Medium-frequency heating and shrinking equipment of servo motor stator and using method thereof

A technology for servo motors and motor stators, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as inability to guarantee the quality of the motor, damage to the motor stator and motor casing, and complicated processes, achieving fast speed, ensuring assembly quality and efficiency, The effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

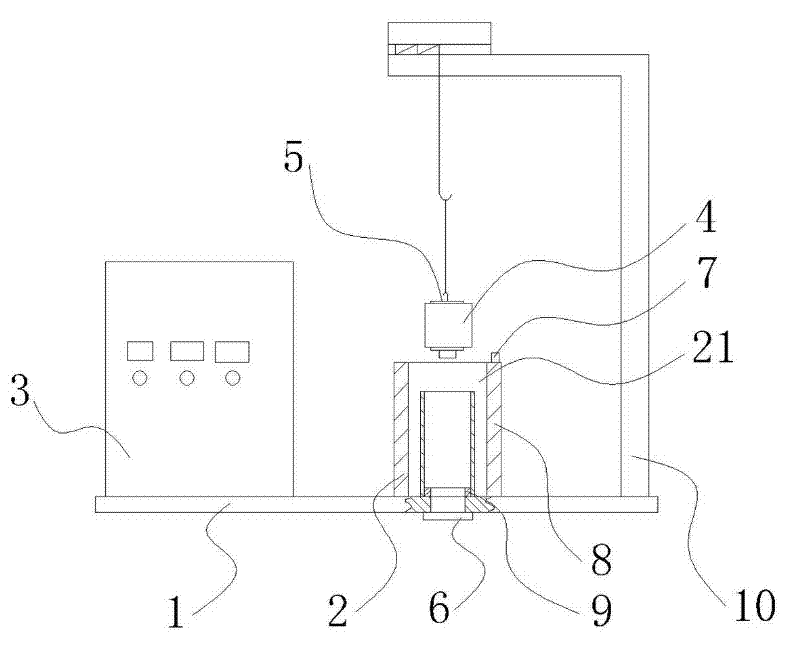

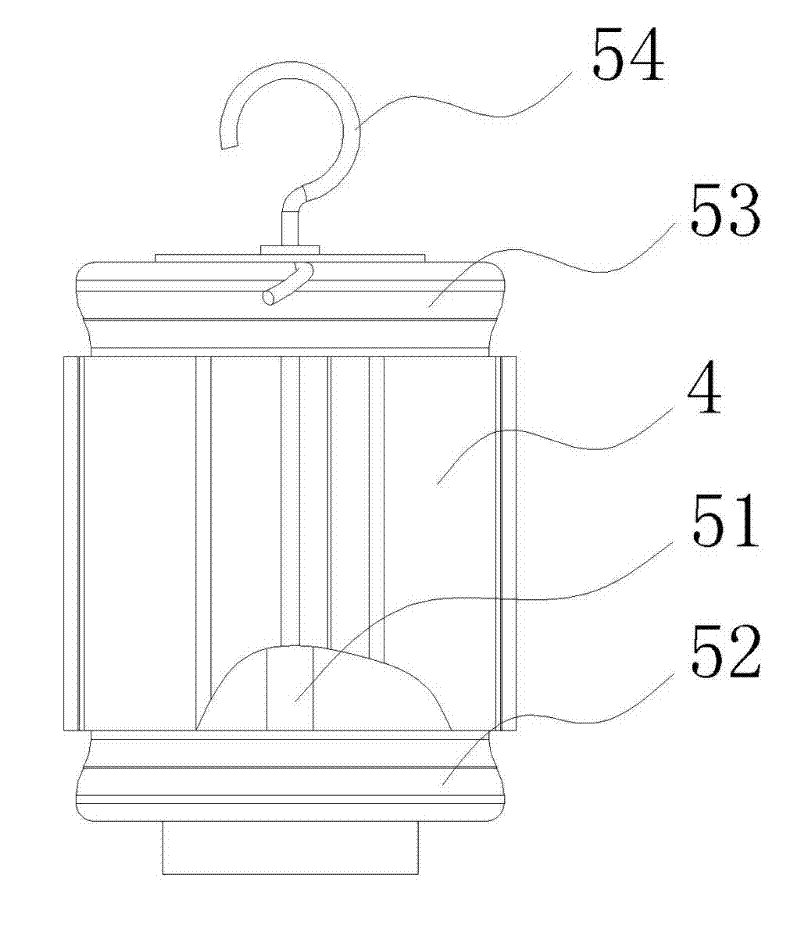

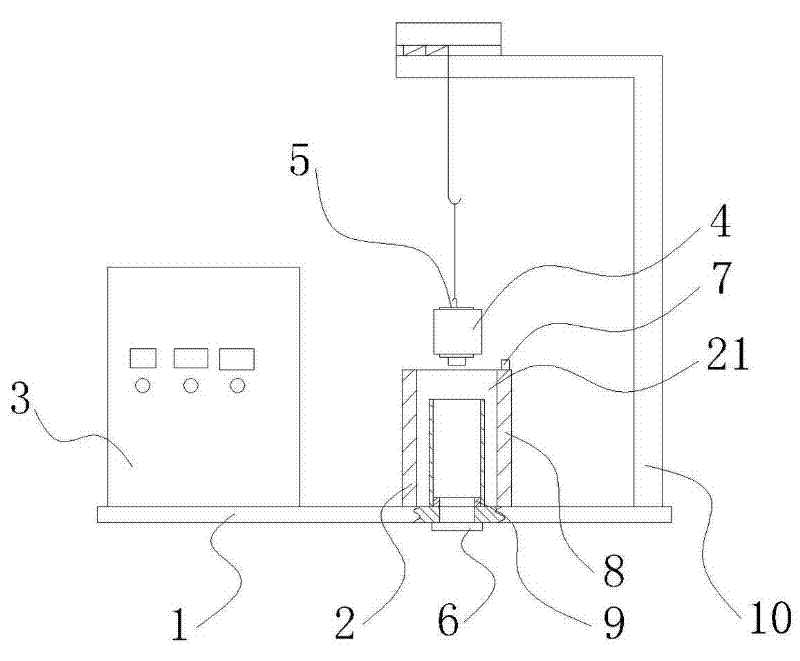

[0031] like figure 1 As shown, the intermediate frequency shrink-fit device of the servo motor stator of the present invention includes a horizontally placed platform 1, and an induction coil 2 is placed vertically on the platform 1, and the induction coil 2 passes through the intermediate frequency power supply controller 3 on the platform 1 Connected to the main power supply, in the middle of the induction coil 2 is a cylindrical heating cavity 21 that can accommodate the motor casing 8, and a ventilation hole 11 is opened on the platform 1 in the heating cavity 21, and the edge of the ventilation hole 11 passes through A limit ring 9 is fixed by screws, and the motor casing 8 is set on the limit ring 9 and is offset against the outer ring surface of the limit ring 9. Both the limit ring 9 and the ventilation hole 11 are coaxial with the induction coil 2, and in the ventilation hole The edge of the bottom port of 11 fixes a fan 6 coaxially by screws, the air outlet of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com