Patents

Literature

30results about How to "Optical performance impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing water absorbent anti-fog film used for automotive glass

The invention relates to a method for preparing a water absorbent anti-fog film used for automotive glass. The method comprises the following steps: step 1, preparing water absorbent resin from raw materials in parts by weight as follows: adding 10-40 parts of resin containing water absorbent groups and 10-50 parts of crosslinkable cured resin to 50-100 parts of organic solvents, mixing up, adding 20-60 parts of curing agent and 1-5 parts of flatting agent. mixing up and obtaining the water absorbent resin; step 2, preparing the anti-fog film: sequentially degreasing the surface of the automotive glass with the organic solvent, performing mechanical polishing, rinsing with tap water and distilled water respectively, and desiccating; performing surface coating on the clean and dry automotive glass with the water absorbent resin prepared according to the step 1, and placing the water absorbent anti-fog film at a temperature of 80-150 DEG C for 0.5-4h after the leveling of the water absorbent anti-fog film. The water absorbent anti-fog film provided by the invention can absorb and desorb steam without creating fog on the glass, and has a long-term anti-fog function.

Owner:CHERY AUTOMOBILE CO LTD

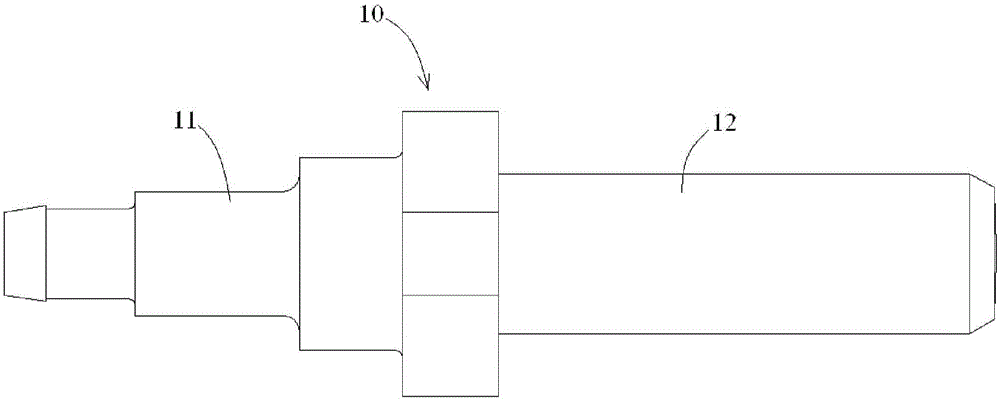

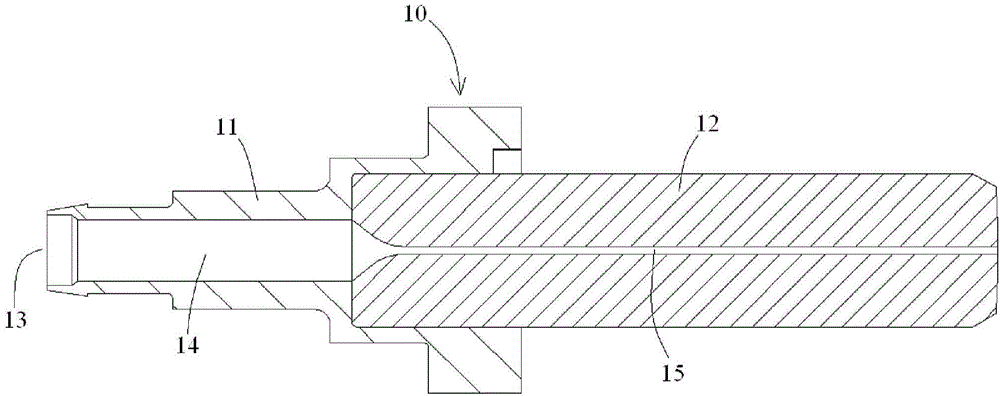

Insertion core device and manufacture method thereof

The invention discloses a manufacture method of an insertion core device of a fiber connector. The manufacture method comprises that an insertion core assembly is provided; a fiber is inserted into a fiber jack of the insertion core assembly till the fiber is protruded out of the front end of the insertion core assembly for a preset distance; and an adhesive is filled into the insertion core assembly so that the adhesive can flow into the fiber jack, and after the adhesive is solidified, the fiber can be kept in a proper position in the fiber jack. According to the invention, the fiber can be smoothly inserted into the insertion assembly without damage, and the adhesive is not adhered to the part, protruded out of the front end of the insertion core assembly, of the fiber.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

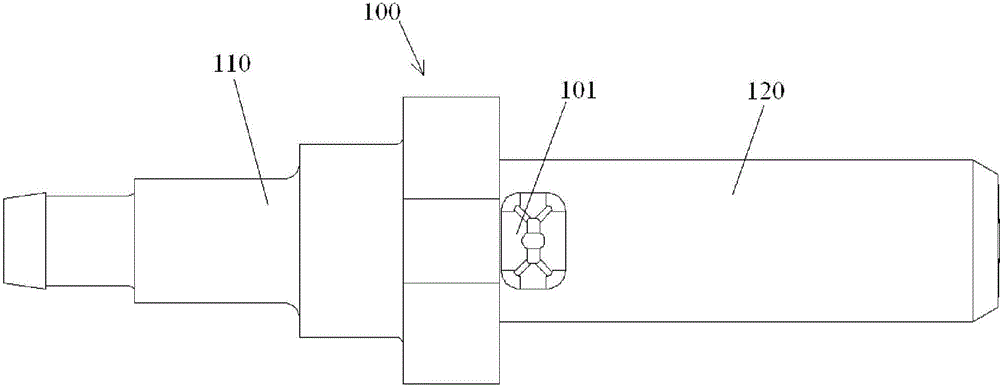

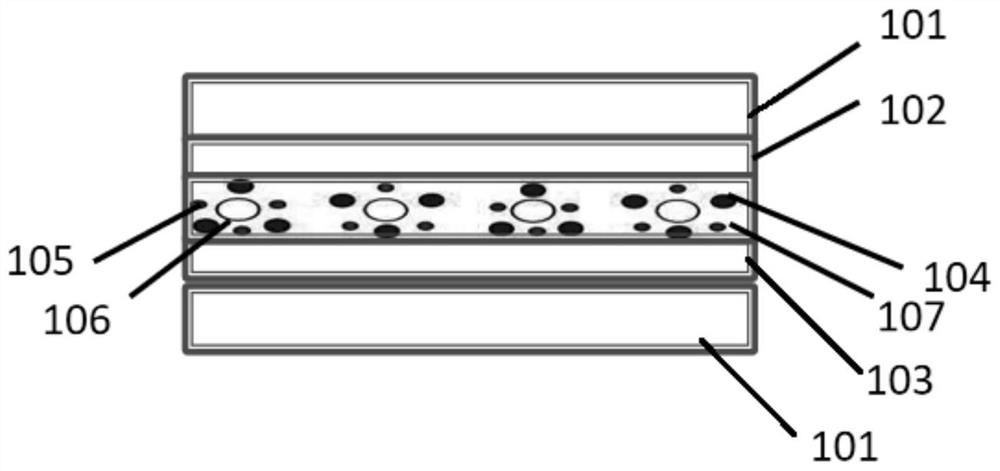

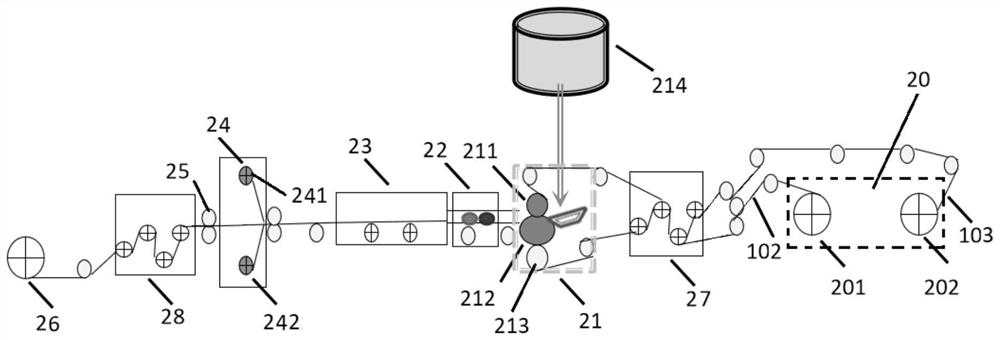

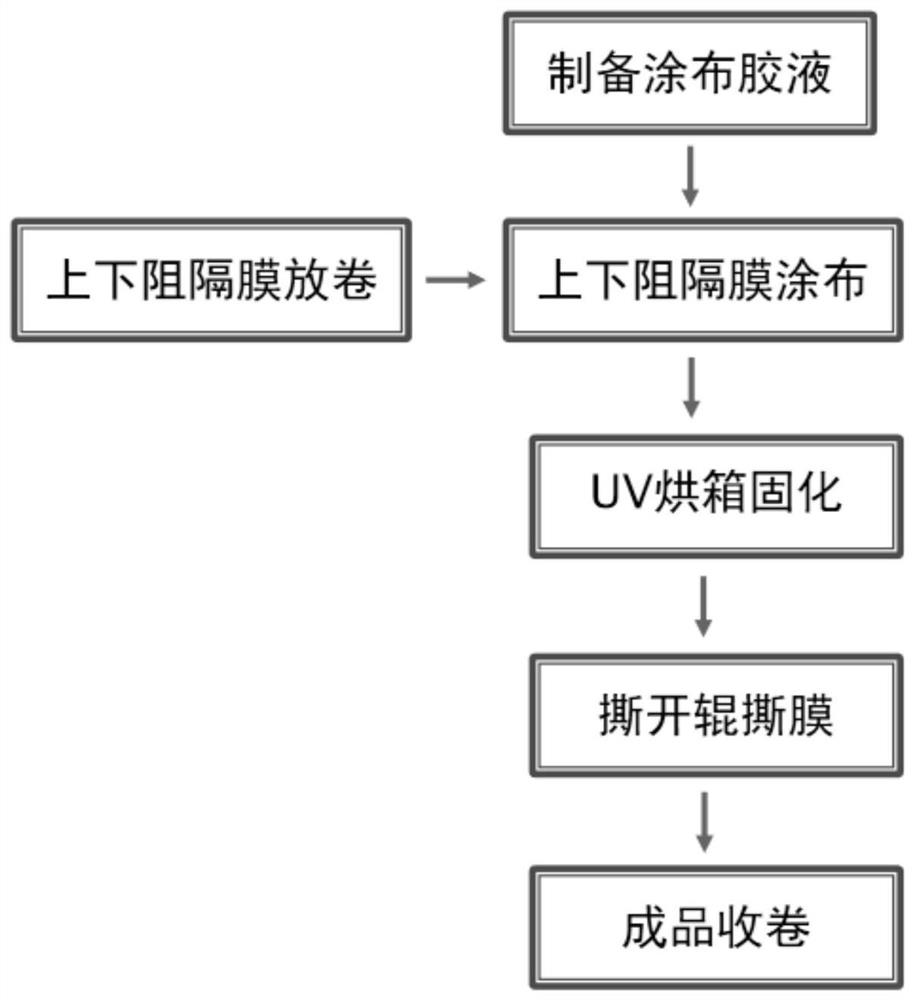

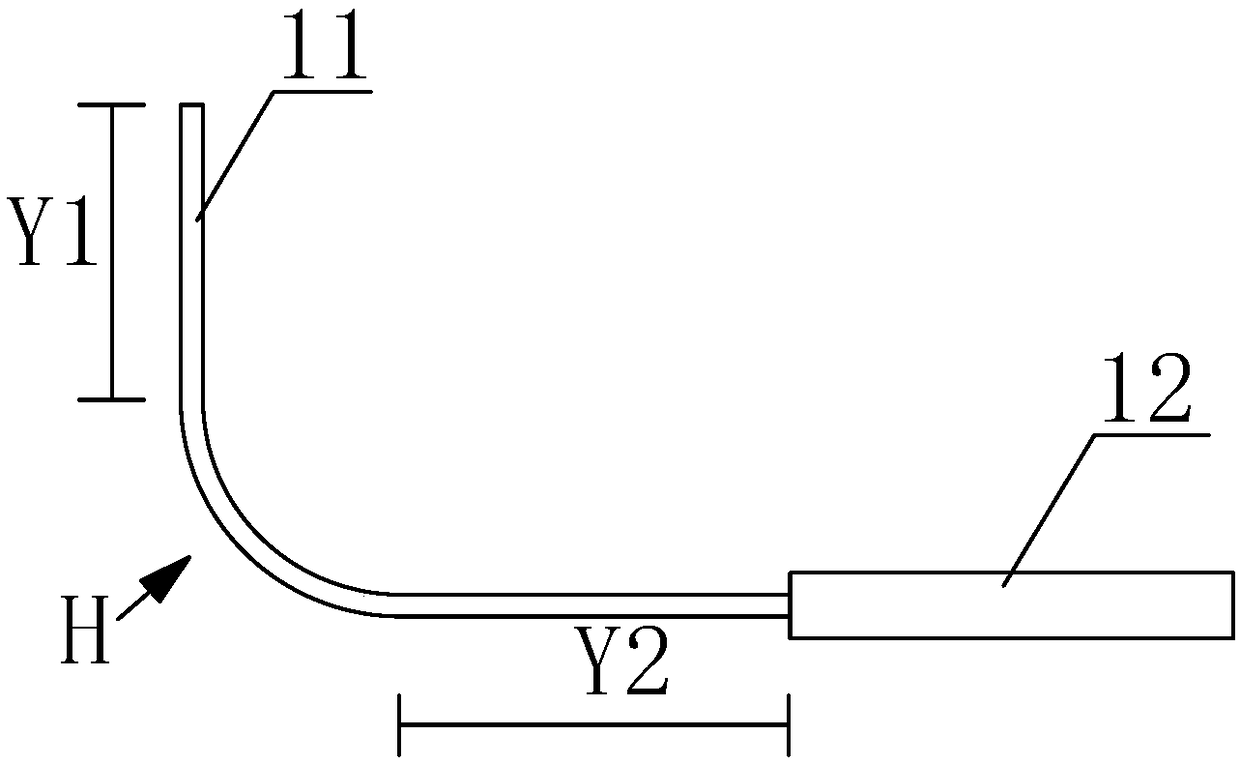

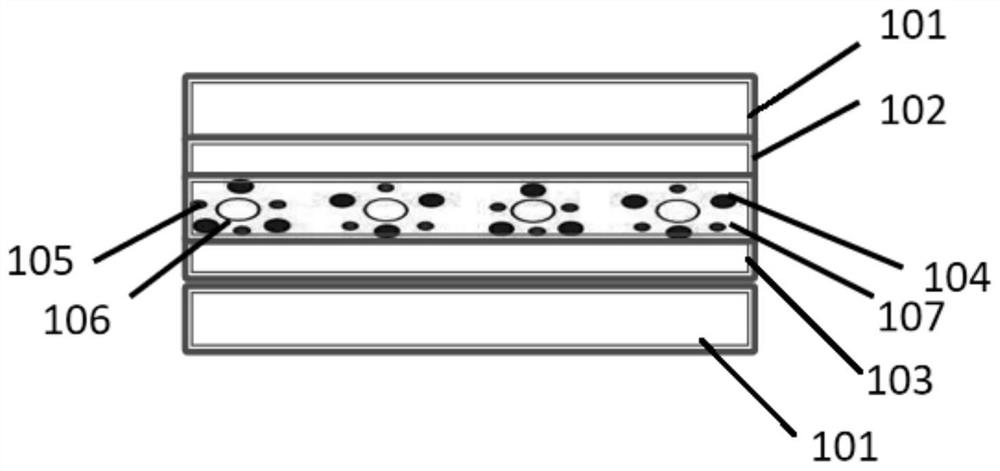

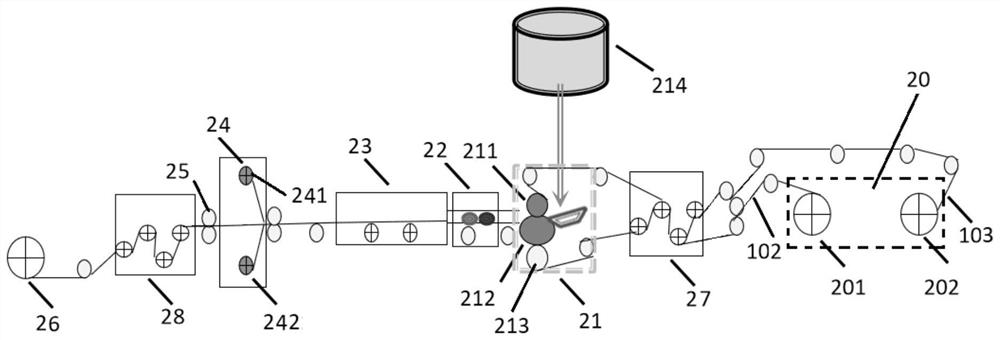

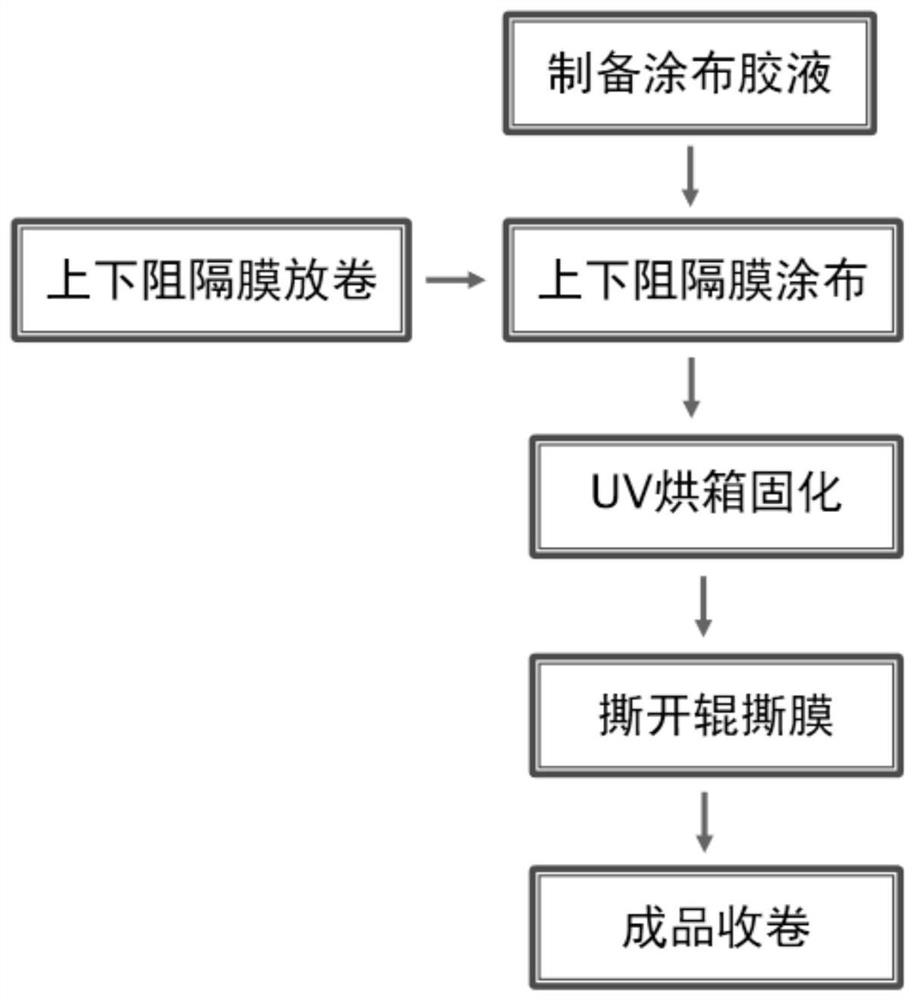

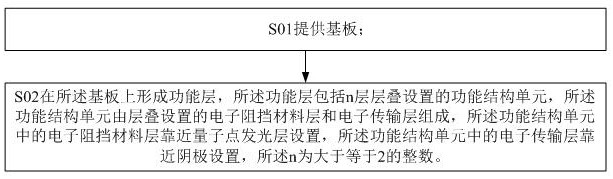

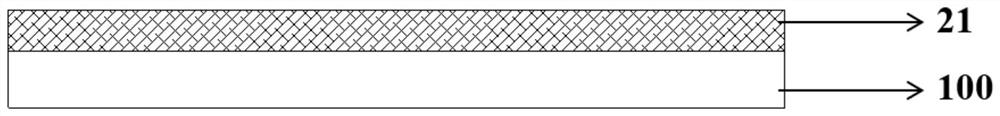

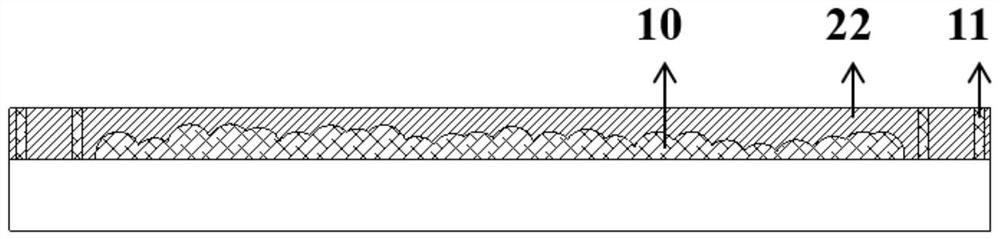

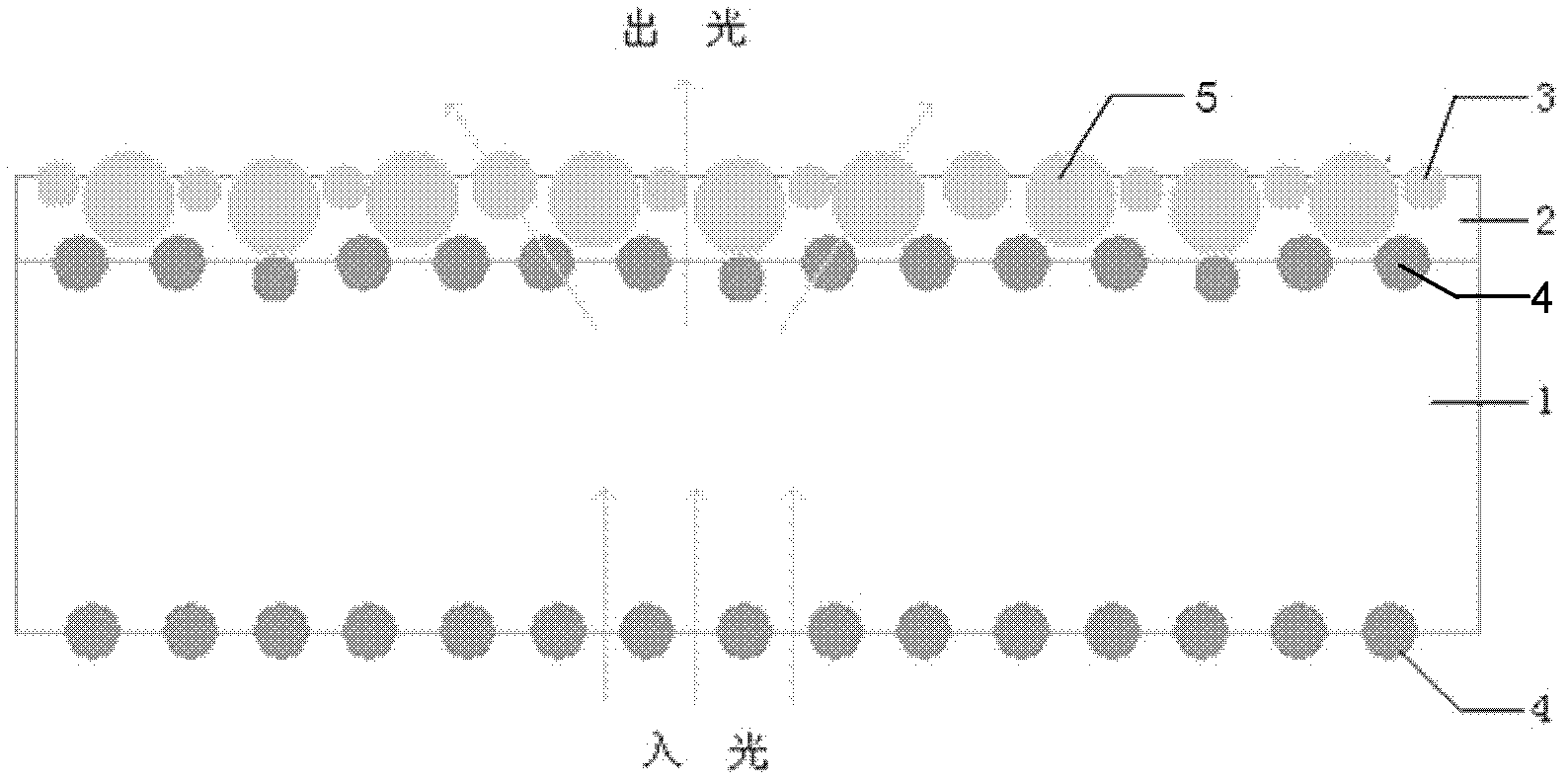

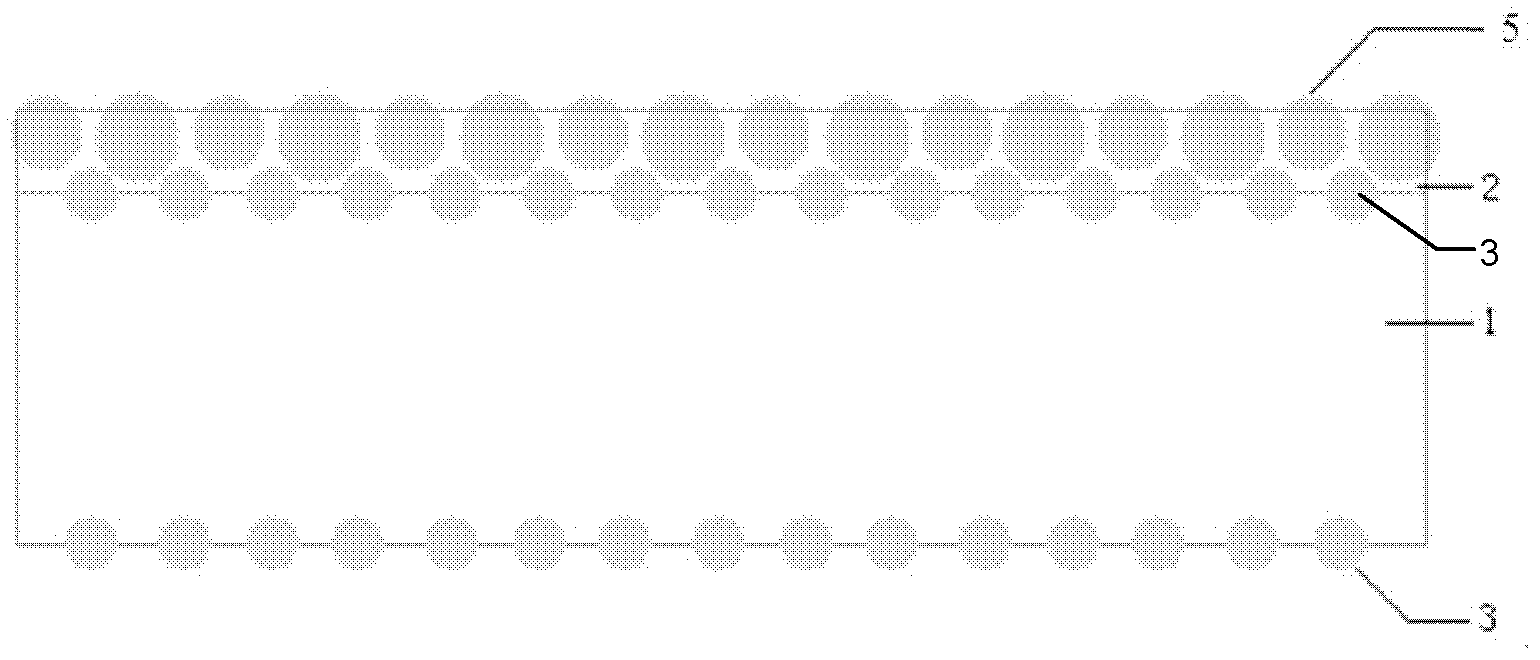

Preparation method and processing equipment of ultrathin quantum dot film

ActiveCN111793448AEasy to operateStable mass productionNon-macromolecular adhesive additivesEster polymer adhesivesLiquid-crystal displayQuantum dot

The invention provides a preparation method and processing equipment of an ultrathin quantum dot film, and relates to the technical field of liquid crystal display. In the preparation process, from the period when unreeling is started to the period when a quantum dot glue solution is coated, cured, and moulded between two barrier films, the lateral surfaces, away from each other, of two barrier films are always attached with release protective films; when the quantum dot glue solution is cured and reeled, the release protective films are gradually peeled-off from two barrier films through a peeling-off roller set so as to obtain the ultrathin quantum dot film, which comprises the quantum dot glue solution layer and two barrier film layers on the external sides of the quantum dot glue solution layer. The preparation method and processing equipment solve the problem that the quantum dot film wrinkles and warps during the traction and curing process due to the face that the film is too thin; the uniformity of the thickness and optical performance of the film is guaranteed, moreover, the operation is simple, and stable and massive production of the ultrathin quantum dot film can be realized without complicated operation.

Owner:NANJING BREADY ELECTRONICS CO LTD

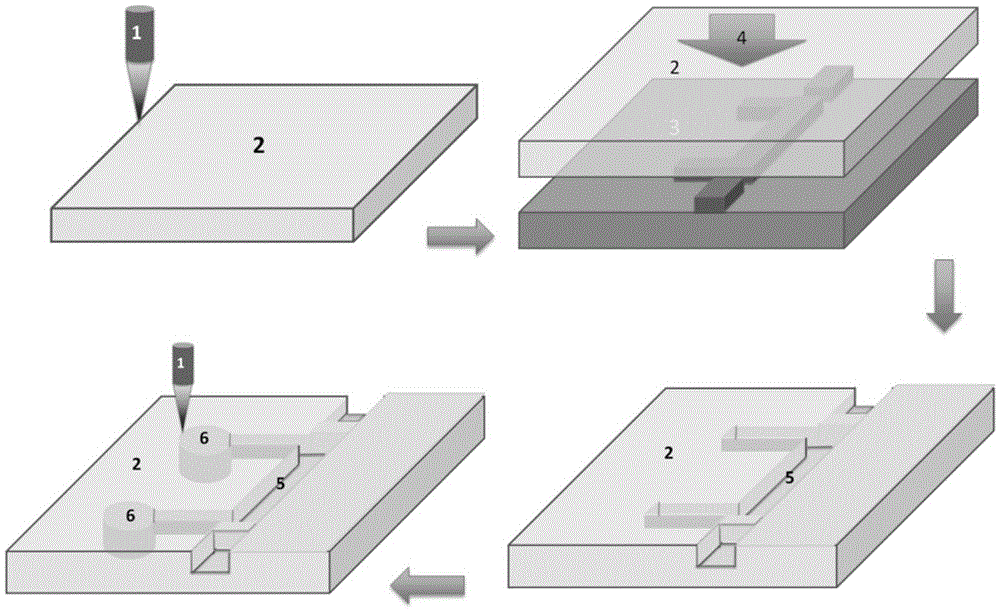

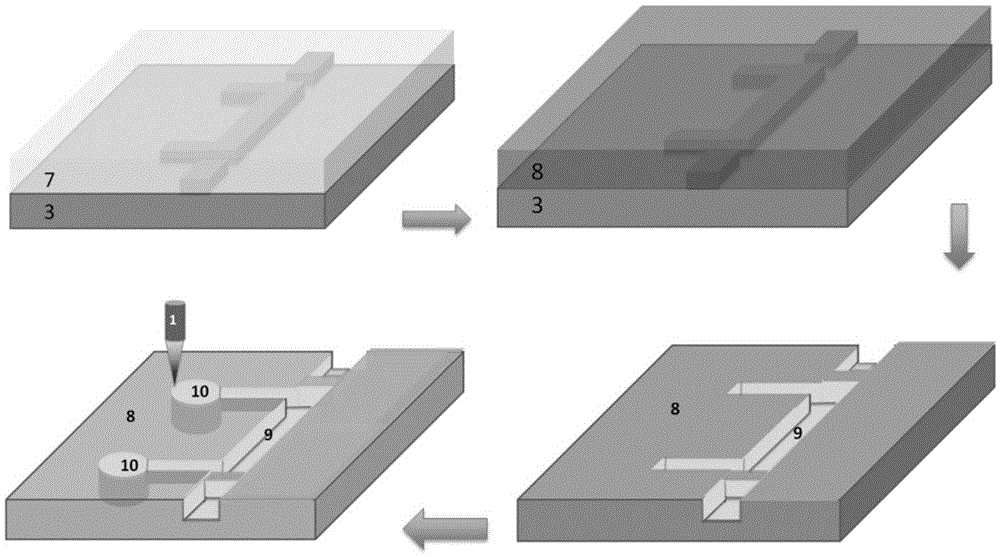

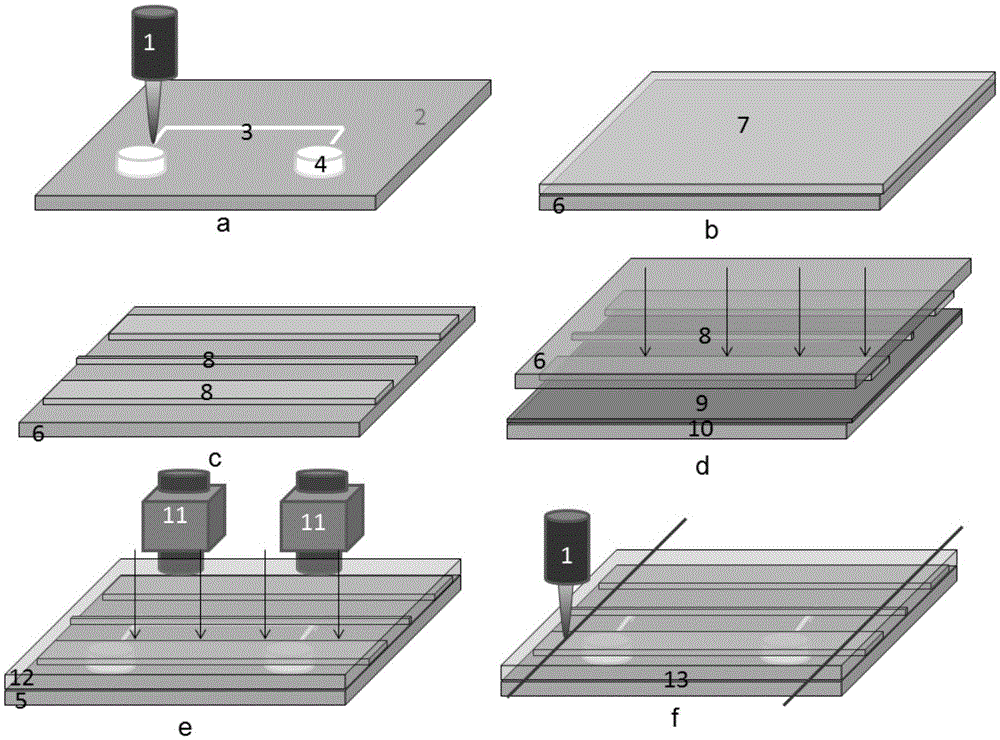

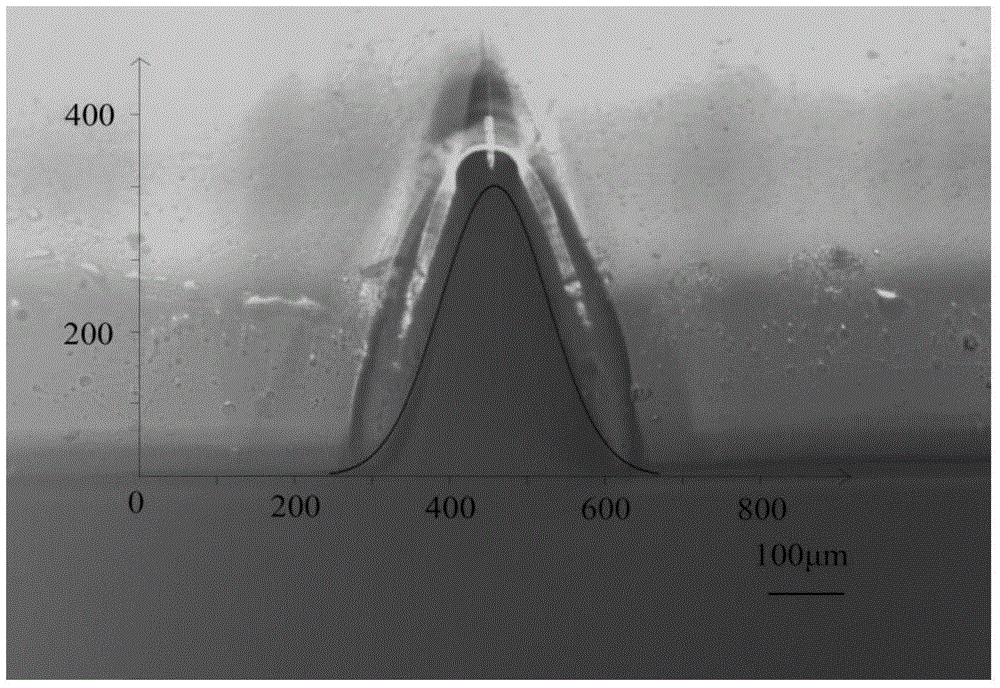

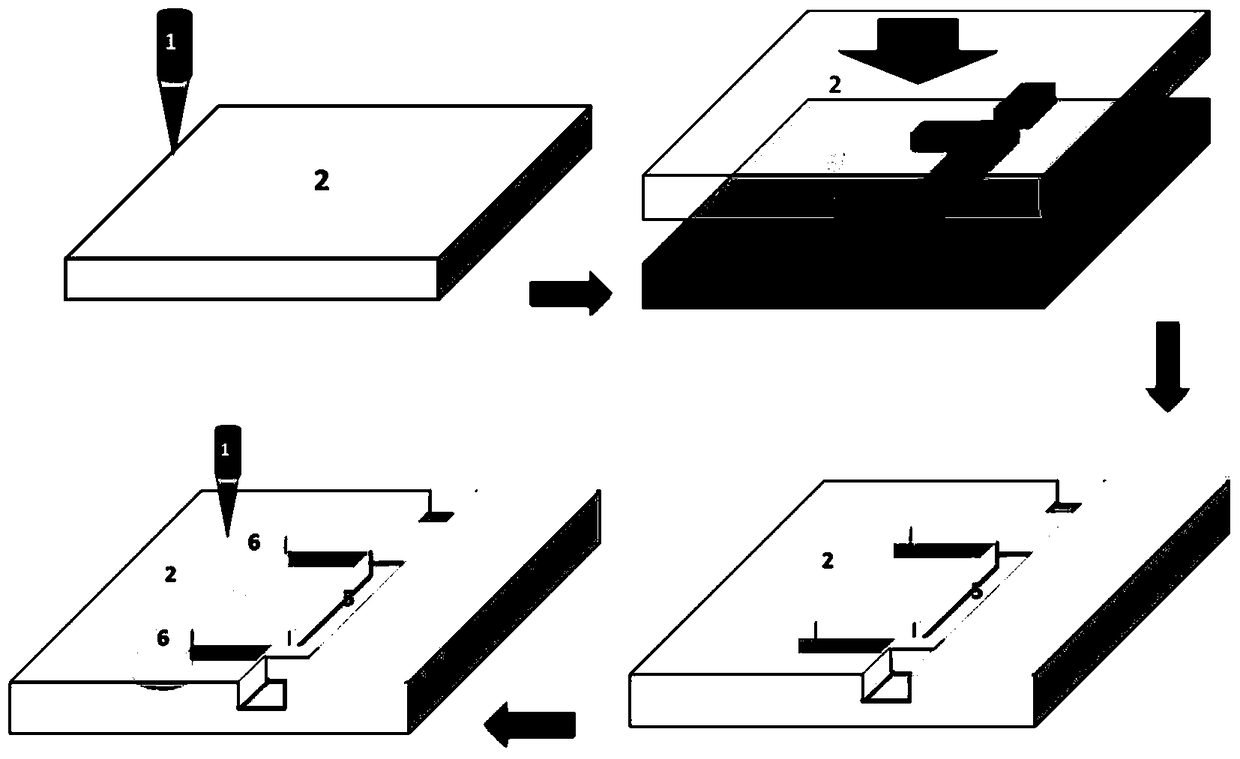

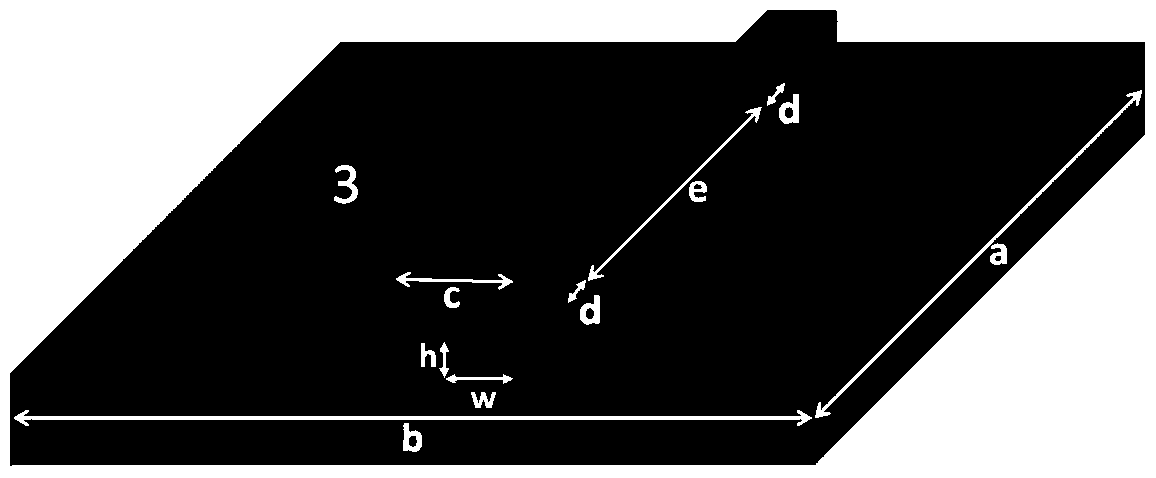

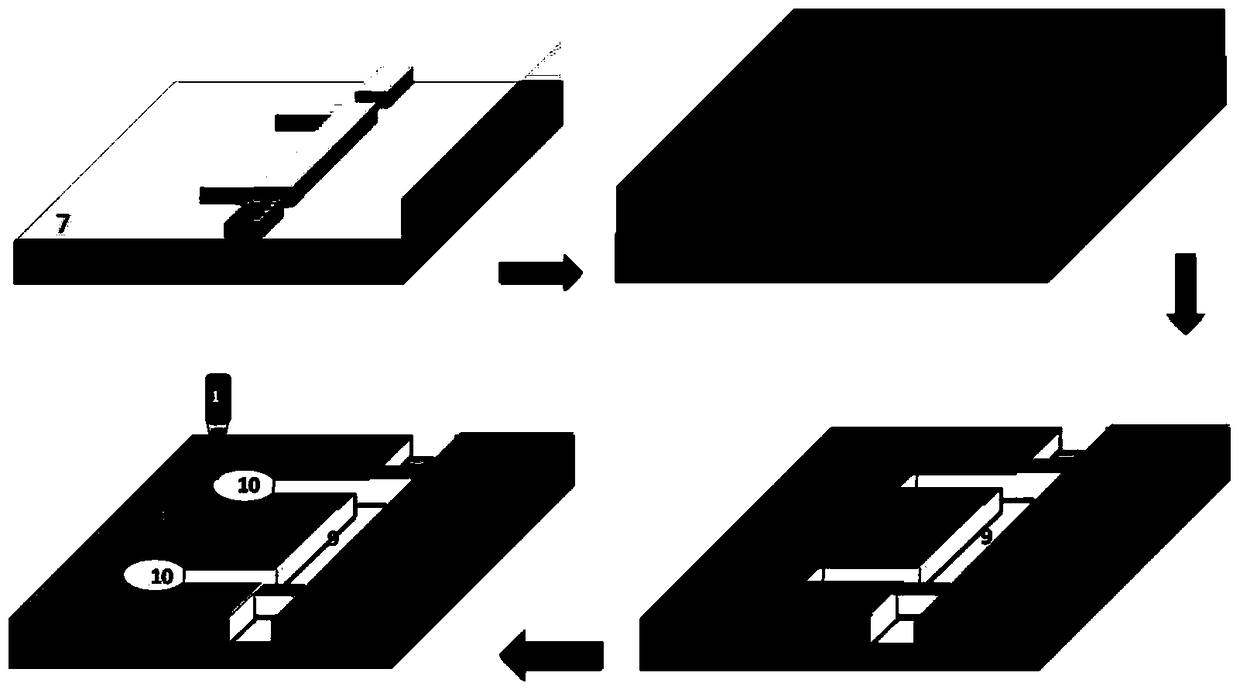

Polymer photobleaching optical waveguide and micro fluidic registration-free integrated chip and preparation method thereof

ActiveCN105589129AAvoid registration errorsReduced bending lossPhotomechanical apparatusOptical waveguide light guidePolymer optical waveguidePhotosensitive polymer

The invention belongs to the polymer optical waveguide and micro fluidic channel integrated chip preparation technical field, and relates to a micro fluidic channel, mask, optical waveguide preparation and end face treatment method which concretely comprises: employing a nanoimprint (hot imprinting or ultraviolet imprinting) method to prepare micro fluidic grooves on a polymer substrate; a carbon dioxide laser cutting and penetrating injecting holes; evaporating an aluminum mask on a chip; spin coating photoresist; performing overall exposure and development to obtain a waveguide mask graph; utilizing a photosensitive polymer to prepare an optical waveguide core layer film on another substrate of the same material with a micro fluidic layer; performing hot imprinting packaging on two layers of chips; employing an upper layer micro fluidic chip as a photomask after packaging; writing in slab waveguide on a photosensitive polymer core layer film, wherein the waveguide is directly located under a micro fluidic channel, thereby avoiding register errors between the upper layer chip and a sensing window in an integration process; cutting a sample end face through laser, and completing an optical waveguide and micro fluidic registration-free integrated chip after polishing.

Owner:JILIN UNIV

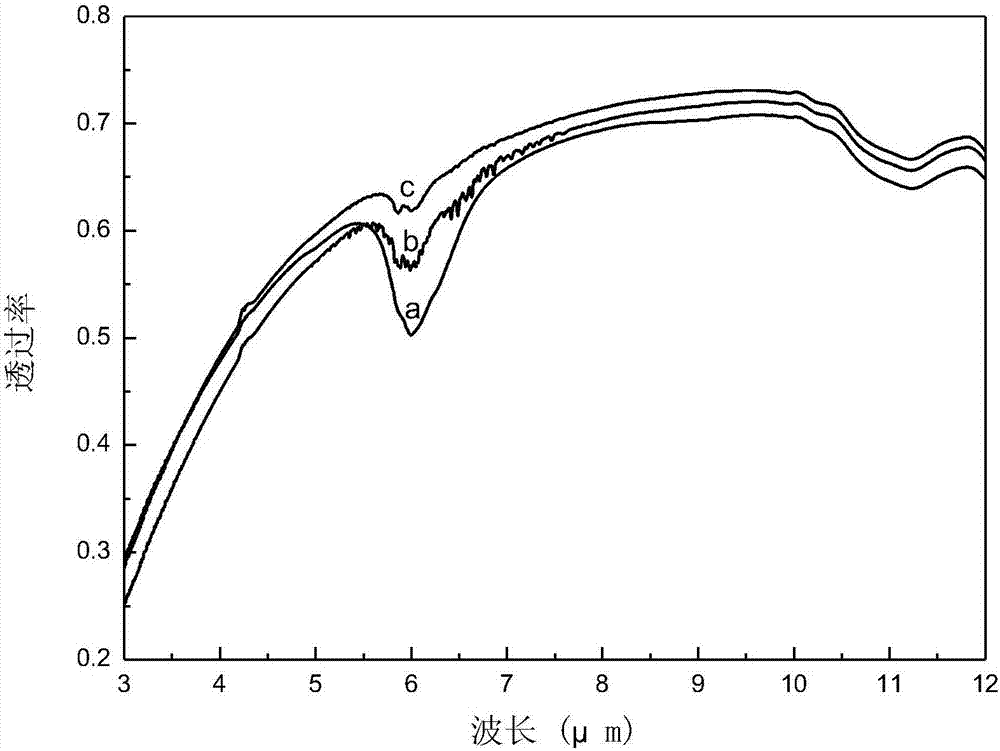

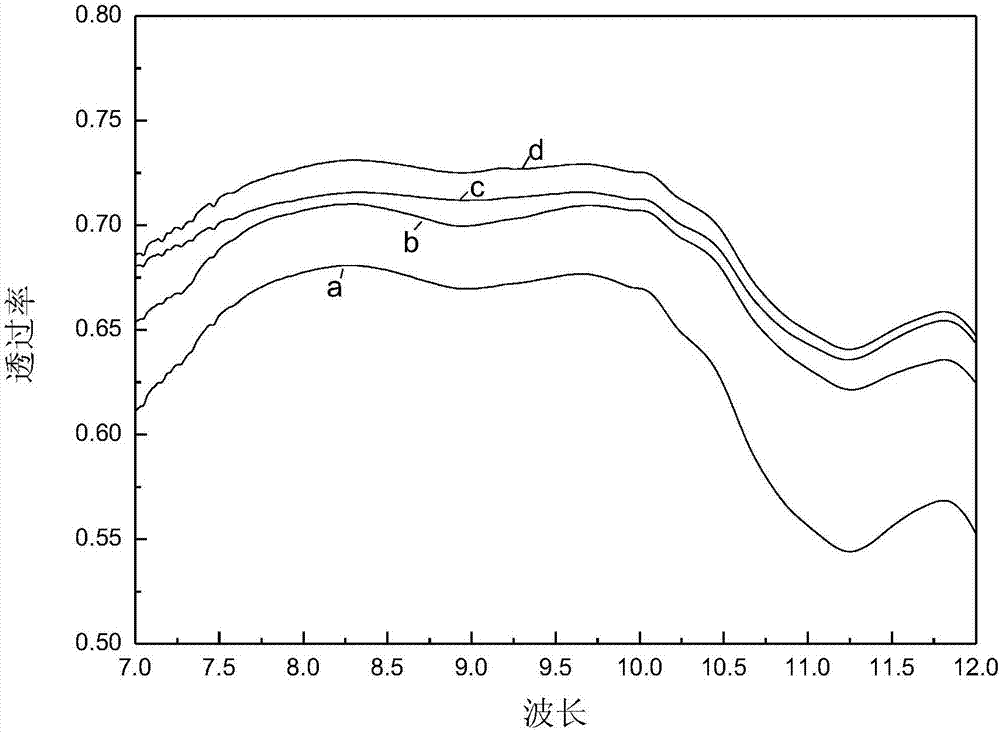

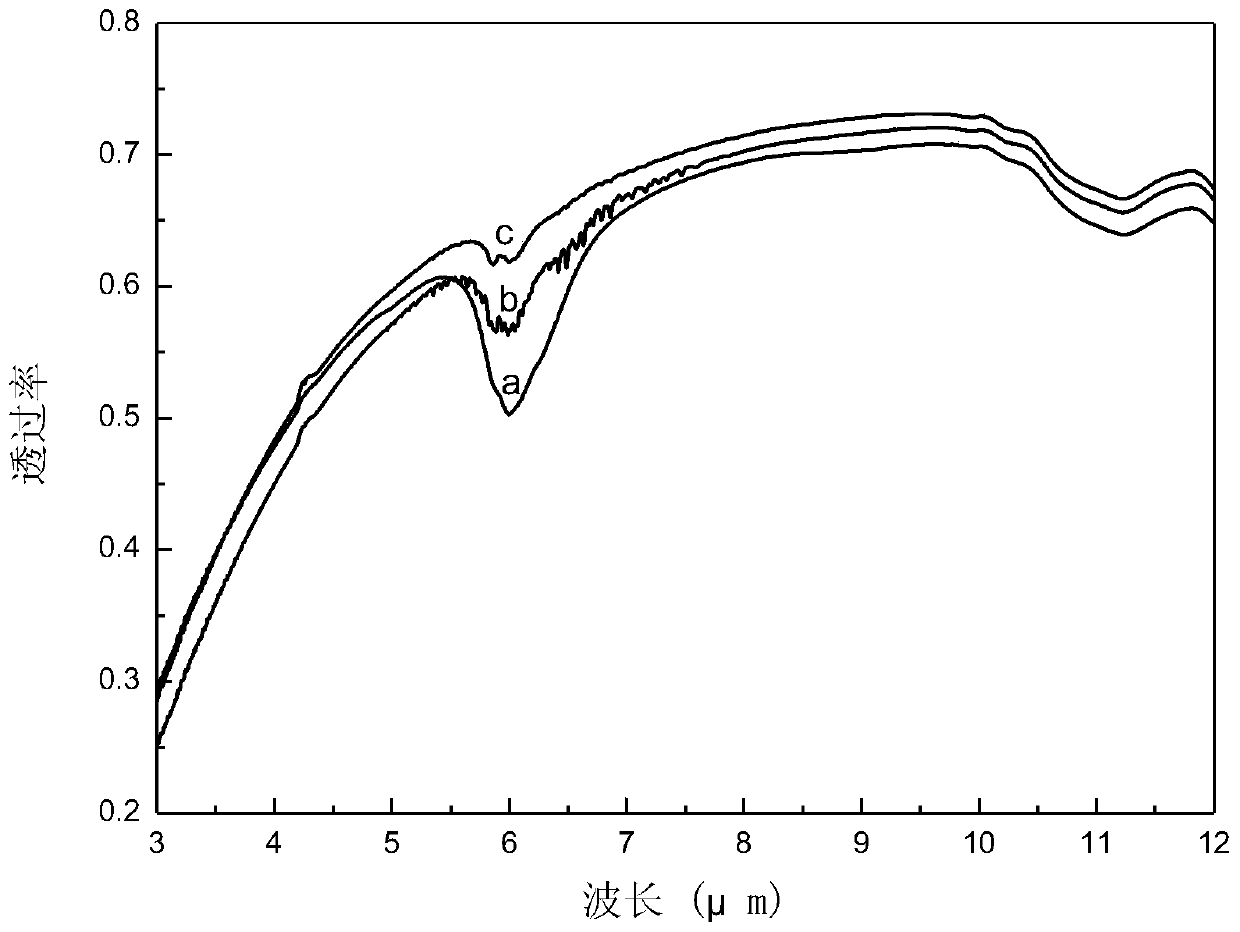

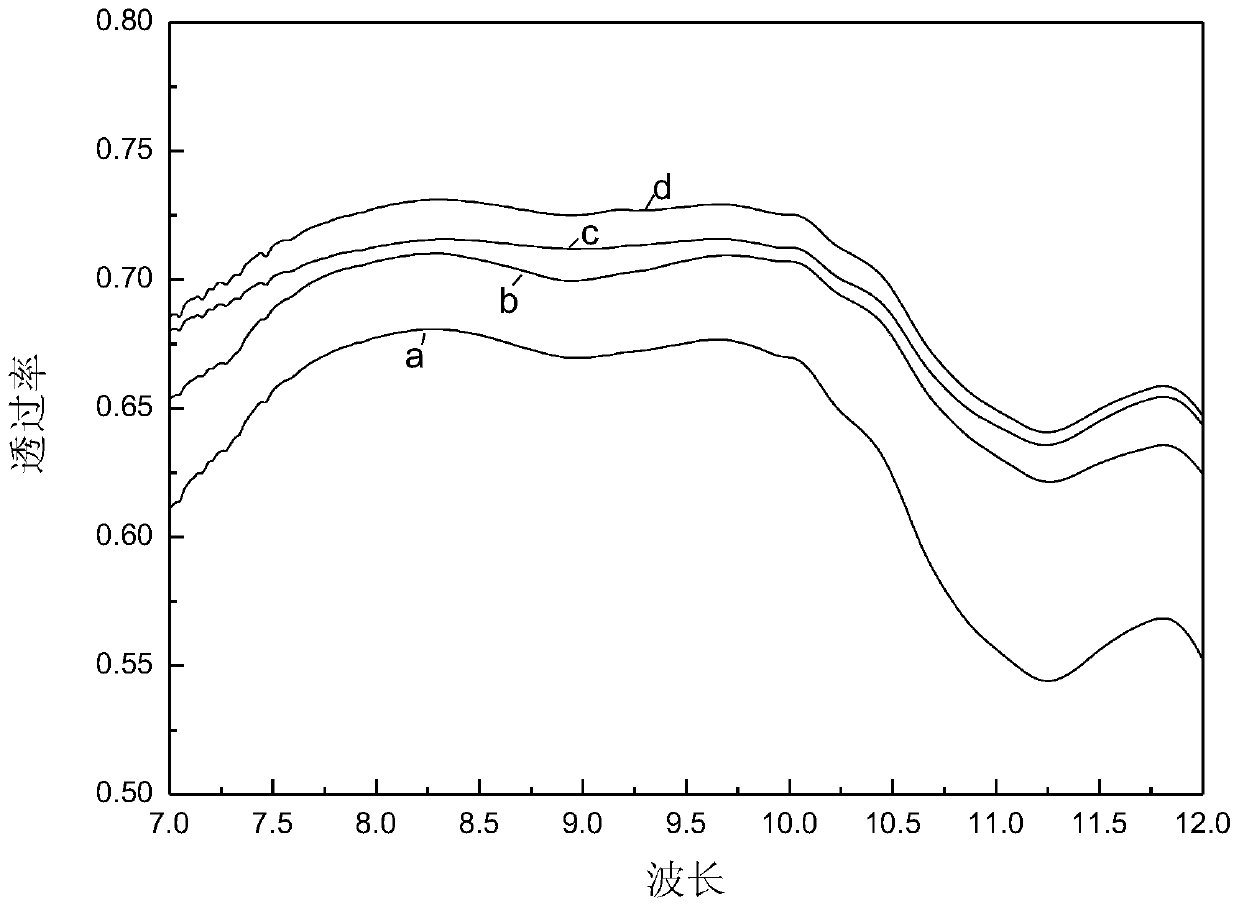

Doping modification method for CVD (Chemical Vapor Deposition) ZnS crystal material

ActiveCN107119323AImprove mechanical propertiesOptical performance impactPolycrystalline material growthDiffusion/dopingAlloyChemical vapor deposition

The invention discloses a doping modification method for a CVD (Chemical Vapor Deposition) ZnS crystal material. The doping modification method comprises the following steps: before deposition, adding a metal M into a zinc crucible, or an alloy Zn-M of M and zinc as a doping agent, performing heating melting, and uniformly mixing so as to obtain an M-doped zinc raw material; further performing chemcial vapor deposition, after deposition is completed, performing constant-temperature constant-pressure thermal treatment, thereby improving the mechanical and mechanical properties of the CVD ZnS crystal material. By adopting the method, on premise that the infrared permeation property of the CVD ZnS crystal material is not remarkably affected, the effect of improving the mechanical property of the CVD ZnS is achieved, the mechanical properties of the CVD ZnS crystal material are improved, the mechanical strength of the CVD ZnS crystal material is improved, the corrosion resistance and the thermal impact resistance is improved, and the method is applicable to on-scale production and commercial application.

Owner:YUNNAN KIRO CH PHOTONICS

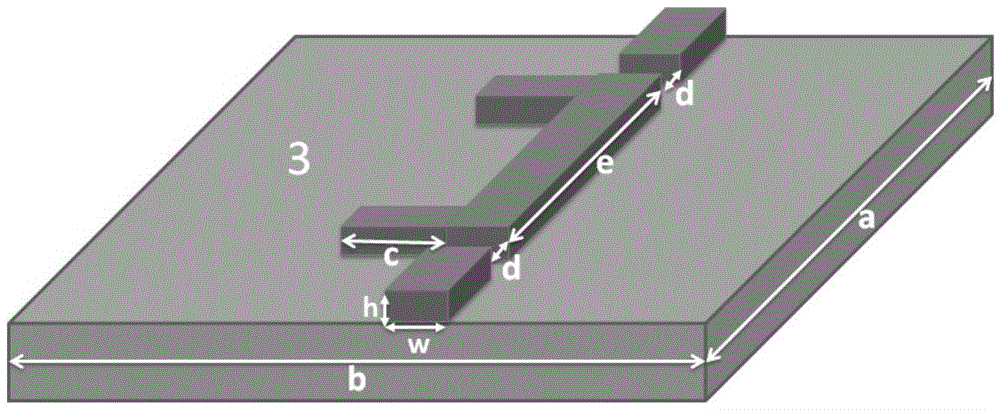

Polymer rectangular optical waveguide and micro-fluidic three-dimensional integrated chip and preparation method thereof

ActiveCN105572795AReduced bending loss and scattering lossSimple processOptical waveguide light guideMicro fluidicChemistry

The invention provides a polymer rectangular optical waveguide and micro-fluidic three-dimensional integrated chip and a preparation method thereof, and belongs to the preparation technical field of polymer rectangular optical waveguide three-dimensional hybrid integrated chips. According to the technical scheme of the invention, the impression or carbon dioxide laser-written method is conducted to prepare a micro-fluidic groove and a liquid injection hole on a methyl methacrylate substrate. Meanwhile, a raised rectangular optical waveguide is prepared on another substrate of the same material with the micro-fluidic layer through the wet etching process, wherein the glass transition temperature of the photosensitivepolymer material for preparing the raised rectangular optical waveguide is higher than the glass transition temperature of methyl methacrylate. Through the one-time hot stamping process, the center ply of the optical waveguide is pressed into the interior of the methyl methacrylate substrate, and the surface layer of the center ply of the optical waveguide is exposed. In this way, the application of the wet etching-based rectangular optical waveguide in the three-dimensional integration field is realized. Meanwhile, the bending loss and the scattering loss of the waveguide are lowered.

Owner:长春市华信科瑞光电技术有限公司

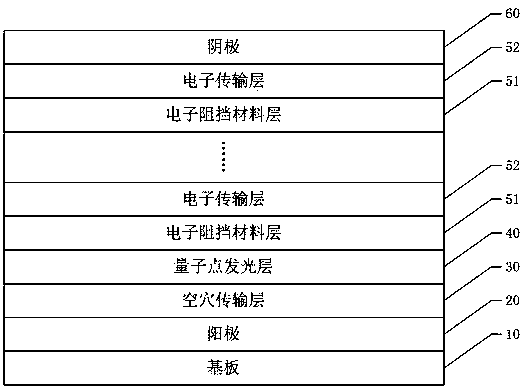

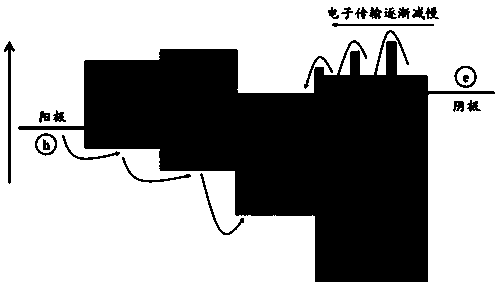

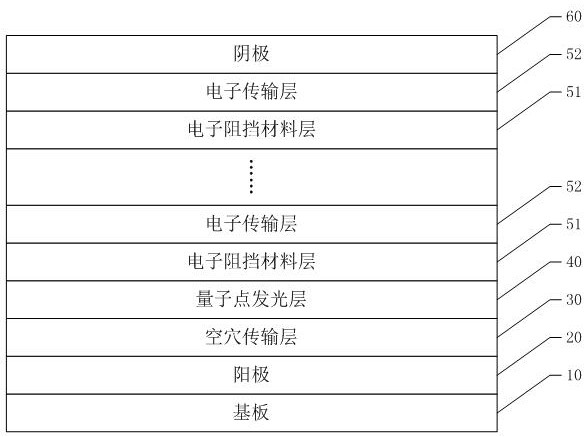

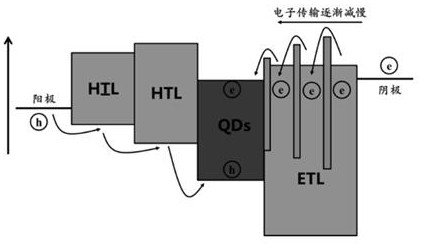

Quantum dot light emitting diode

ActiveCN111384279AImprove luminous efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron holeQuantum dot

The invention discloses a quantum dot light emitting diode. The quantum dot light-emitting diode comprises a cathode, an anode and a quantum dot light-emitting layer arranged between the cathode and the anode, and a functional layer is arranged between the cathode and the quantum dot light-emitting layer; the functional layer comprises n layers of functional structure units which are arranged in astacked mode, wherein the functional structure unit is composed of an electron blocking material layer and an electron transmission layer which are arranged in a stacked mode, the electron blocking material layer in the functional structure unit is arranged close to the quantum dot light-emitting layer, the electron transmission layer in the functional structure unit is arranged close to the cathode, and n is an integer larger than or equal to 1. According to the quantum dot light-emitting diode, the transmission rate of electrons transmitted to the quantum dot light-emitting layer can be reduced through the arrangement of the functional layer, so that the injection rate of the electrons and holes is balanced, the recombination efficiency of carriers in the quantum dot layer is improved,the light-emitting efficiency and stability of the quantum dot light-emitting diode are improved, and the service life of the quantum dot light-emitting diode is prolonged.

Owner:TCL CORPORATION

A preparation method of high wear-resistant transparent microcrystalline frit glaze and glaze layer for architectural ceramics and the prepared product

The invention discloses a high abrasion resistance transparent crystallite fritted glaze, wherein a high-melting-point and high-hardness glass material is formed by taking silicon dioxide, aluminum oxide and magnesium oxide as main ingredients, and a low-melting-point and high-hardness glass material is formed by taking boric acid and silicon dioxide as main ingredients; the two glass materials are mixed at an optimal ratio, so as to form the high abrasion resistance transparent crystallite fritted glaze. Additionally, the invention also discloses a preparation method of the fritted glaze and an enamel layer and a prepared product. Through adjustment and optimization of the formula, a large number of superfine crystals with tiny particles can be generated in the sintered enamel layer, so that the abrasion resistance of the glaze is greatly improved, and the influence on the glossiness and the transmittance of the enamel layer is reduced, therefore, the requirements of the market for a high abrasion resistance glaze ceramic product can be well met, and the transformation, upgrading and development of the traditional ceramic industry are promoted.

Owner:JINGDEZHEN CERAMIC UNIV

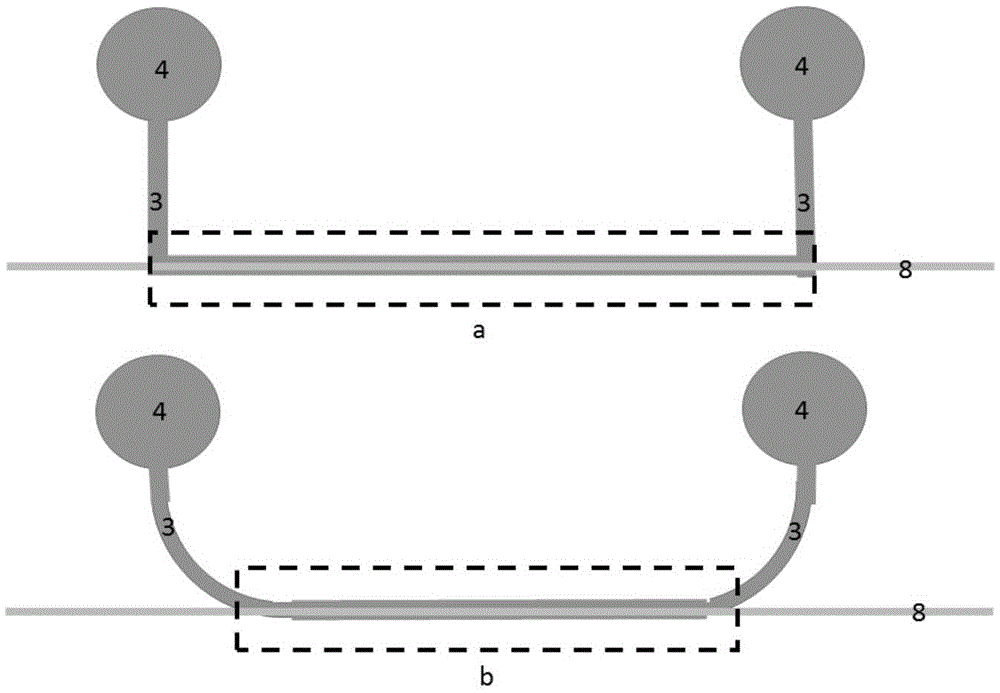

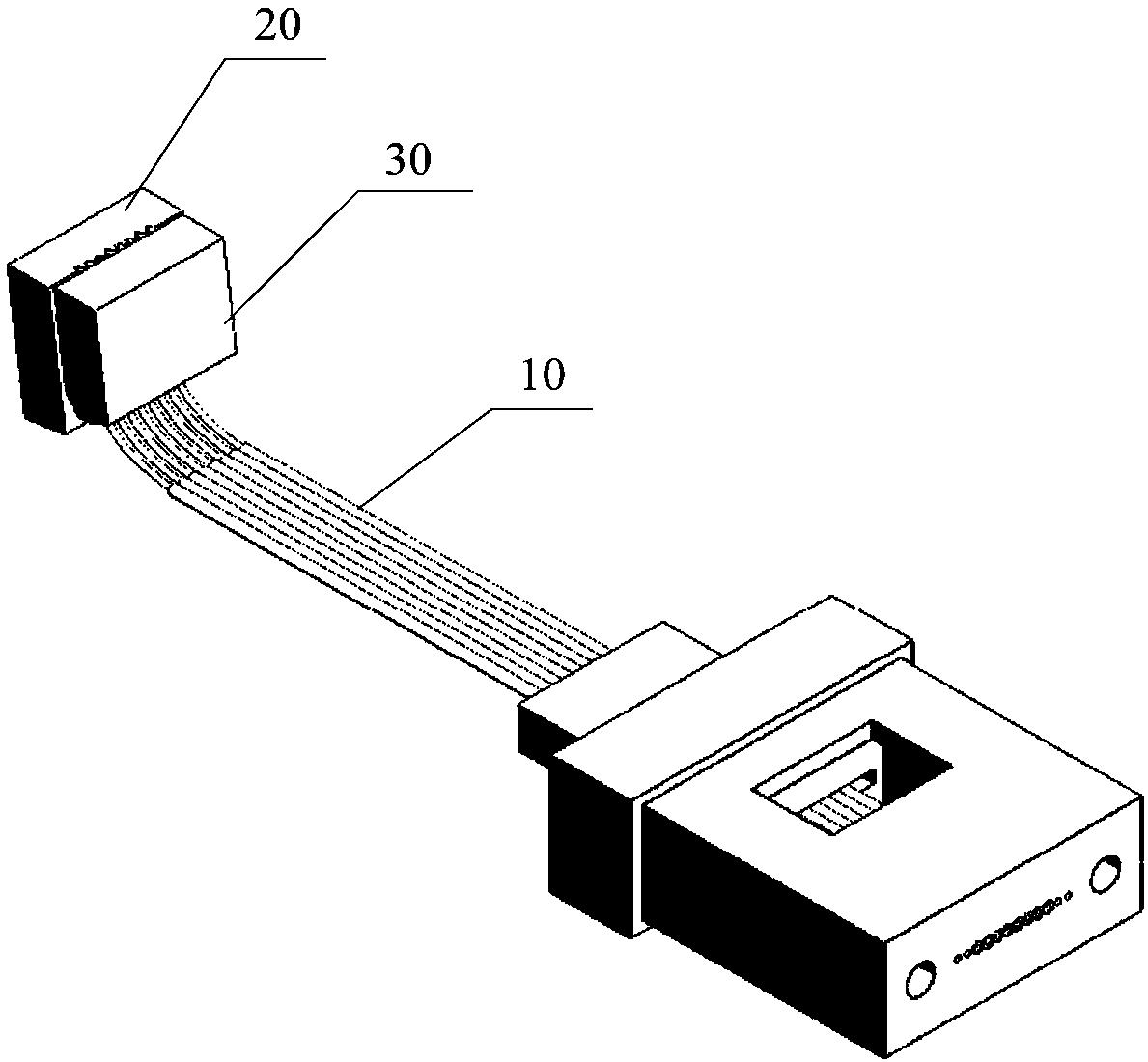

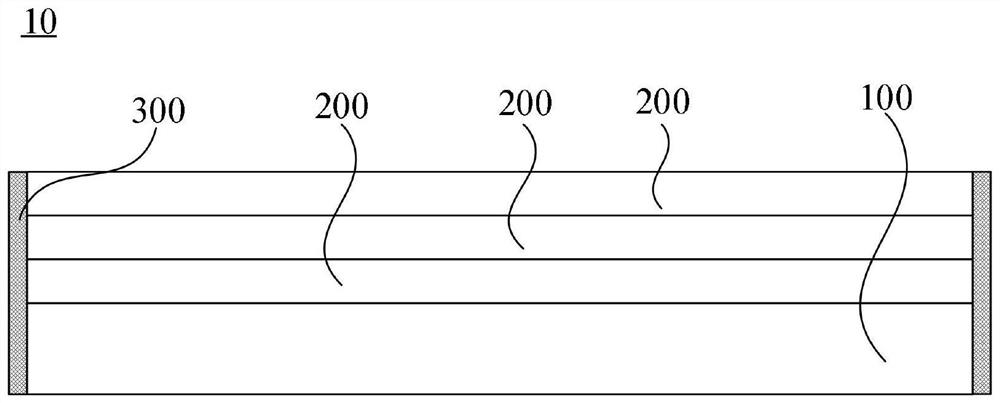

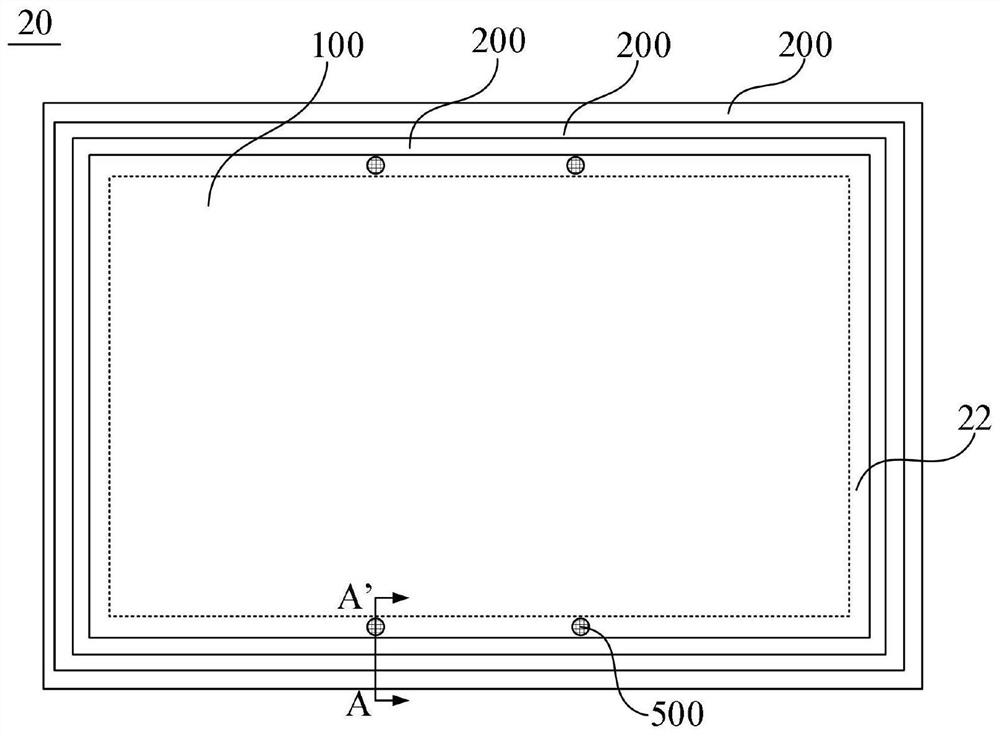

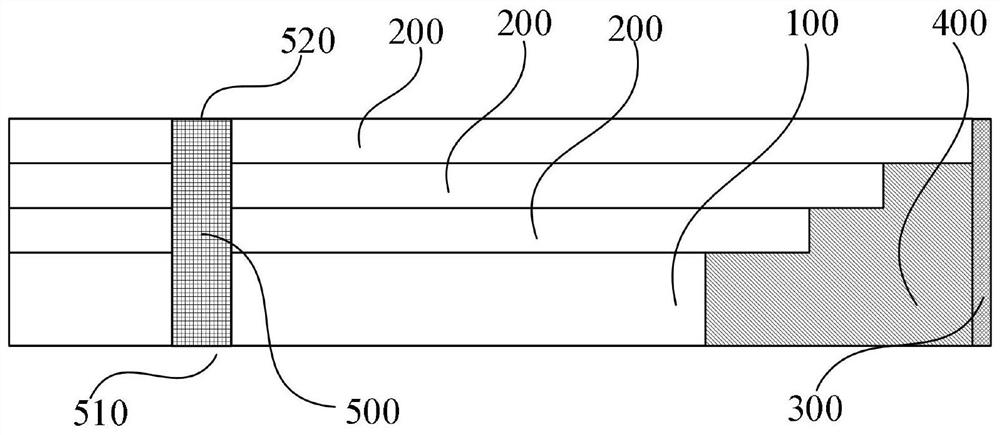

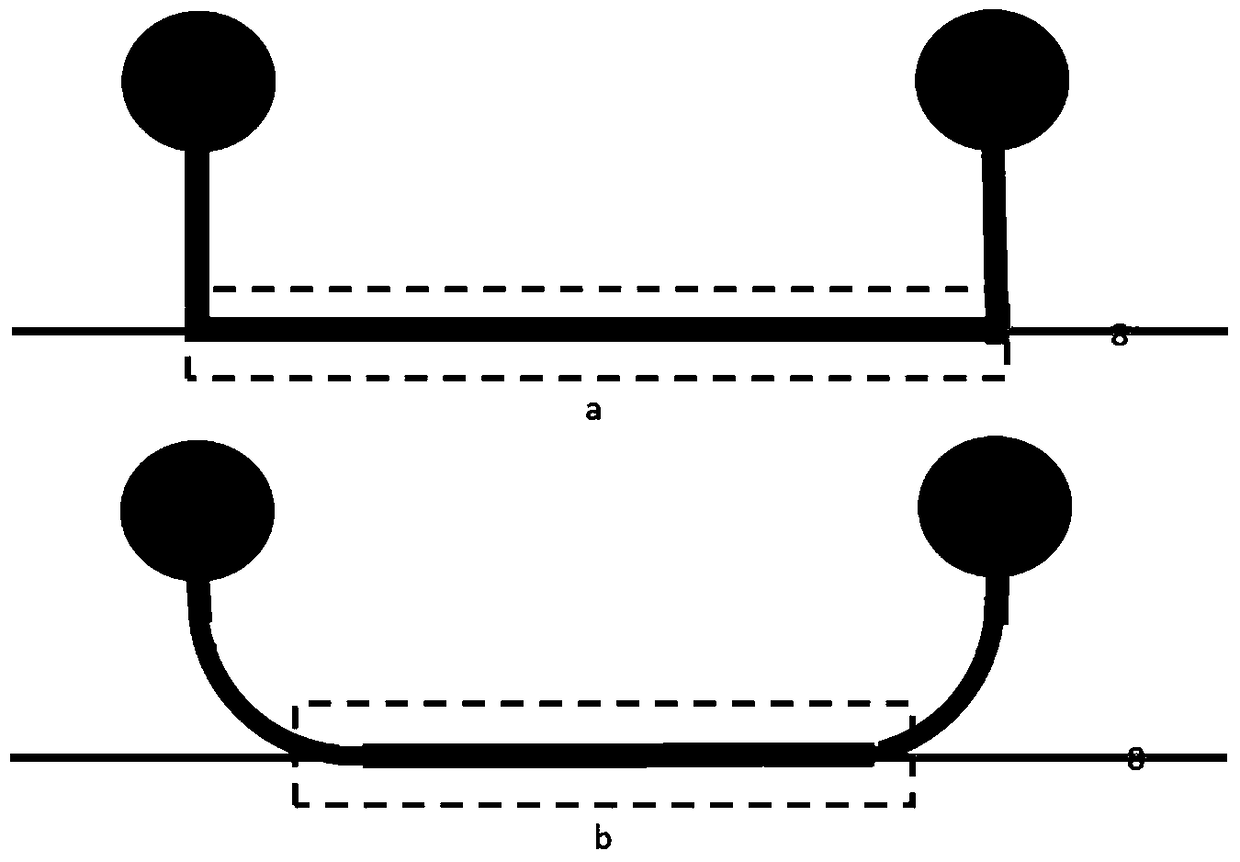

Bending optical fiber array and preparation method thereof

PendingCN108254832ANot easily damaged or brokenEasy to installCoupling light guidesEngineeringOptical fiber cable

The invention relates to a bending optical fiber array. The bending optical fiber array comprises a cover plate, a baseplate and optical fibers between the cover plate and the baseplate, the optical fibers are pre-bent strip-shaped multi-channel optical fibers and comprise strip-shaped naked optical fiber parts without coating layers and strip-shaped optical fiber parts with coating layers, the strip-shaped naked optical fiber parts without the coating layers are bent to a preset angle A, and the preset angle A is larger than or equal to 80 degrees and smaller than or equal to 150 degrees. According to the bending optical fiber array, the strip-shaped multi-channel optical fibers are pre-bent to the required angle, then the baseplate and the cover plate are mounted, so that the optical fiber array does not have the bending stress in the mounting process, the optical fibers are not easily damaged or broken, and the bending optical fiber array is convenient to mount and lower in cost; inaddition, according to the optical fiber array, the optical fibers can be bent into any required angle through heating equipment in advance, the angle can be extremely small, and the loss of the optical fibers cannot be too large.

Owner:VLINK OPTICS CORPORATION

Aviation organic glass protective coating and preparation method thereof

The invention relates to an aviation organic glass protective coating which contains the following ingredients: acrylic acid, polyethylene glycol, water-soluble polyether-modified polysiloxane, fumed silica, n-dodecyl mereaptan, potassium persulphate and water. The invention is mainly characterized in that the protective coating doesn't contain an organic solvent at all, has flexibility, can be used to protect optical functional polymer materials such as aircraft cabin glass during transportation and production processes, can conveniently be removed after implementing the protective function and will not influence optical performance of the materials.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

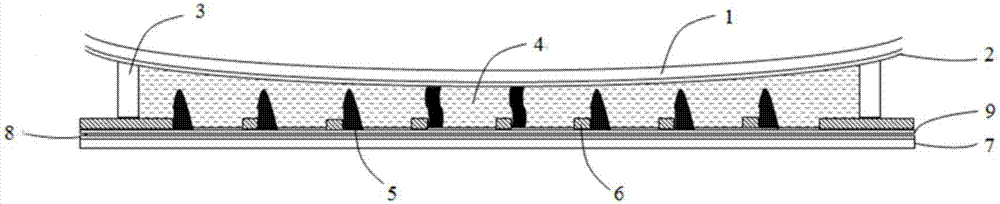

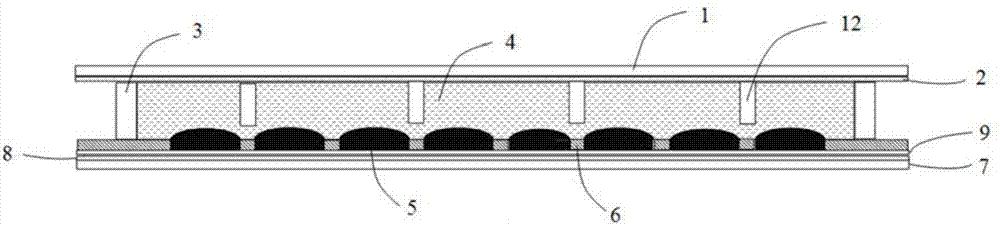

Electrowetting device and preparation method thereof

The invention belongs to the field of electrowetting, and discloses an electrowetting device. The electrowetting device includes an upper substrate and a lower substrate; a cavity formed by the opposite upper and lower substrates is filled with encapsulation liquid; the upper substrate includes an upper support plate, a first electrode, a sealing plastic frame and support columns; the lower substrate includes a lower support plate, a second electrode, a hydrophobic insulation layer and a pixel wall. The invention further discloses a preparation method of the electrowetting device. According to the electrowetting device, the support column structure is arranged on the upper substrate, which is different from other electrowetting devices of which support columns are arranged on the lower substrate, the support column on the upper substrate can be subjected to several kinds of physical and chemical hydrophilic modifications, so that the support column achieves the conditions of super hydrophilicity and super oleophobicity, and therefore the influence of the support column on ink movement is greatly reduced.

Owner:SHENZHEN GUOHUA OPTOELECTRONICS +2

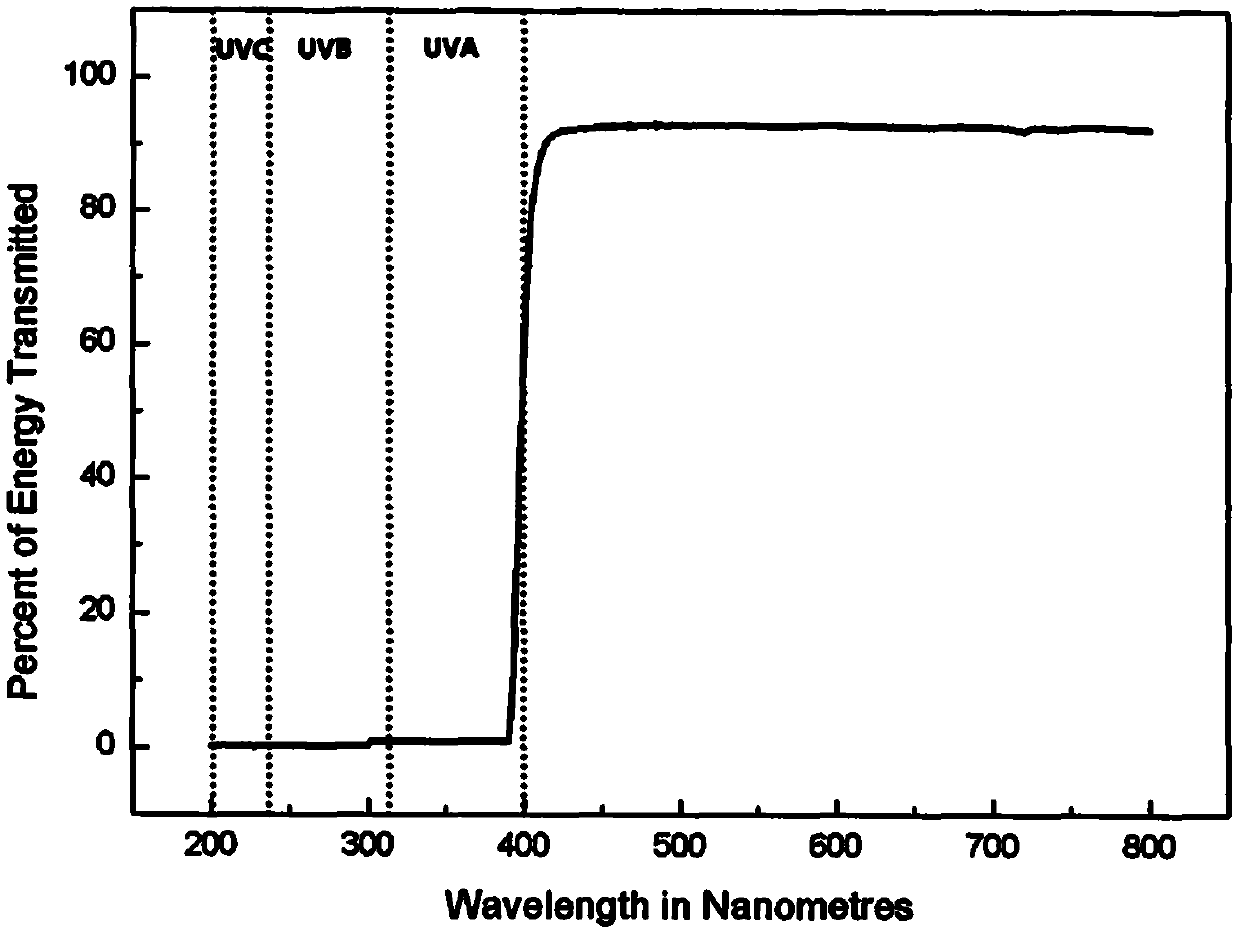

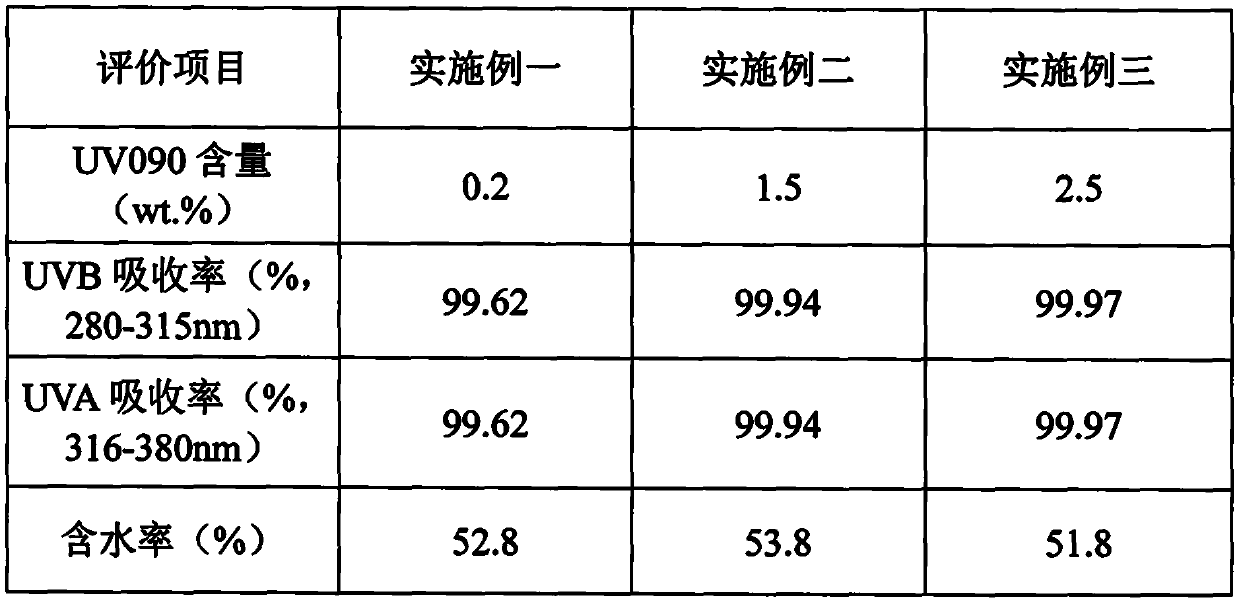

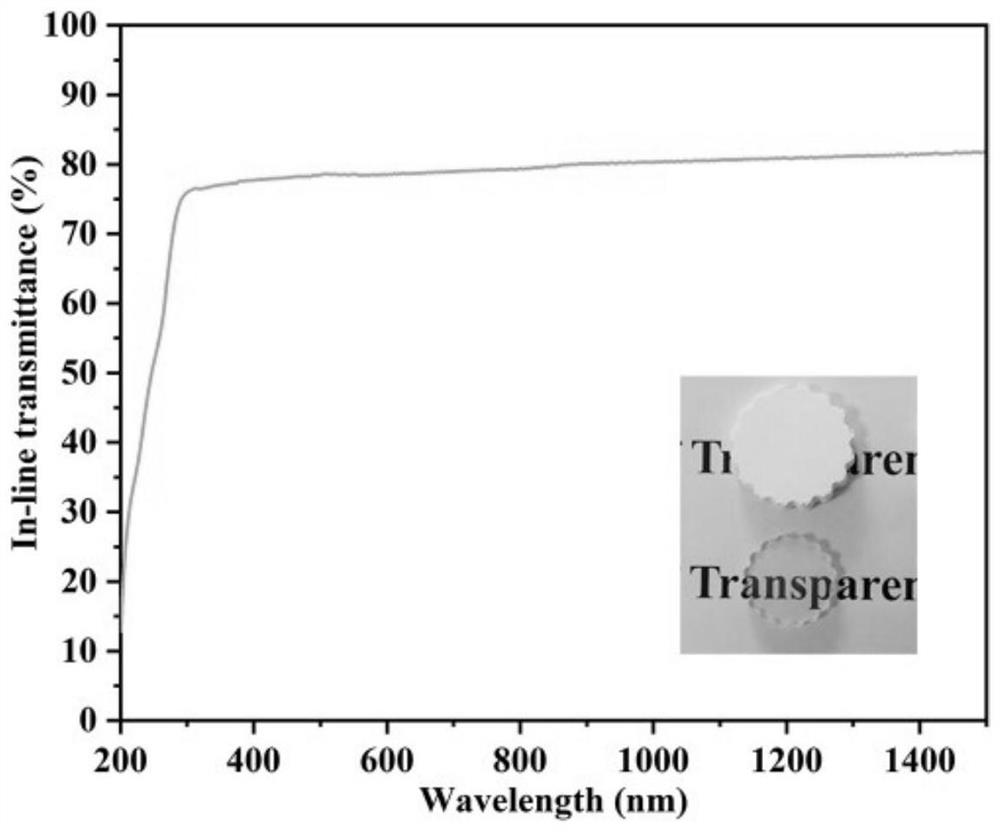

Preparation method for improving ultraviolet resistance of contact lenses through ultraviolet absorbent agent

InactiveCN109796557AImproves UV resistanceOptical performance impactOptical partsCross-linkMixed materials

The invention discloses a preparation method for improving the ultraviolet resistance of contact lenses through an ultraviolet absorbent agent. The preparation method involves, by weight, 90-98.8% ofcontact lens monomer mixed liquid with HEMA as a main base material, 0.2-2.5% of the ultraviolet absorbent agent, 0.3-1.0% of an initiator and 0.7-0.9% of a cross-linking agent. The preparation methodhas the advantages that 1, by using a proper amount of the ultraviolet absorbent agent 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl methacrylate in the contact lens mixed material, so that the contact lenses prepared by using the method are high in ultraviolet resistance; the contact lenses prepared by using the method has high ultraviolet resistance, but has no influence on the lens opticalperformance in the visible region; the preparation method for improving the ultraviolet resistance of the contact lenses is simple in preparation process and low in production cost.

Owner:华诺森(武汉)生物医药技术有限公司

A kind of preparation method of water-absorbing anti-fog film layer for automobile glass

The invention relates to a method for preparing a water absorbent anti-fog film used for automotive glass. The method comprises the following steps: step 1, preparing water absorbent resin from raw materials in parts by weight as follows: adding 10-40 parts of resin containing water absorbent groups and 10-50 parts of crosslinkable cured resin to 50-100 parts of organic solvents, mixing up, adding 20-60 parts of curing agent and 1-5 parts of flatting agent. mixing up and obtaining the water absorbent resin; step 2, preparing the anti-fog film: sequentially degreasing the surface of the automotive glass with the organic solvent, performing mechanical polishing, rinsing with tap water and distilled water respectively, and desiccating; performing surface coating on the clean and dry automotive glass with the water absorbent resin prepared according to the step 1, and placing the water absorbent anti-fog film at a temperature of 80-150 DEG C for 0.5-4h after the leveling of the water absorbent anti-fog film. The water absorbent anti-fog film provided by the invention can absorb and desorb steam without creating fog on the glass, and has a long-term anti-fog function.

Owner:CHERY AUTOMOBILE CO LTD

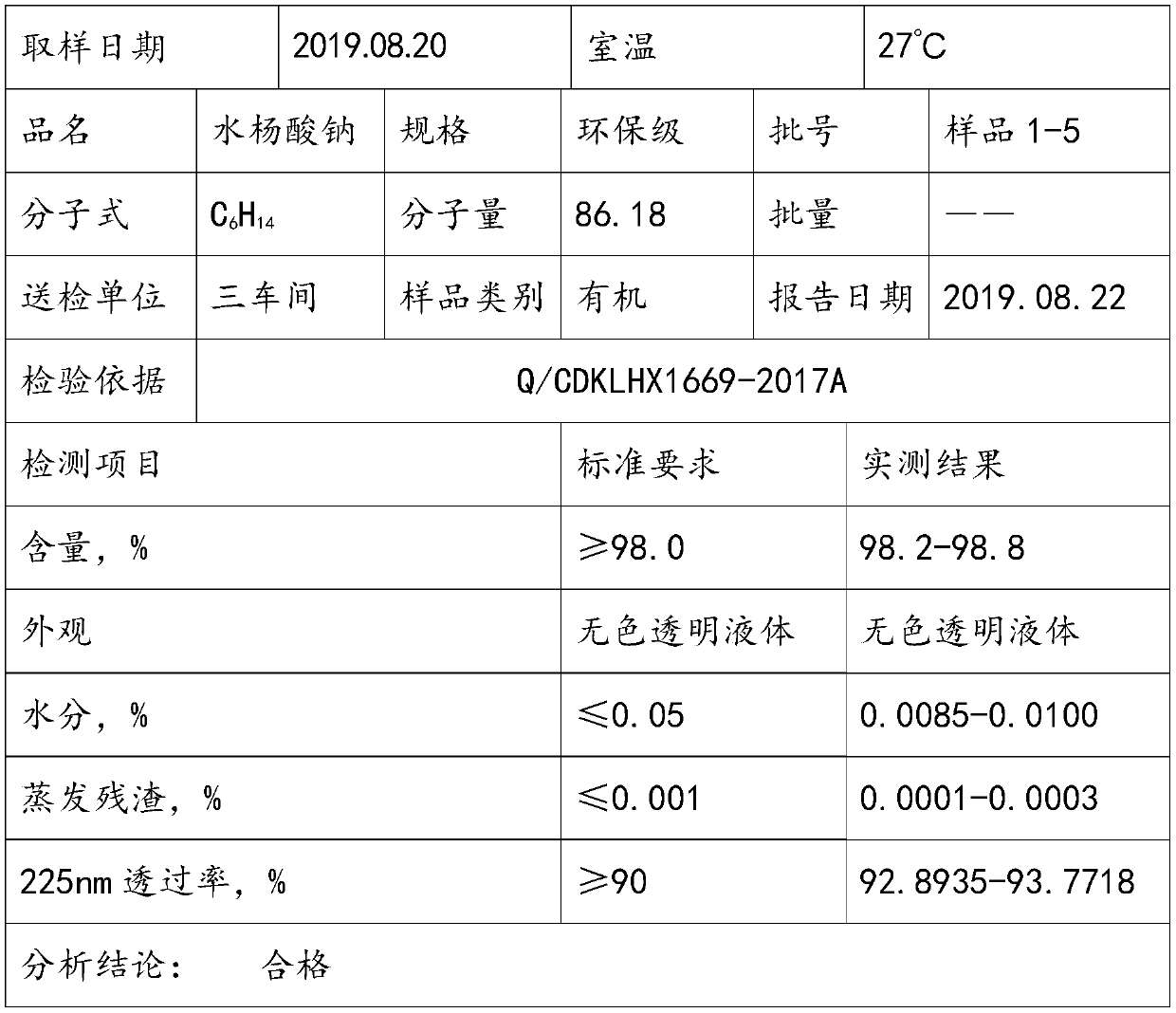

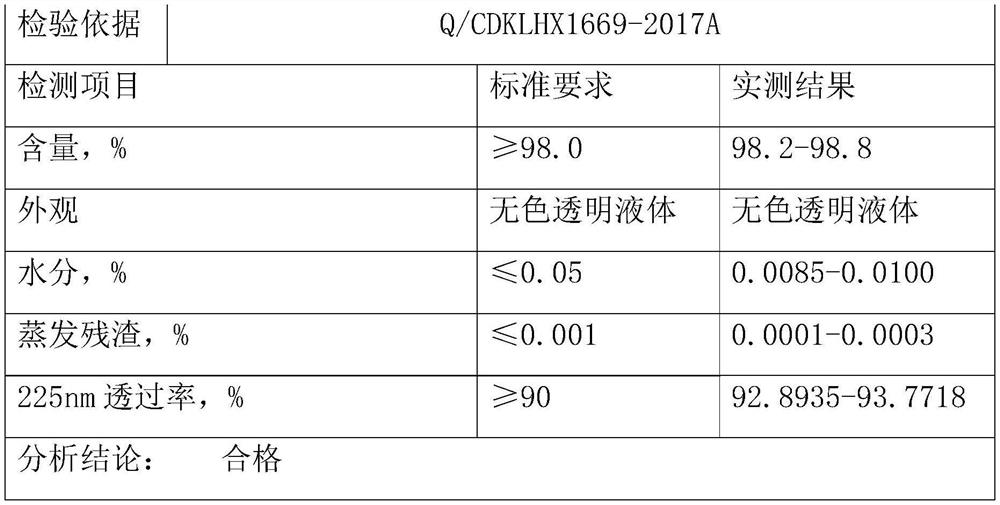

Purification method of environmentally-friendly n-hexane

ActiveCN110668909AControl distillation temperatureOptical performance impactDistillation purification/separationHydrocarbonsPurification methodsProcess engineering

The invention discloses a purification method of environmentally-friendly n-hexane. The method comprises the following steps: 1, taking industrial n-hexane, adding AR-grade sulfuric acid into the industrial n-hexane, performing stirring, standing the obtained mixture, and separating out the obtained lower-layer liquid; 2, introducing n-hexane obtained in step 1 into an alkali column for circular flow for treatment, and then separating out the n-hexane; and 3, rectifying the n-hexane separated in step 2, and collecting the rectified n-hexane to obtain the environmentally-friendly n-hexane. Sulfuric acid and alkali column treatment modes are adopted to obtain the environmentally-friendly n-hexane with the purity of 98% or above and the 225 nm ultraviolet ray transmittance of 90% or above, the influences of impurities such as metal ions on the optical performances of the n-hexane are effectively controlled, the parameter requirements of the environmentally-friendly n-hexane are met, and the problem that currently enterprises cannot normally produce the environment-friendly n-hexane is solved.

Owner:成都市科隆化学品有限公司

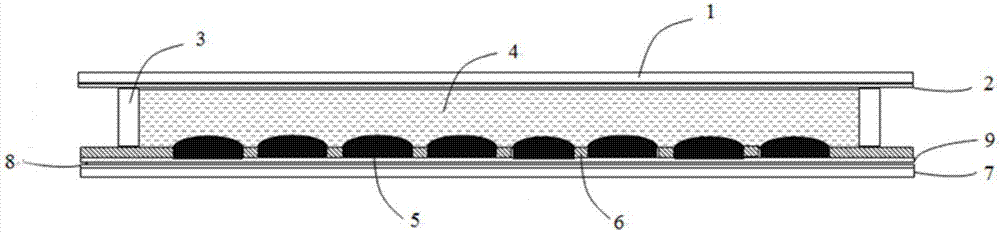

Liquid crystal display device and its backlight module

ActiveCN107688256BAvoid wrinklesIncrease frictionOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

Owner:INTERFACE TECH CHENGDU CO LTD +2

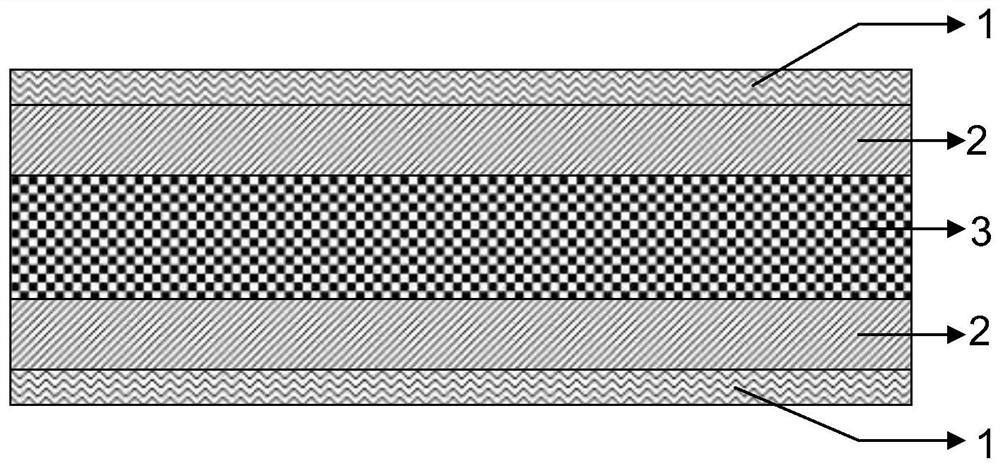

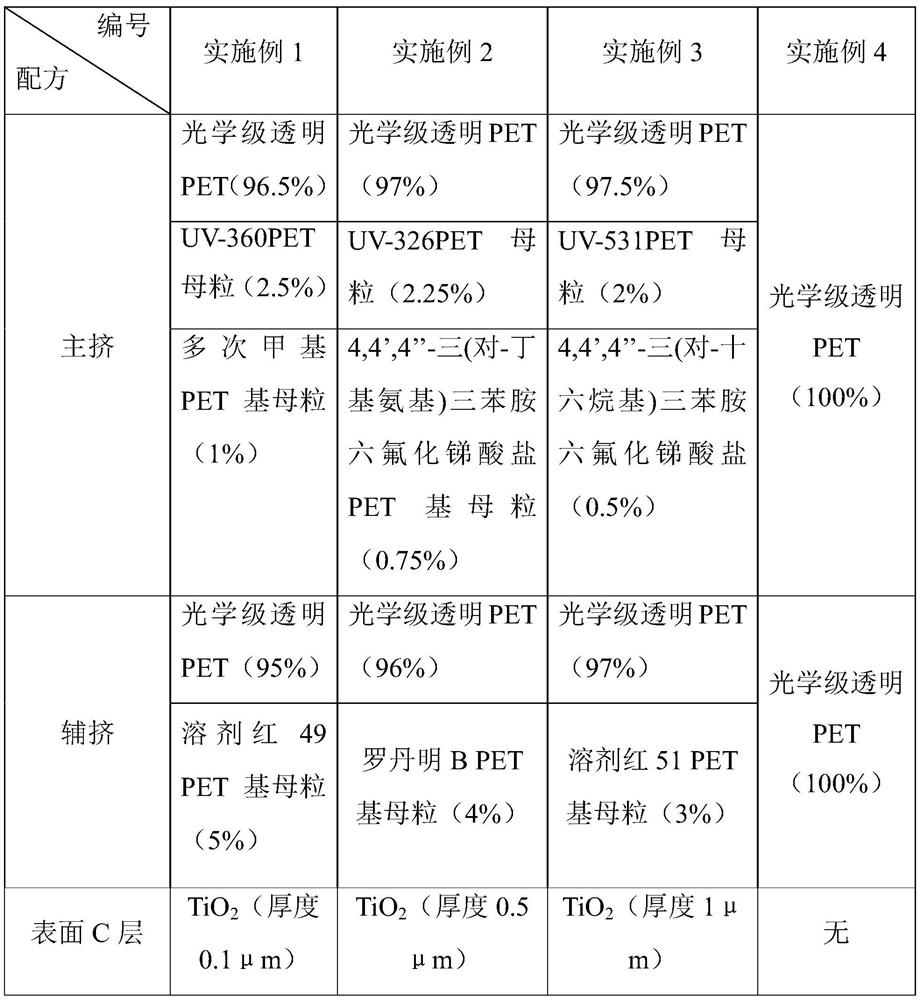

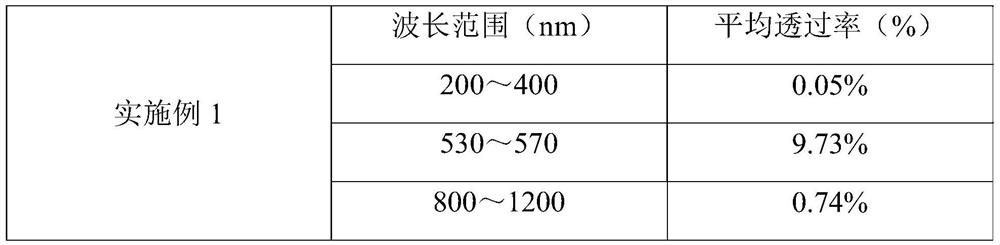

A flexible multi-band light-absorbing bopet film and its preparation method

ActiveCN110254019BGood optical performanceOptical performance impactLamination ancillary operationsSynthetic resin layered productsUv absorbanceBoPET

The invention discloses a flexible multi-waveband light absorbing BOPET film and a preparation method thereof. The film is a CBABC type five-layer structure film, wherein the A layer is an ultraviolet and infrared absorbing layer, the B layer is a visible light absorbing layer, the C layer is a surface hardening layer, the total thickness is 80-120 [mu]m, the raw materials of the layer A comprise 96.5-97.5% by weight of optical-grade transparent PET slices, 2-2.5% by weight of ultraviolet absorbing masterbatch, and 0.5-1% by weight of infrared absorbing masterbatch, the raw materials of the B layer comprise 95-97% by weight of optical-grade transparent PET slices and 3-5% by weight of visible light absorbing masterbatch, the C layer is plated with TiO2 to achieve the hardening effect on the surface of the film, the A layer and the B layer are prepared through a three-layer co-extrusion biaxial stretching method, and the C layer is prepared through an electron beam evaporation method. The flexible multi-waveband light absorbing BOPET film of the present invention has characteristics of high flatness, high hardness and strong light absorption.

Owner:ZHEJIANG HESHUN NEW MATERIAL CO LTD

A kind of preparation method and processing equipment of ultra-thin quantum dot film

ActiveCN111793448BIncreasing the thicknessEasy to operateNon-macromolecular adhesive additivesEster polymer adhesivesLiquid-crystal displayQuantum dot

The preparation method and processing equipment of the ultra-thin quantum dot film provided by the present invention relate to the field of liquid crystal display technology. During the initial unwinding of the production and preparation process until the coating of the quantum dot glue layer is solidified and formed between two barrier films, The sides of the two layers of barrier films that are far away from each other are always attached with a release protective film. When the quantum dot glue layer is solidified and reaches the winding section, the two layers of barrier films are gradually peeled off by the tearing roller group to obtain an ultra-thin film. Quantum dot film, that is, quantum dot glue layer and two layers of barrier film layers located outside the quantum dot glue layer; Wrinkle and warpage problems occur during the traction curing process to ensure uniform product thickness and optical properties, and the operation is simple, enabling stable mass production of ultra-thin quantum dot films without complicated operations.

Owner:NANJING BREADY ELECTRONICS CO LTD

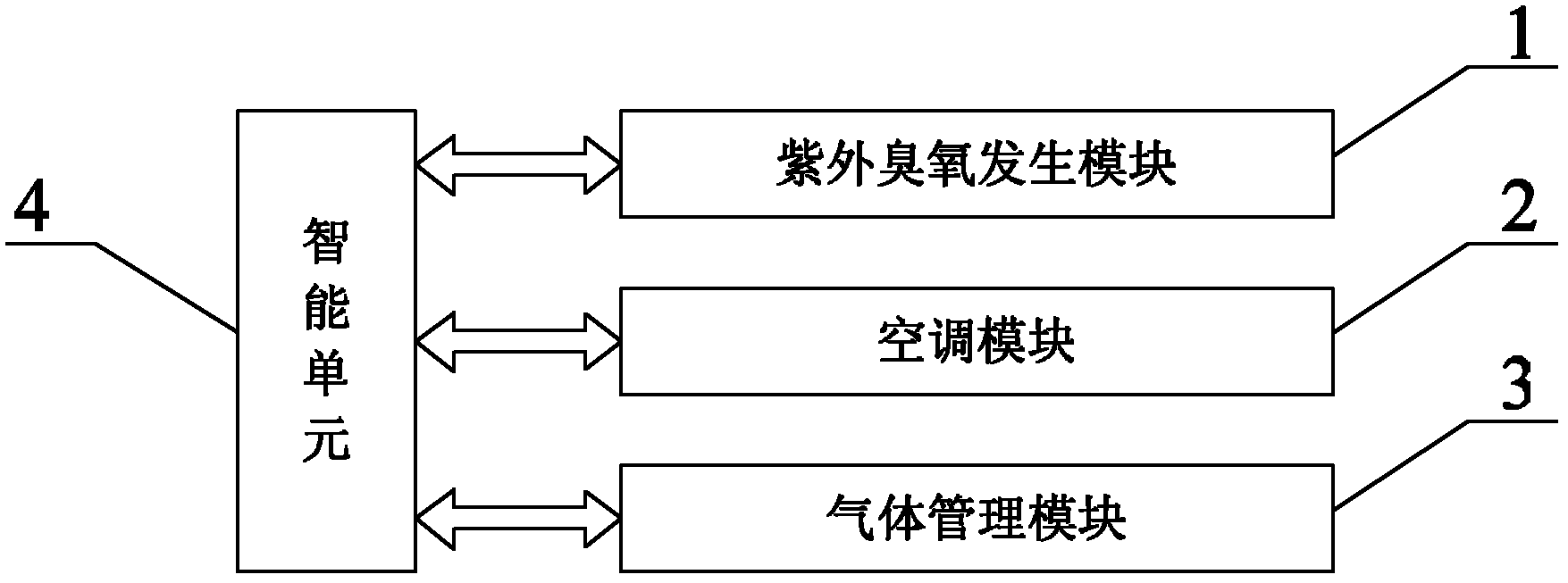

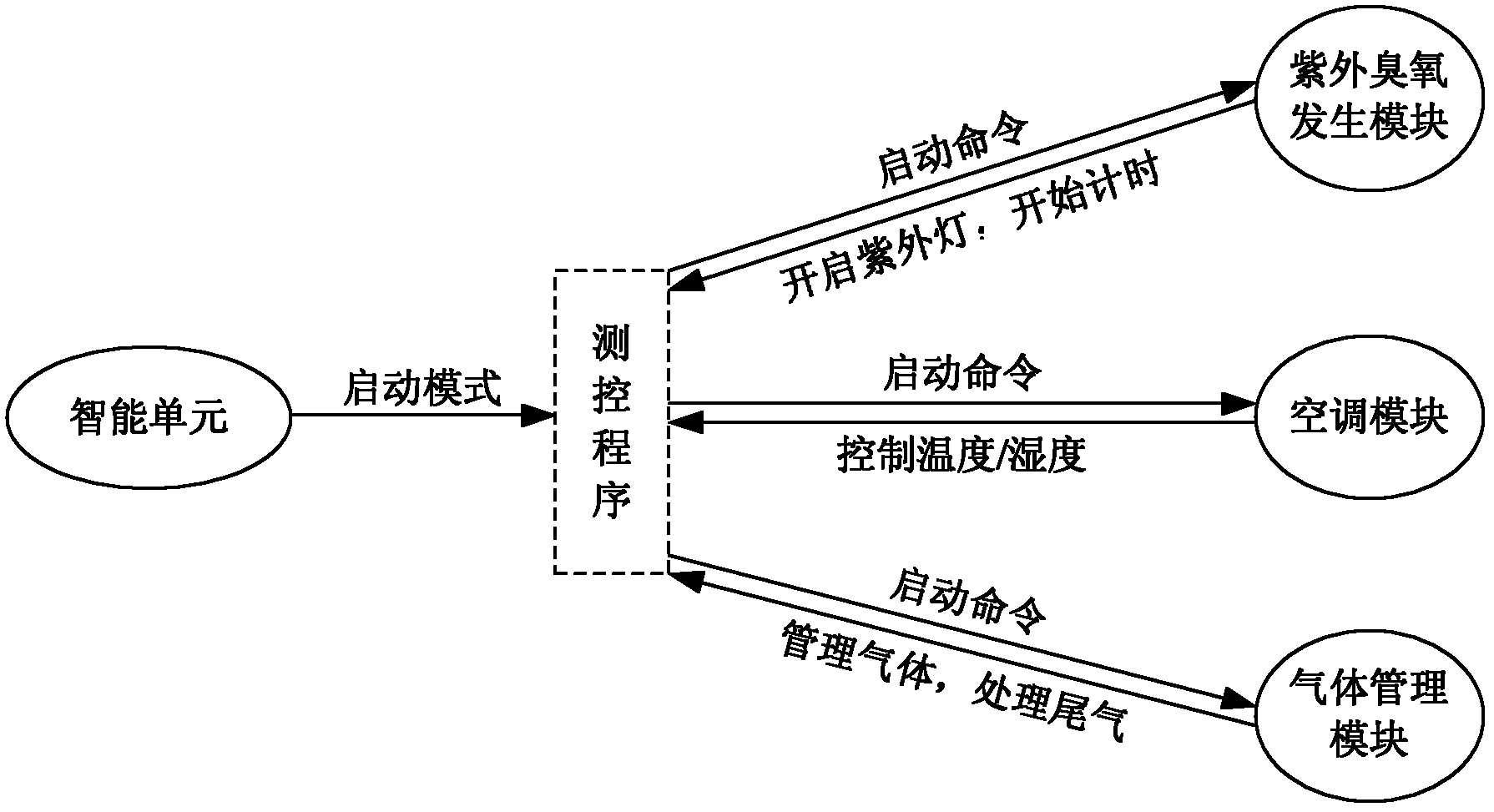

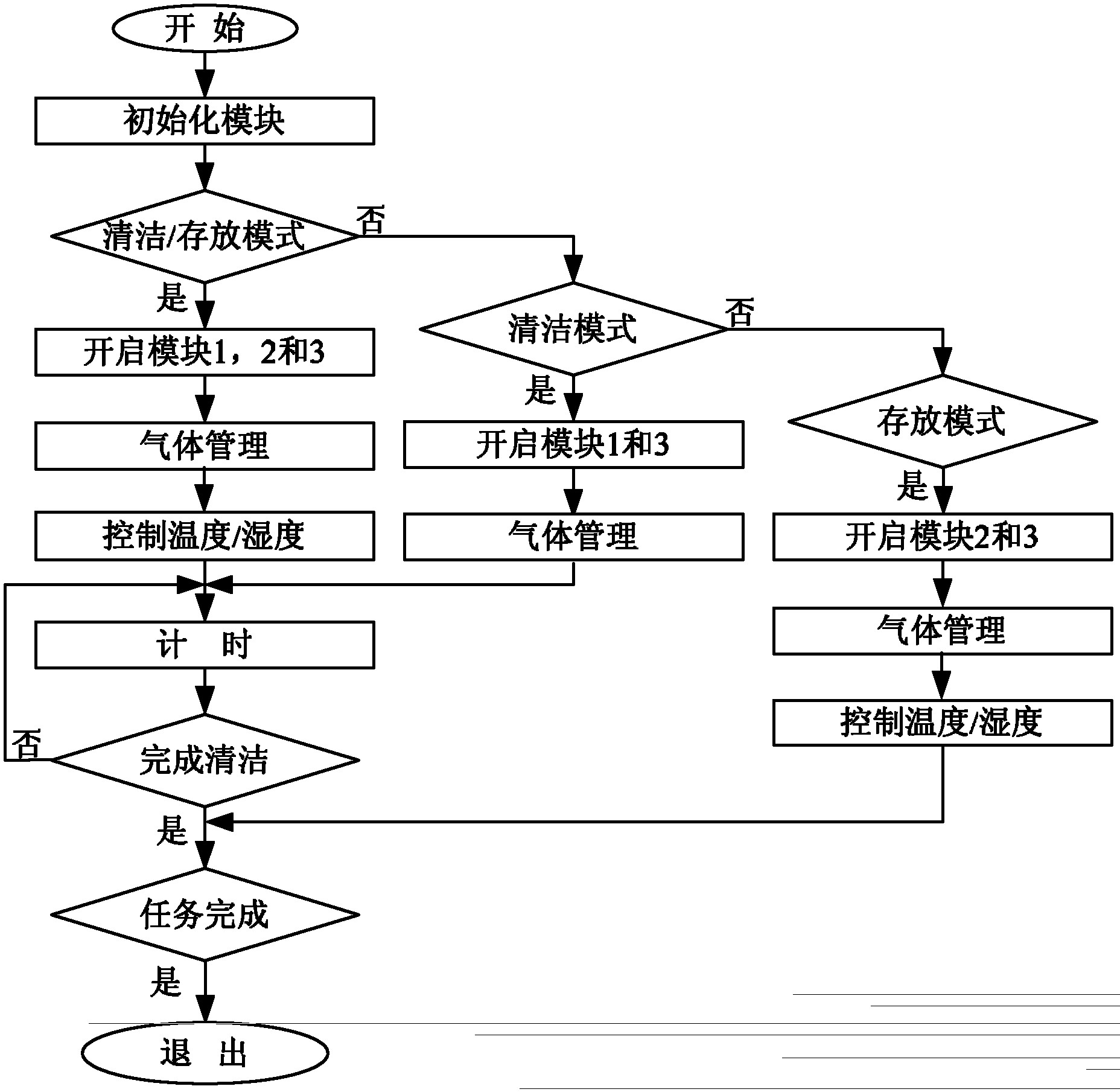

Ultraviolet ozone drying cabinet for cleaning and storing vacuum ultraviolet optical elements

InactiveCN102512002BEasy to removeOptical performance impactCabinetsCleaning processes and apparatusWater vaporUltraviolet

An ultraviolet ozone drying cabinet for cleaning and storing vacuum ultraviolet optical elements comprises an ultraviolet ozone generating module, an air-conditioning module, a gas managing module and an intelligent unit. The ultraviolet ozone generating module cleans the vacuum ultraviolet optical elements; the air-conditioning module controls the temperature and the humidity in the drying cabinet in a vacuum ultraviolet optical element cleaning / storing process; the gas managing module manages gas in the drying cabinet in the vacuum ultraviolet optical element cleaning and storing process; and the intelligent unit controls the total vacuum ultraviolet optical element cleaning / storing process. Hydrocarbon pollutants on the vacuum ultraviolet optical elements can be removed fast, adverse effects to optical performances of the vacuum ultraviolet optical elements due to water vapor are stopped, the problem that the performances of the vacuum ultraviolet optical elements are degraded due to an improper storage mode is effectively avoided, and the ultraviolet ozone drying cabinet is particularly applicable to cleaning and storing the vacuum ultraviolet optical elements.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

A quantum dot light emitting diode

ActiveCN111384279BImprove luminous efficiencyImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron holeQuantum dot

Owner:TCL CORPORATION

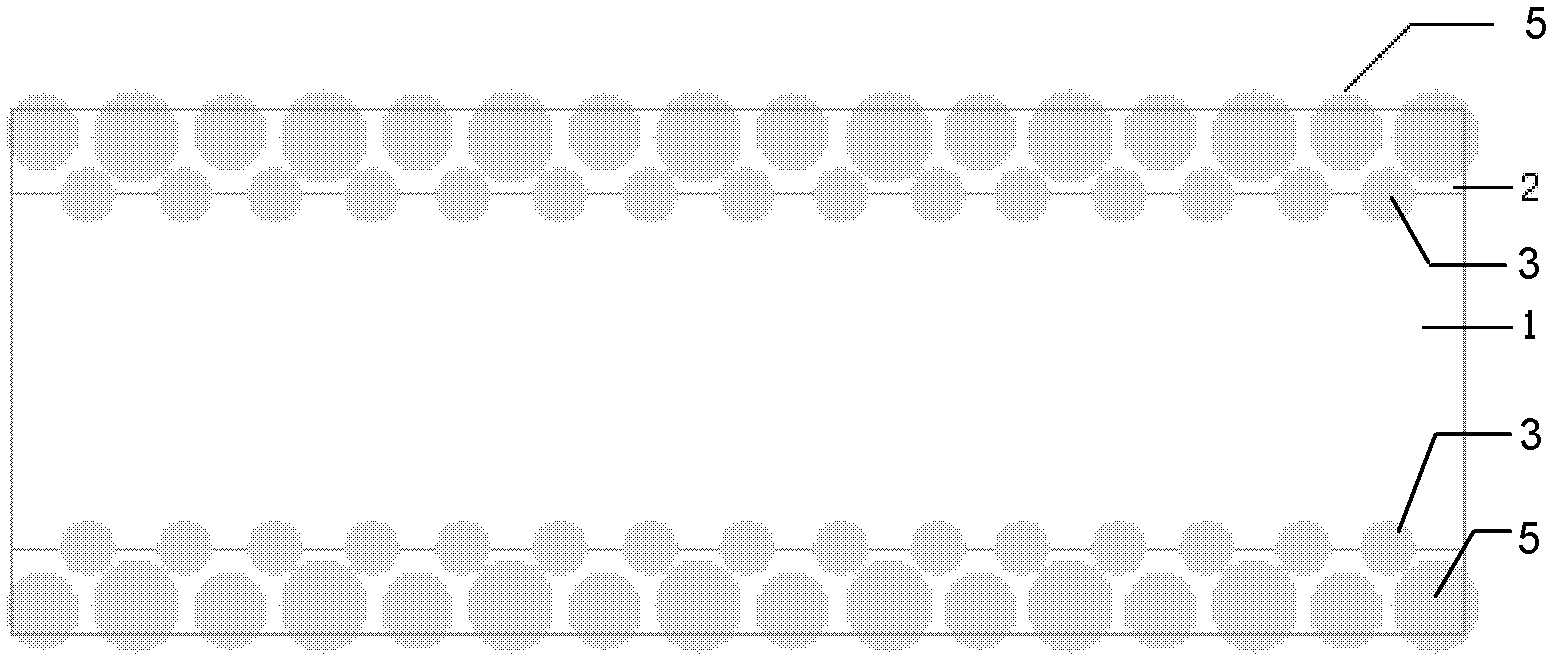

Preparation method of light diffusion sheet

ActiveCN110346855BPrevent glue overflowOptical performance impactDiffusing elementsPhotomechanical exposure apparatusPhysical chemistryEngineering

The invention provides a preparation method of a light diffusion sheet. The preparation method includes the following steps: forming a photoresist layer on the surface of the substrate, defining the photoresist layer to have a central area and a peripheral area, the peripheral area includes n first peripheral areas and n+1 second peripheral areas, the first A peripheral region and a second peripheral region are alternately arranged around the central region, n is a natural number ≥ 1; the photoresist layer is sequentially exposed and developed to form a microstructure layer in the central region, and the first peripheral region and the second peripheral area to form an anti-overflow glue structure with grooves, the anti-overflow glue structure surrounds the microstructure layer, wherein the exposure intensity to the central area is less than the exposure intensity to the first peripheral area, and the exposure intensity to the second peripheral area The intensity is less than the exposure intensity for the first peripheral region. Utilizing the above-mentioned anti-overflow structure effectively prevents possible glue overflow when the light diffusion sheet is fixed in the lens, and avoids the influence of the overflow on the optical performance of the device.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

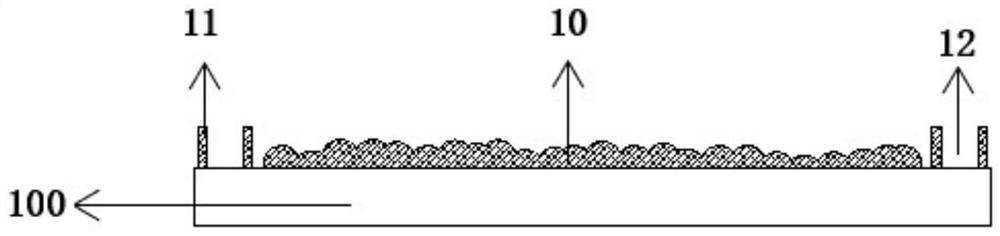

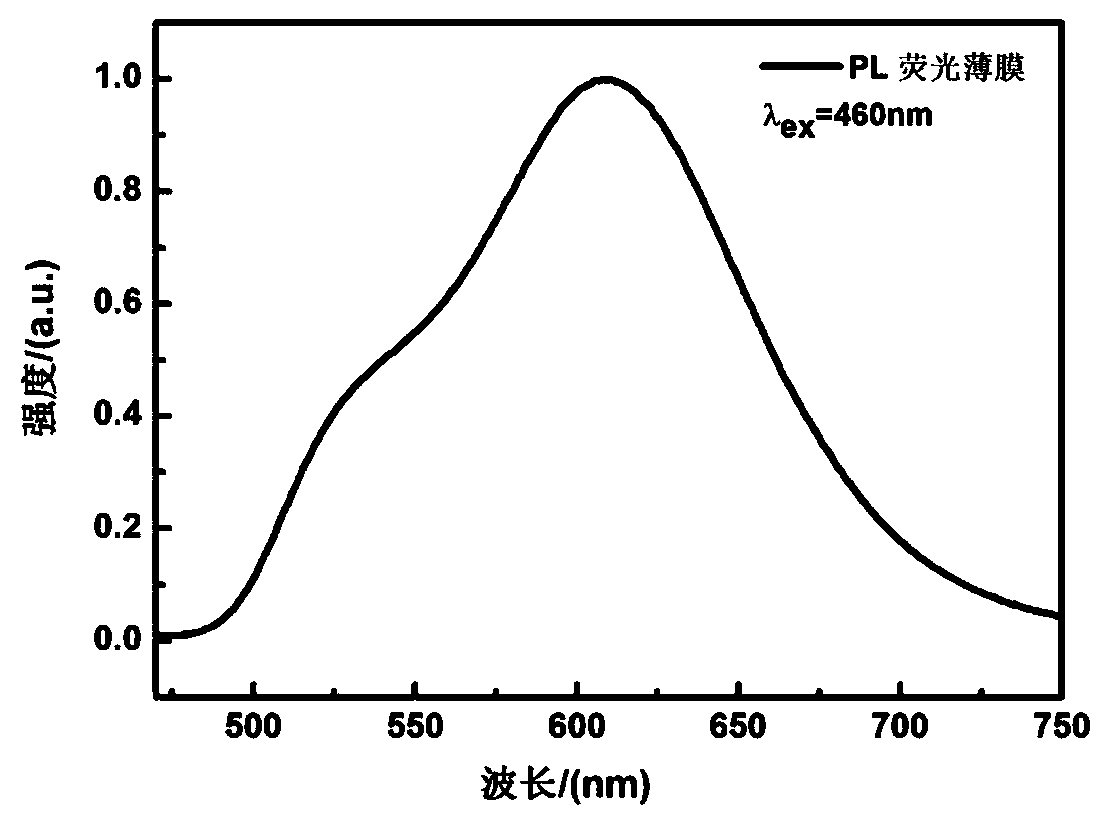

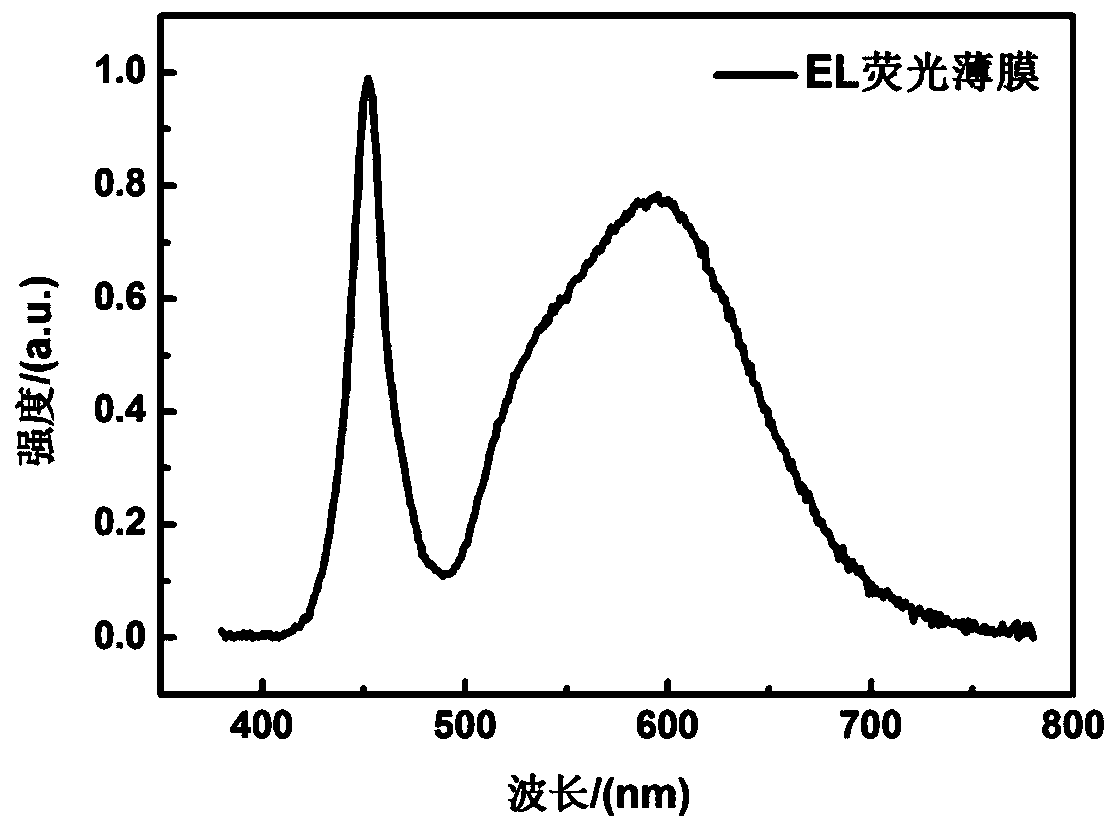

A preparation method of fluorescent film with "hamburger" structure for white light LED

ActiveCN107579146BOptical performance impactAddressing resorption effectsSemiconductor devicesOptical propertyAdhesive

The invention discloses a preparing method of a hamburger-structure fluorescent film for a white light LED. The method includes the following steps that multiple groups of fluorescent powder and adhesive are weighed to serve as combined raw materials, each combined raw material group is placed into an adhesive preparing beaker and stirred to be mixed uniformly, and multiple fluorescent adhesive mixture groups are formed; the fluorescent adhesive mixtures mixed uniformly are vacuumized for defoamation; a spin coater is adopted to coat the multiple fluorescent adhesive mixture groups on a carrier on a substrate in a spinning mode to form multiple fluorescent film layers, after each fluorescent film layer is coated in the spinning mode, the fluorescent film layer and the substrate are placedinto a drying oven to be cured so that the fluorescent film layer can reach the micro curing state, after being coated in the spinning mode, the multiple fluorescent film layers are placed into the drying oven to be cured completely, and then the hamburger-structure fluorescent film for the white light LED is obtained. The preparing method is simple in preparing process and reduces the productioncost of a factory, the fluorescent powder of the prepared fluorescent film is distributed uniformly, and the fluorescent film is good in optical property.

Owner:NINGBO LONGER LIGHTING

A polymer rectangular optical waveguide and microfluidic three-dimensional integrated chip and its preparation method

The invention provides a polymer rectangular optical waveguide and micro-fluidic three-dimensional integrated chip and a preparation method thereof, and belongs to the preparation technical field of polymer rectangular optical waveguide three-dimensional hybrid integrated chips. According to the technical scheme of the invention, the impression or carbon dioxide laser-written method is conducted to prepare a micro-fluidic groove and a liquid injection hole on a methyl methacrylate substrate. Meanwhile, a raised rectangular optical waveguide is prepared on another substrate of the same material with the micro-fluidic layer through the wet etching process, wherein the glass transition temperature of the photosensitivepolymer material for preparing the raised rectangular optical waveguide is higher than the glass transition temperature of methyl methacrylate. Through the one-time hot stamping process, the center ply of the optical waveguide is pressed into the interior of the methyl methacrylate substrate, and the surface layer of the center ply of the optical waveguide is exposed. In this way, the application of the wet etching-based rectangular optical waveguide in the three-dimensional integration field is realized. Meanwhile, the bending loss and the scattering loss of the waveguide are lowered.

Owner:长春市华信科瑞光电技术有限公司

A kind of doping modification method of cvdzns crystal material

ActiveCN107119323BImprove mechanical propertiesOptical performance impactPolycrystalline material growthDiffusion/dopingAlloyPermeation

Owner:YUNNAN KIRO CH PHOTONICS

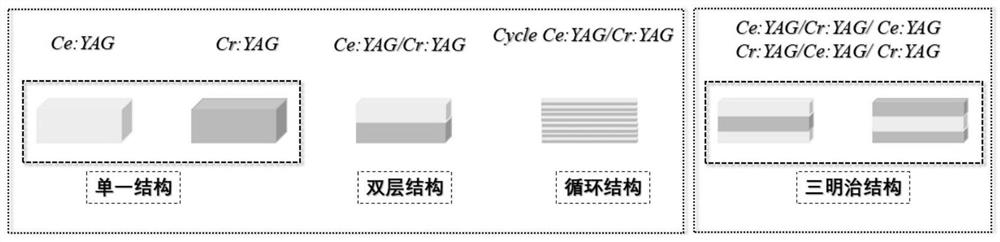

Method for preparing YAG (yttrium aluminum garnet)-based transparent ceramic by direct writing forming

PendingCN114853462AOptical performance impactImprove optical qualityAdditive manufacturing apparatusCeramic shaping apparatusOrganosolvDirect writing

The invention discloses a method for preparing YAG (yttrium aluminum garnet)-based transparent ceramic by direct writing. The method comprises the following steps: ball-milling and mixing an organic solvent, a dispersing agent A, a sintering aid and ceramic powder, drying, sieving with a 100-mesh sieve, a 200-mesh sieve and a 500-mesh sieve, and calcining to obtain raw material powder; the 500-mesh calcined powder, a polyelectrolyte dispersing agent and deionized water are subjected to ball milling and mixing, and slurry B is obtained; the 100-mesh calcined powder, 3-8 wt% of PVP aqueous solution and a dispersing agent B are subjected to ball-milling mixing, then the 200-mesh calcined powder is added, ball milling is continued, and slurry C is obtained; the slurry C and the slurry B are subjected to ball milling mixing according to the mass ratio of 3.5-5.5; vacuum defoaming, direct writing forming and glue discharging are carried out; and carrying out vacuum sintering, annealing and processing on the biscuit subjected to glue removal to obtain the YAG transparent ceramic. The YAG-based ceramic biscuit prepared by the method does not need cold isostatic pressing and warm isostatic pressing, controllable preparation of a transparent ceramic material with a composite structure and a complex shape is realized at the same time, the product preparation speed is high, the yield is high, and the application prospect is good.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD +1

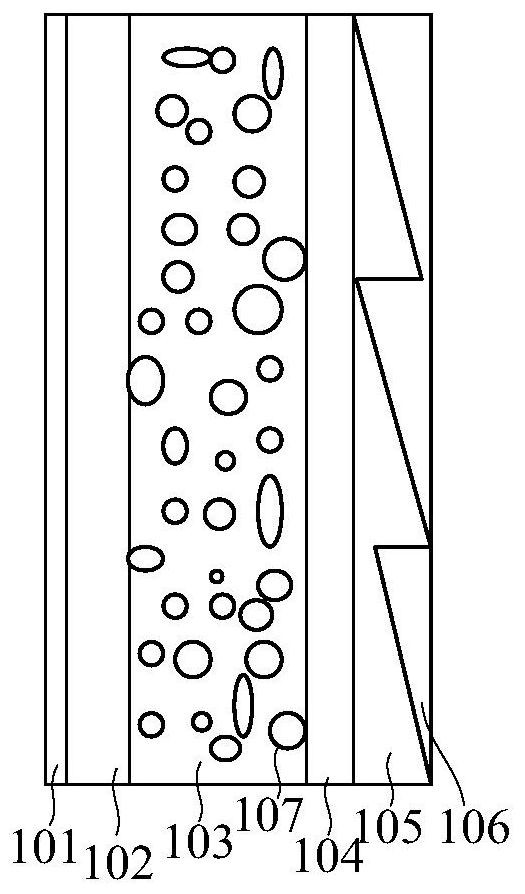

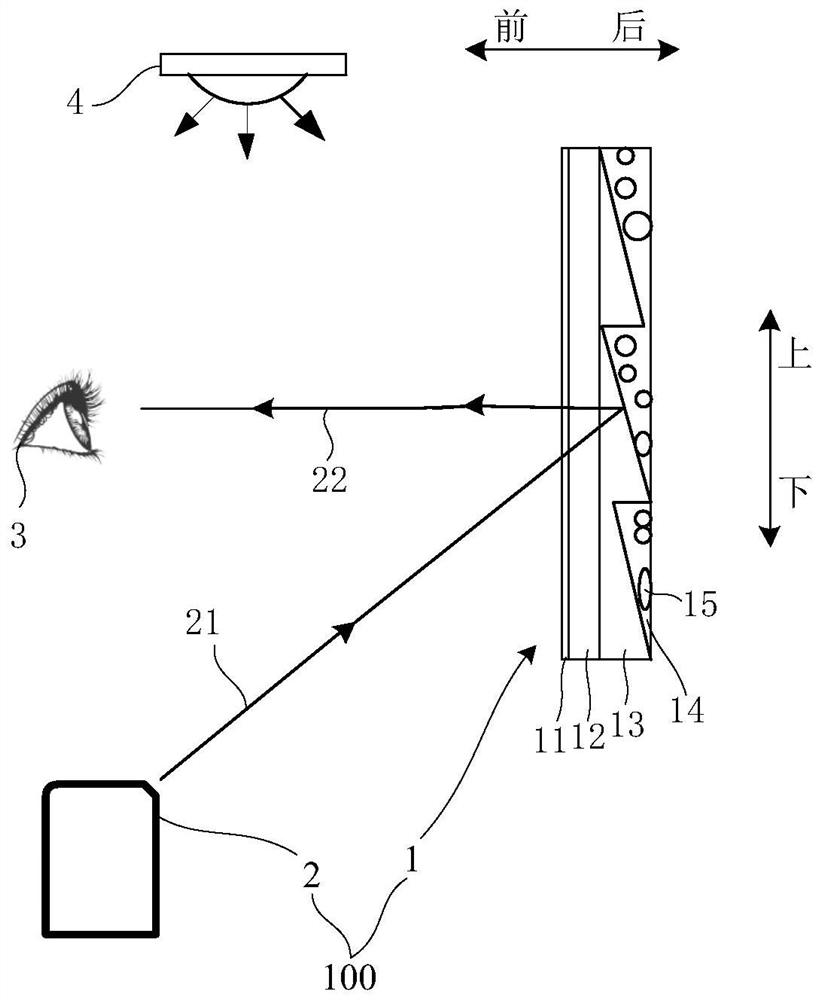

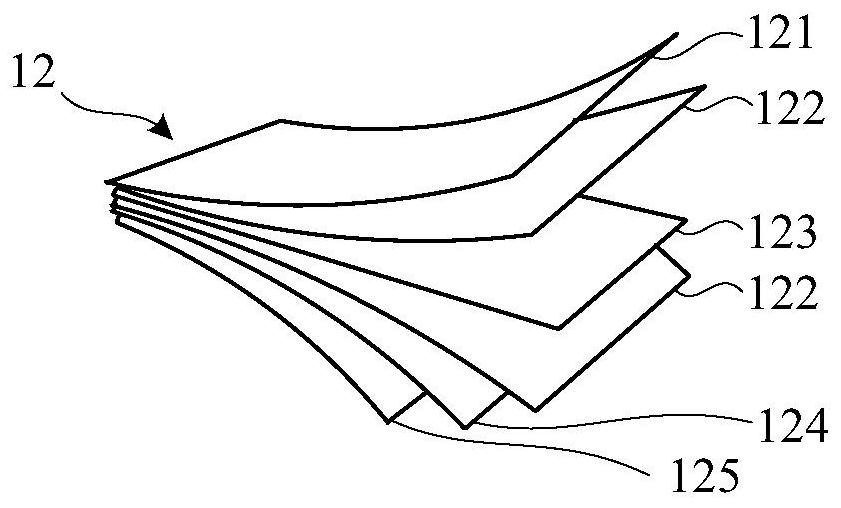

Projection screen and projection device

PendingCN113741135AImprove the ability to resist ambient lightImproved resistance to ambient lightProjectorsFresnel lensProjection screen

The invention discloses a projection screen and a projection device, relates to the technical field of projection display, and is used for solving the problem of poor ambient light resistance of a projection screen in the prior art. The projection screen comprises a surface layer, a polaroid layer, a Fresnel lens layer and a reflecting layer which are stacked. The polaroid layer is configured to transmit linearly polarized light in a preset polarization direction. The projection screen is used for displaying images projected by the projector.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

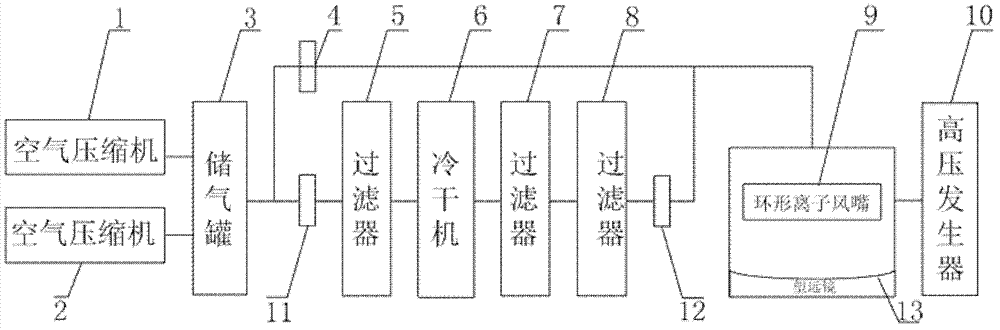

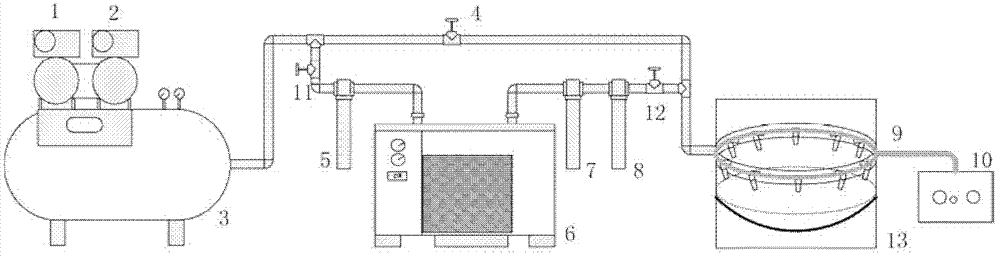

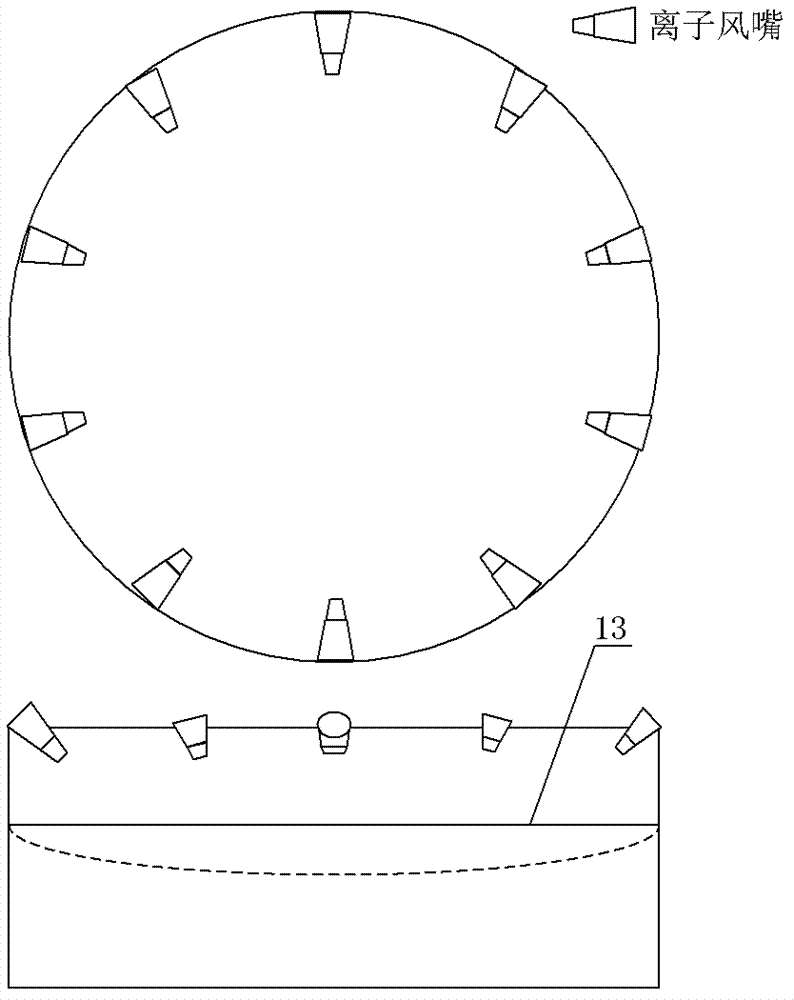

Dustproof frost-proof optical telescope system in direct contact with atmosphere

InactiveCN102269865BImprove detection efficiencyImprove adaptabilityWave based measurement systemsTelescopesFrostAtmospheric air

The invention discloses a dustproof frost-proof optical telescope system in direct contact with atmosphere. The telescope system comprises a telescope, annular ion tuyeres, a high-pressure generator and a cleaning drying device; the annular ion tuyeres are respectively arranged in a plurality of symmetric directions above a barrel of the telescope, the high-pressure generator is connected with the annular ion tuyeres, the high-pressure airflow passing through the annular ion tuyeres is ionized through the high-pressure generator to generate a large amount of positive and negative ions which are rapidly blown to the telescope together with the airflow along the barrel wall of the telescope, the positive and negative ions are close to an arc surface of the telescope and concentrated on the centre of the telescope to finally form uniform and steady upward airflow; the dry and clean air generated by the cleaning drying device is used as ionization air of the annular ion tuyeres. The telescope can work directly in the air; therefore, the detection efficiency of the telescope is improved, weak vibration is resisted, and the adaptability of the optical laser radar in a special weather condition is improved.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of purification method of environment-friendly n-hexane

ActiveCN110668909BControl distillation temperatureOptical performance impactDistillation purification/separationHydrocarbonsOptical propertyPhysical chemistry

The invention discloses a purification method of environmental protection grade n-hexane, which is characterized in that it comprises the following steps: Step 1, taking industrial grade n-hexane, adding AR grade sulfuric acid to the industrial grade n-hexane, stirring and standing, and separating the lower layer liquid ; Step 2, passing the normal hexane obtained in step 1 into the alkali column for circulation and processing, and then separating the normal hexane; n-Hexane. Through the treatment of sulfuric acid and alkali column, an environmentally friendly n-hexane with a purity of more than 98% and a transmittance of 225nm ultraviolet rays of more than 90% was obtained, which effectively controlled the influence of impurities such as metal ions on the optical properties of n-hexane and met the requirements The parameter requirements of environmental-grade n-hexane are met, and the problem that enterprises cannot normally produce environmental-grade n-hexane is solved.

Owner:成都市科隆化学品有限公司

A polymer photobleaching optical waveguide and microfluidic plate-free integrated chip and its preparation method

ActiveCN105589129BAvoid registration errorsGuaranteed nudityPhotomechanical apparatusOptical waveguide light guidePhotosensitive polymerPolymer optical waveguide

The invention belongs to the polymer optical waveguide and micro fluidic channel integrated chip preparation technical field, and relates to a micro fluidic channel, mask, optical waveguide preparation and end face treatment method which concretely comprises: employing a nanoimprint (hot imprinting or ultraviolet imprinting) method to prepare micro fluidic grooves on a polymer substrate; a carbon dioxide laser cutting and penetrating injecting holes; evaporating an aluminum mask on a chip; spin coating photoresist; performing overall exposure and development to obtain a waveguide mask graph; utilizing a photosensitive polymer to prepare an optical waveguide core layer film on another substrate of the same material with a micro fluidic layer; performing hot imprinting packaging on two layers of chips; employing an upper layer micro fluidic chip as a photomask after packaging; writing in slab waveguide on a photosensitive polymer core layer film, wherein the waveguide is directly located under a micro fluidic channel, thereby avoiding register errors between the upper layer chip and a sensing window in an integration process; cutting a sample end face through laser, and completing an optical waveguide and micro fluidic registration-free integrated chip after polishing.

Owner:JILIN UNIV

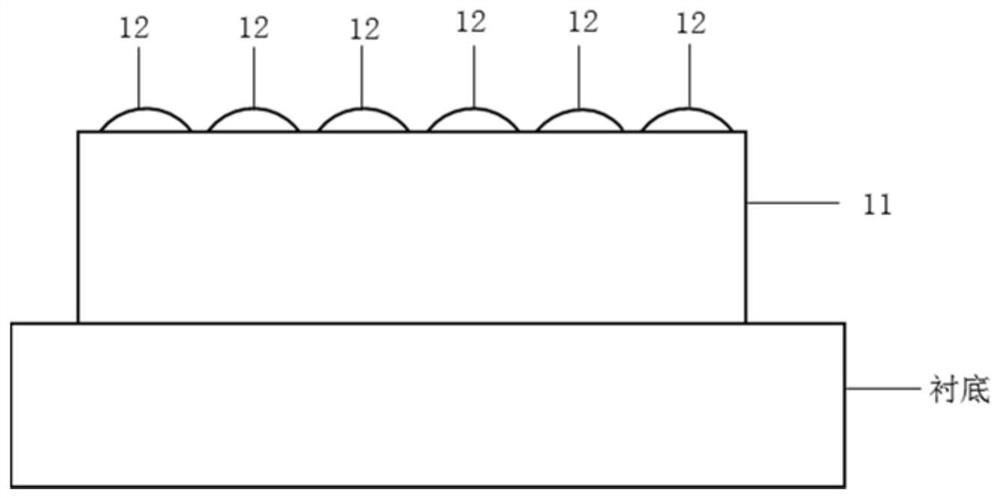

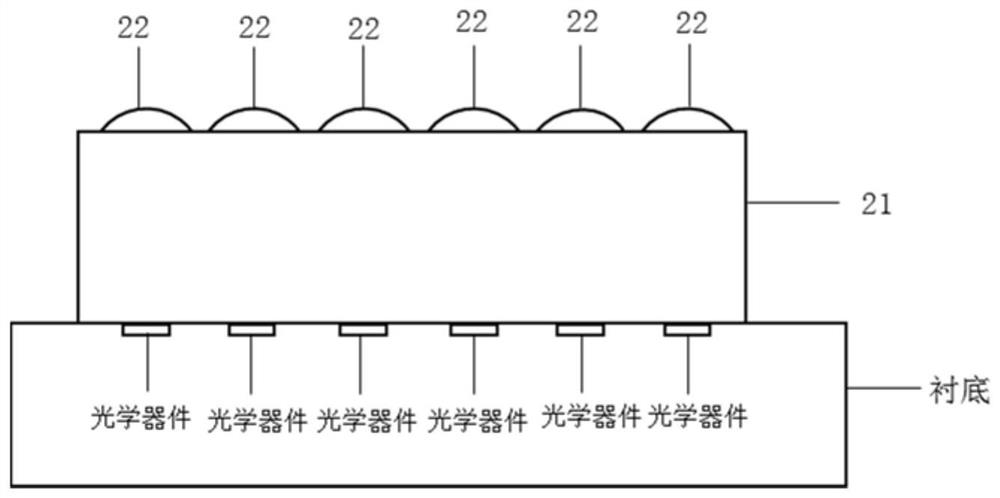

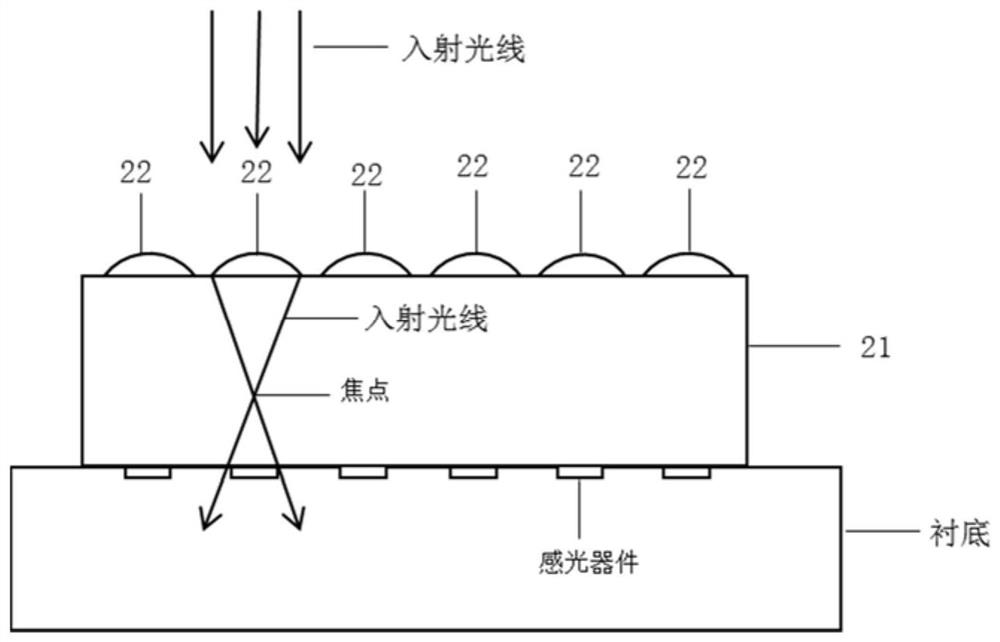

Microlens array

PendingCN113419300ALarge adjustment rangeImprove optical performanceCondensersLensEngineeringLens array

An embodiment of the invention discloses a microlens array. The microlens array comprises: a platform structure, which is located on the surface of a substrate; and a plurality of microlens structures, which are arranged above the platform structure in an array manner. According to the invention, when parallel incident light passes through the microlens array to cover the surface of the substrate, the height of the platform structure, the focal length of the microlens structures and the area, covered by the incident light, of the surface of the substrate satisfies the relationship that through the height of the platform structure and the focal length of the microlens structures which are respectively set, the parallel incident light passes through the micro-lens structures and the platform structure and then covers the surface of the substrate with a preset area.

Owner:SIWAVE INC

Preparation method of optical diffusion film

ActiveCN102540291BIncrease brightnessImprove spotlight effectDiffusing elementsSynthetic resin layered productsTransmittanceBrightness perception

Owner:NINGBO CHANGYANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com