Substrate adhesion method

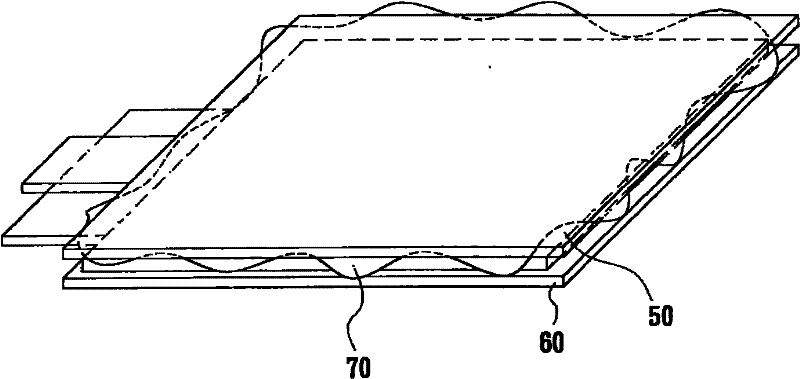

A substrate and bonding technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of glue overflow between the substrate 50 and the display panel 60, and achieve the effect of improving the glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

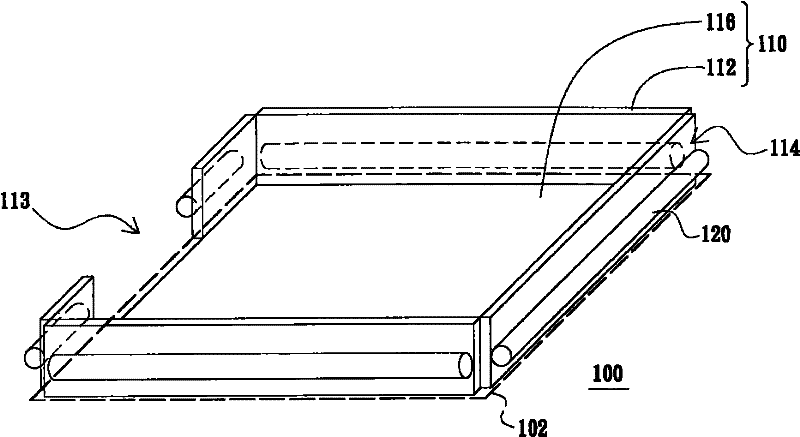

[0034] figure 2 It is a schematic diagram of an anti-overflow glue device according to an embodiment of the present invention. Please refer to figure 2 , the anti-overflow glue device 100 of this embodiment includes a frame body 110 and at least one glue curing part 120 , and in this embodiment, a plurality of glue curing parts 120 are taken as an example. The frame body 110 has a side wall 112 arranged along a closed track 102 , and in this embodiment, the closed track 102 is, for example, a rectangular closed track. In addition, the sidewall 112 has at least one notch 113 , and one notch 113 is taken as an example in this embodiment. In addition, the glue curing member 120 is disposed on the outer surface 114 of the side wall 112 .

[0035] In the above-mentioned anti-overflow glue device 100, the material of the side wall 112 is, for example, a transparent material, such as polymethyl methacrylate, polycarbonate or a combination thereof, but is not limited thereto. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com