Intelligent detecting installing equipment for multiple types of piston rings

A technology for intelligent detection and installation of equipment, applied in the field of vehicle engineering, can solve the problems of hidden dangers buried in the normal operation of the engine, affecting the consistency of assembly quality, and high labor intensity of workers, so as to ensure assembly accuracy and overall assembly efficiency, and eliminate The problem of finger scratches and the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

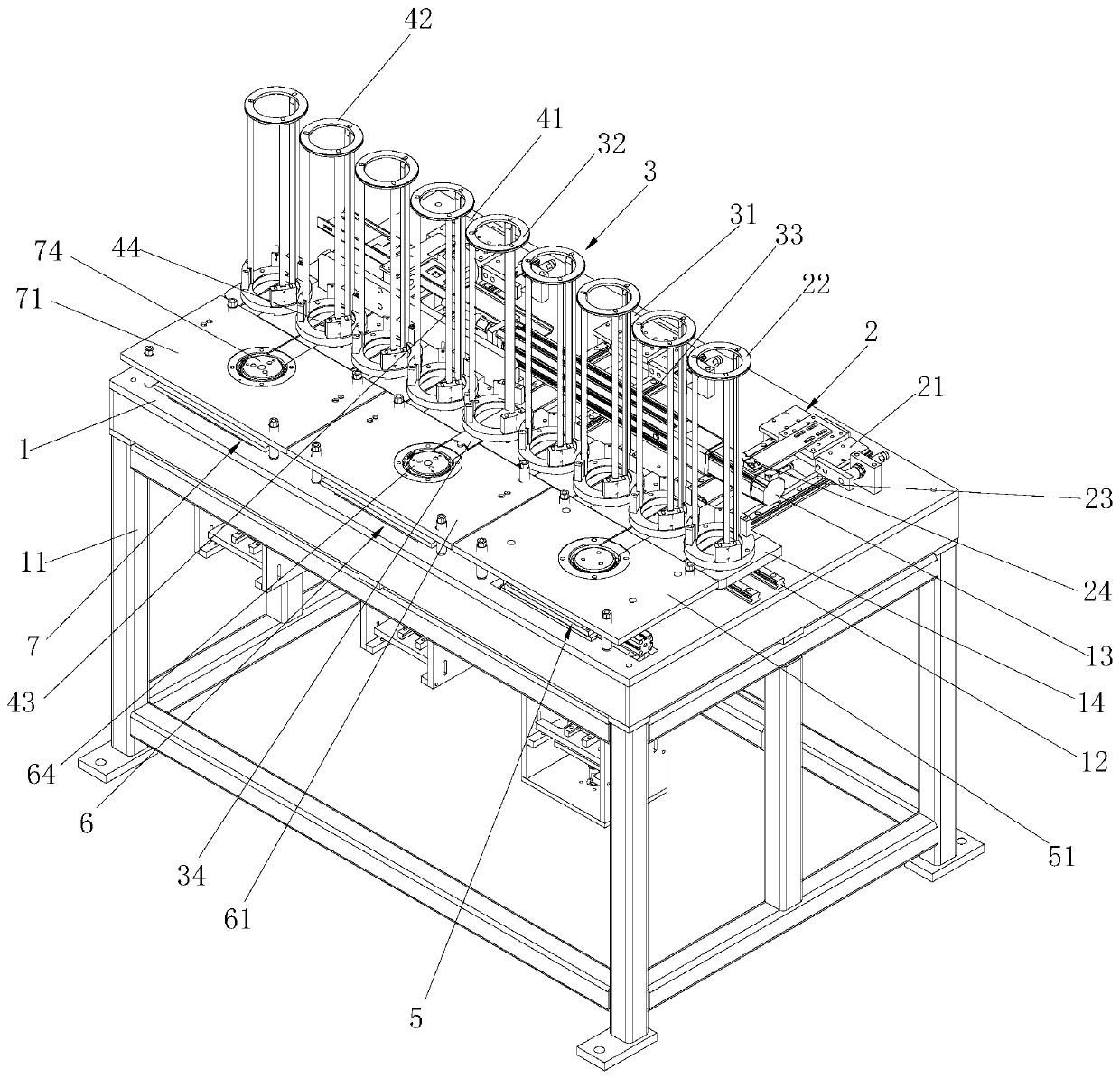

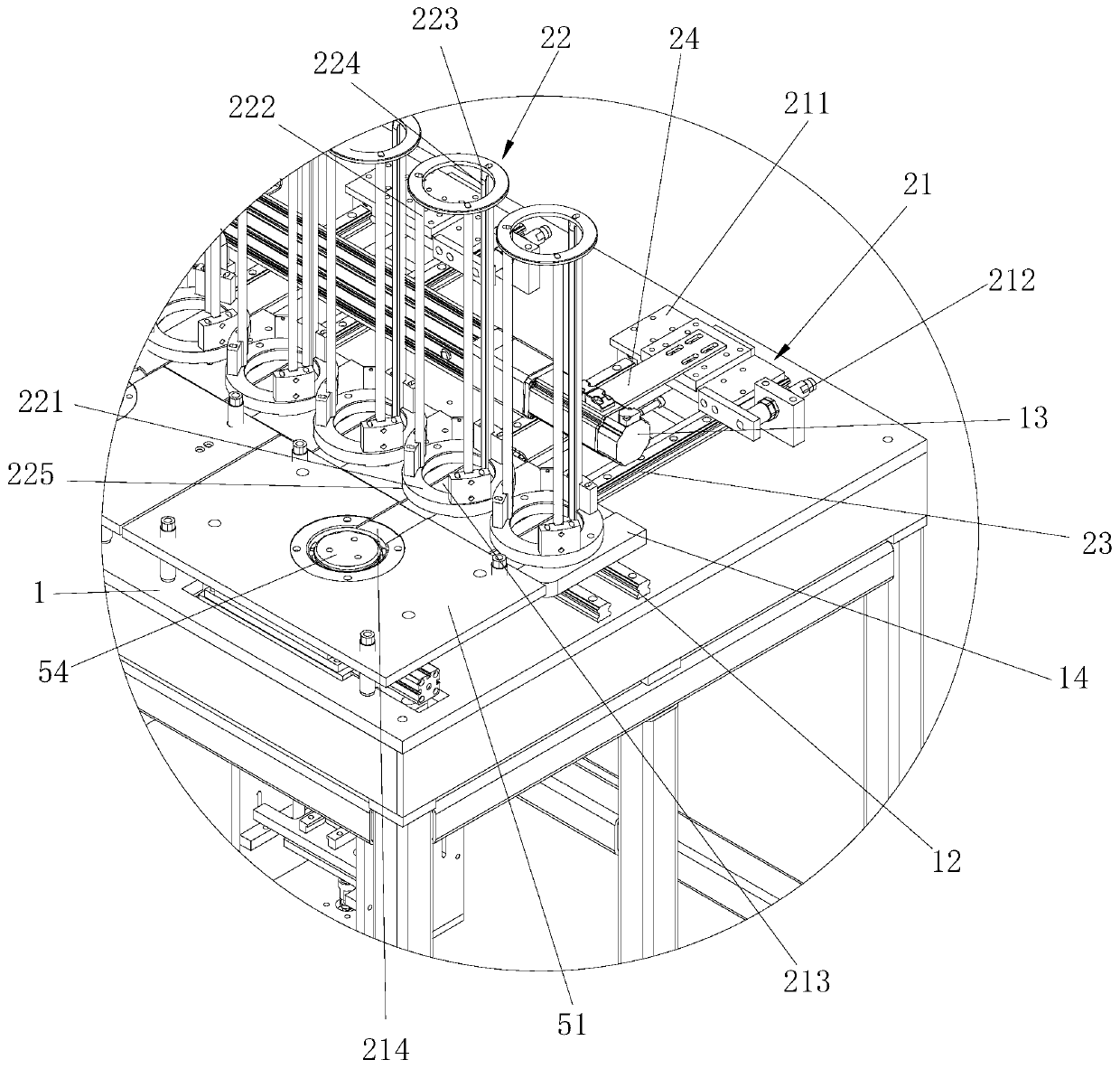

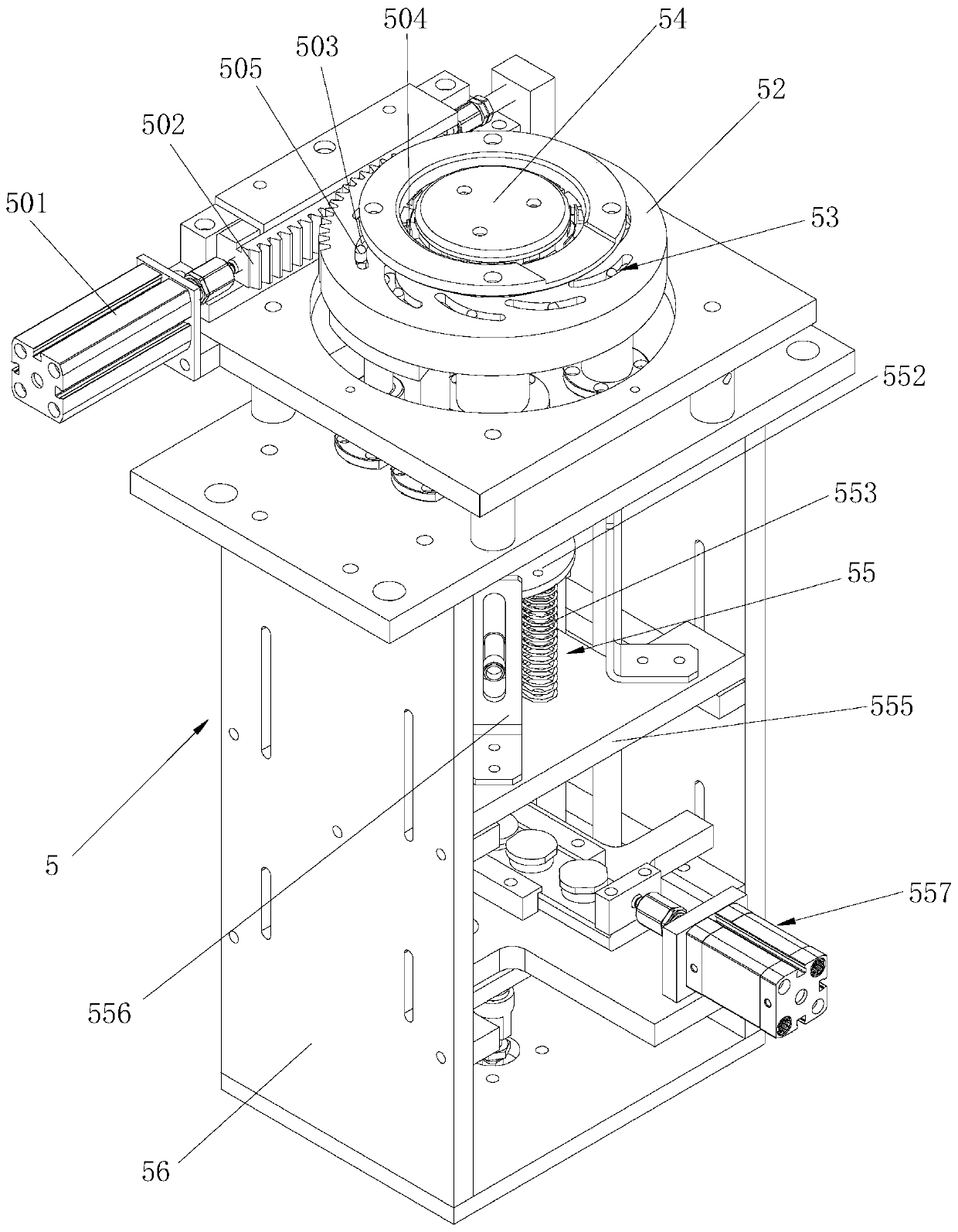

[0051] combine Figure 1 to Figure 5 , a multi-type piston ring intelligent detection and installation equipment, including a mounting platform 1, an oil ring positioning device 2, a cone surface gas ring positioning device 3 and a barrel surface gas ring positioning device 4 are connected to the mounting platform 1. A bracket 11 is connected to the lower end of the installation platform 1 , and a first longitudinal slide rail 12 and a first switching electric cylinder 13 are arranged transversely in the middle of the installation platform 1 . A first bunker brace 14 is slidably connected to the first longitudinal slide rail 12 , and the first bunker brace 14 is connected to the cylinder shaft of the first switching electric cylinder 13 .

[0052] The oil ring positioning device 2 includes a first push mechanism 21, an oil ring material rack 22 and an oil ring expansion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com