Manufacturing method for multi-module multi-layer bolted anchoring beam

A manufacturing method and multi-level technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of low manufacturing modularity, low efficiency, time-consuming assembly, etc., to ensure assembly accuracy and assembly efficiency, and reduce cumulative Error, the effect of ensuring the installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

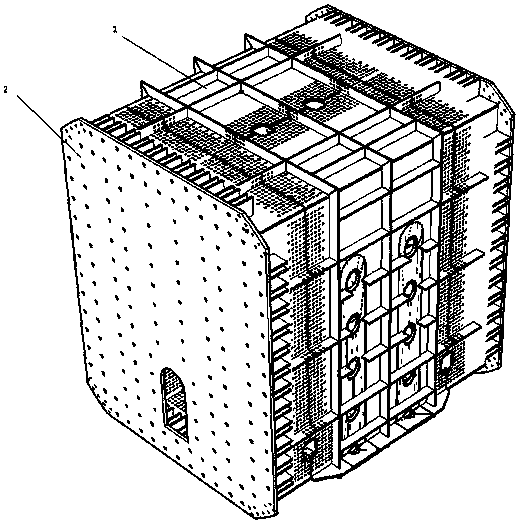

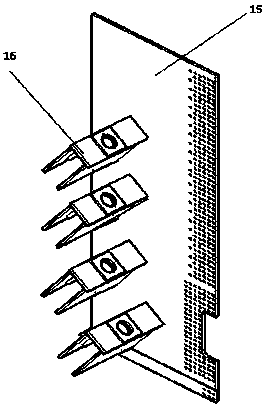

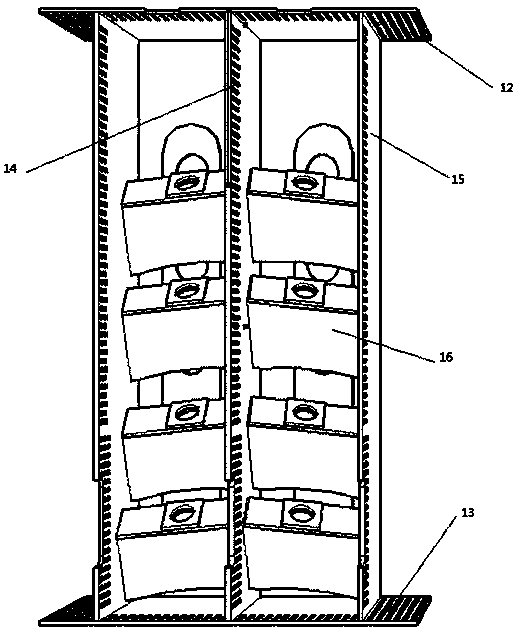

[0048] like Figure 1 to Figure 9 Shown is a multi-module and multi-layer bolted anchor beam manufacturing method. The anchor beam includes a pair of cable tower anchor blocks and a pair of transverse blocks; the cable tower anchor blocks and the transverse blocks are staggered and connected end to end to form a cuboid structure; the anchor beam The fabrication of the S1 cable tower anchor block includes the construction method of the S1 cable tower anchor block, the construction method of the S2 transverse block and the processing of the S3 splice plate.

[0049] S1: The construction method of the tower anchor block 1 includes: S1.1 wall plate processing, S1.2 top plate and bottom plate processing, S1.3 middle web and side web processing, S1.4 joint plate processing, S1. 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com