Preparation method for improving ultraviolet resistance of contact lenses through ultraviolet absorbent agent

A UV absorber, contact lens technology, applied in glasses/goggles, instruments, optics, etc., can solve the problem of lack of high-efficiency anti-ultraviolet contact lens technology, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

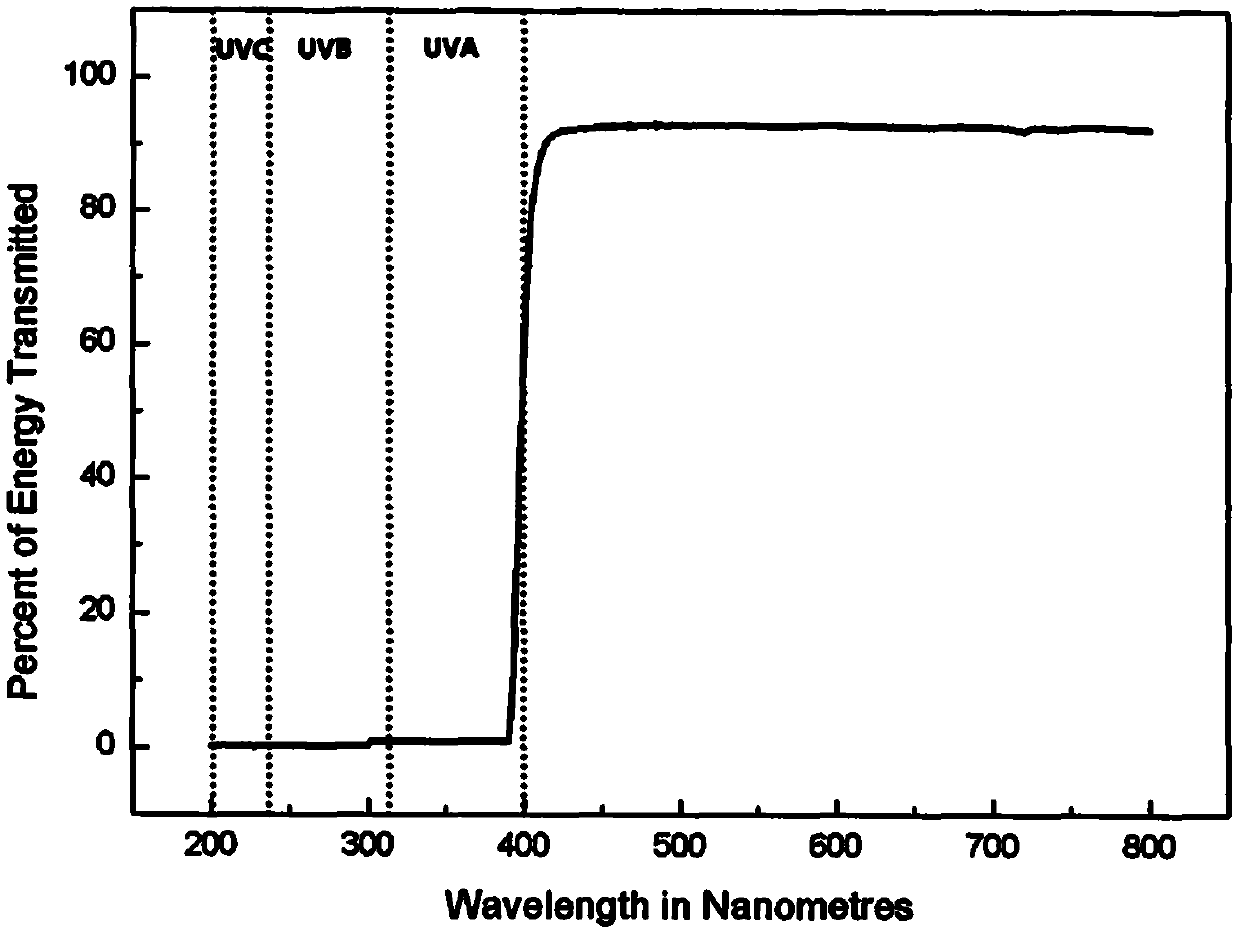

Image

Examples

Embodiment ( 1

[0032] 98.5% hydroxyethyl methacrylate, 0.2% 2-[3-(2H-benzotriazole-2-methyl)-4 hydroxyphenyl] ethyl methacrylate, 0.5% azobisiso Nitrile, 0.8% ethylene glycol dimethacrylate, stirred evenly, the lens is clear, and the transmittance is detected by an ultraviolet spectrophotometer.

Embodiment ( 2

[0034] 97.7% hydroxyethyl methacrylate, 1.5% 2-[3-(2H-benzotriazole-2-methyl)-4 hydroxyphenyl] ethyl methacrylate, 0.5% azobisiso Nitrile, 0.8% ethylene glycol dimethacrylate, stirred evenly, the lens is clear, and the transmittance is detected by an ultraviolet spectrophotometer.

Embodiment ( 3

[0036] 96.2% hydroxyethyl methacrylate, 2.5% 2-[3-(2H-benzotriazole-2-methyl)-4 hydroxyphenyl] ethyl methacrylate, 0.5% azobisiso Nitrile, 0.8% ethylene glycol dimethacrylate, stirred evenly, the lens is clear, and the transmittance is detected by an ultraviolet spectrophotometer. In the present invention, the value of T% is the average value of the transmittance in this band.

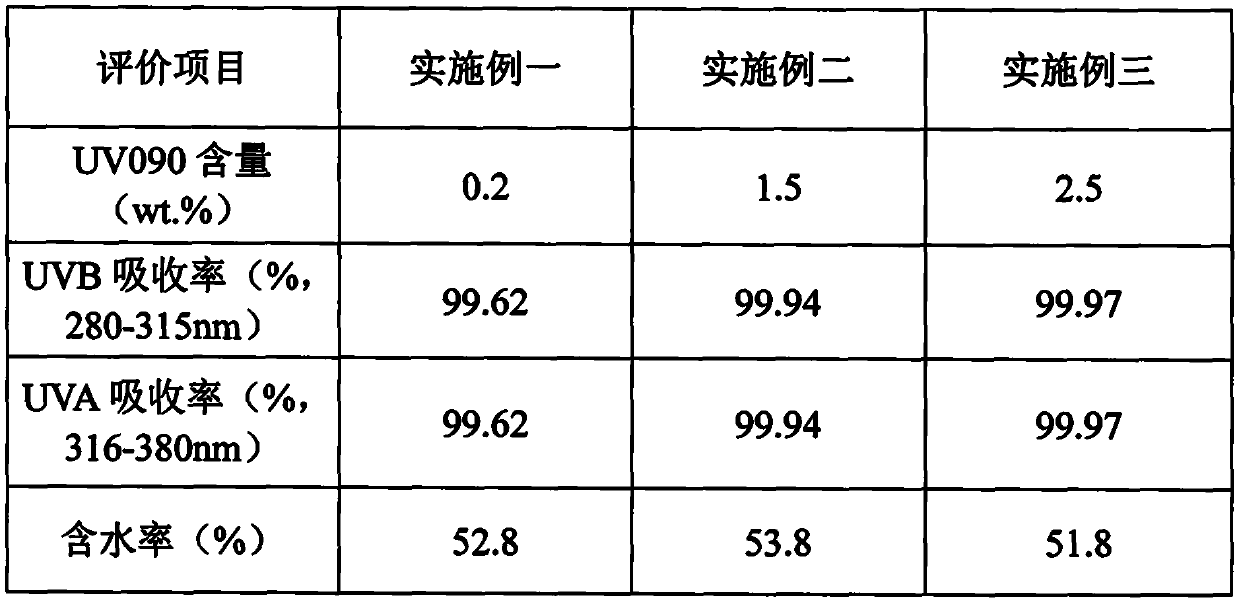

[0037] The test data of each embodiment of table one:

[0038]

[0039] Can find out from example one, two, three contrast, add ultraviolet absorber 2-[3-(2H-benzotriazole-2-methyl)-4 hydroxyphenyl] ethyl methacrylate, can obviously have good The anti-ultraviolet performance meets the anti-ultraviolet standard ANSI CLASS I, that is, it blocks more than 90% of UVA absorption and more than 99% of UVB absorption. This kind of lens enables the wearer to reduce the damage of ultraviolet light to his eyes; at the same time, it has no effect on the optical performance of the lens in the visible light reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com