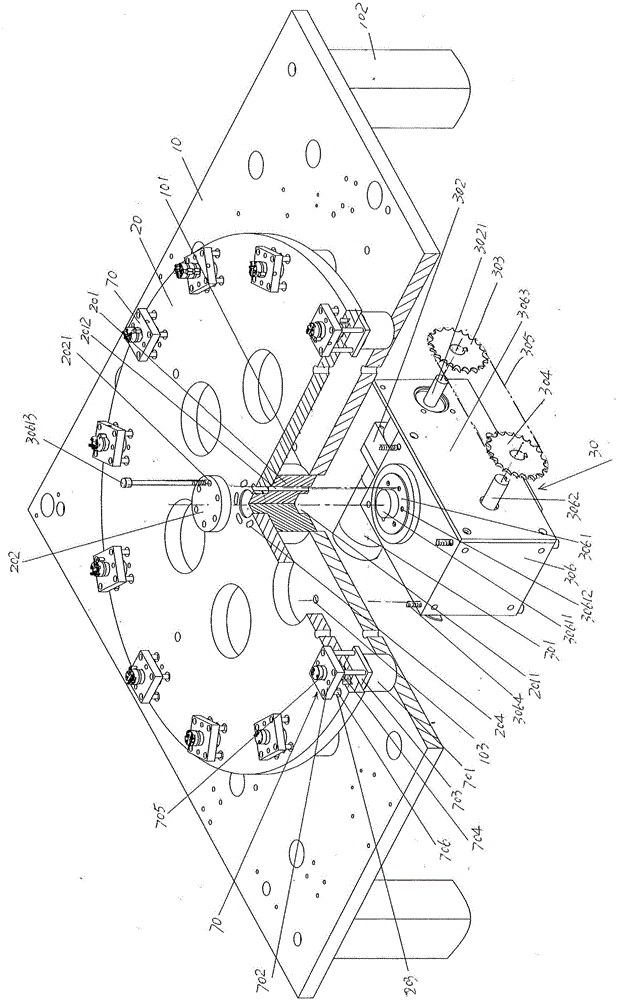

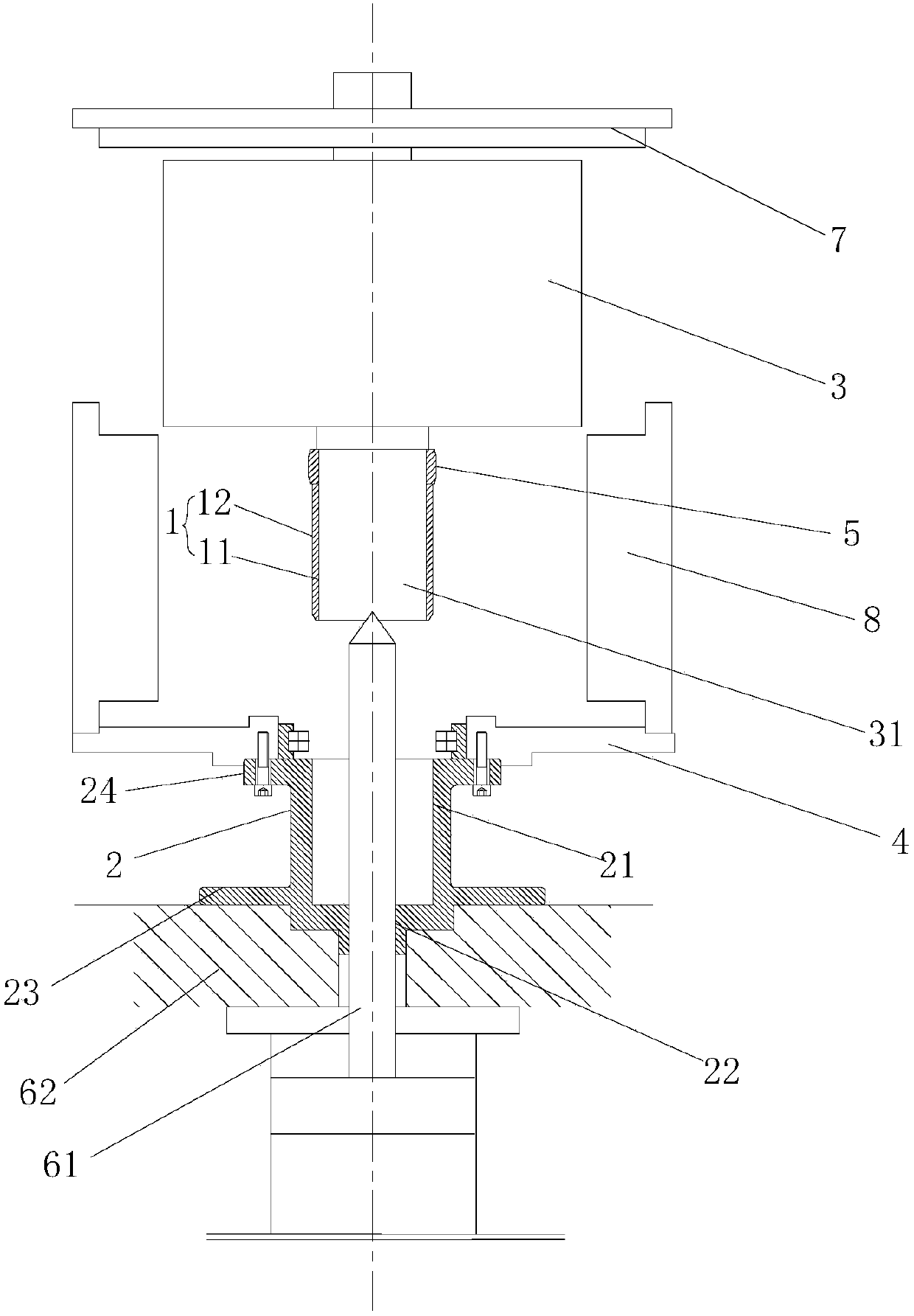

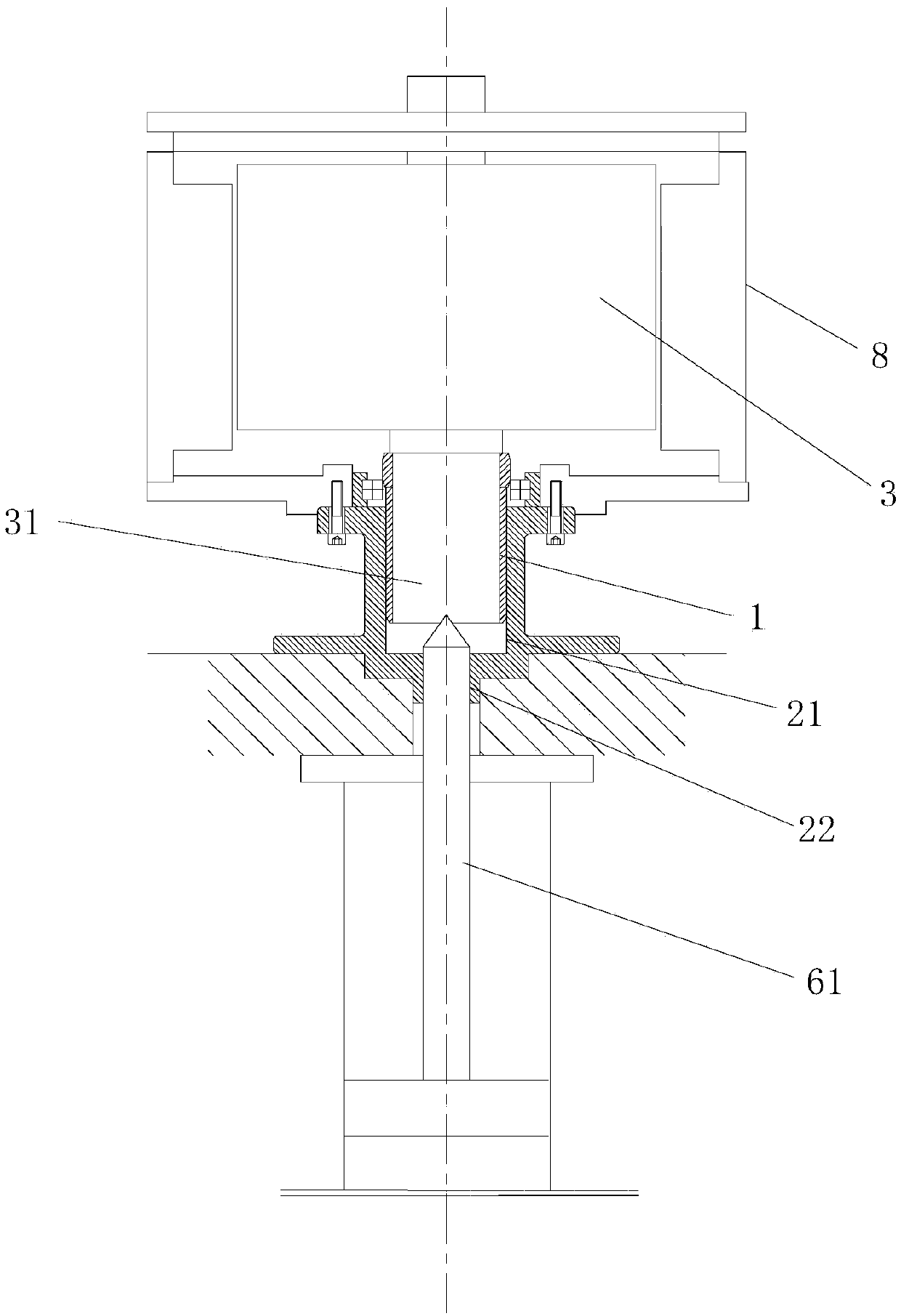

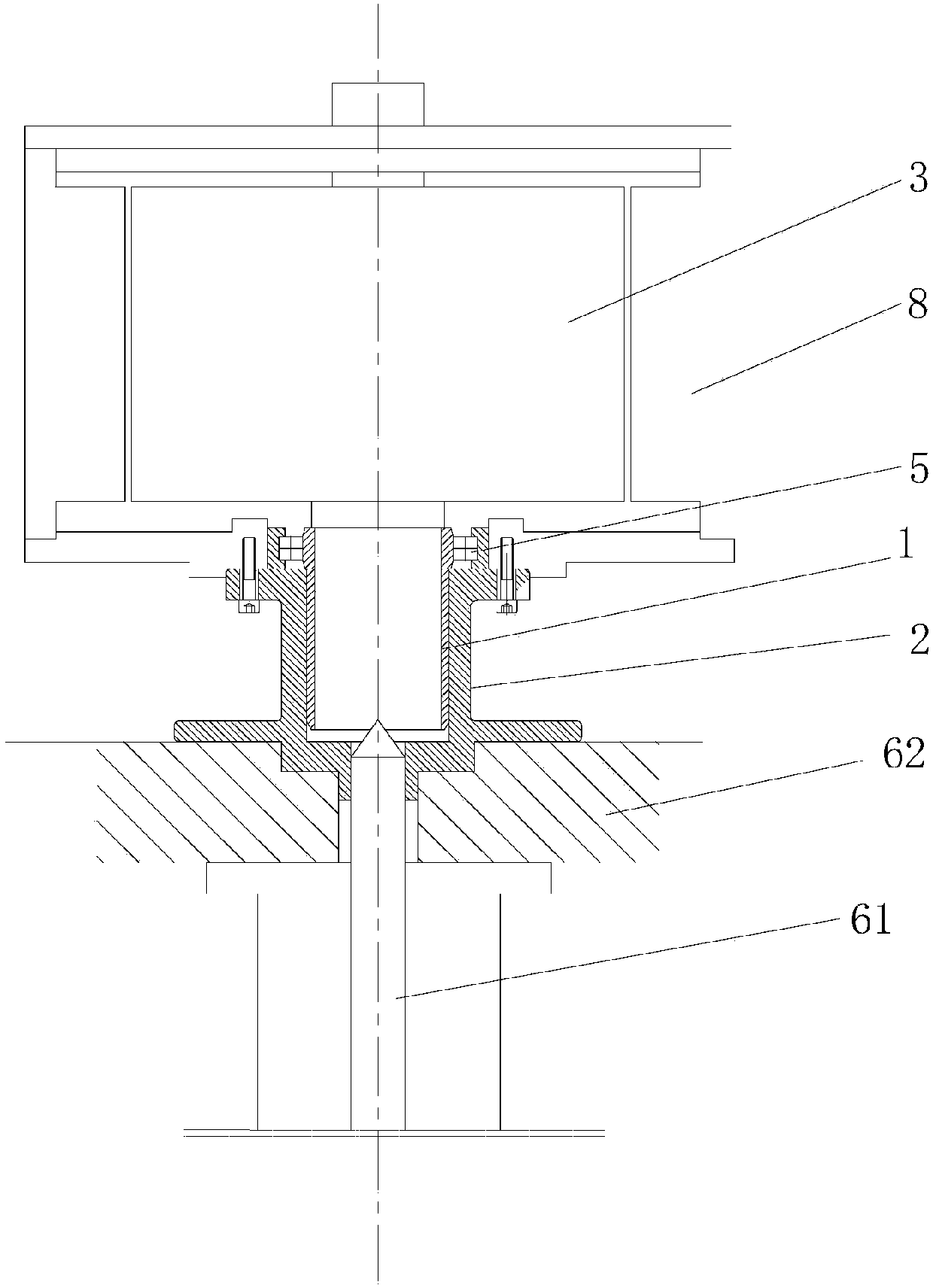

Rotary table mechanism capable of preventing line from winding

ActiveCN105598693AAvoid entanglementGuaranteed assembly efficiencyAssembly machinesEngineeringConductor Coil

The invention provides a rotary table mechanism capable of preventing a line from winding. The rotary table mechanism comprises a bottom plate, a rotary module which is fixedly arranged in the middle of the bottom plate, a rotary table arranged on the rotary module, a fixed loading table which is fixedly connected onto the bottom plate through a fixed loading table connection block, and is located above the rotary table, a pneumatic component or an electric component which is arranged on the fixed loading table and is pneumatically or electrically arranged on the fixed loading table, and a wiring hole which is formed in the fixed loading table and is matched with the pneumatic component or the electric component to use. According to the rotary table mechanism capable of preventing the line from winding, provided by the invention, the fixed loading table is arranged for arranging the pneumatic component or the electric component for driving; a pneumatic or electric wire of the pneumatic component or the electric component is arranged in a wiring groove which has no corresponding contact with the rotary table; and the rotation of the rotary table does not cause the winding of the wire of the pneumatic component or the electric component and the working of a mouse is not influenced, so that the assembling efficiency of the mouse is guaranteed.

Owner:BOZHON PRECISION IND TECH CO LTD

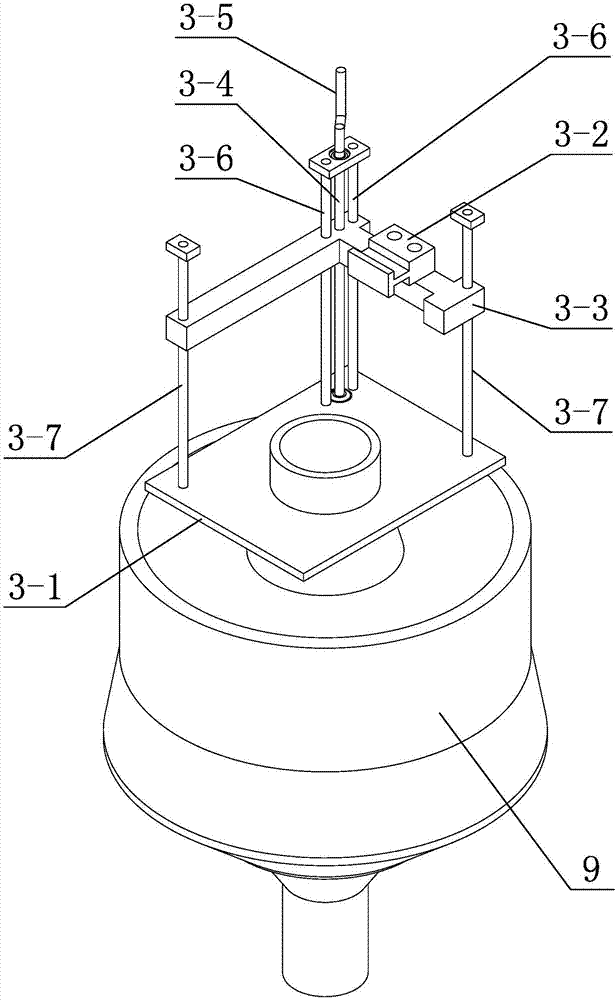

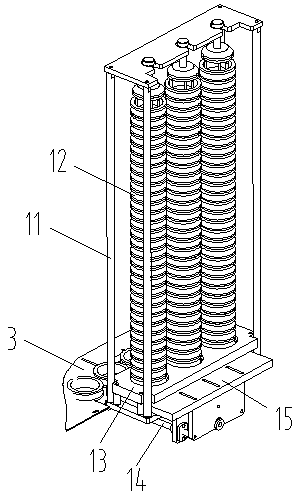

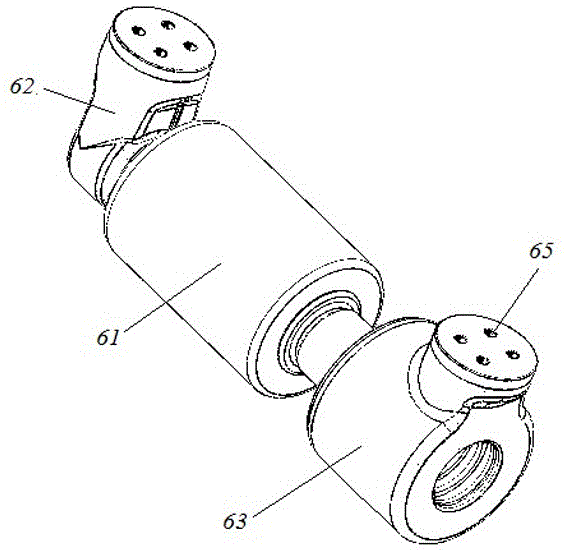

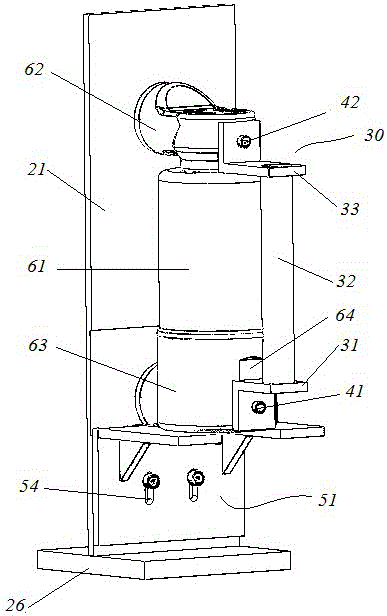

Bearing transshipment mechanism of motor rotor assembly machine

InactiveCN107645226AGuaranteed assembly efficiencyHigh degree of automationManufacturing stator/rotor bodiesMetal working apparatusEngineeringAssembly machine

The invention relates to the technical field of motor component transferring, and particularly relates to a bearing transshipment mechanism of a motor rotor assembly machine. The bearing transshipmentmechanism comprises a pedestal which is provided with a first transshipment mechanism. The first transshipment mechanism comprises a material loading device and a carrying device. The material loading device comprises a first supporting stand, a rotating disc and a first driving motor. The output end of the first driving motor and the bottom part of the rotating disc are matched in a transmissionway through a belt pulley. The top part of the rotating disc is provided with multiple material canisters which are circumferentially distributed. The bottom part of the carrying device is provided with a shifting and transporting mechanism used for transshipment of the bearings in the material canisters. The carrying device comprises a second supporting stand, a clamping component and a transferstand. The top part of the second supporting stand is provided with a second supporting frame. The upper part of the second supporting frame is horizontally provided with a second lead screw slide block. According to the bearing transshipment mechanism of the motor rotor assembly machine, the degree of automation is high, the manual labor intensity can be effectively reduced, working is enabled to be safer, the processing quality can also be enhanced and the assembling efficiency of the motor rotor can be ensured.

Owner:傅淑君

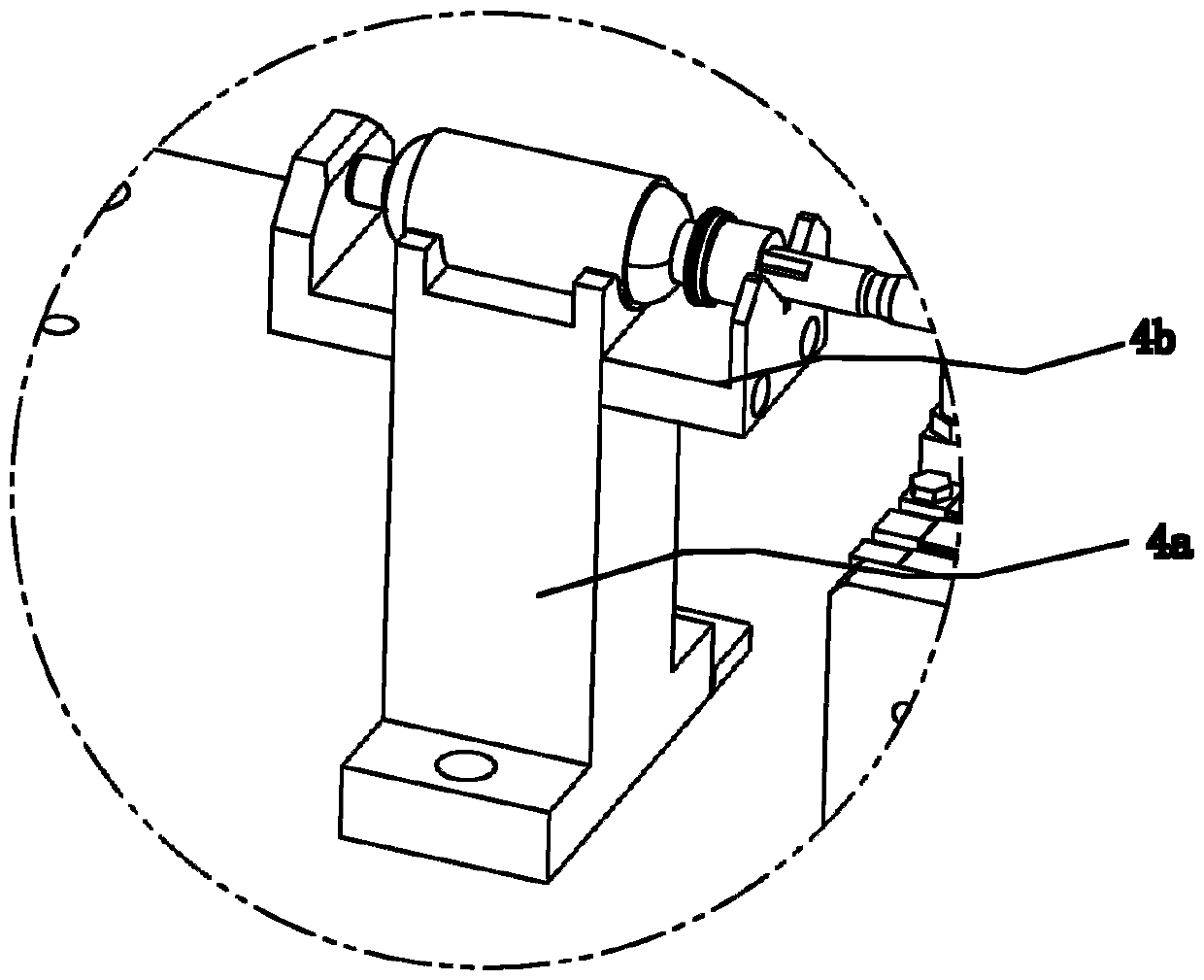

Single pole assembly tool for immobilized and encapsulated post terminal and casting method for immobilized and encapsulated post terminal

ActiveCN106024460AGuaranteed assembly efficiencyGuaranteed loading efficiencyElectric switchesEngineeringMechanical engineering

The invention relates to a single pole assembly tool for an immobilized and encapsulated post terminal and a casting method for the immobilized and encapsulated post terminal. The single pole assembly tool for the immobilized and encapsulated post terminal comprises a wire outgoing base support frame. the wire outgoing base support frame is provided with an upper wire outgoing base positioning structure and a lower wire outgoing base positioning structure, wherein the upper wire outgoing base positioning structure and the lower wire outgoing base positioning structure are used for enabling an upper wire outgoing base and a lower wire outgoing base for the single pole assembly of the immobilized and encapsulated post terminal to meet a preset positional relationship. The single pole assembly tool further comprises a wire outgoing base connecting piece. The wire outgoing base connecting piece is provided with a fixation part fixedly connected with one of the upper wire outgoing base and the lower wire outgoing base, and a positioning part in axial and circumferential location fit with the other one of the upper wire outgoing base and the lower wire outgoing base. By using the above tool, the single-pole assembly of the above immobilized and encapsulated post terminal is prevented from relatively rotating or axially moving to cause the relative position change during the transferring and preheating process. Therefore, the assembling efficiency and the die-filling efficiency of the single-pole assembly of the immobilized and encapsulated post terminal are ensured. Meanwhile, the yield and the production efficiency of the immobilized and encapsulated post terminal are ensured. The cost is lowered.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

Portable pipeline inner wall electric cleaning device

InactiveCN106623291AGuaranteed AxialGuaranteed fixed effectHollow article cleaningPower controllerAxis of symmetry

The invention belongs to the field of pipeline cleaning equipment and particularly relates to a portable pipeline inner wall electric cleaning device. The portable pipeline inner wall electric cleaning device comprises a work assembly, a power controller and a flexible shaft. A special-shaped sheave is fixed to a power input shaft in a sleeving mode, the appearance of the special-shaped sheave is cylindrical, the cylinder surface of the special-shaped sheave is surrounded by a wavy groove part, the waving direction of the groove part is parallel to the axis direction of the special-shaped sheave, and the groove part is of an axial symmetry structure with the axis of the special-shaped sheave as the axis of symmetry. The special-shaped sheave is coaxially sleeved with a cleaning shaft sleeve, a ball containing hole or a ball containing groove is formed in the inner cylinder wall of the cleaning shaft sleeve in a recessed mode, and containing space for containing a ball and enabling the ball to roll is defined by the ball containing hole or the ball containing groove and the groove part jointly. The outer wall of the cleaning shaft sleeve is fixedly connected with a cleaning brush. The device is low in use cost and high in portability, and meanwhile conforms to the operating purposes of high efficiency, automation and the high cleaning effect required by existing pipeline cleaning.

Owner:中国人民解放军陆军军官学院

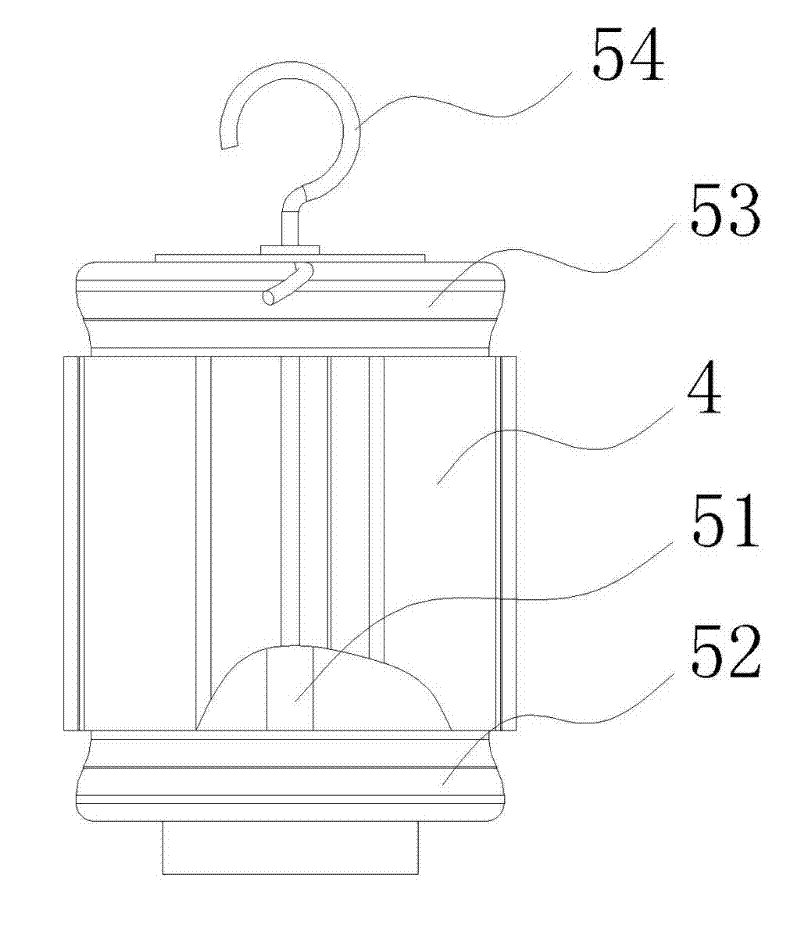

Inter-structural-disk connecting force limiting device

ActiveCN102873662ACause untightenedOptimize assembly processMetal-working hand toolsEngineeringMechanical engineering

An inter-structural-disk connecting force limiting device is used for limiting force and screwing nuts, in an inner cavity of the device, which are less easy to screw. The inter-structural-disk connecting force limiting device is structurally characterized by comprising an operating handle, a matching screwing part (55) and a connecting part, wherein the matching screwing part (55) is used with a screwed nut (2) to be screwed, and the connecting part is used for connecting the operating handle and the matching screwing part (55) and is integrated with the same. The defect that position of the nut and contact with the nut cannot be ensured with human eyes and human hands is overcome, and screwing and force limiting for the nut are achieved. The inter-structural-disk connecting force limiting device is simple and reasonable in design, assembly process of nut screwing is optimized, the technical difficulty in screwing and force limiting for the nut of the special structural disk is overcome, and application of the connecting force limiting device is achieved. In addition, the concept of design can be used for reference and applied to other projects of inter-structural-disk connecting force limiting, and the inter-structural-disk connecting force limiting device is worthy of wide application.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

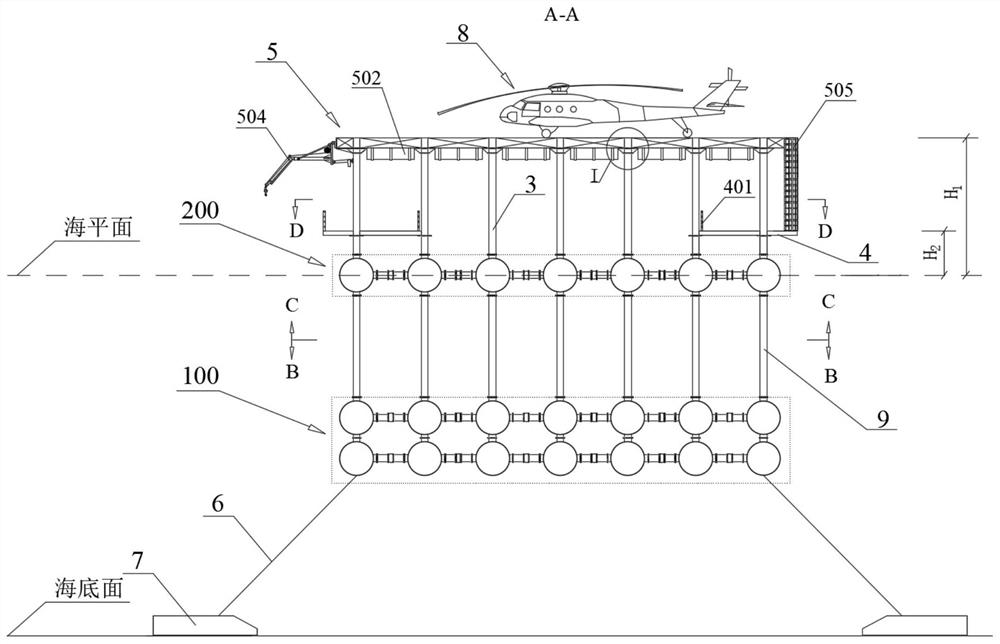

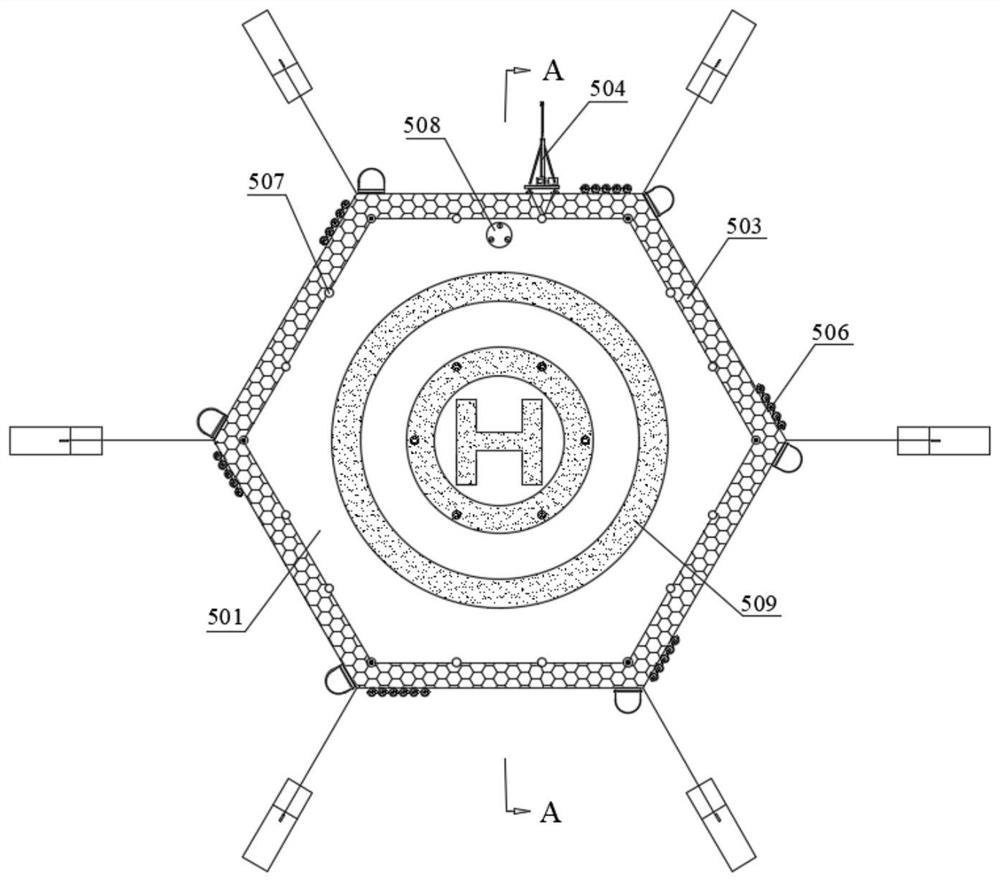

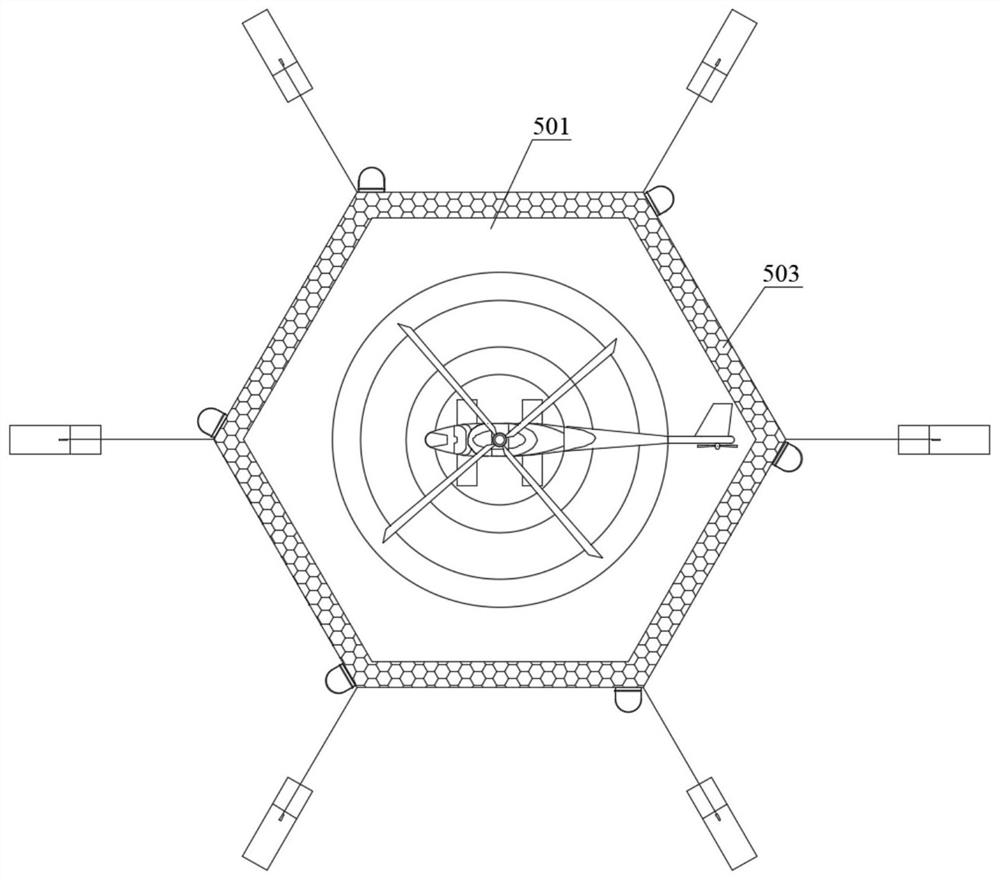

Intelligent new energy semi-submersible offshore floating helicopter platform

The invention discloses an intelligent new energy semi-submersible offshore floating helicopter platform, and belongs to the technical field of ocean platforms. Through the arrangement of buoyancy adjustable points with adjustable buoyancy and buoyancy fixed or adjustable semi-submersible buoyancy nodes and the array arrangement and corresponding connection of the corresponding buoyancy nodes in aplane or a space, the buoyancy main body and the semi-submersible buoyancy body can be rapidly obtained; and then the semi-submersible offshore floating type helicopter platform can be rapidly arranged through combined arrangement of the diving stand column, the lifting stand column and the deck assembly above the semi-submersible buoyancy body. The platform is simple in structure and easy and convenient to arrange, rapid arrangement of the helicopter platform can be achieved, the construction efficiency of the helicopter platform is improved, the arrangement cost of the helicopter platform is reduced, the influence of sea waves on a buoyancy structure is reduced, the arrangement stability and wind and wave resistance of the helicopter platform are guaranteed, and the continuous development of the deep sea culture industry is promoted.

Owner:深圳埃吉尔海洋科技有限公司

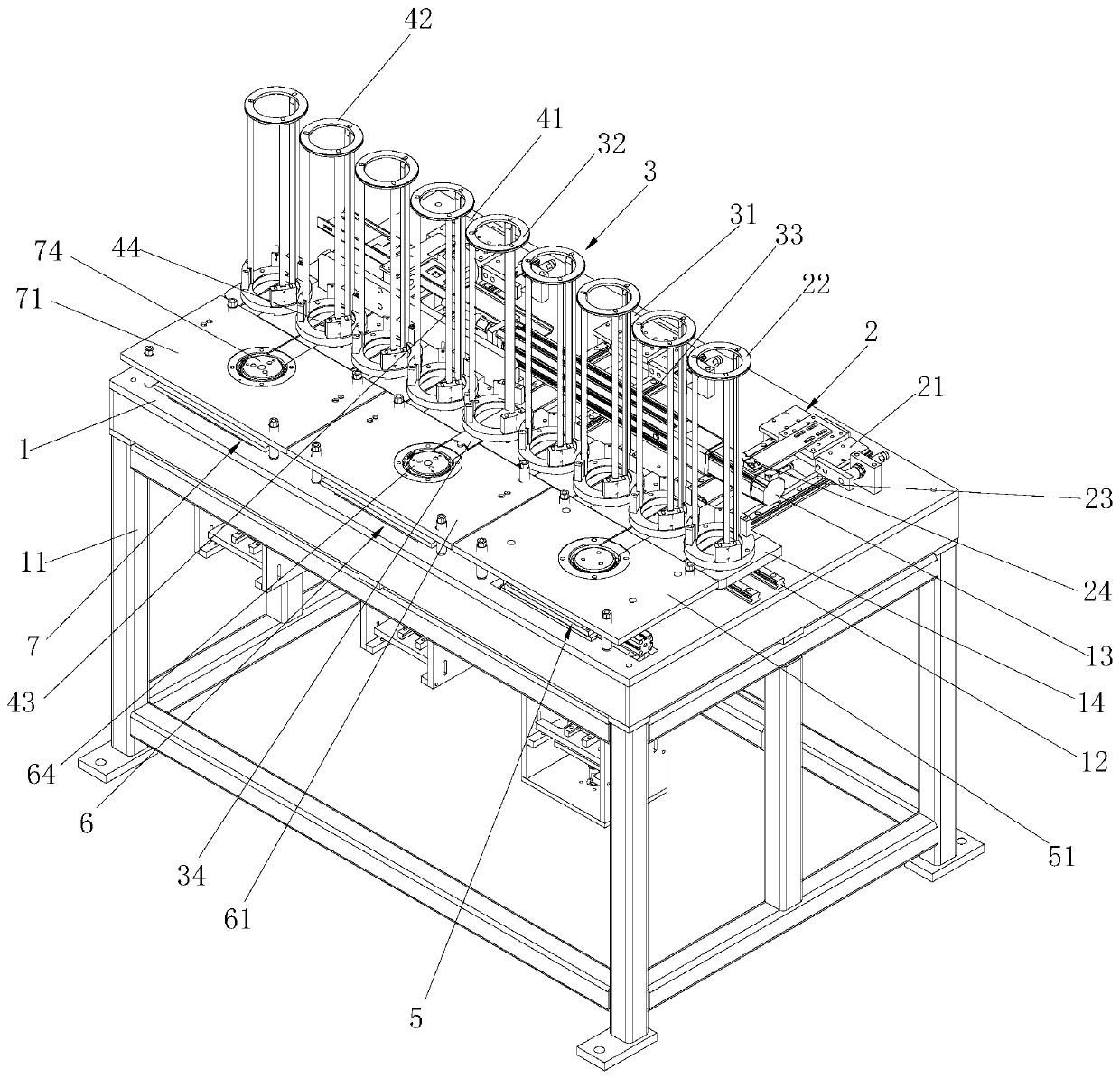

Intelligent detecting installing equipment for multiple types of piston rings

PendingCN109909723AAccurate installation controlImprove assembly efficiencyMetal working apparatusPiston ringPetroleum engineering

The invention discloses intelligent detecting installing equipment for multiple types of piston rings. The intelligent detecting installing equipment for the multiple types of piston rings comprises an installing platform, an oil ring positioning device, a conical surface gas ring positioning device and a barrel surface gas ring positioning device are connected to the installing platform, and first longitudinal slide rails, a first switching electric cylinder and a first material bin supporting plate are transversely arranged in the middle of the installing platform; the oil ring positioning device comprises first pushing mechanisms, oil ring material frames and oil ring expanding devices, and the oil ring material frames are connected to the first material bin plate; each oil ring expanding device comprises a first material receiving plate, a first transmission gear ring and a first expanding mechanism, a first piston supporting block is arranged in each first material receiving plate, and a first buffering reset mechanism and a first buffering support are connected to the lower end of each first piston supporting block; each first transmission gear ring is located at the lower end of the corresponding first material receiving plate and arranged outside the corresponding first piston supporting block in a sleeving mode; and the conical surface gas ring positioning device and the barrel surface gas ring positioning device are arranged on the portion, on the right side of the oil ring positioning device, of the installing platform. According to the installing equipment intelligent installing of the piston rings can be achieved, operation is easy and convenient, and the installing efficiency is high.

Owner:QINGDAO BESTONE IND EQUIP

Check tool for handlebar of curved beam motorcycle

InactiveCN101696868ASpeed up incoming quality inspectionIncoming quality controlAngles/taper measurementsMechanical counters/curvatures measurementsSoftware engineeringCam

The invention relates to a check tool for a handlebar of a curved beam motorcycle, wherein the middle of a bottom plate is fixed with a first positioning column and is provided with a first detection pin; supports are fixed on the left and right ends of the board surface of the bottom board, a first supporting board and a second positioning sleeve are arranged on the top of each supports, the board surface of the first supporting board is provided with a cam mechanism on the front end and a second positioning column on the back end, positioning pins are penetrated into the second positioning sleeves at the left and the right sides; second pillars are arranged between the first positioning column and the left support and between the first positioning column the right support, the top of each second pillar is fixed with a second supporting board, the second supporting board at the left side is provided with a second detection rod, a third supporting board and a second detection pin, and the second supporting board at the right side is provided with a second detection rod and a third detection pin. The invention can greatly improve the speed and the accuracy of quality detection when the handlebars are brought into motorcycle enterprises, ensures the conformation of the quality of the handlebar to requirements, effectively improves handlebar assembling speed and meets the requirement of consistent production.

Owner:力帆科技(集团)股份有限公司

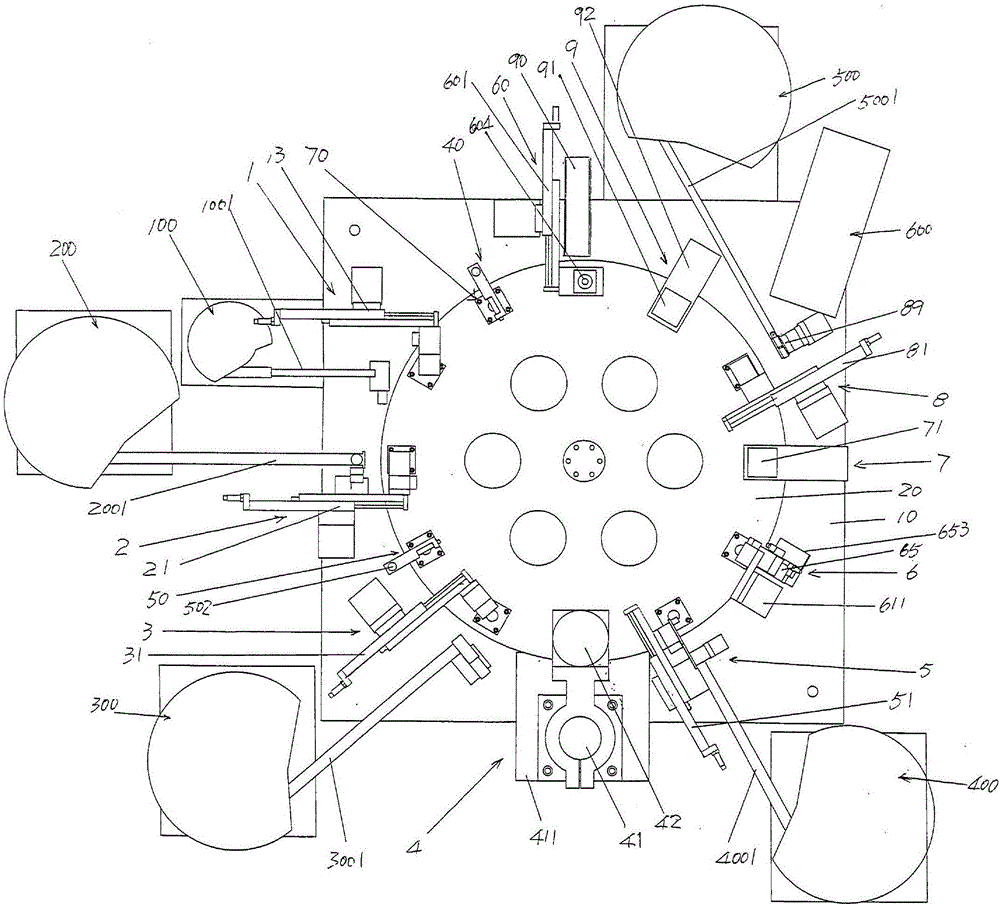

Automatic assembling device of protector having retained workpiece detecting function

An automatic assembling device of a protector having a retained workpiece detecting function comprises a worktable, a rotary disk, a rotary disk driving mechanism, a rivet installing mechanism, a protector base extracting and releasing mechanism, a workpiece absence detecting mechanism, a static contact piece installing mechanism, a rivet spinning and riveting mechanism, a movable contact piece extracting and releasing mechanism, a movable contact piece pre-pressing mechanism, a movable contact piece pressing mechanism, an insertion piece extracting and releasing mechanism, an insertion piece pressing and fixing mechanism and a protector moving mechanism and is characterized by further comprising a retained workpiece detecting mechanism located between the protector moving mechanism and the rivet installing mechanism, a rivet supplying vibration disk is arranged at the position of the rivet installing mechanism, a protector base supplying vibration disk is arranged at the position of the protector base extracting and releasing mechanism, a static contact piece supplying vibration disk is arranged at the position of the static contact piece installing mechanism, a movable contact piece supplying vibration disk is arranged at the position of the movable contact piece extracting and releasing mechanism, and an insertion piece supplying vibration disk is arranged at the position of the insertion piece extracting and releasing mechanism. The automatic assembling efficiency is guaranteed, and operating strength is reduced.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

Stator, rotor and bearing one-time assembled precision guiding device for permanent magnetism motor

InactiveCN109698587AGuaranteed assembly efficiencyAvoid contactManufacturing dynamo-electric machinesStatorEngineering

The invention discloses a stator, rotor and bearing one-time assembled precision guiding device for a permanent magnetism motor. The device includes a rotor guiding tool and a stator guiding tool; theinner surface of the rotor guiding tool is an installation surface, and the rotor guiding tool is installed on the rotating shaft of a rotor; a bearing inner ring is located between the rotor guidingtool and the rotor; the stator guiding tool is detachably connected to the end cover of a driving end of a permanent magnetism motor; the outer surface of the stator guiding tool is an excircle guiding surface, and the diameter of the excircle guiding surface is not greater than the external diameter of the bearing inner ring; and the stator guiding tool is provided with an upper inner circle guiding surface matching the excircle guiding surface. The device has advantages of being simple in structure, good in assembling quality and high in assembling efficiency.

Owner:ZHUZHOU CSR ELECTROMECHANICAL TECH

Counter character wheel assembly assembling machine and assembling method thereof

PendingCN113857814ARealize Orientation AdjustmentAchieve correctionAssembly machinesMetal working apparatusMan machineStructural engineering

The invention discloses a counter character wheel assembly assembling machine and an assembling method thereof, wherein the assembling machine comprises a workbench, a moving track arranged on the workbench, a wheel set containing station, a character wheel shaft penetrating station and an assembling station, the wheel set containing station, the character wheel shaft penetrating station and the assembling station are sequentially arranged along the moving track, and a code arranging station is further arranged between the character wheel shaft penetrating station and the assembling station; and the moving track is provided with a moving seat, the moving seat is provided with a combination die, the combination die is provided with combination grooves matched with character wheels, the moving seat and the workbench are provided with code arranging assemblies matched with each other, and a shaft adjusting assembly is used for adjusting the exposed lengths of the two ends of a character wheel shaft. When the assembling machine and the corresponding assembling method are adopted for assembling, orientation adjustment of transition wheels and correction of the character wheels and character codes can be rapidly achieved, secondary operation is reduced, meanwhile, the equipment structure can be effectively simplified through man-machine combination, the overall structure is compact, implementation is convenient, the better reliability is achieved, the assembling efficiency and quality are ensured, and meanwhile, the equipment manufacturing cost is reduced.

Owner:CHONGQING SMART METER GRP CO LTD

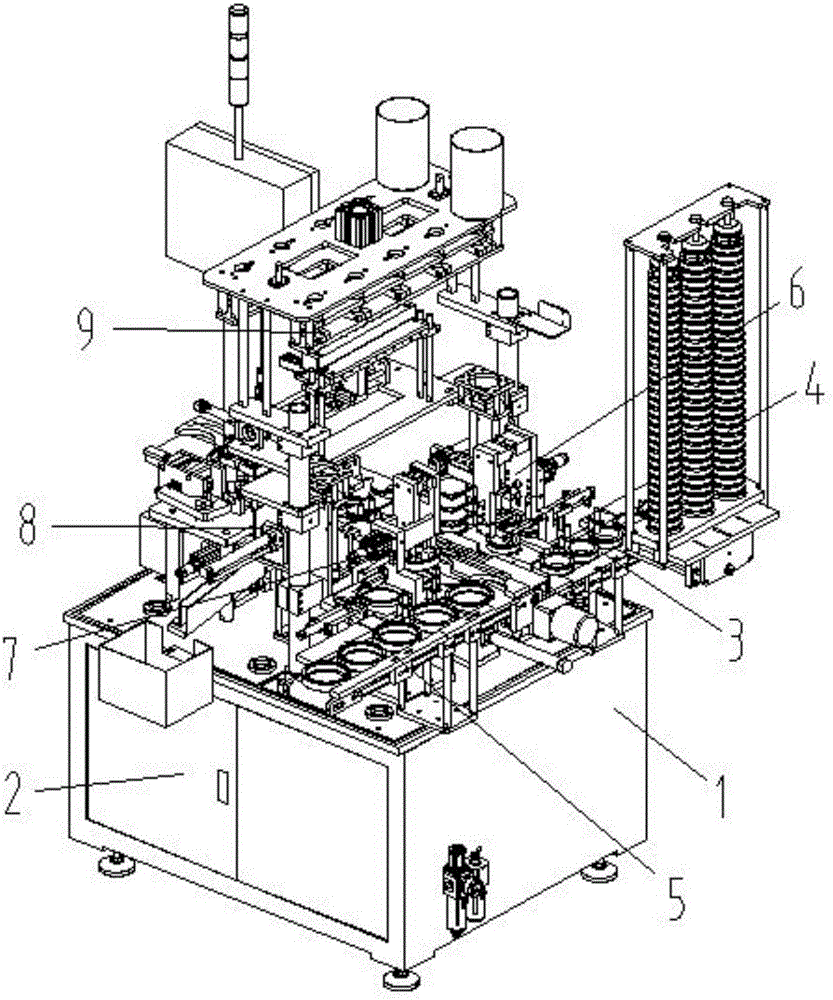

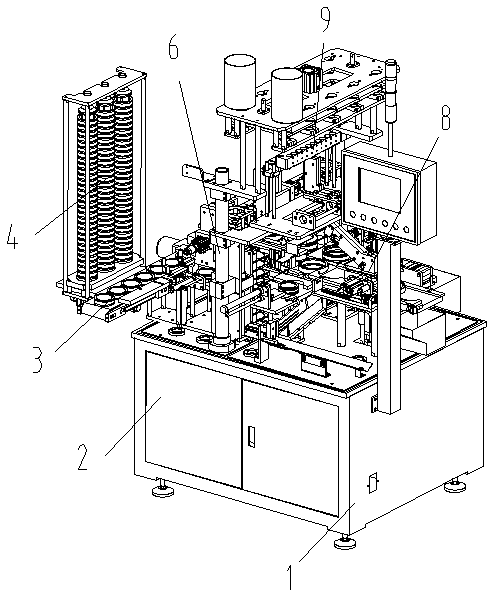

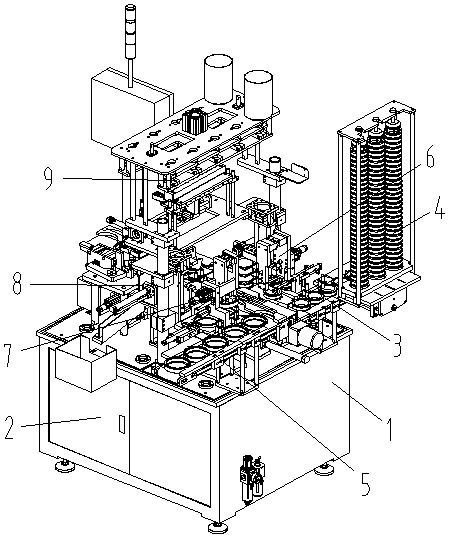

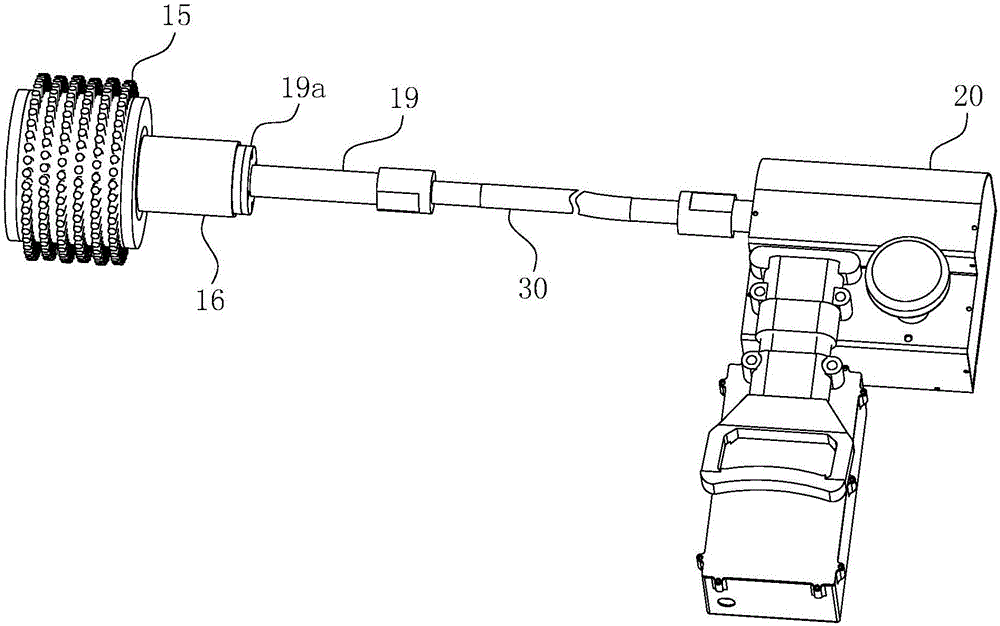

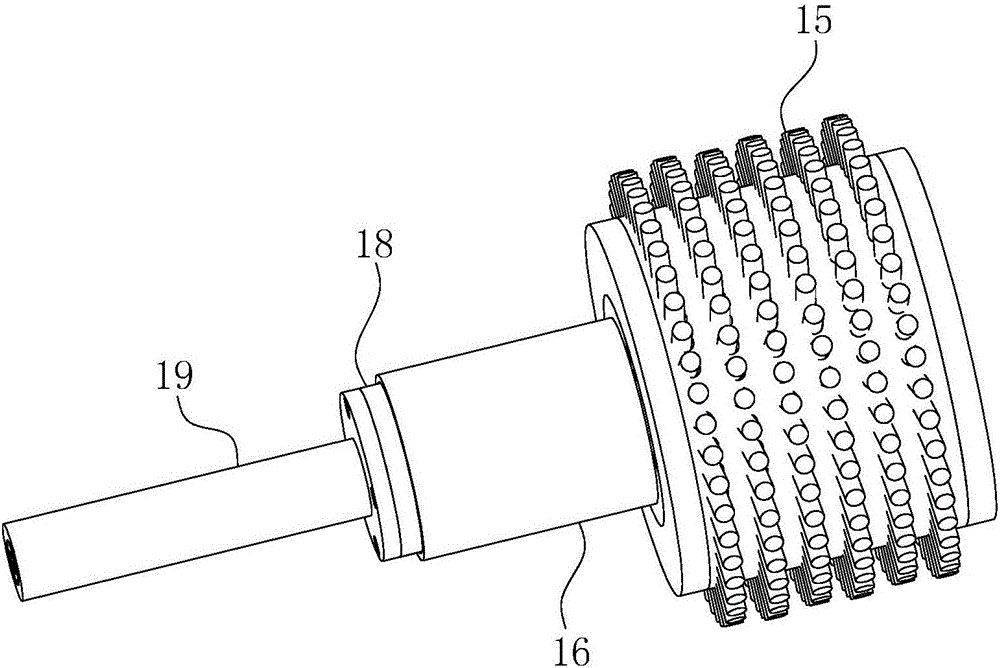

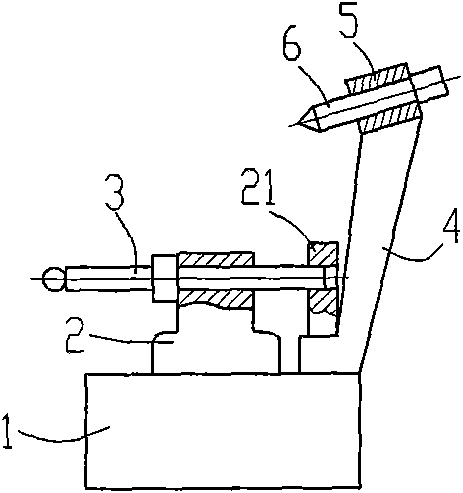

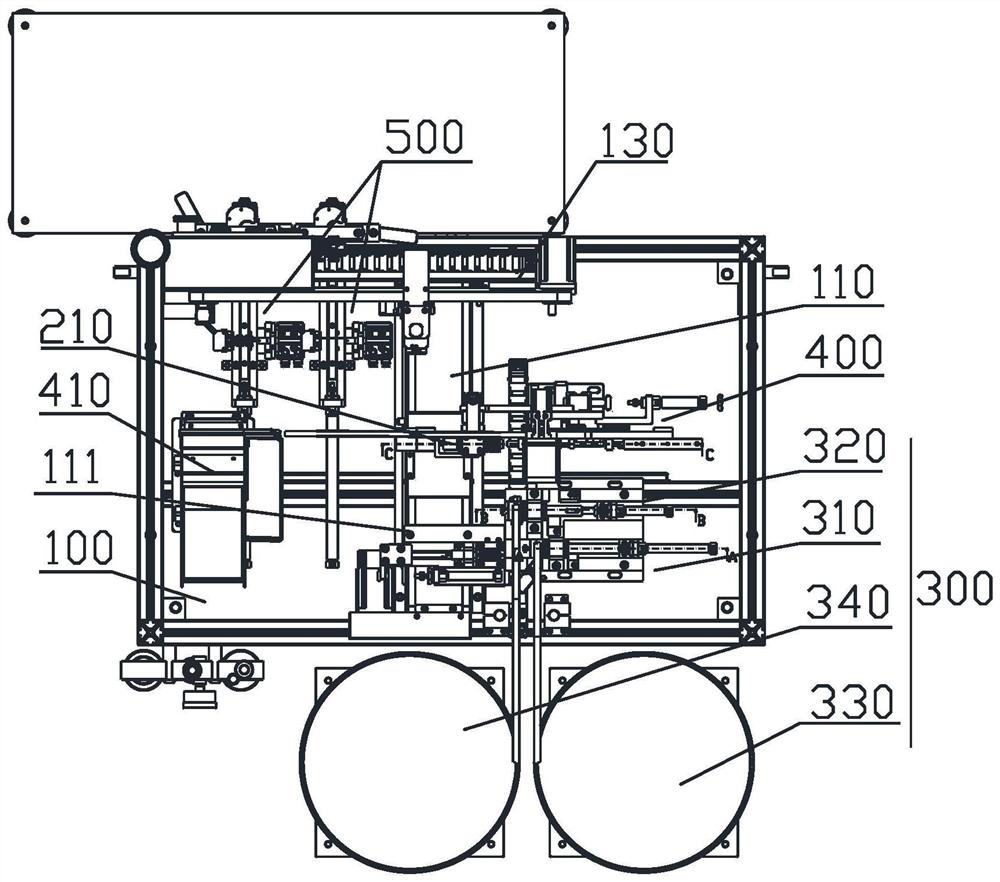

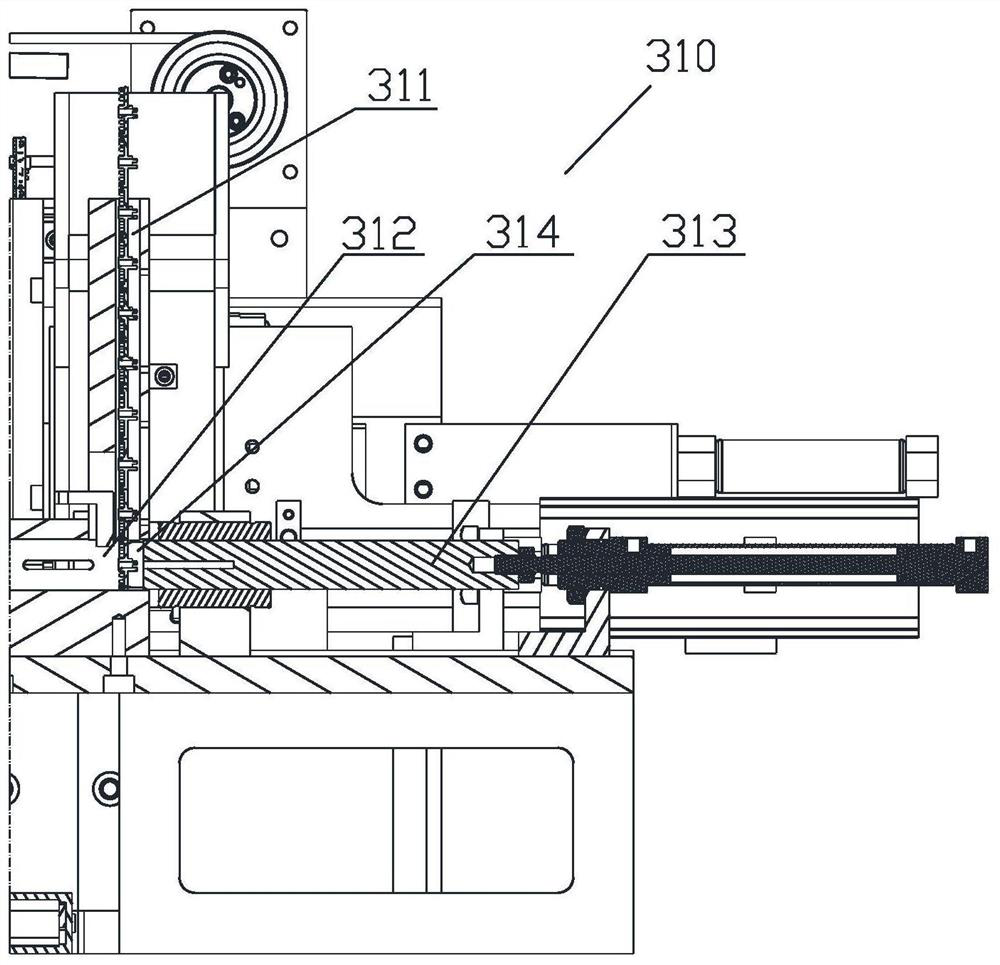

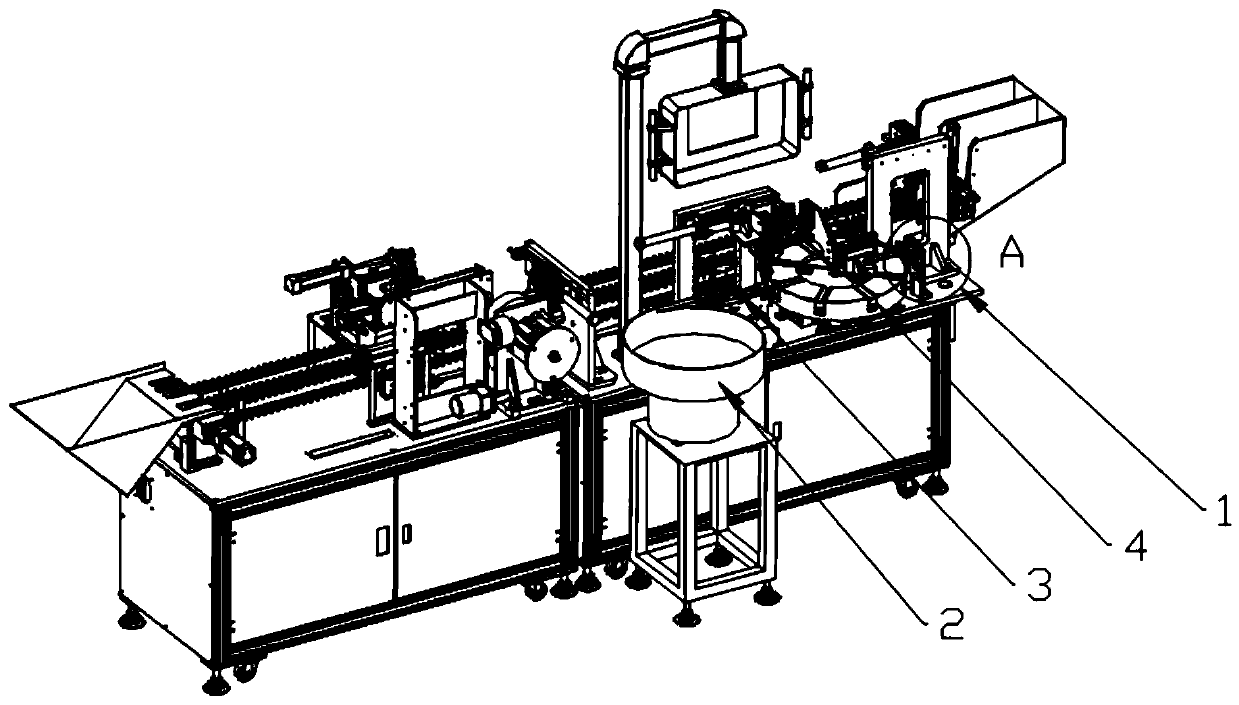

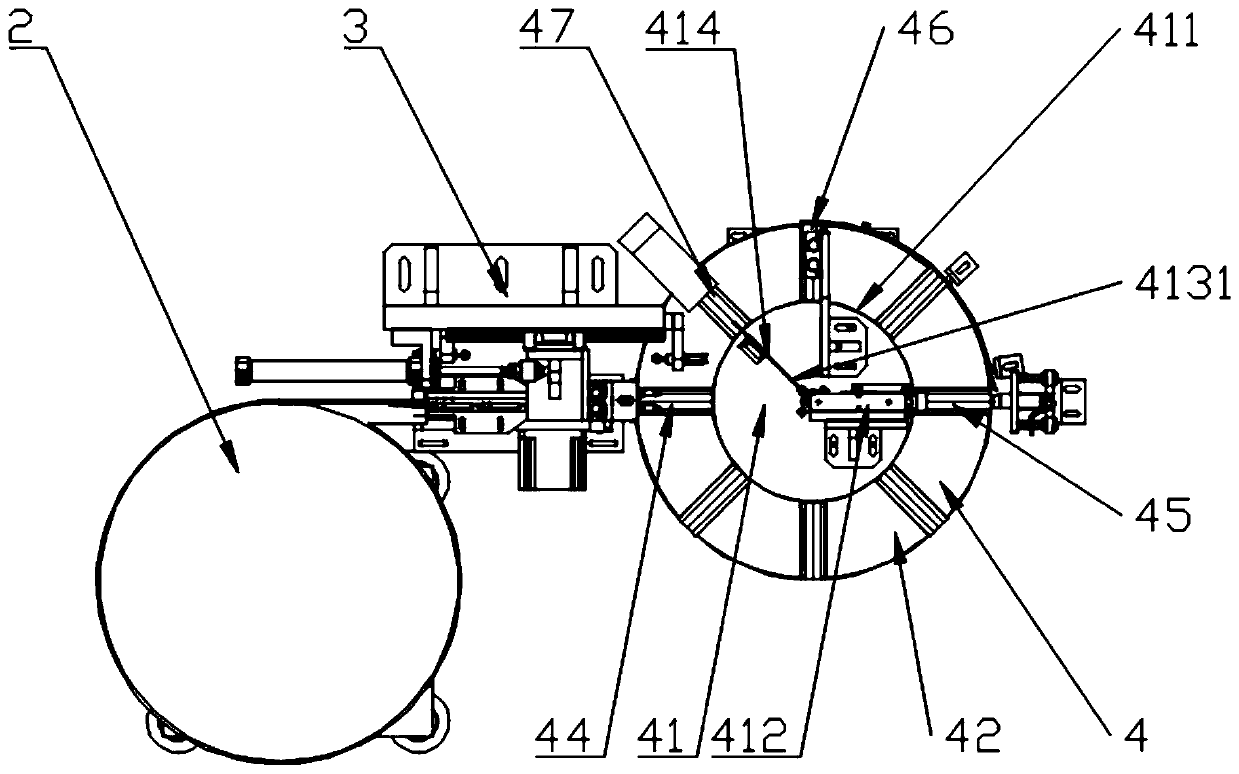

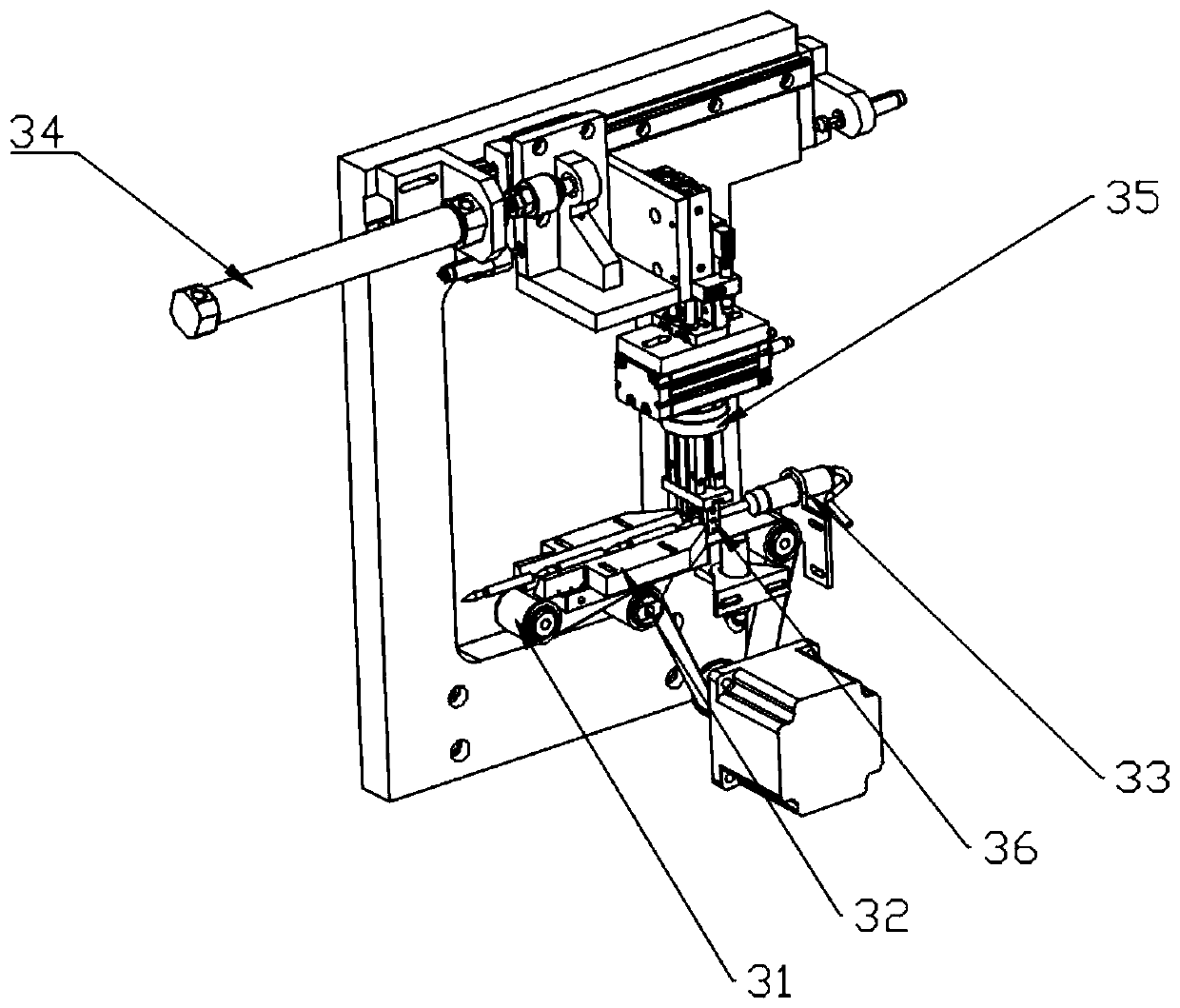

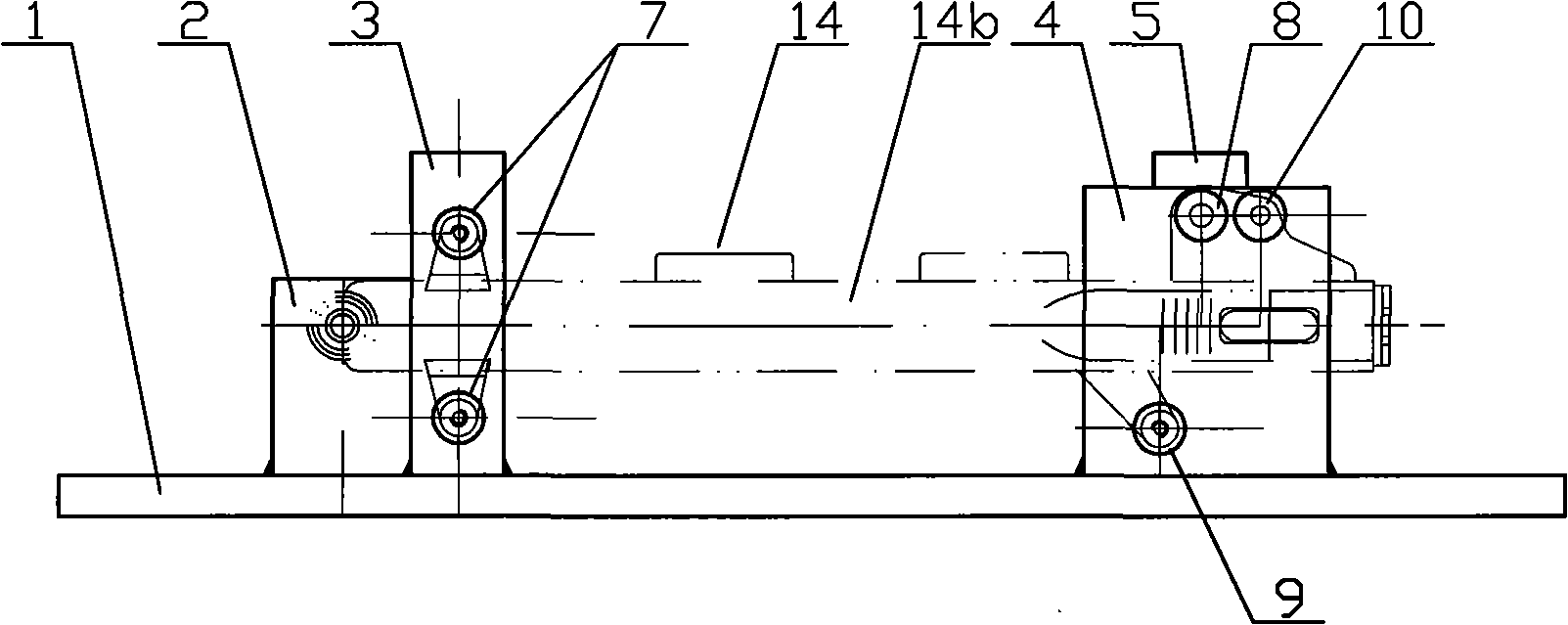

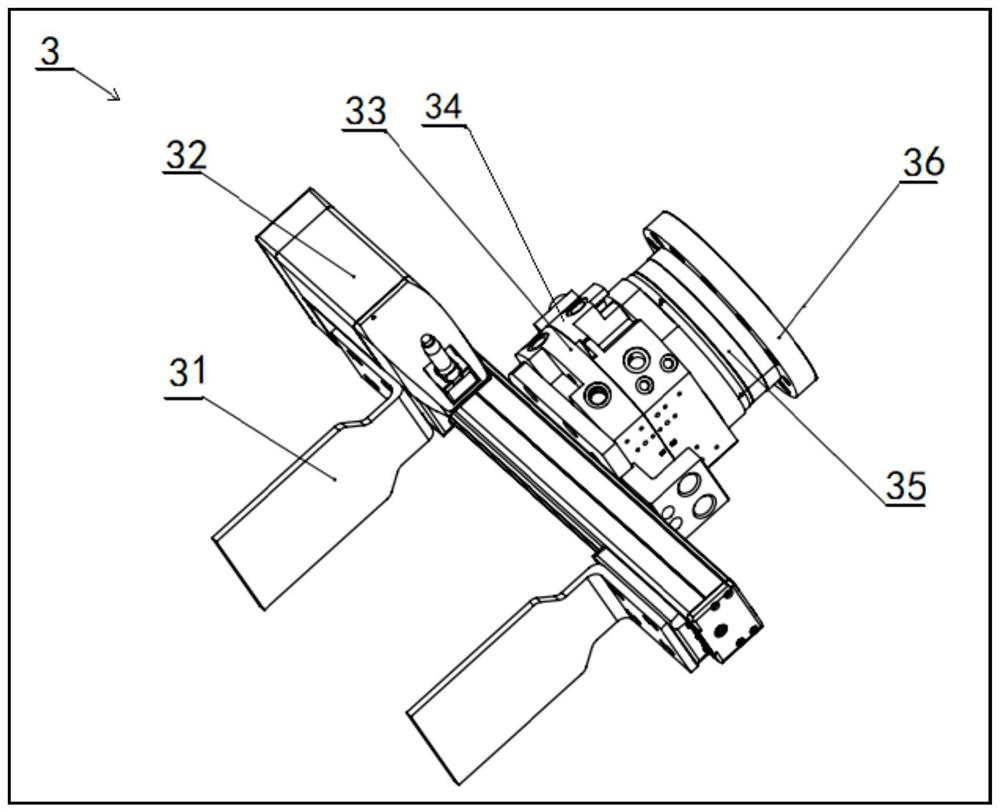

Plunger rotary-assembling machine

InactiveCN109623344AImprove transfer efficiencyHighly unifiedMetal working apparatusPlungerSupport plane

The invention discloses a plunger rotary-assembling machine. The plunger rotary-assembling machine comprises a machine frame. One end of the machine frame is slidably connected with a movable workbench through a sliding rod and a transmission lead screw. A supporting frame is fixedly arranged at the other end of the machine frame. A rotary shaft is rotatably arranged on the supporting frame through a rolling bearing. A chuck is arranged on the rotary shaft. The transmission lead screw and the rotary shaft are separately connected with a rotary motor and a servo motor. According to the plungerspin-assembling machine, a to-be-assembled cylinder body is fixed to the movable workbench, a plunger is mounted on the chuck, the chuck drives the plunger to rotate, the movable workbench drives theto-be-assembled cylinder body to move linearly, and then the plunger is rotatably assembled into the to-be-assembled cylinder body; and the assembling efficiency is high, the assembling difficulty isgreatly lowered, and the labor intensity of workers is relieved.

Owner:四川普什宁江机床有限公司

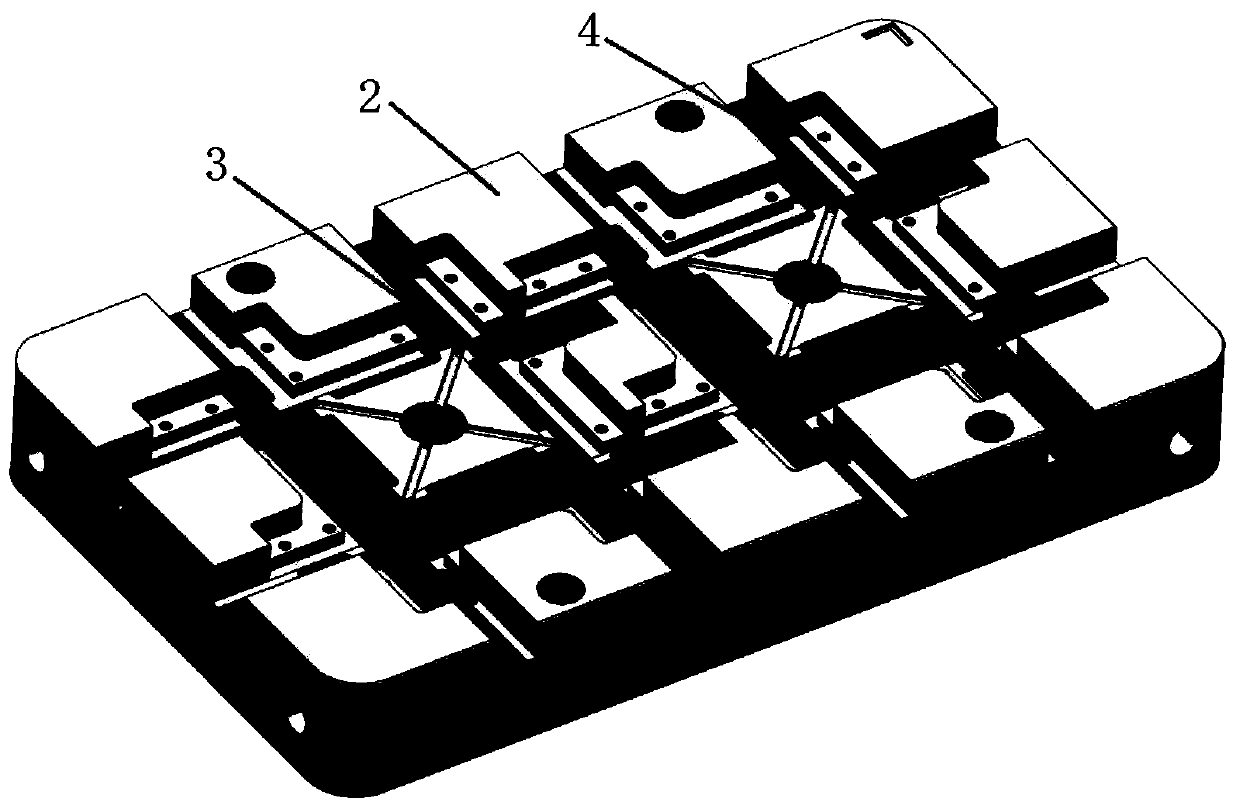

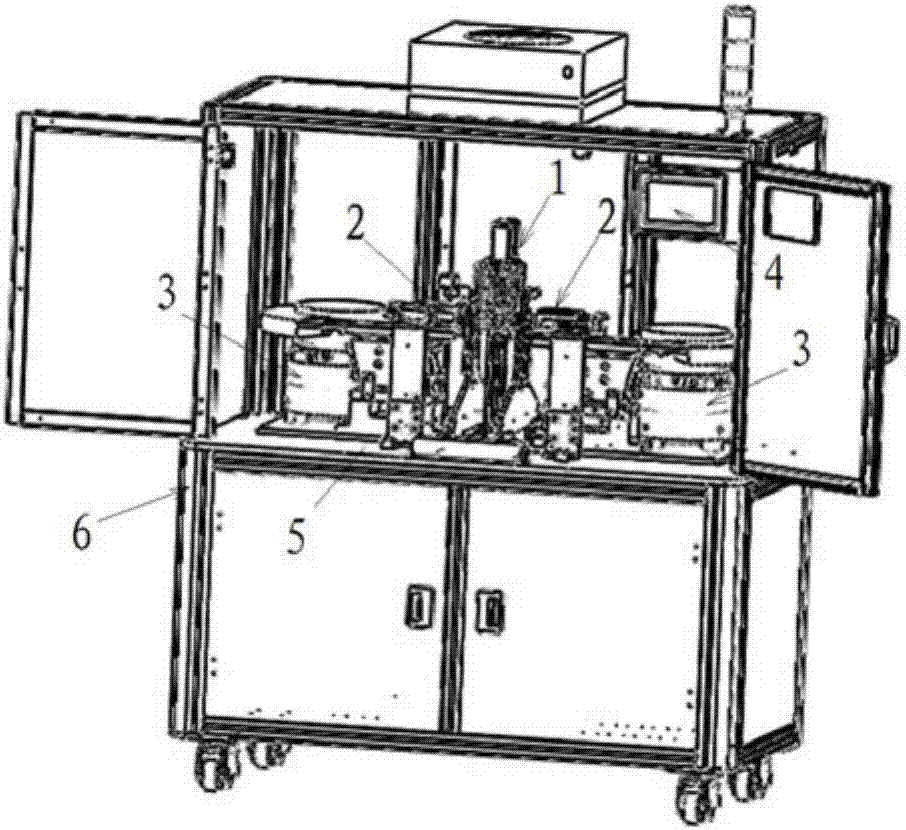

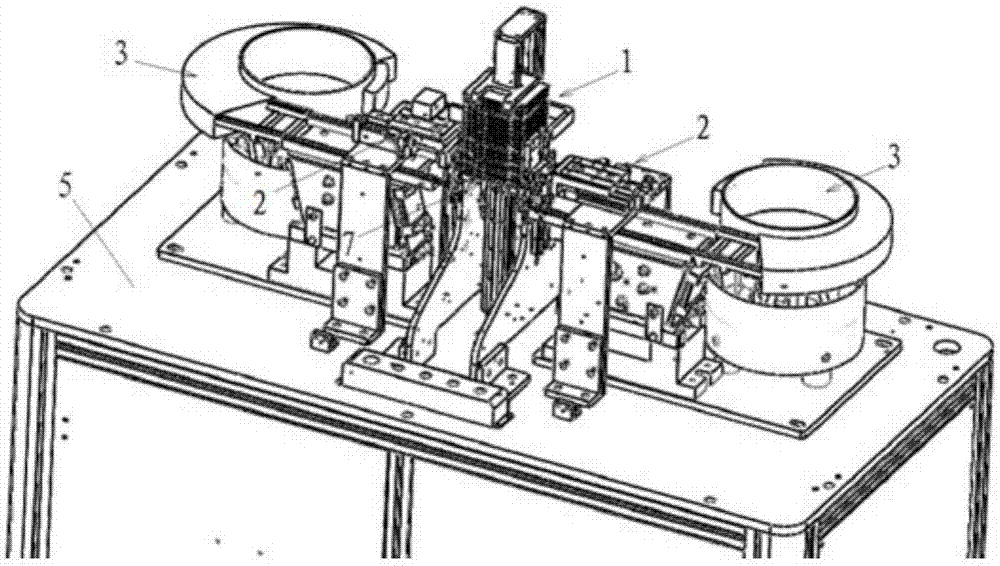

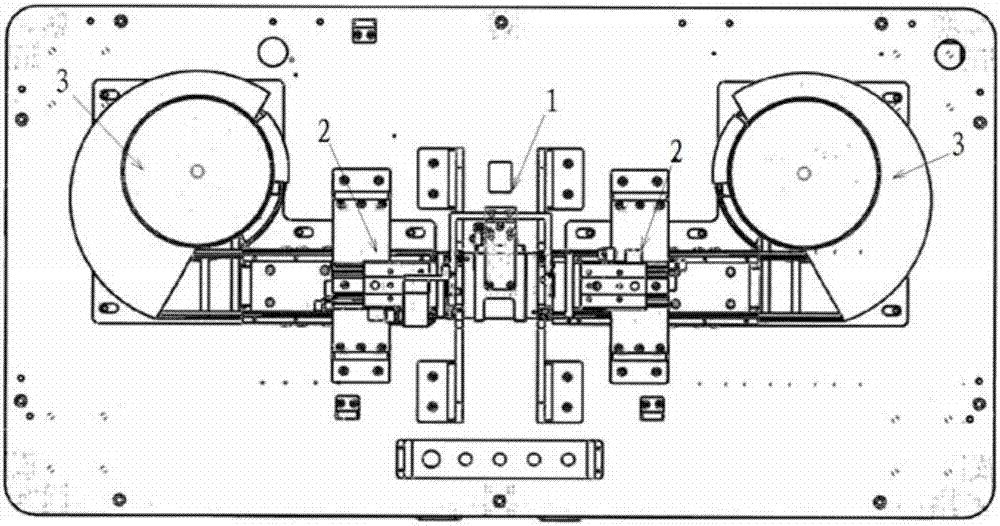

Buckle assembling device

PendingCN107538200AFirmly assembledReal-time continuous transportMetal working apparatusControl cellStructural engineering

The invention relates to a buckle assembling device. The buckle assembling device comprises a bearing unit (1), assembling units (2), conveying units (3) and a control unit (4). The two assembling units (2) are symmetrically arranged relative to the bearing unit (1). The conveying units (3) correspond to the assembling units (2). The control unit (4) is used for parameter setting and running control. The bearing unit, the assembling units and the conveying units are in a coordinated effect, accordingly real-time and continuous transportation of buckles is achieved, and the buckles can be automatically assembled to clamps. By means of the above arrangement, manual participation is not needed in the buckle and clamp assembling process, and the clamp and buckle assembling efficiency is improved. Meanwhile, the buckles are automatically assembled to the clamps through a mechanical device, the output force in the whole assembling process is the same, and accordingly buckle assembling firmness is guaranteed.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

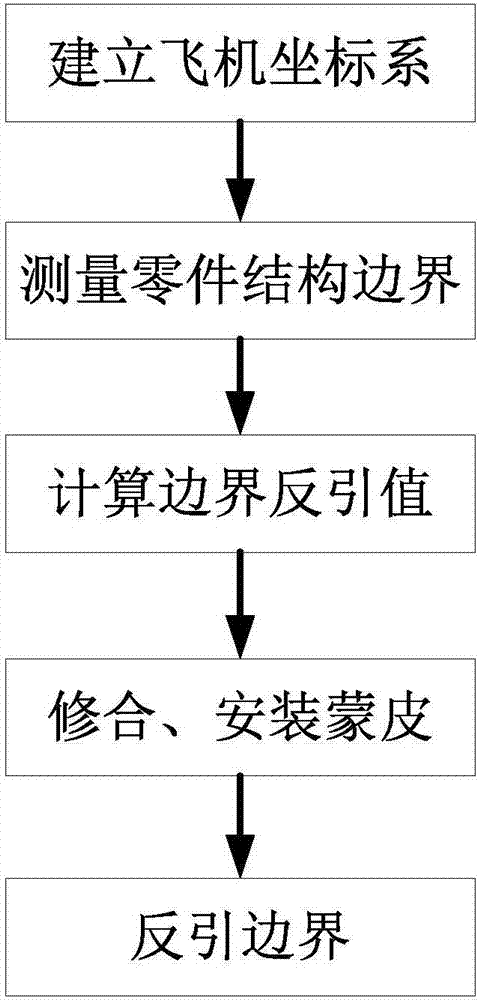

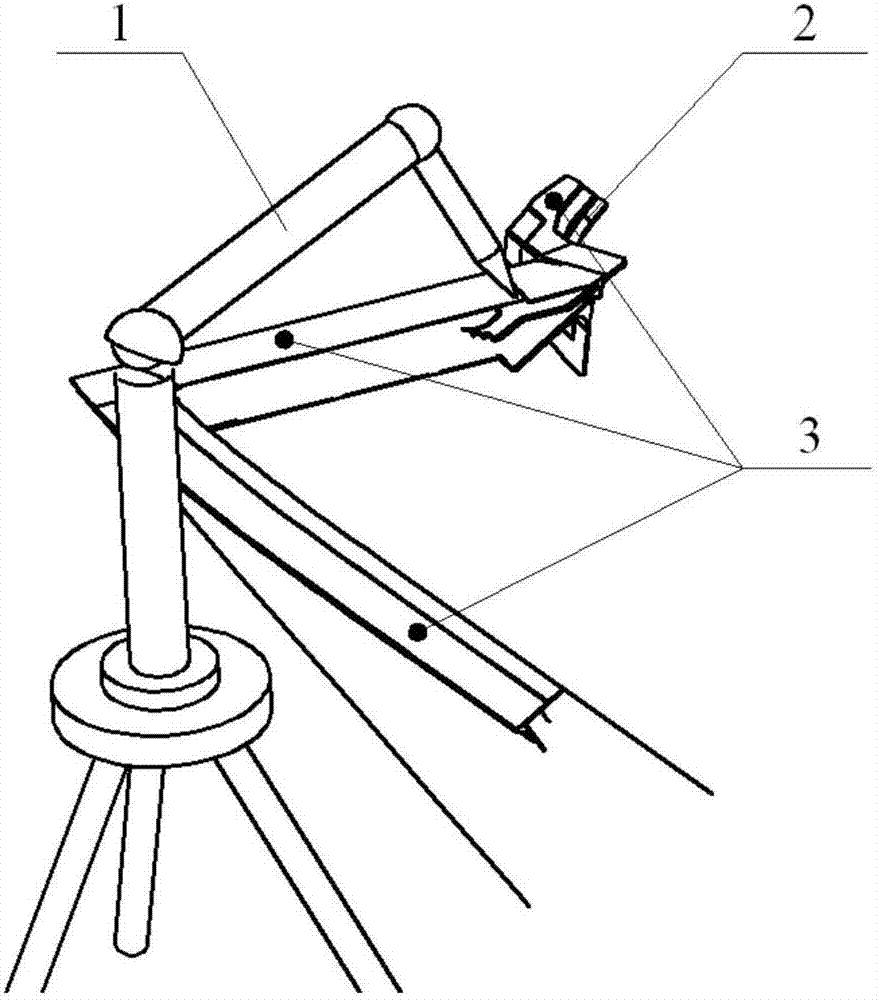

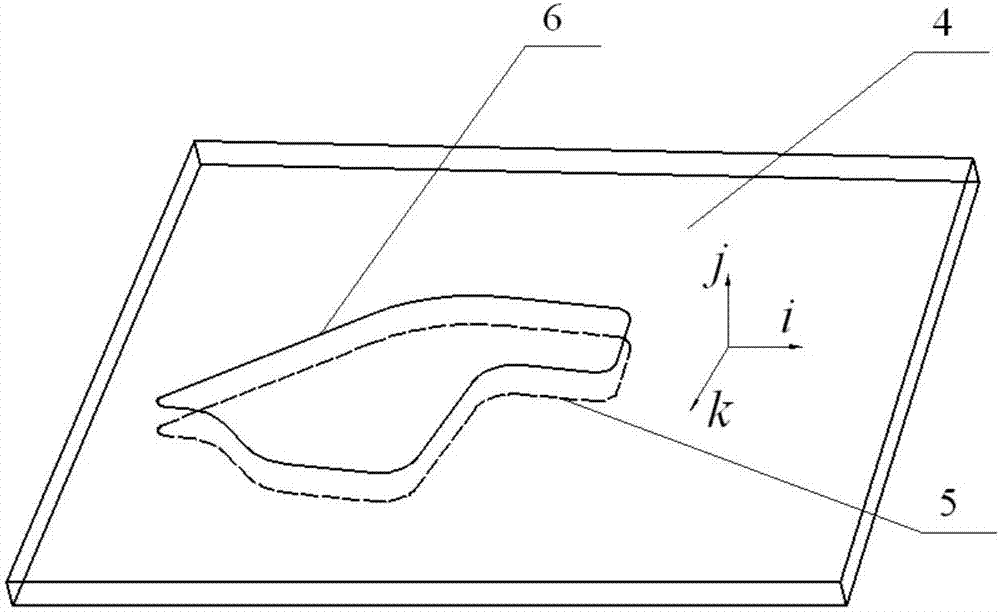

Aircraft internal complicated structure boundary reverse leading method adopting digital measurement

ActiveCN107283140AGuaranteed assembly qualityGuaranteed assembly efficiencyAircraft componentsMetal working apparatusProjection algorithmsEngineering

The invention provides an aircraft internal complicated structure boundary reverse leading method adopting digital measurement to achieve calculation, measurement and boundary reverse leading. Using an aircraft designed coordinate system as reference, the method comprises the following steps: data is acquired through digital measurement system, and an aircraft coordinate system is built by adopting an optimal fitting algorithm; a measurement head of the digital measurement system is adopted to measure the surface of a part near a boundary to be reversely leaded; aircraft part three-dimensional digital analogies are combined to extract a vector direction in the boundary, and a space curve of aircraft internal complicated structure boundary on the outer surface of a cover is obtained through a projection algorithm according to the thickness of the cover; the cover is finished and mounted; and the boundary is reversely leaded. The method reversely leads the aircraft internal complicated structure boundary by dint of three-dimensional digital measurement technology, can reach the boundary reverse leading precision of 0.5 mm, provides the basis for determination of hole positions of standard parts, and effectively improves the hole connecting precision and efficiency.

Owner:SHENYANG AIRCRAFT CORP

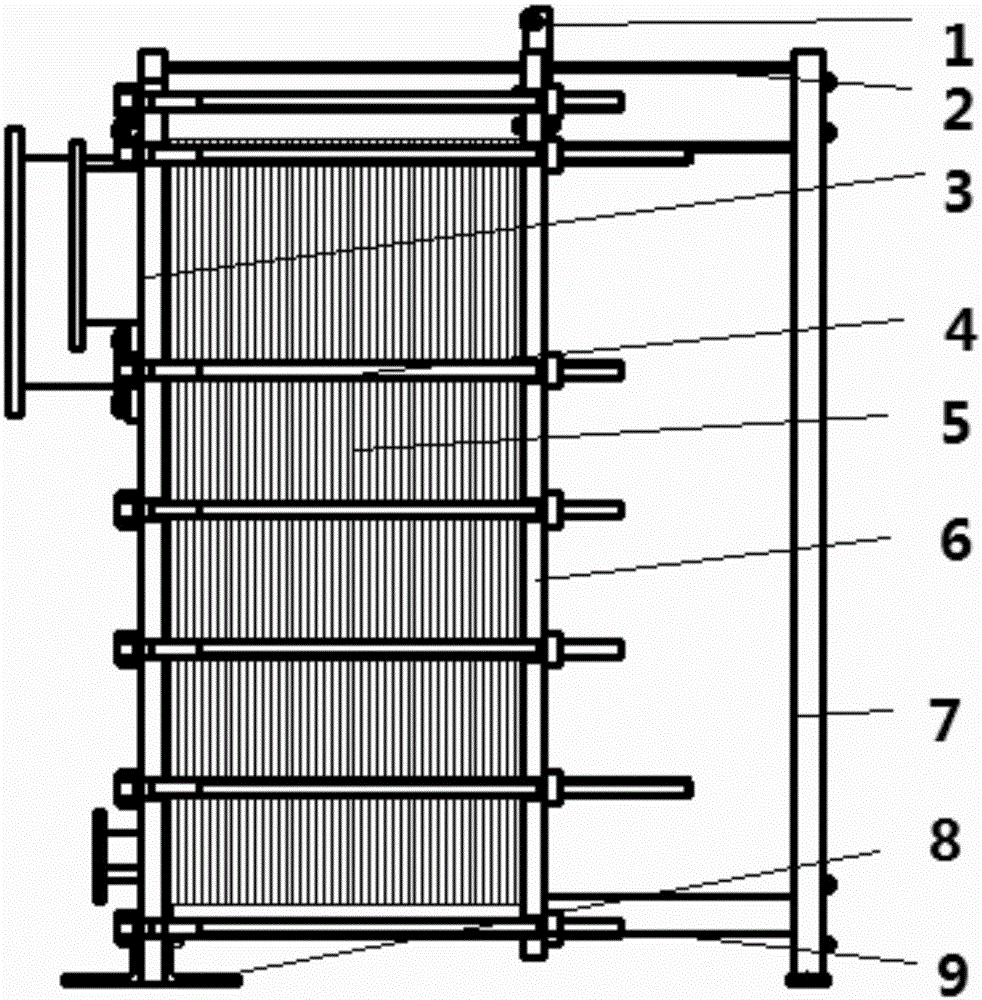

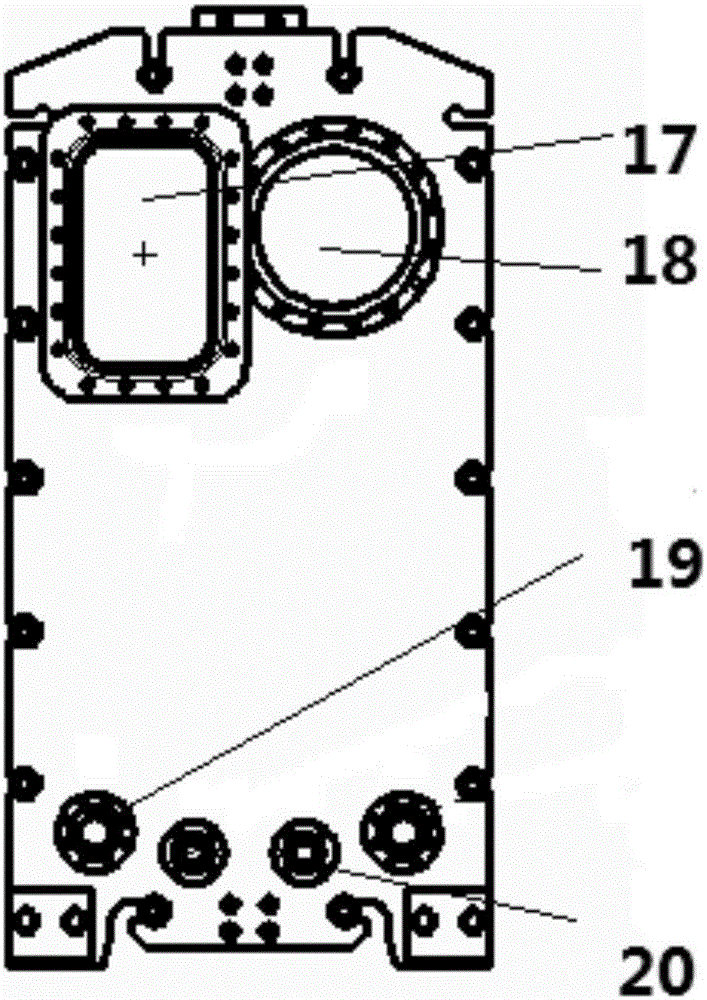

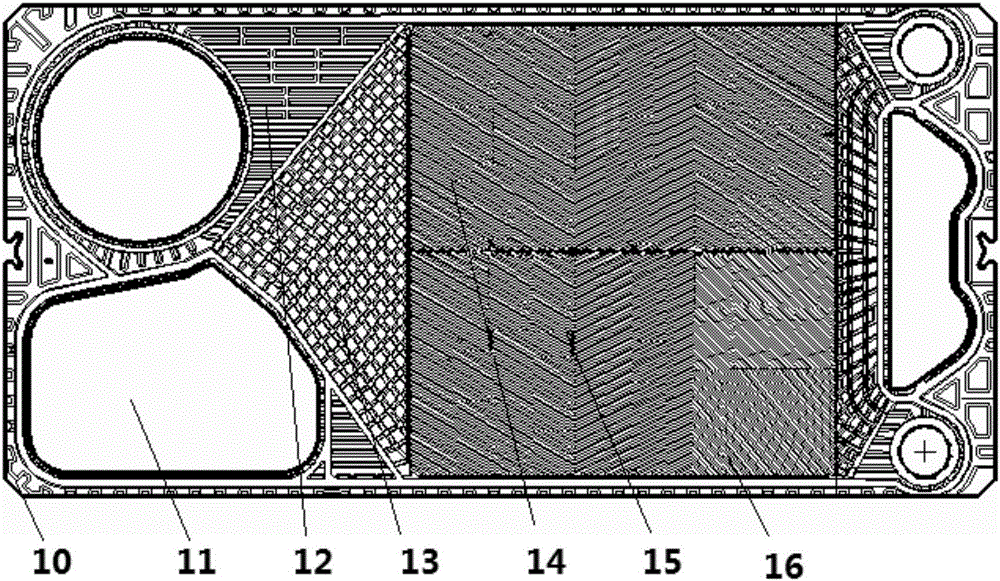

Simple evaporator

InactiveCN106288889AEasy to increase or decreaseMeet heat transfer needsHeat exhanger sealing arrangementStationary plate conduit assembliesEngineeringEvaporator

The invention provides a simple evaporator which comprises a fixing plate, a heat exchange unit, a moveable plate and a lateral bracket, wherein the heat exchange unit, the moveable plate and the lateral bracket are successively arrayed on a side wall of the fixing plate; U-shaped slots are arranged on the peripheries of the fixing plate and the moveable plate; the heat exchange unit comprises a plurality of heat exchange sets and a sealing gasket; corner holes for medium runners are formed in the four corners of a heat exchange plate; a flow guide area, a flow-splitting area and a heat exchange area are successively distributed on the heat exchange plate along the corner holes toward the center of the heat exchange plate; the heat exchange area is divided into a first heat exchange area and a second heat exchange area by taking the vertical central line of the heat exchange plate as a datum; the corner holes include a first medium inlet, a first medium outlet, a second medium inlet and a second medium outlet arranged in the flow guide area. The simple evaporator provided by the invention can meet the heat exchange requirement and can increase the heat exchange efficiency; a simple and compact structure is adopted, so that the device can be conveniently cleaned and maintained; the detaching is convenient; the heat exchange plate can be conveniently added and reduced; the sealing effect is better; the simple evaporator is fit for industrial wide popularization.

Owner:TIANJIN BOTAI HEAT EXCHANGE EQUIP

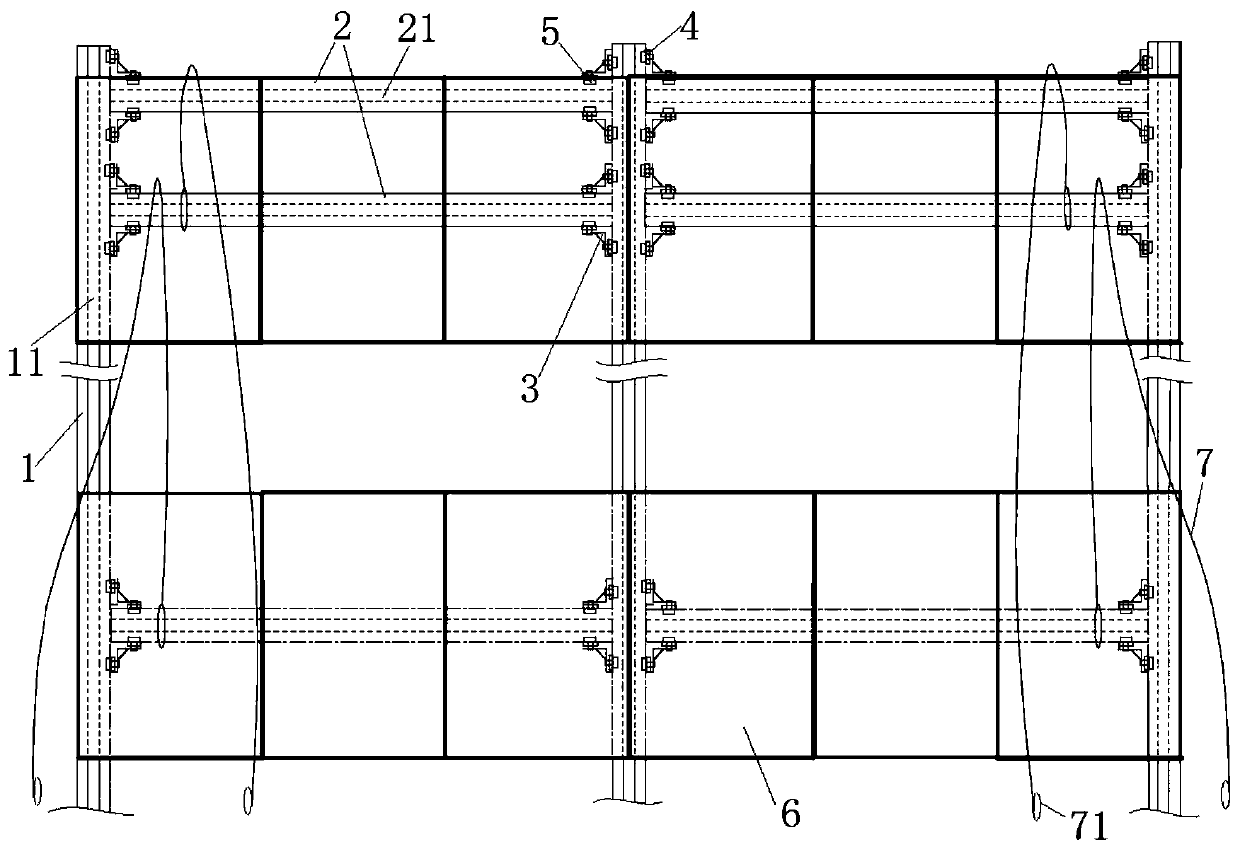

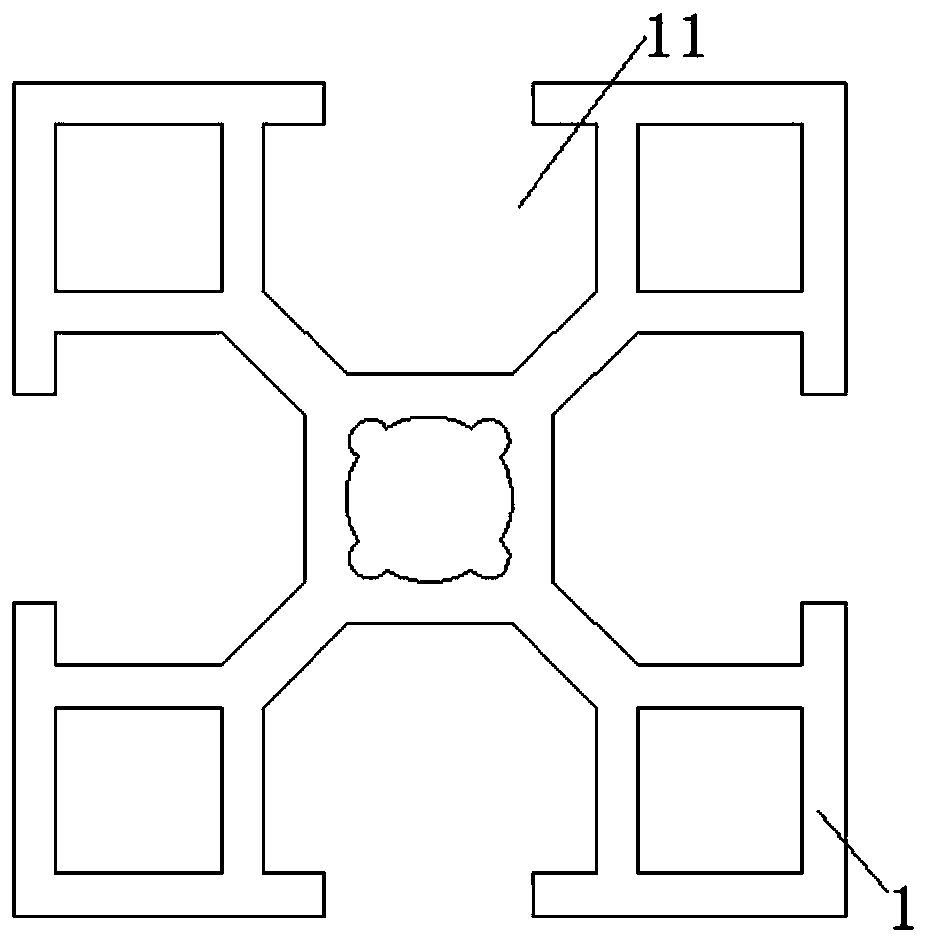

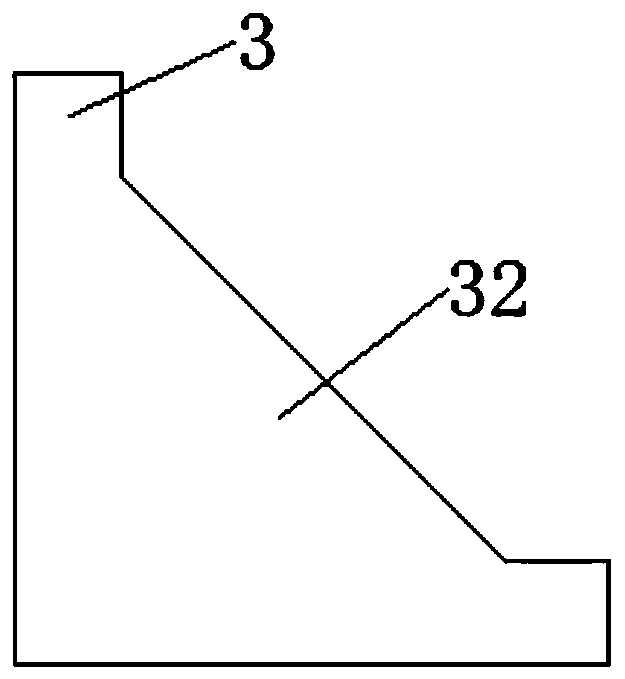

Assembly type television splicing screen mounting device and mounting method thereof

The invention relates to an assembly type television splicing screen mounting device and a mounting method thereof. The assembly type television splicing screen mounting device comprises vertical brackets, transverse brackets, connectors, lifting ropes and splicing screens; the bottoms of the vertical brackets are connected onto the ground; the transverse brackets are parallelly erected between the adjacent vertical brackets; first mounting rails are arranged on the vertical brackets; second mounting rails are arranged on the transverse brackets; one end of each connector is connected with thecorresponding first mounting rail by a first locking piece; the other end of each connector is connected with the corresponding second mounting rail by a second locking piece; one lifting rope is arranged between the two adjacent transverse brackets, and is wound on the transverse bracket on the upper side; one end of each lifting rope is connected with the corresponding transverse bracket on thelower side; a pull handle is arranged at the other end of each lifting rope and the other ends of the lifting ropes extend to the bottoms of the vertical brackets; the splicing screens are connectedwith the second mounting rails by hooks; all the splicing screens are on the same plane. The mounting device and the mounting method have the advantages of convenience in adjusting, high assembling accuracy, convenience in dismounting and mounting, and high safety.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL INSTALLATION +2

Pen point feeding system

PendingCN111573167AImprove assembly efficiencyThere is no problem of misalignmentControl devices for conveyorsMetal working apparatusEngineeringMechanical engineering

The invention discloses a pen point feeding system. The pen point feeding system comprises a rack, a vibration disc is installed on the rack, the discharging end of the vibration disc is connected with a second-stage conveying mechanism through a first-stage conveying mechanism, the second-stage conveying mechanism comprises a fixed disc, the outer side of the fixed disc is sleeved with a movabledisc, the movable disc is provided with a driving device, the driving device drives the movable disc to intermittently rotate around the axis in an indexing mode, a plurality of V-shaped supporting plates are arranged on the upper end face of the movable disc at equal intervals, first air cylinders are arranged on the V-shaped supporting plates, a fence fixedly connected with the rack is arrangedon the outer side of the movable disc, an in-place mechanism corresponding to the fence is installed on the fixed disc, a pressing mechanism fixedly connected with the fixed disc is arranged on a station behind the in-place mechanism, the pressing mechanism comprises a sliding block and a second air cylinder driving the sliding block to move up and down, and a pen point is fixed through the downwards-pressed sliding block and the jacked V-shaped supporting plates so as to be used for assembling a pen holder. According to the pen point feeding system, the problems that in the prior art, feedingis unstable, and the assembling efficiency of the pen point and the pen holder is low are solved.

Owner:扬州威远机械制造有限公司

Rear fork detecting fixture of motorcycle

InactiveCN101315265AEasy to placeEvenly placedVehicle testingMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a detection tooling apparatus for a rear fork of a two-wheeled motorcycle. A front positioning seat is fixed at the front part of a base, through-holes penetrating left and right end surfaces are formed on the front positioning seat, and positioning shafts are inserted into the through-holes; a left front positioning seat is positioned on the left side of the rear part of the front positioning seat, an upper through-hole and a lower through-hole which respectively penetrate the left and the right end surfaces are formed on the left front positioning seat, and a first positioning pin is inserted in each through-hole from outside to inside; a left rear positioning seat and a right rear positioning seat are positioned at left and right ends of the rear part of the base, second positioning pins are inserted into the upper parts of the left rear positioning seat and the right rear positioning seat from outside to inside, positioning holes penetrating the inner end surface of the second positioning pin are formed at the inner end thereof, and a third positioning pin and a fourth positioning pin are respectively arranged on front and rear sides of the second positioning pins at the left end. The detection tooling apparatus can greatly improve the rate and the accuracy of the quality detection when the rear fork enters a factory of a motorcycle manufacturer, ensure that the quality of the rear forks meet the requirements, effectively improve the assembly speed of the rear fork and meet the requirement of uniform production.

Owner:力帆科技(集团)股份有限公司

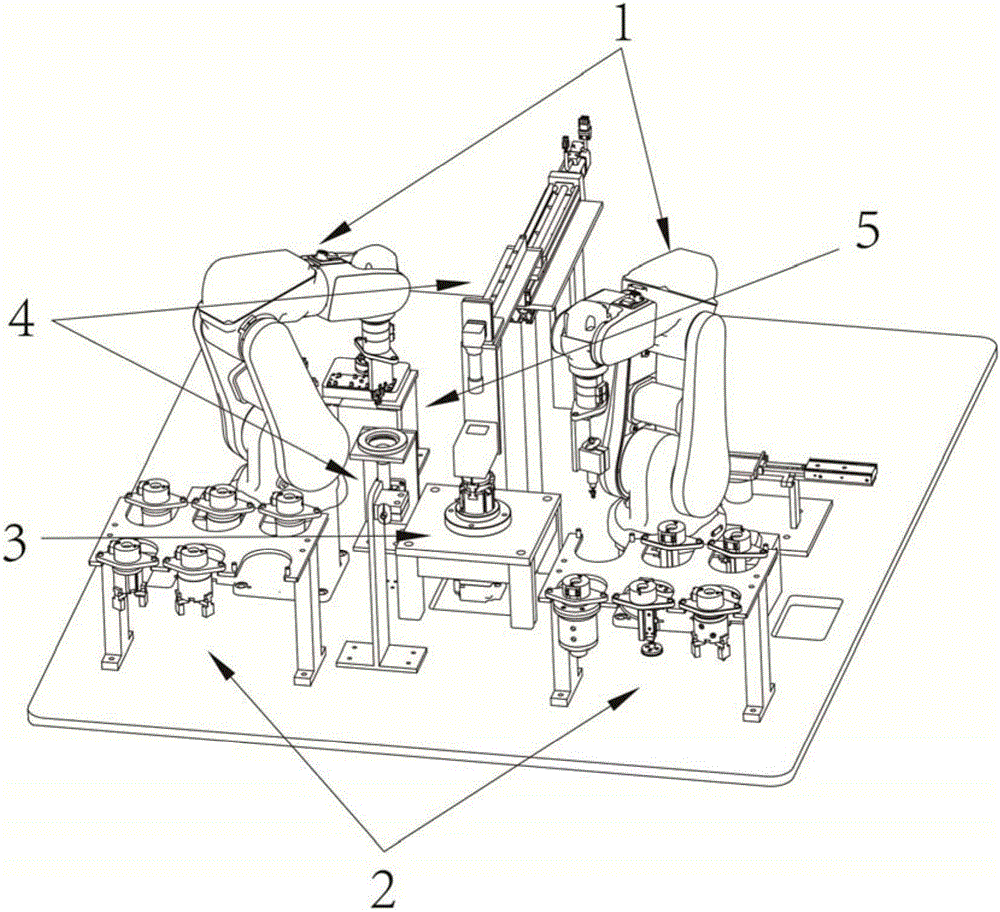

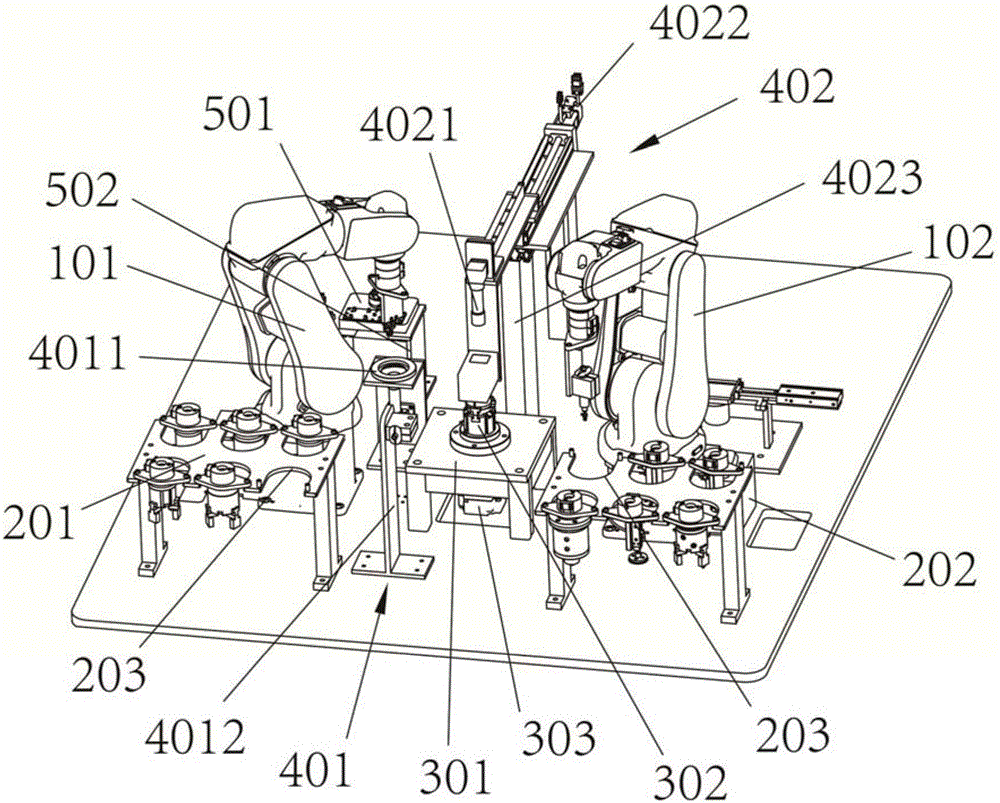

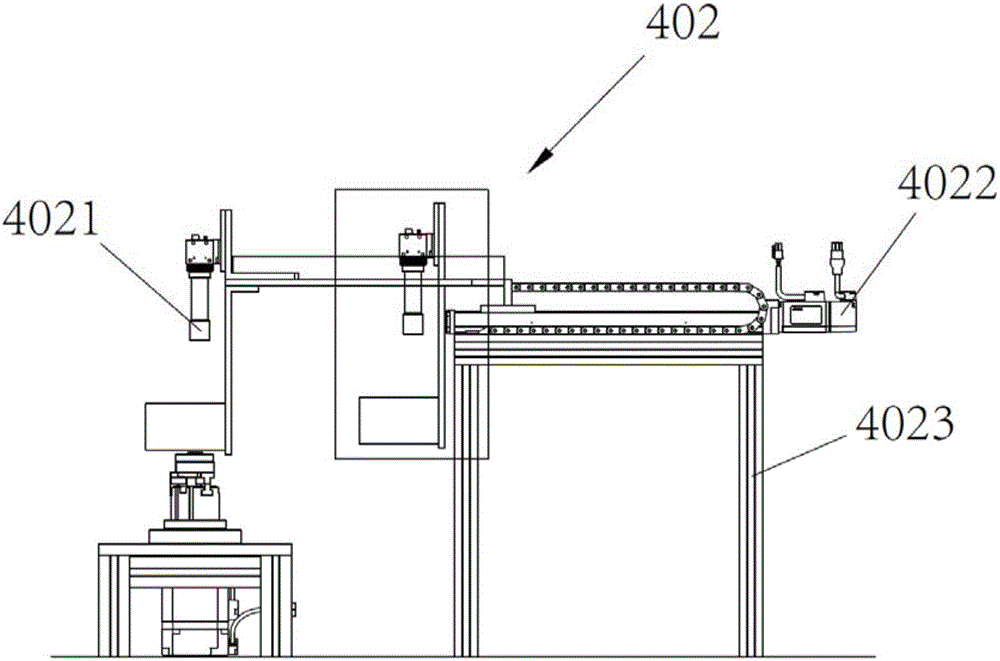

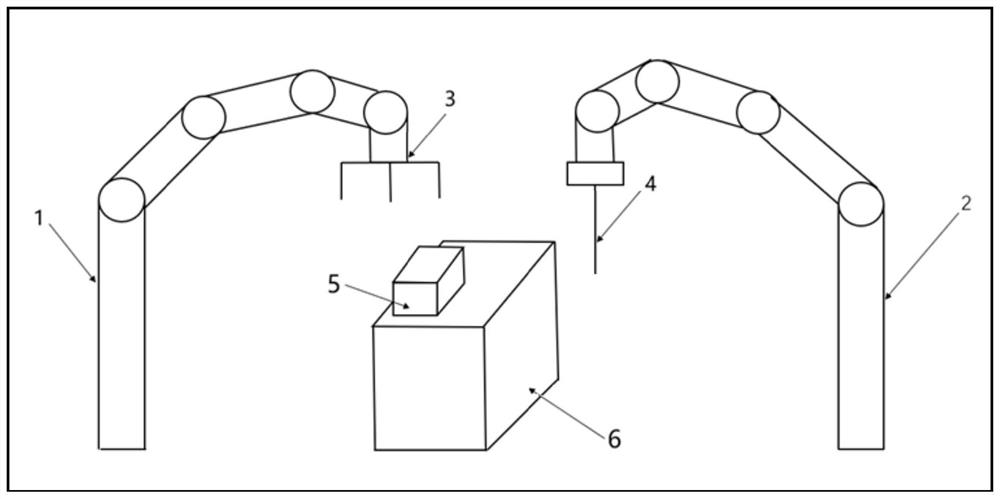

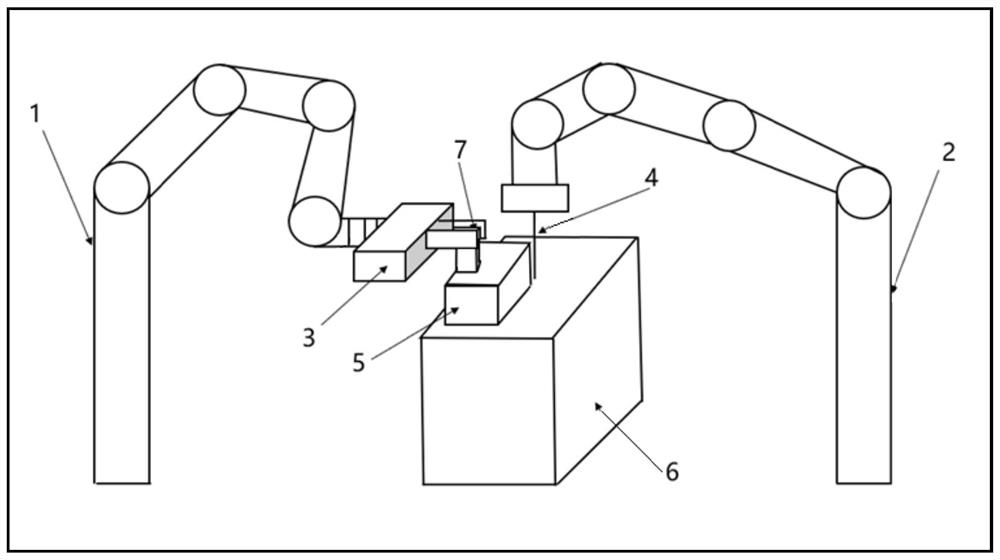

Assembly system and method based on cooperation of double manipulators

ActiveCN113681562AHigh degree of automationHigh positioning accuracyProgramme-controlled manipulatorGripping headsProcess engineeringManipulator

The embodiment of the invention provides an assembly system and method based on cooperation of double manipulators. The assembly system and method are applied to the technical field of automation. During cooperative assembly of the double manipulators, the first manipulator obtains a placing position corresponding to a to-be-assembled material through a first visual system, and grabs the to-be-assembled material through a gripper at the tail end; after the to-be-assembled material is placed on the placing position, a pressing block is grabbed through the grabber, and the to-be-assembled material is pressed on the placing position through the pressing block; and the second manipulator obtains an assembly position in the to-be-assembled material through a second visual system, and the assembly position in the to-be-assembled material is accurately assembled through an assembling tool. Through cooperative assembly of the double manipulators, the intelligent level of assembly is improved, the assembly efficiency and the assembly precision are also improved, and the assembly system and method can be used for automatic assembly of high-precision instruments.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com