Counter character wheel assembly assembling machine and assembling method thereof

A counter and assembly machine technology, applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of complex assembly equipment and low reliability, and achieve the goal of reducing equipment manufacturing costs, improving reliability, and reducing secondary operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings.

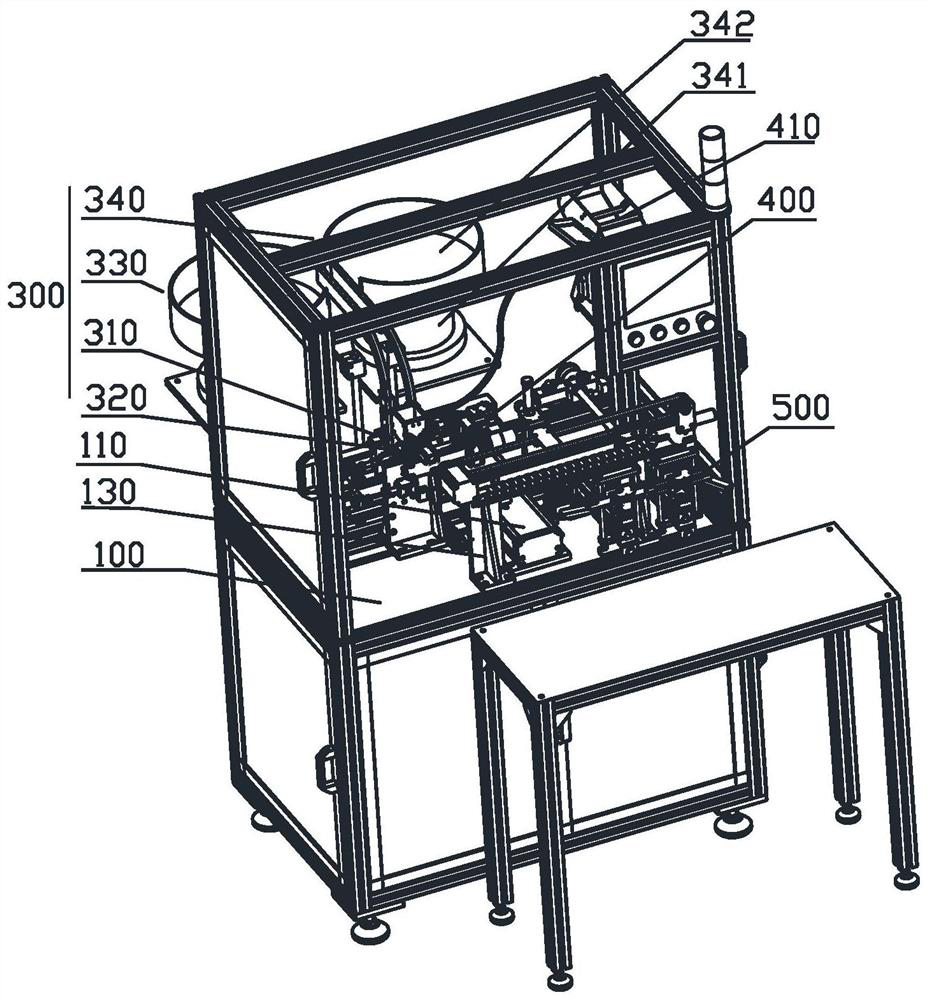

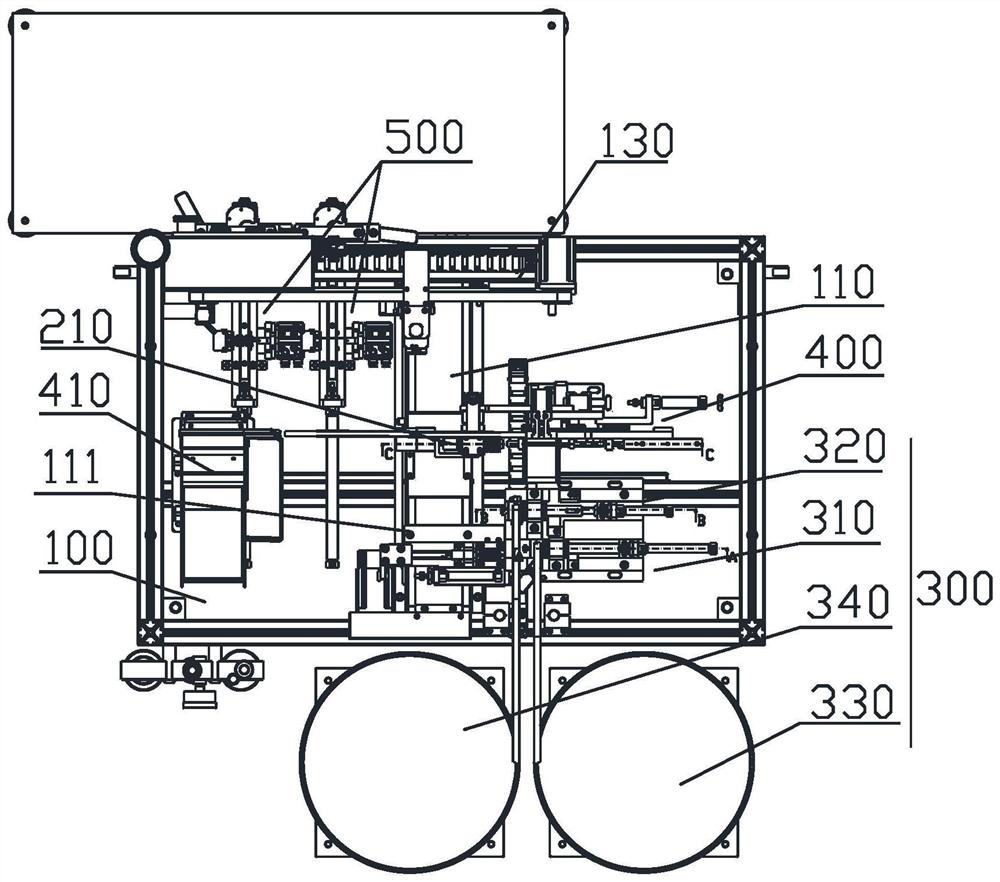

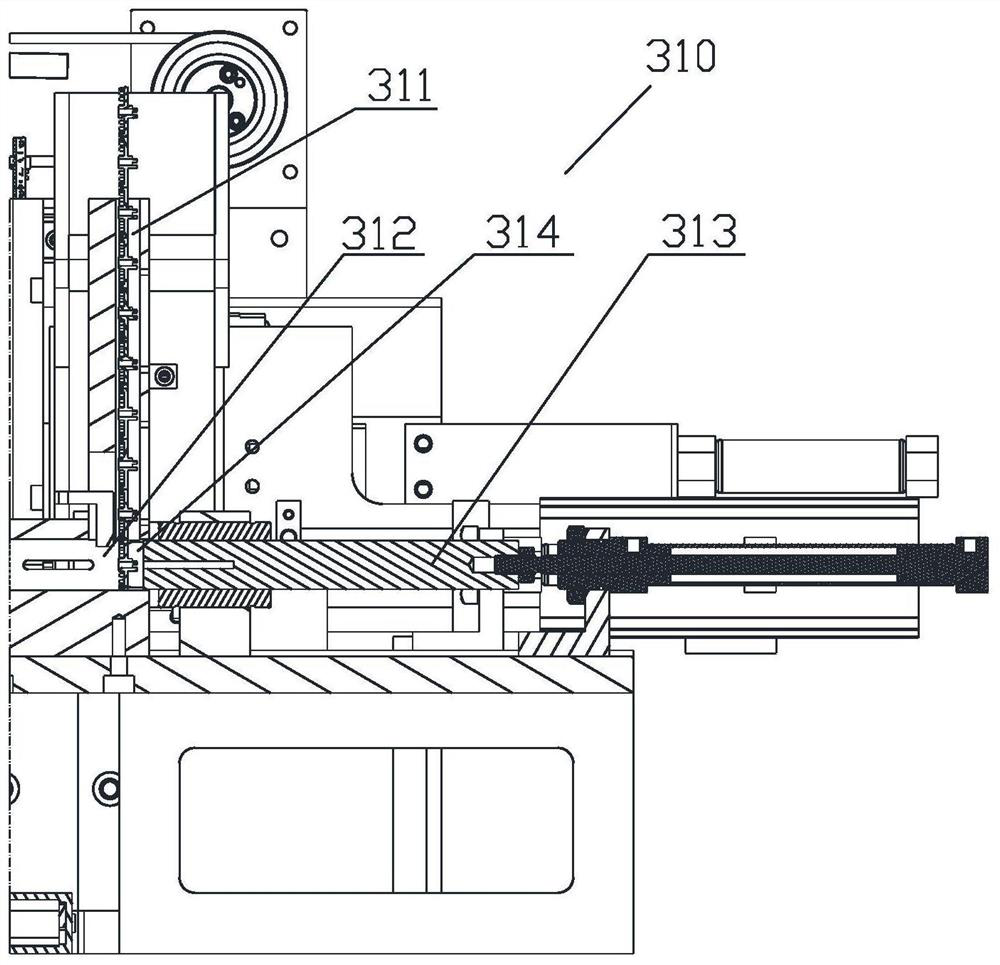

[0062] refer to Figure 1 to Figure 26 The shown counter word wheel assembly machine and its assembly method, in order to facilitate the understanding, first briefly explain the structure of the counter 600, the core part of the counter 600 is mainly composed of the character wheel chamber 610 and the bottom plate 620, usually the bottom plate 620 is circuit board, and the character wheel chamber 610 is mainly used to install the character wheel assembly. The character wheel assembly in this application includes a transition wheel 630, a character wheel 640 and a character wheel shaft 650. The diameters of the transition wheel 630 and the character wheel 640 are consistent, and the assembled Usually, a transition wheel 630 and a plurality of character wheels 640 are threaded on a character wheel shaft 650 in sequence, wherein the outer edge of one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com