Method for assembling concrete prefabricated wallboards and special mechanical device therefor

A mechanical device and prefabricated wall panel technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of bulky concrete prefabricated wall panel components, affecting the bonding quality of wall panels and wall panels, and the difficulty of crack and impact resistance. Satisfactory and other issues to achieve the effect of ensuring assembly quality, improving work efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

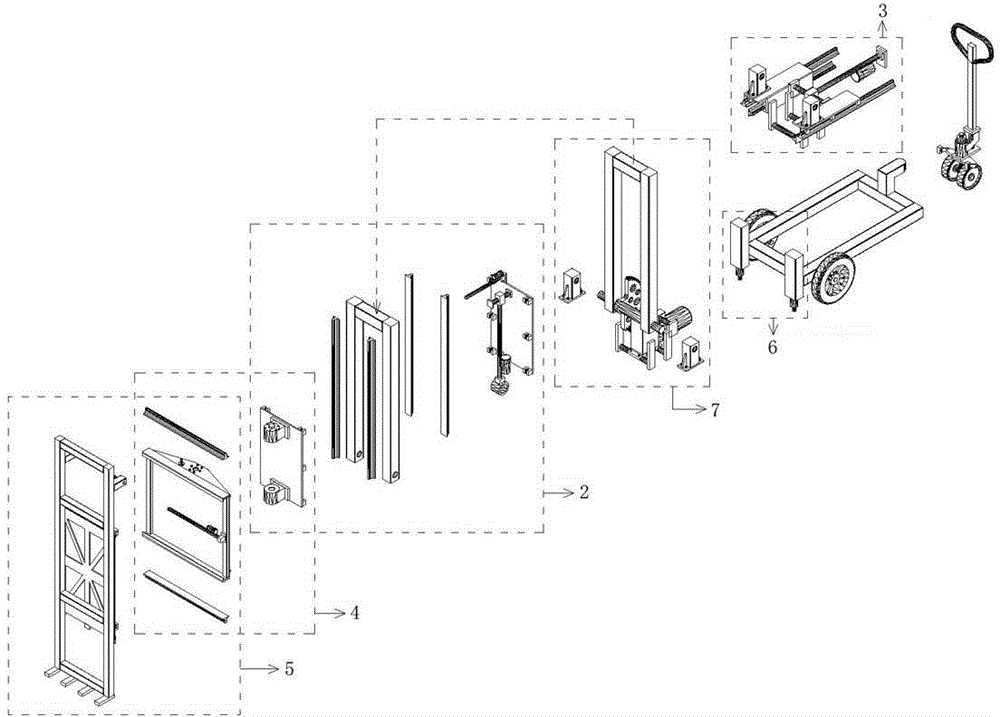

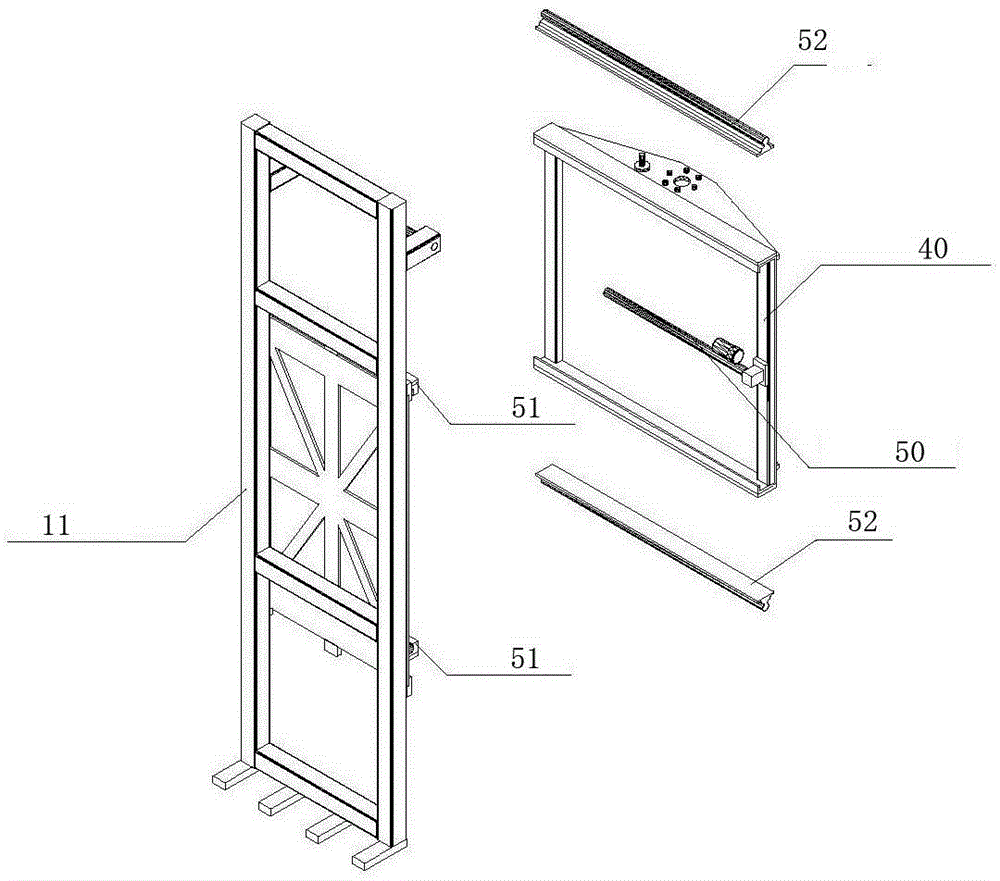

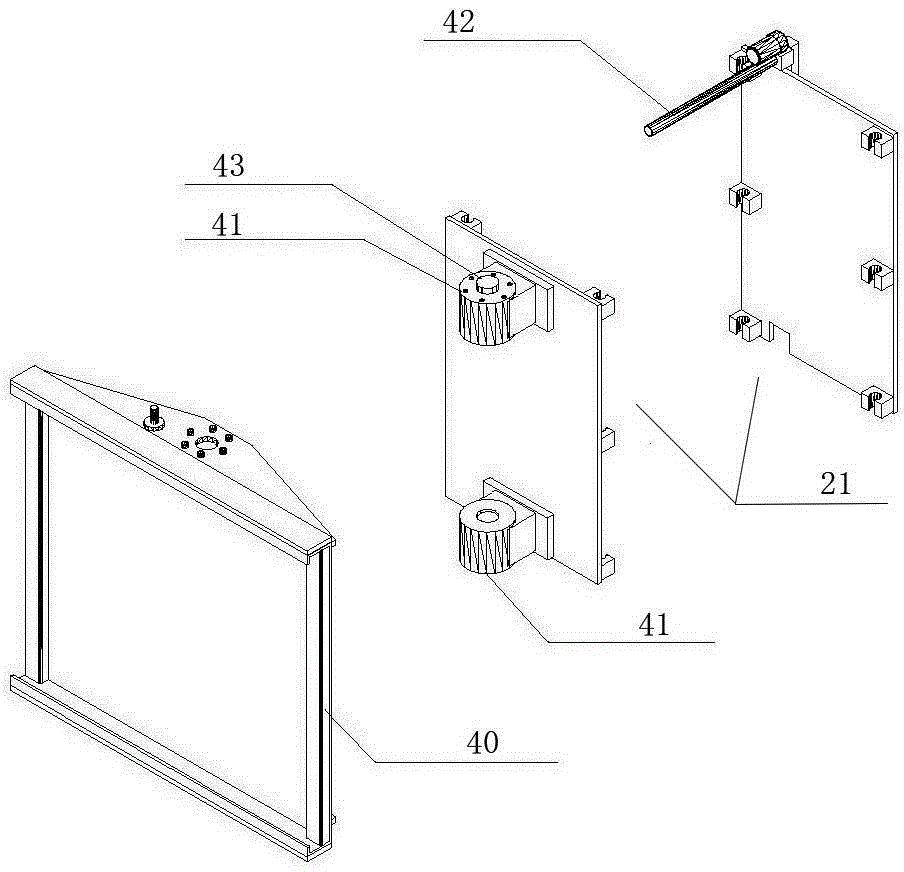

[0069] like Figure 1 to Figure 7 As shown, a special mechanical device for assembling concrete prefabricated wall panels according to the present invention, the special mechanical device is equipped with a movable chassis 1 with a moving wheel 10, and is also equipped with a movable chassis 1 The supporting wallboard frame 11 used to bind the wallboards, and the vertical lifting system 2 that can make the wallboards bound on the supporting wallboard frame 11 move smoothly and vertically respectively, and the front and rear translation system 3 that can move back and forth smoothly , a lateral swing system 4 for making lateral stable swings, a lateral translation system 5 for lateral translational movement, a side straightening system 6 for adjusting the verticality of the splicing surfaces on both sides of the wall panels, and making adjustments to the wall panels Front elevation rectification system for board verticality7. The front and rear translation system 3 is arranged...

Embodiment 2

[0078] like Figure 8 to Figure 15 As shown, a special mechanical device for assembling concrete prefabricated wall panels described in Embodiment 2 of the present invention, the special mechanical device is equipped with a movable chassis 1 with a moving runner 10, and is also equipped with a The supporting wallboard frame 11 used to bind the wallboard on the frame 1, and the vertical lifting system that can make the wallboards bound on the supporting wallboard frame 11 to make a smooth vertical lift respectively. Translation system 3, lateral swing system 4 for stable lateral swing, lateral translation system 5 for horizontal translation movement, side alignment system 6 for adjusting the verticality of the splicing surfaces on both sides of the wallboard, and adjustment The front elevation rectification system 7 that describes the verticality of the wall panel surface. The movable bottom frame 1 is provided with a vertical main frame 16, and the vertical main frame 16 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com