Method for preparing YAG (yttrium aluminum garnet)-based transparent ceramic by direct writing forming

A direct-writing molding, transparent ceramic technology, applied in ceramic molding machines, manufacturing tools, energy-saving lighting, etc., can solve the problem that complex shapes cannot be prepared at the same time, and achieve the effect of solving cracking and delamination, high yield rate and fast preparation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

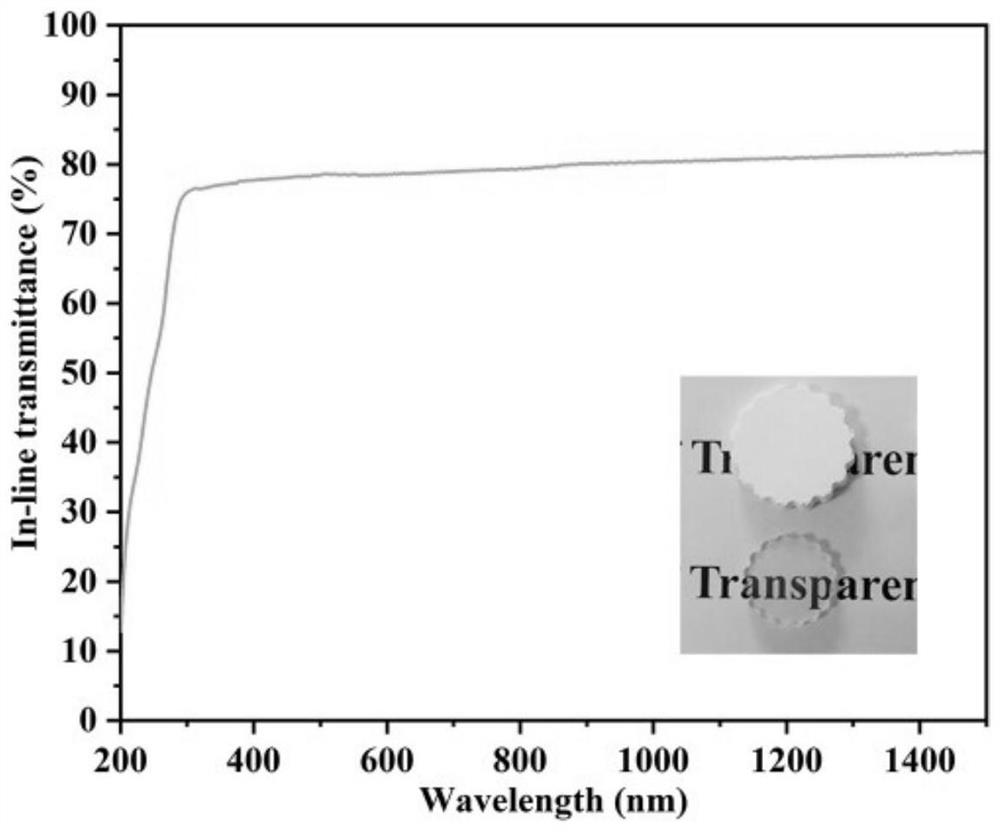

[0040] Example 1: Preparation of YAG transparent ceramics

[0041] (1) 500g Y according to the preparation 3 Al 5 O 12 The stoichiometric ratio of each element, respectively weighing Y 2 O 3 285.297g and Al 2 O 3214.703g, add 0.5g PEI as dispersant, add 2.5g sintering aid TEOS and 0.5g sintering aid MgO;

[0042] (2) the powder obtained in step (1) is subjected to planetary ball milling, the ball milling time is 15h, the solvent is dehydrated alcohol, and the material of the ball milling tank is nylon; the obtained slurry is dried and sieved, and the sieving mesh number is 100 respectively. , 200, 500 mesh;

[0043] (3) calcining the powder obtained in step (2), the calcining temperature is 600° C., the holding time is 10h, the calcining environment is an air atmosphere, and the calcining container is an alumina crucible;

[0044] (4) The 500-mesh calcined powder obtained in step (3) and the polyelectrolyte dispersant are prepared into a slurry, the solid content of t...

Embodiment 2

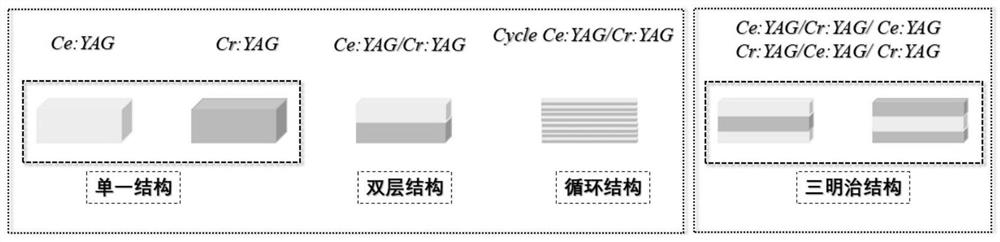

[0053] Example 2: Preparation of 0.1 at% Ce:YAG transparent ceramics

[0054] (1) According to the preparation 500g (Y 0.999 Ce 0.001 ) 3 Al 5 O 12 The stoichiometric ratio of each element, respectively weighed commercial 0.435g CeO 2 , 284.938g of Y 2 O 3 and 214.647g of Al 2 O 3 , adding 0.75g PEI as dispersant, adding 0.5g sintering aid TEOS and 0.5g sintering aid MgO;

[0055] (2) the powder obtained in step (1) is subjected to planetary ball milling, the ball milling time is 15h, the solvent is dehydrated alcohol, and the material of the ball milling tank is nylon; the obtained slurry is dried and sieved, and the sieving mesh number is 100 respectively. , 200, 500 mesh;

[0056] (3) calcining the powder obtained in step (2), the calcining temperature is 800°C, the holding time is 6h, the calcining environment is an air atmosphere, and the calcining container is an alumina crucible;

[0057] (4) The 500-mesh calcined powder obtained in step (3) and the polyelect...

Embodiment 3

[0064] Example 3: Preparation of 0.6 at% Cr:YAG transparent ceramics

[0065] (1) 500g Y according to the preparation 3 (Al 0.994 Cr 0.006 ) 5 O 12 The stoichiometric ratio of each element, respectively weighing 1.919g of commercial Cr 2 O 3 , 284.937g of Y 2 O 3 and 214.145g of Al 2 O 3 , adding 1.0g of PEI as a dispersant, adding 0.5g of sintering aid TEOS and 0.5g of sintering aid MgO;

[0066] (2) the powder obtained in step (1) is subjected to planetary ball milling, the ball milling time is 15h, the solvent is dehydrated alcohol, and the material of the ball milling tank is nylon; the obtained slurry is dried and sieved, and the sieving mesh number is 100 respectively. , 200, 500 mesh;

[0067] (3) calcining the powder obtained in step (2), the calcining temperature is 900° C., the holding time is 3h, the calcining environment is an air atmosphere, and the calcining container is an alumina crucible;

[0068] (4) The 500-mesh calcined powder obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com