Manufacturing method of high-weather-resistance fragile label material

A technology for label materials and manufacturing methods, applied to film/sheet adhesives, identification devices, film/sheet release coatings, etc., can solve problems such as poor aging resistance and poor fragility of PVC fragile labels, Achieve the effect of high weather resistance grade, excellent chemical stability and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

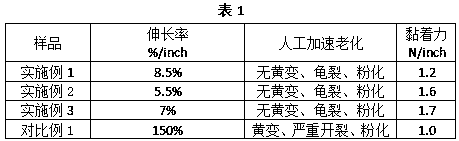

Examples

Embodiment 1

[0064] A method for making a highly weather-resistant and fragile label material, comprising the following steps:

[0065] Q1: Select a non-corona-treated PET substrate with a thickness of 36 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at a temperature of 70 ° C for 2 minutes, and then dry it at 100 ° C for 3 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0066] Q2: Coat the color layer paint on the surface of the weather-resistant layer of composite film A, place it in an environment with a temperature of 60°C to dry for 3 minutes, and then dry it in an environment with a temperature of 100°C for 3 minutes to form a color layer to obtain a composite film B and winding;

[0067] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0068] Q4: Coat the pressure-sensitive adhesive layer paint on the grid-shaped release paper o...

Embodiment 2

[0109] A method for making a highly weather-resistant and fragile label material, comprising the following steps:

[0110] Q1: Select a non-corona-treated PET substrate with a thickness of 100 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at 100°C for 3 minutes, and then dry it at 150°C for 5 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0111] Q2: Coat the color layer paint on the surface of the weather-resistant layer of the composite film A, place it in an environment with a temperature of 100°C to dry for 5 minutes, and then dry it in an environment with a temperature of 150°C for 6 minutes to form a color layer to obtain a composite film B and winding;

[0112] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0113] Q4: Coat the pressure-sensitive adhesive layer paint on the grid-like release paper or release film, ...

Embodiment 3

[0154] A method for making a highly weather-resistant and fragile label material, comprising the following steps:

[0155] Q1: Select a non-corona-treated PET substrate with a thickness of 70 μm, apply a weather-resistant layer coating on the surface of the PET substrate, place it at a temperature of 85°C for 2.5 minutes, and then dry it at 125°C for 4 minutes Form weather-resistant layer, make composite membrane A and wind up;

[0156] Q2: Coat the color layer paint on the surface of the weather-resistant layer of the composite film A, place it in an environment with a temperature of 80°C to dry for 4 minutes, and then dry it in an environment with a temperature of 125°C for 4.5 minutes to form a color layer to obtain a composite film B and winding;

[0157] Q3: Form a covering layer on the surface of the colored layer of the composite film B, make a composite film C and wind it up;

[0158] Q4: Coat the pressure-sensitive adhesive layer coating on the grid-shaped release p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com