Rotary table mechanism capable of preventing line from winding

A circuit and rotating disc technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as easy winding of pneumatic circuits and electric circuits, interference with the work of the indexing turntable, and affecting the assembly efficiency of the mouse, so as to ensure the efficiency , to avoid the effect of line winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

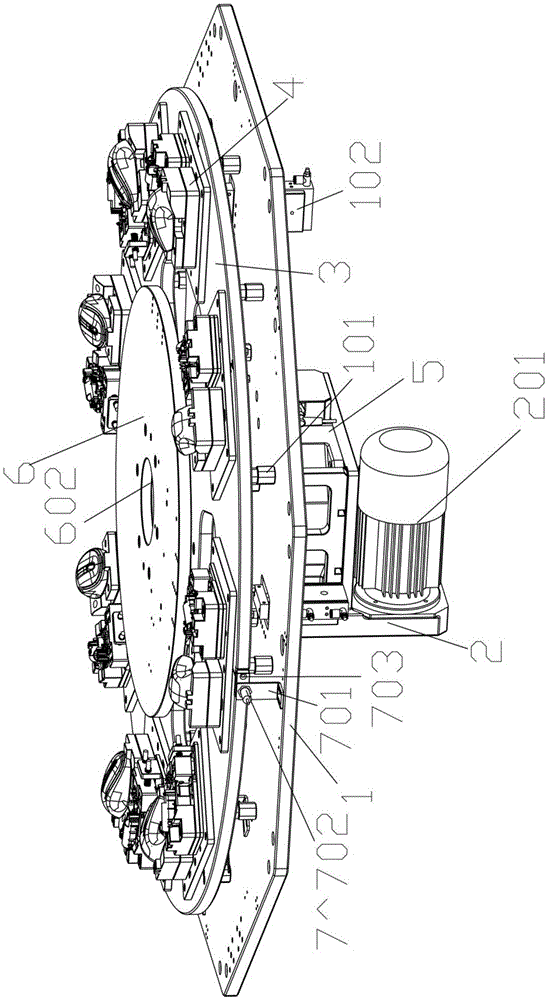

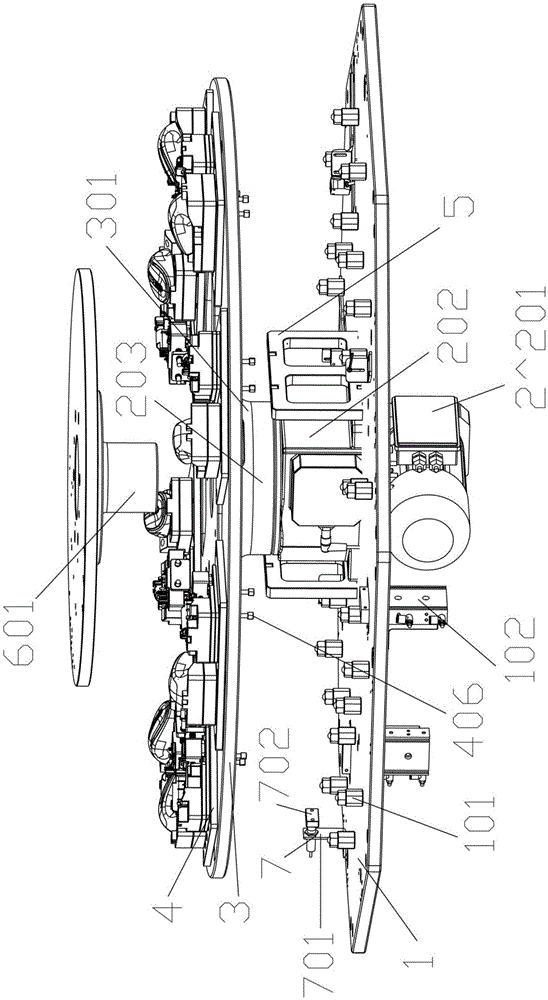

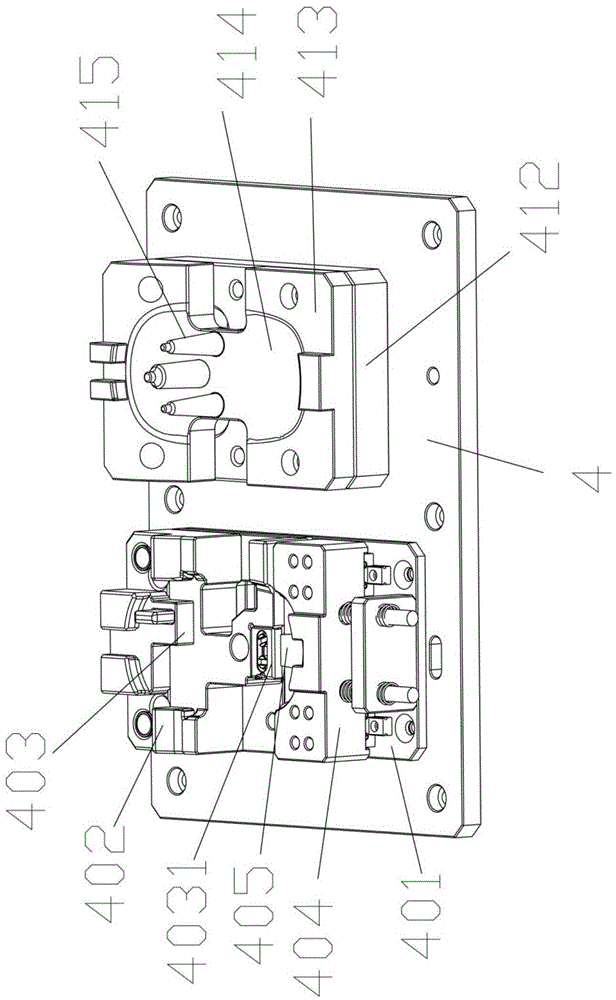

[0038] refer to Figure 1-Figure 5 , the present embodiment provides a turntable mechanism, including a bottom plate 1, a rotating module 2 fixedly arranged in the middle of the bottom plate 1, a rotating disk 3 arranged on the rotating module 2, and a rotating disk 3 uniformly distributed in a circle on the basis of the center of the rotating disk 3. 3, the fixed loading tray 6 fixedly connected to the bottom plate 1 through the fixed loading tray connection block 601 and located above the rotating tray 3, and the arrangement of pneumatic or electric components arranged on the fixed loading tray 6 The pneumatic original (not shown in the figure) or the electric original (not shown in the figure), and the connection block 601 that is arranged on the fixed loading tray 6 and runs through the fixed loading tray connection block 601 and the fixing device tray 6 and is connected with the pneumatic original (not shown in the figure) ) or the wiring hole 602 used in conjunction with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com