Plunger rotary-assembling machine

A screwing machine and plunger technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of speeding up the transfer efficiency of the plunger pump, uneven quality, low assembly efficiency, etc. Distribution efficiency, high assembly efficiency, and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

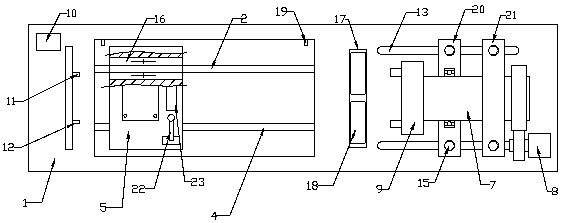

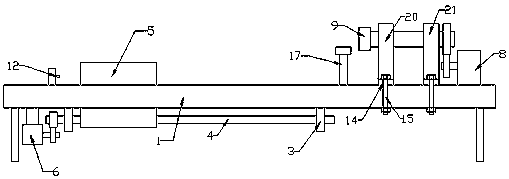

[0029] This embodiment, as the basic embodiment of the present invention, discloses a plunger screwing machine, the specific structure is as follows figure 1 As shown, it includes a frame 1, the frame 1, the frame 1 is fixedly provided with a slide bar 2, and at the same time, the frame 1 is also fixedly provided with a rolling bearing 3, and the rolling bearing 3 is fixedly provided with a transmission screw 4, and The transmission lead screw 4 is level with the slide bar 2, and the slide bar 2 is provided with a mobile workbench 5 slidingly through the linear motion bearing 17, and the mobile workbench 5 is connected with the drive lead screw 4 threaded at the same time; One end of the frame 1 is fixedly provided with a rotating motor 6, and the rotating motor 6 is connected to the transmission screw 4 through a transmission gear; the other end of the frame 1 is fixedly provided with a left support frame 20 and a right support frame 21, and the left support frame 20 and Roll...

Embodiment 2

[0031] This embodiment, as a preferred embodiment of the present invention, discloses a plunger screw, the specific structure is as follows figure 1 and figure 2 As shown, a stopper is arranged on the frame 1, and a speed sensor 11 and a distance sensor 12 are arranged on the stopper and the mobile workbench 5, and the speed sensor 11 and the distance sensor 12 are connected with the controller 10 respectively. The input end is connected, and the frame 1 is also provided with a travel switch 19 for limiting the range of movement of the mobile workbench, and the travel switch 19 is connected with the input end of the controller 10; the frame 1 is provided with a waist hole 13, The left support frame 20 and the right support frame 21 are all provided with the installation hole 14 that is adapted to the waist hole 13, and the installation hole 14 is provided with a frame for connecting the frame 1 with the left support frame 20 and the right support frame 21. fastening bolts 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com