Thermal assembling method for angular contact ball bearing and heating apparatus

A technology for angular contact ball bearings and heating devices, which is applied to bearing components, shafts and bearings, non-electric variable control, etc. It can solve problems such as fire hazards, personal injury, environmental hazards, and slow speed, so as to improve production safety, The effect of ensuring assembly efficiency and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

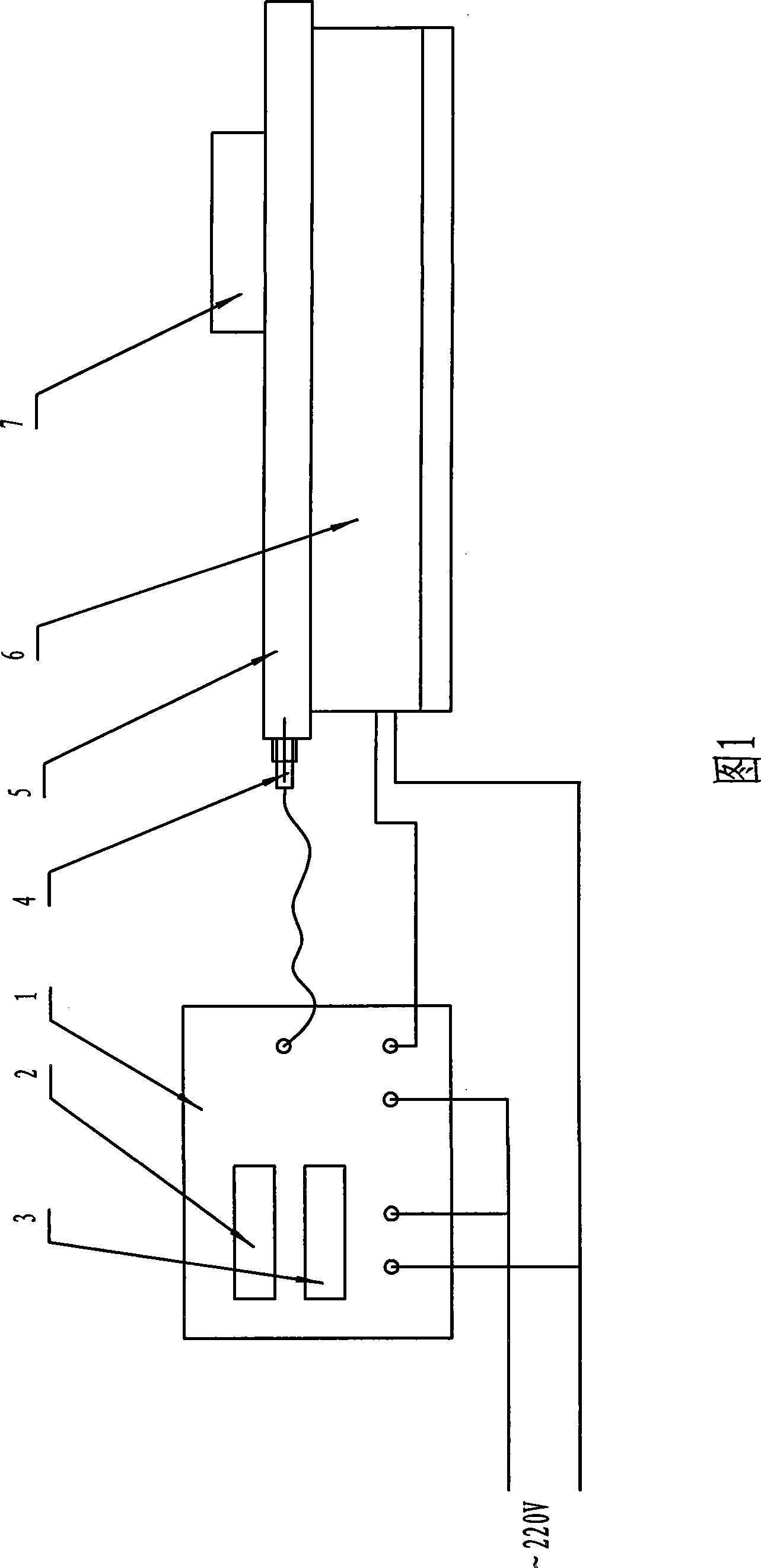

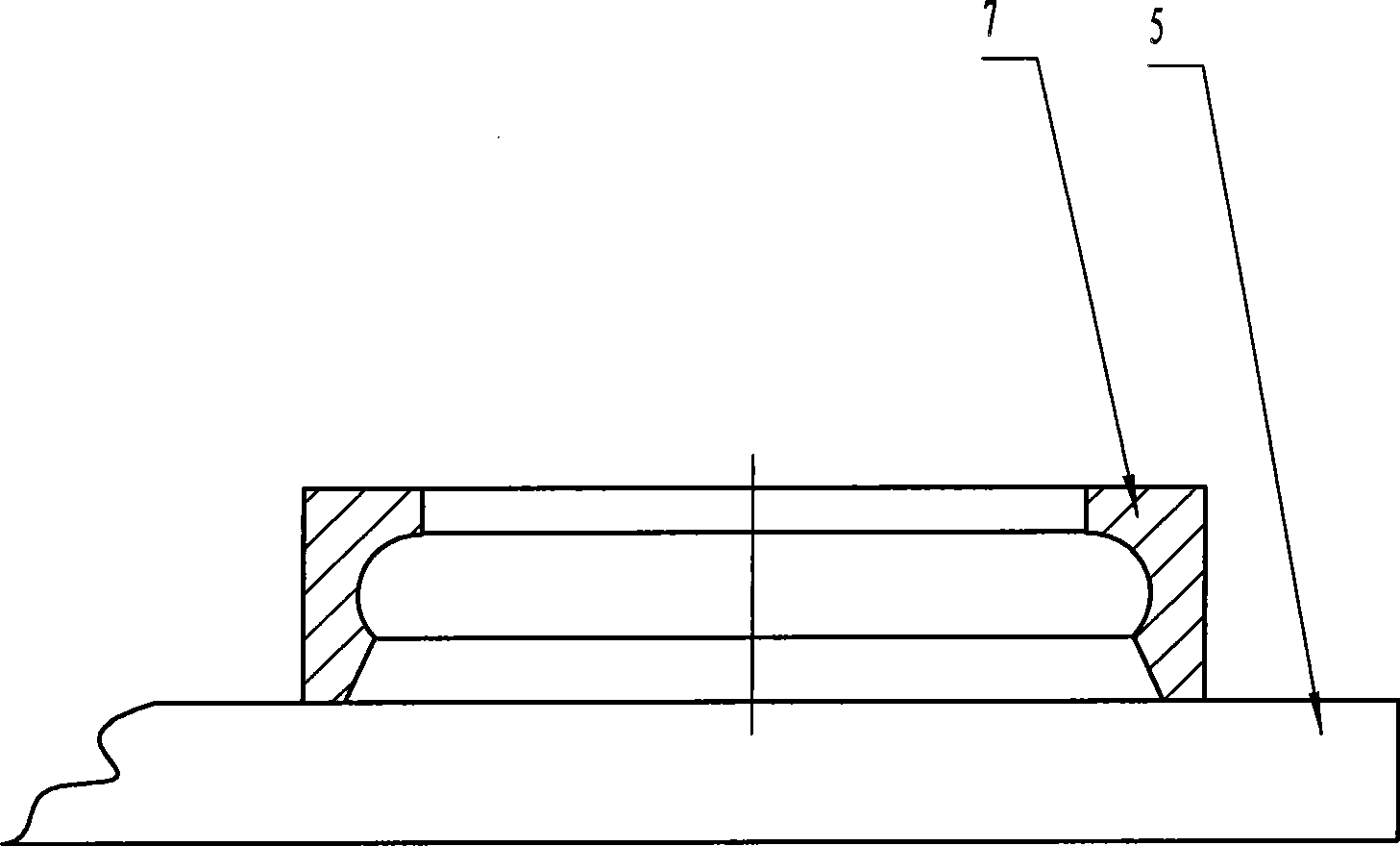

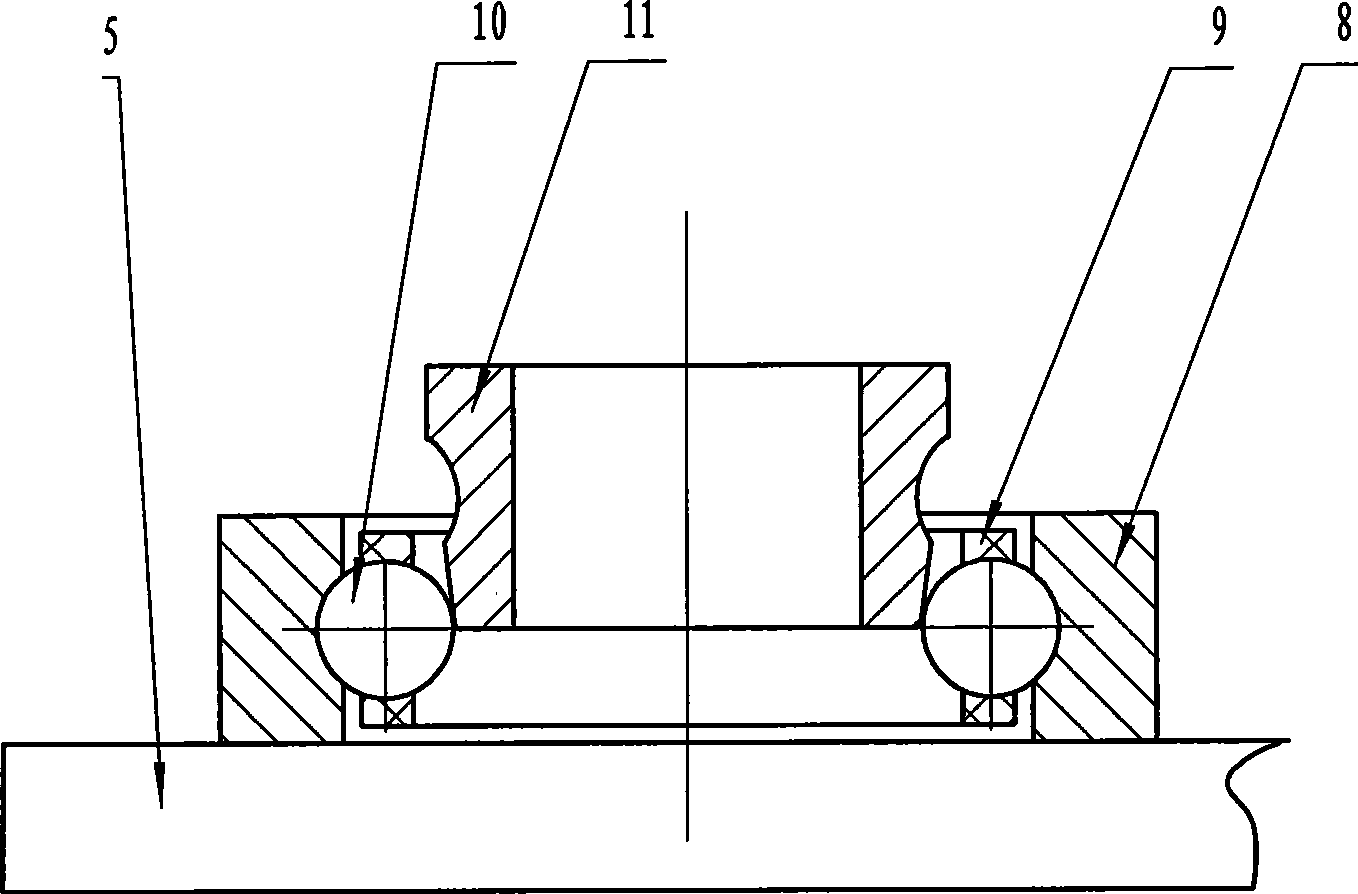

[0010] As shown in Figure 1, the heating device for thermal assembly of angular contact ball bearings of the present invention is composed of a temperature controller 1 and an electric heating device 6. The heating element of the heating device 6 is powered, and the top of the electric heating device 6 is electrically connected to an electric heating plate table 5 for heating the bearing ring 8. The electric heating plate table 5 is a thick metal plate, and the temperature controller 1 with temperature control function There are preset temperature display 3 and temperature display 2. The temperature controller 1 is externally connected with a thermocouple 4. The thermocouple 4 is inserted into the thick plate of the heating plate table top 5, so that the temperature change of the heating plate table 5 can be monitored at any time, that is The temperature change of the bearing ring 7 on the table, the thermocouple 4 can feed back the actual temperature signal of the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com