Stator, rotor and bearing one-time assembled precision guiding device for permanent magnetism motor

A permanent magnet motor and guiding device technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of assembly gap offset, damage to the outer surface of the inner ring of the bearing, and reduce production efficiency, so as to avoid contact, Ease of operation and guaranteed assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

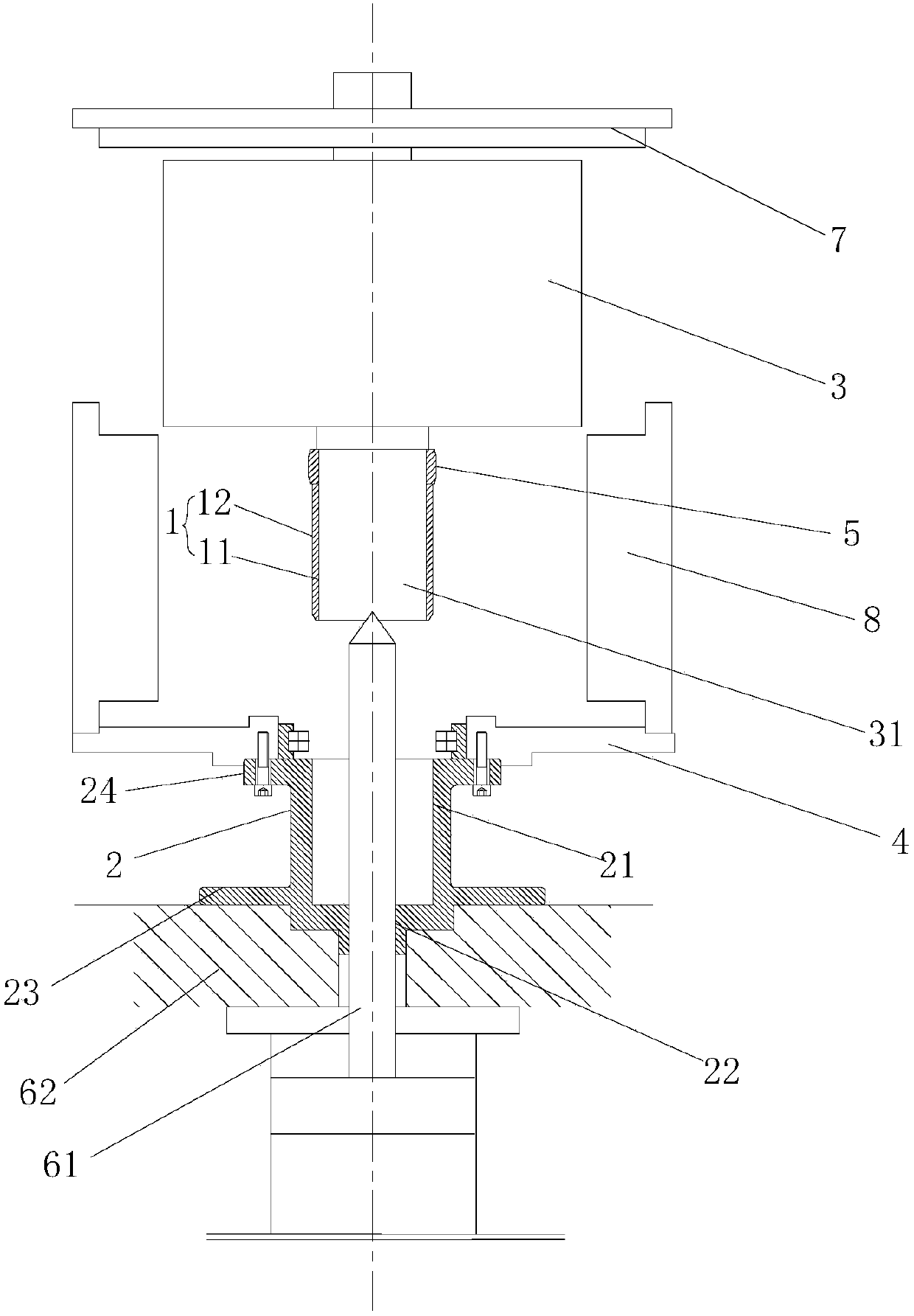

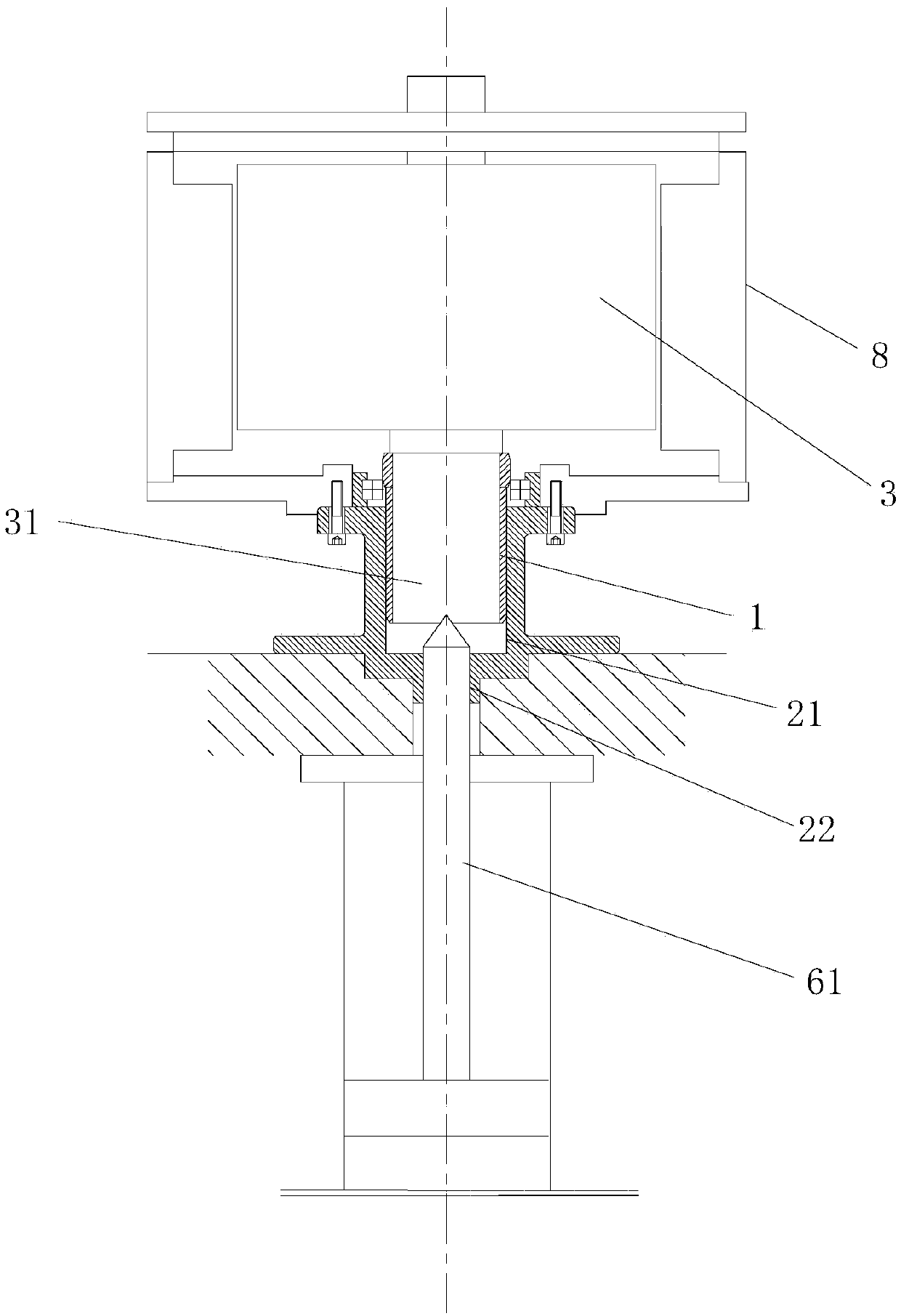

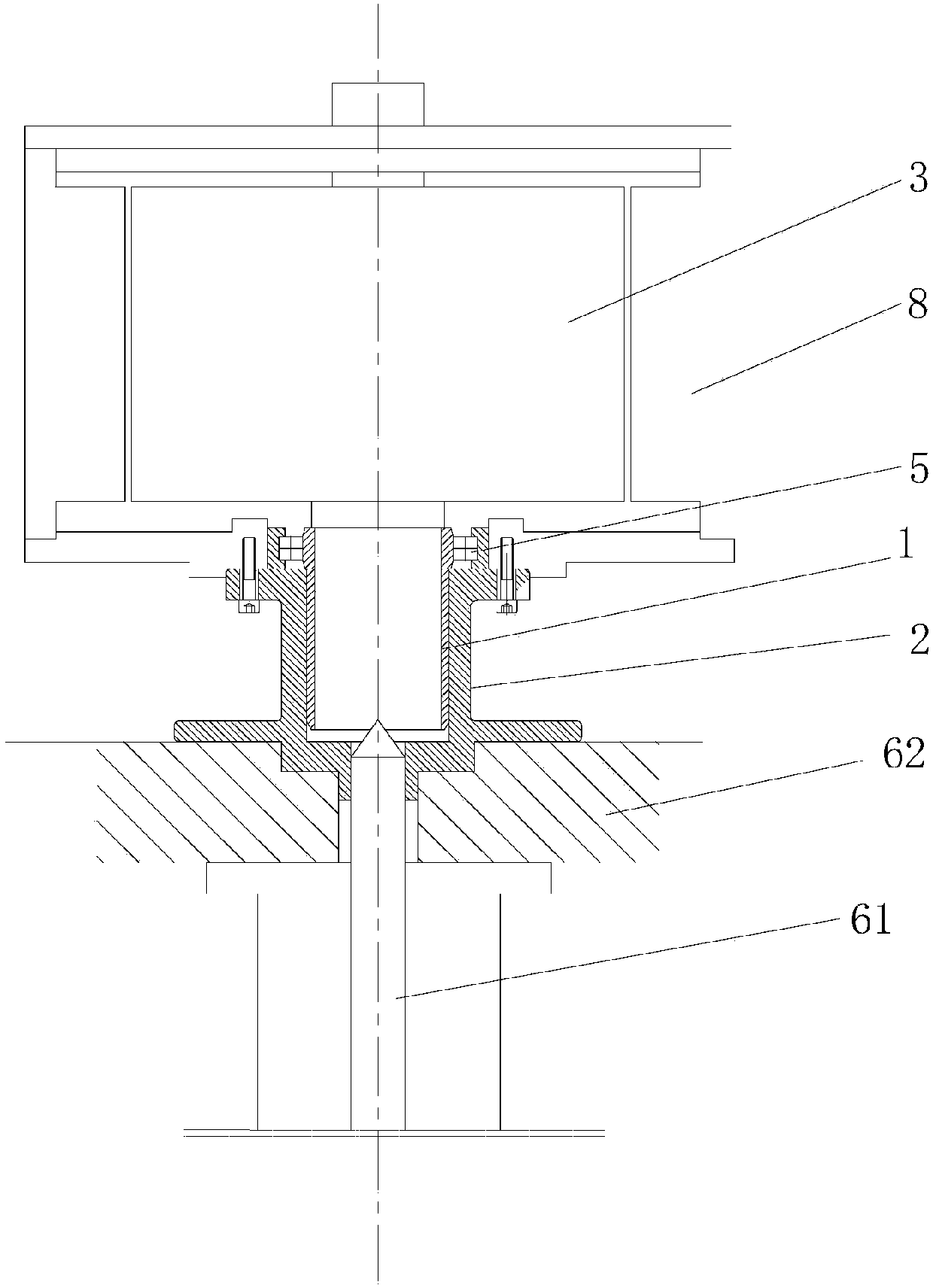

[0021] Figure 1 to Figure 3 An embodiment of the present invention is shown. The permanent magnet motor stator, rotor and bearing of the present embodiment are combined into a compact guide device at one time, including a rotor guide tool 1 and a stator guide tool 2, and the inner surface of the rotor guide tool 1 is a mounting surface 11 and installed on the rotating shaft 31 of the rotor 3, the inner ring of the bearing 5 is located between the rotor guide tool 1 and the rotor 3, the stator guide tool 2 is detachably connected with the transmission end cover 4 of the permanent magnet motor, and the outer part of the rotor guide tool 1 The surface is an outer circle guide surface 12, and the diameter of the outer circle guide surface 12 is not greater than the outer diameter of the inner ring of the bearing 5. The stator guide tooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com