Single pole assembly tool for immobilized and encapsulated post terminal and casting method for immobilized and encapsulated post terminal

A technology of solid-sealed poles and assembly tooling, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of axial movement and relative rotation, and achieve the effect of ensuring assembly efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

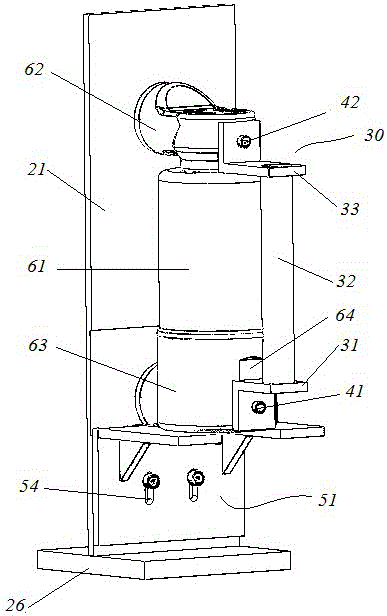

[0027] The embodiments of the present invention will be further described below in conjunction with the drawings.

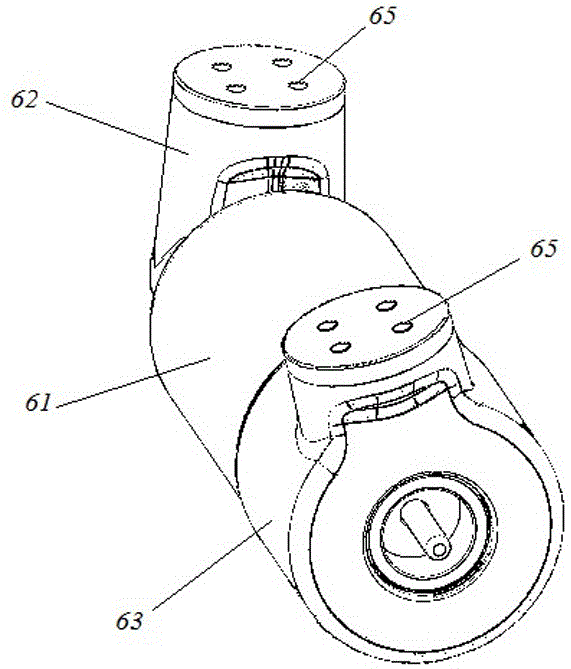

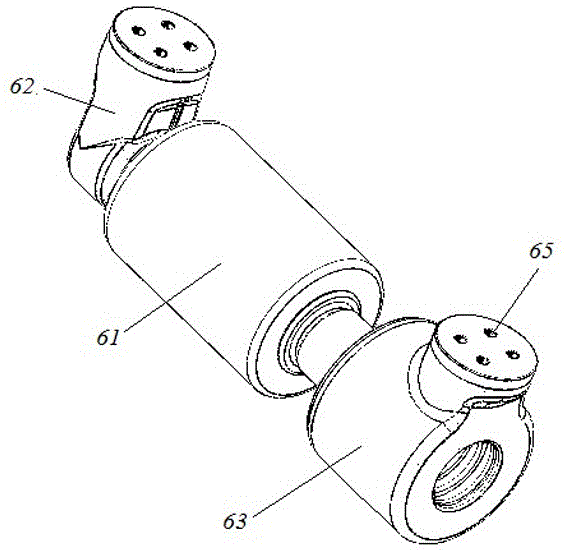

[0028] An embodiment of the solid-sealed pole unipolar assembly tooling of the present invention Figure 3~Figure 8 As shown, the outlet seat support frame 10, the outlet seat connection frame 30 and the lower outlet seat bracket 51 are included. The outlet seat support frame 10 includes a bottom plate 26 and a fixing plate 21 erected on the bottom plate 26. The outlet seat connecting frame 30 constitutes an outlet seat connecting piece, including a hand-held part 32 and a fixed part 31 and a positioning part 33 provided at both ends of the hand-held part 32 , The fixing portion 31 is used for fixed connection with the lower outlet seat 63, and the positioning portion 33 is used for fixing with the upper outlet seat 62 to realize axial and circumferential positioning.

[0029] The fixing plate 21 is provided with three sets of through holes from top to bottom, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com