Coupler knuckle casting method

A knuckle and mold frame technology, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of long preparation period, increased casting cost, and difficulty in meeting short-term delivery requirements, so as to reduce production costs, The effect of improving production efficiency and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following describes the implementation of the present invention in conjunction with the accompanying drawings to describe in detail the technical solutions provided by the present invention; the description in this part is only exemplary and explanatory, and the specific description language or order should not have any influence on the protection scope of the present invention. Limiting effect.

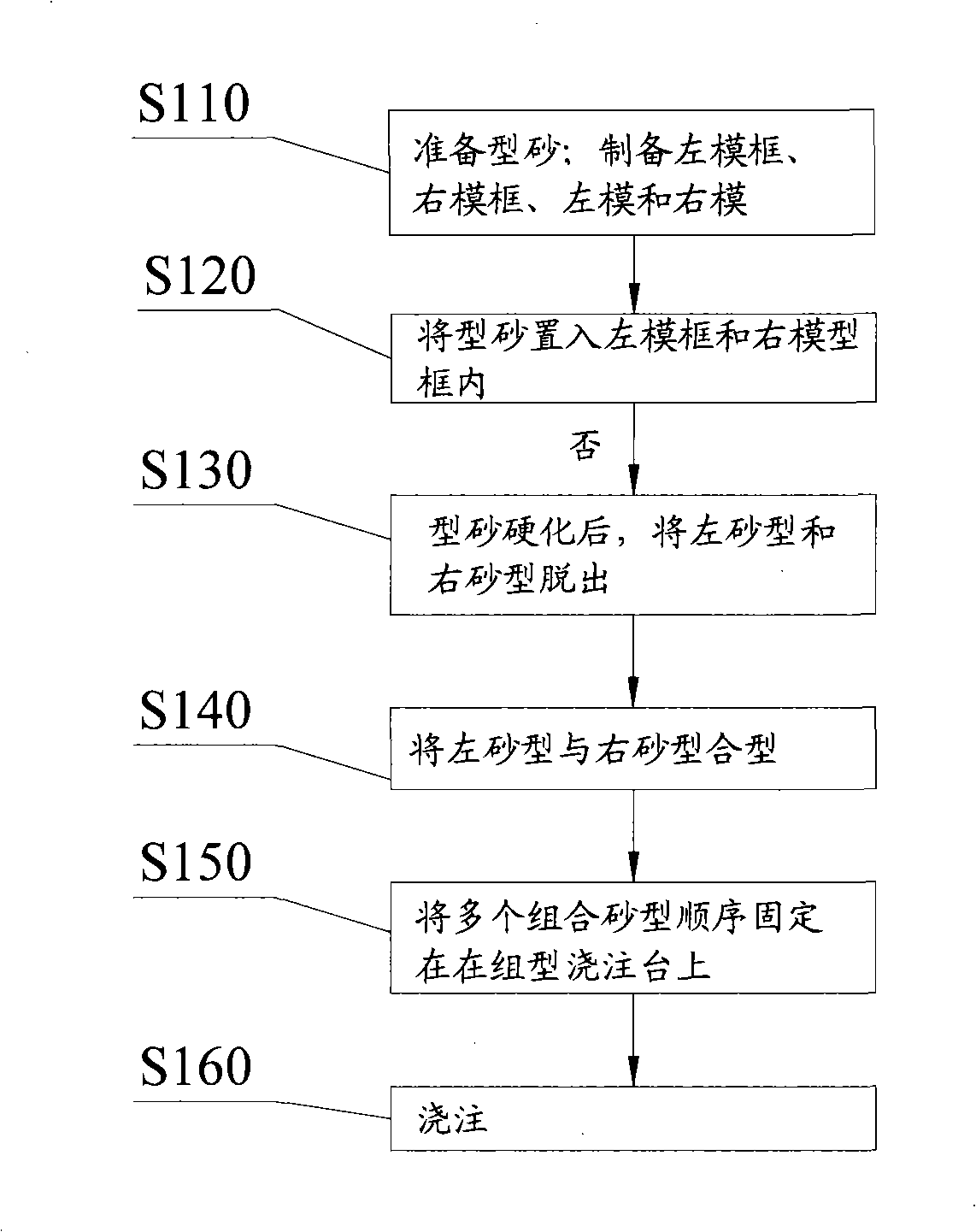

[0045] combine figure 1 , the knuckle casting method provided by Embodiment 1 includes the following steps:

[0046] S110, preparing molding sand; preparing a left mold frame, a right mold frame, a left mold and a right mold.

[0047] Preparation of molding sand is the premise of casting. In this example, ester hardened water glass sand is preferred as molding sand. Since ester hardened water glass sand can be hardened at room temperature and has the characteristics of easy sand falling, it can obtain accurate dimensions and smooth surface. The mold cavity ensures the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com