Magnetic steel assembling equipment and magnetic steel assembling method therefor

A magnetic steel and equipment technology, applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of mechanical positioning wear, magnetic steel falling off positioning accuracy, and insufficient magnetization intensity, etc., to reduce The effect of contact error, ensuring accuracy and assembly efficiency, improving production flexibility and use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

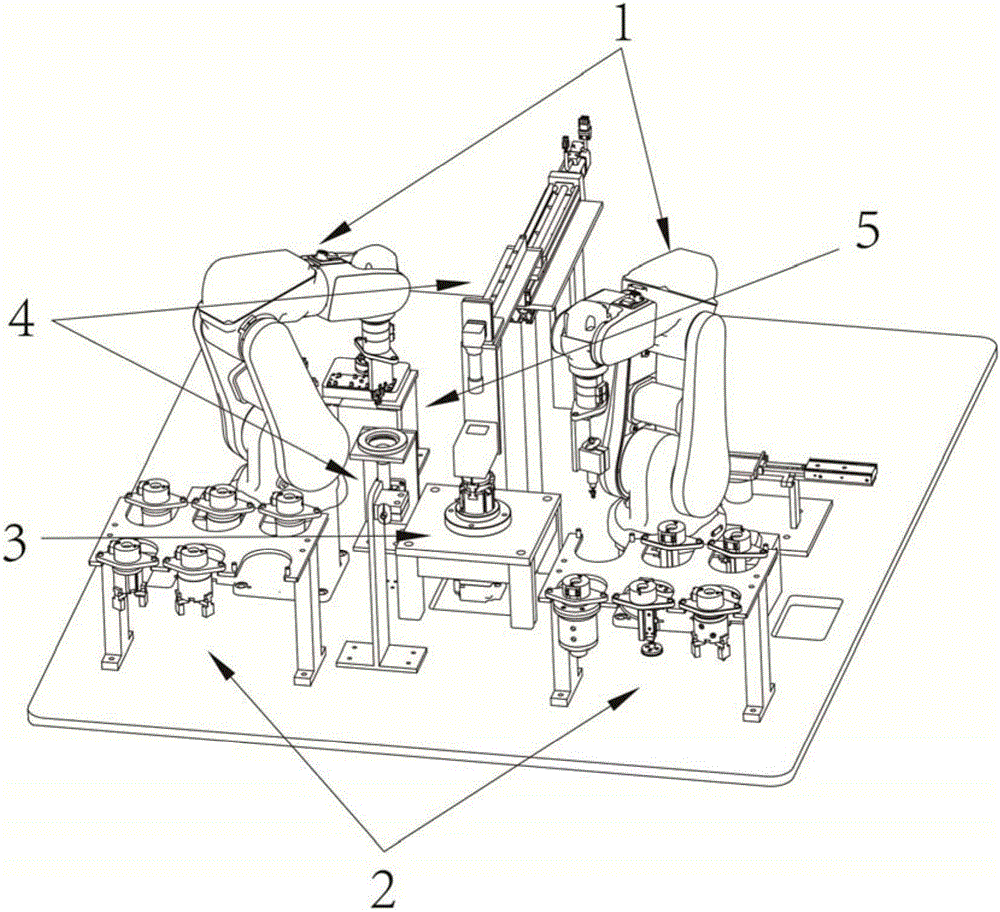

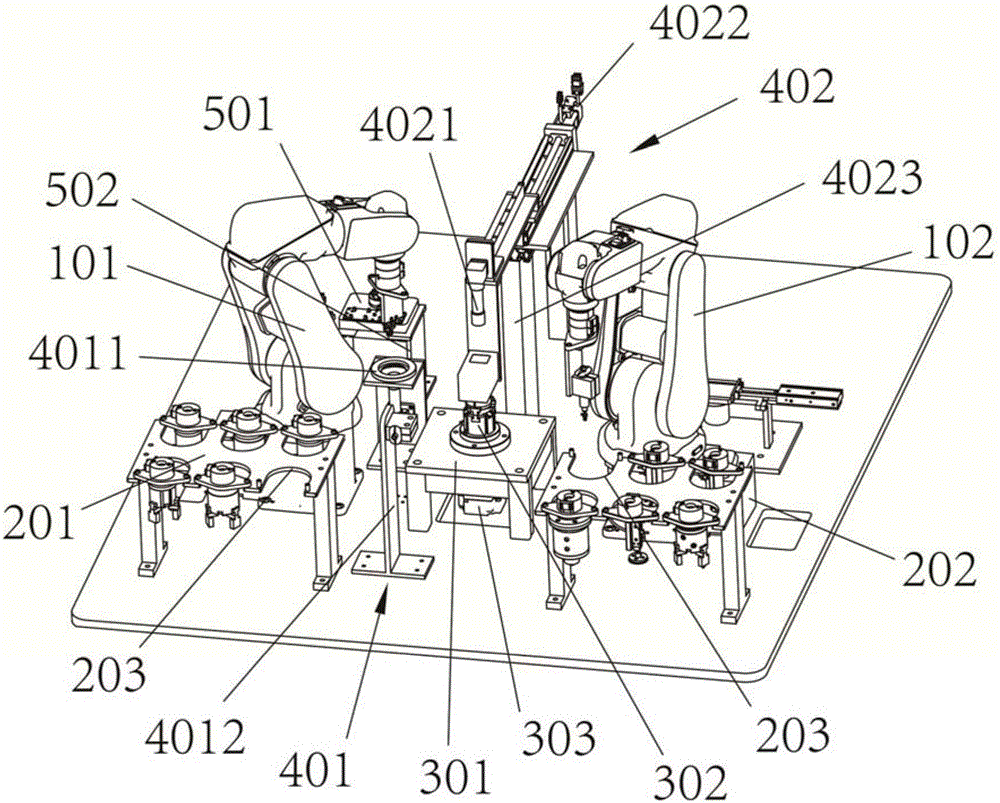

[0053] Such as figure 2 As shown, according to an embodiment of the present invention, the tooling unit 2 includes a clamping tooling platform 201 and a fastening tooling platform 202 . As shown in the figure, in this embodiment, the clamping tool table 201 is adjacent to the clamping mechanism 101 and is located on the same side in the longitudinal direction in the figure, that is, the left side in the figure. As shown in the figure, the clamping tool table 201 and the clamping mechanism 101 are located on one side of the assembly unit 3 . The fastening tool table 202 and the fastening mechanism 102 are arranged at intervals corresponding to each other, and are located on the same side of the longitudinal direction in the figure together with the fastening mechanism 102 , that is, the right side as shown in the figure. As shown in the figure, in this embodiment, the clamping tool table 201 and the fastening tool table 202 are located on the same side of the transverse centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com