Bolt ball welding ball mixed node large span cantilever grid structure construction method

A large-span cantilever and spatial grid technology, which is applied in the field of large-span cantilevered spatial grid structure construction of bolt-ball-welded-ball hybrid joints, can solve the problems of large manpower, material resources, increased construction costs, and easy safety accidents. , to achieve the effect of improving work efficiency, ensuring assembly and welding quality, and high construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

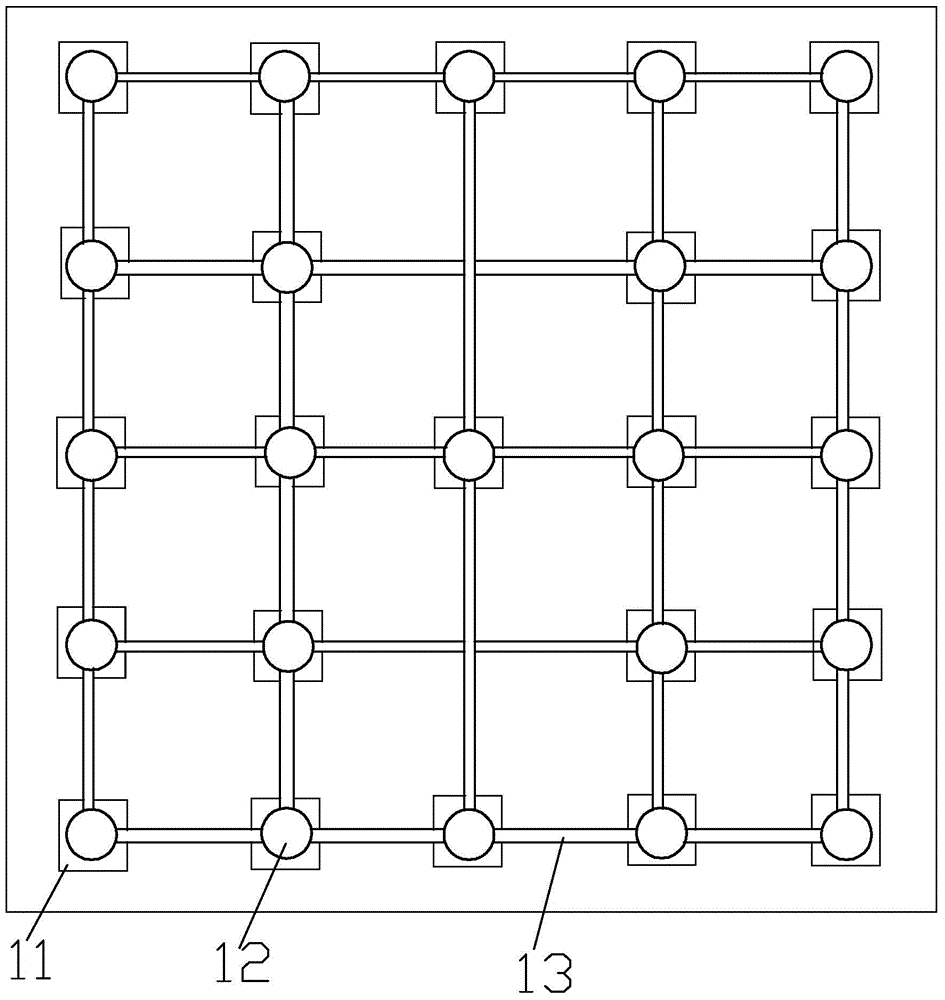

[0044] The construction method of the large-span cantilever space grid structure of the bolt-ball-welded-ball mixed joint in this embodiment is suitable for the construction of the space grid structure of the bolt-ball-welded ball mixed joint. The large-span cantilever space grid structure with bolt ball welded ball mixed nodes means that some nodes in the same network frame use bolt balls, and some nodes use welded balls, and usually the bolt ball nodes account for a large proportion of the total number of nodes , both ends of most rods are still connected by bolts and bolt balls, only some nodes use welding balls according to the special requirements of the building grid structure, and the rods that meet these nodes are connected by welding and welding balls.

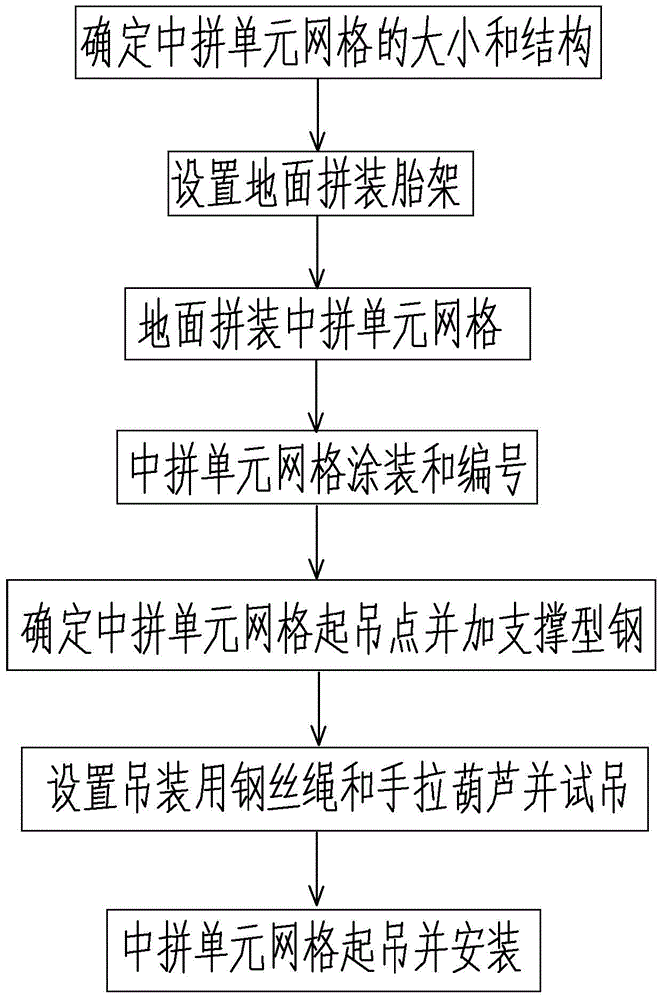

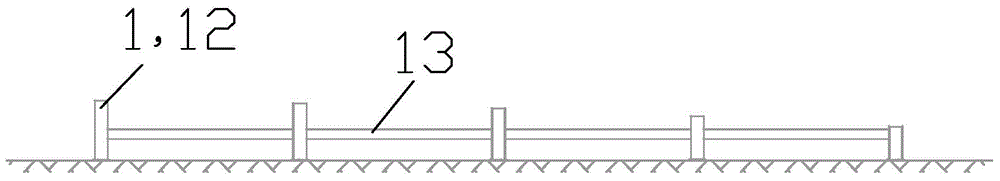

[0045] See Figure 1 to Figure 7 , the construction method of the large-span cantilever space grid structure of the bolted ball welded ball hybrid joint in this embodiment, the main construction steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com