Preparation method and processing equipment of ultrathin quantum dot film

A quantum dot film and processing equipment technology, applied in the direction of film/sheet adhesives, chemical instruments and methods, film/sheet without carrier, etc., can solve the problem of poor uniformity of optical properties, large fluctuation of finished product thickness, and occurrence of wrinkles Eliminate problems such as pleats, and achieve the effects of simple operation, stable mass production, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

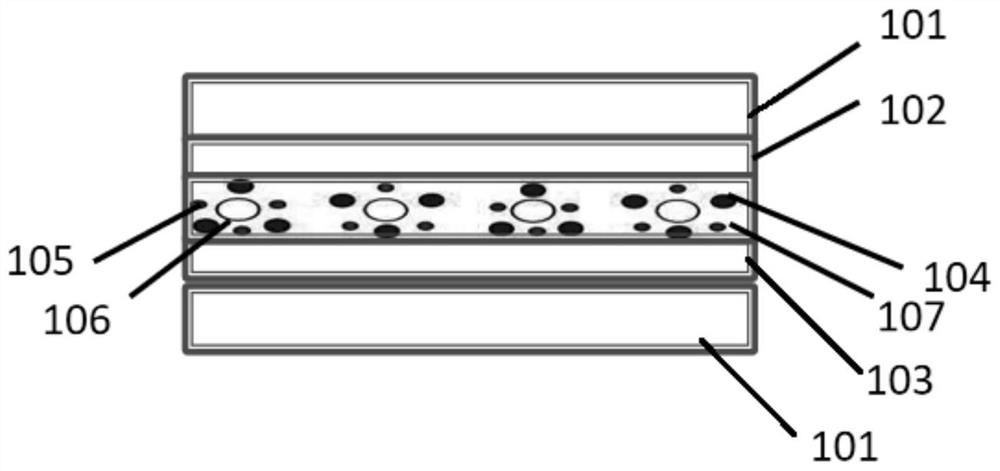

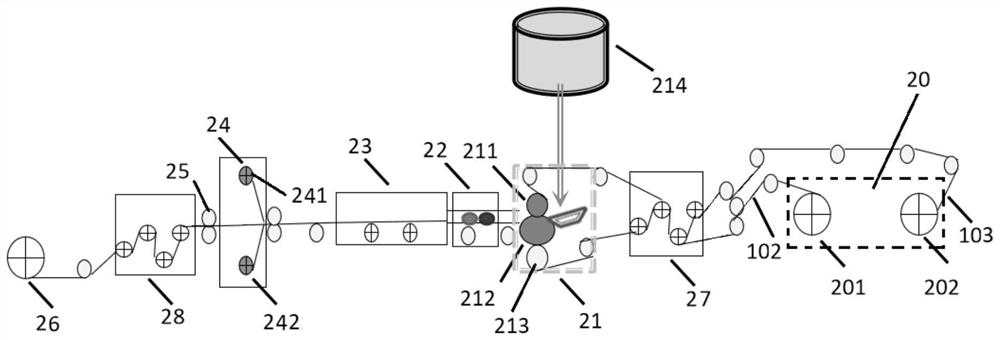

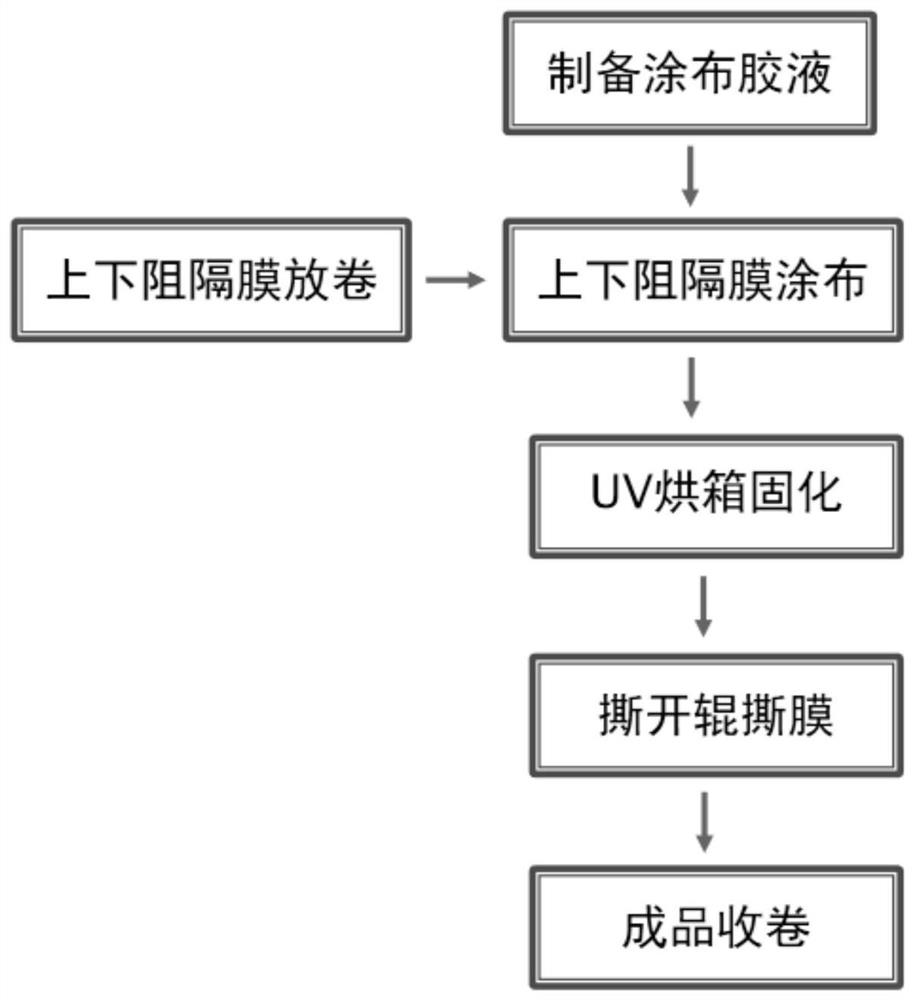

[0041] A method for preparing an ultra-thin quantum dot film, comprising the following steps: 1) selecting quantum dots 105 according to the performance requirements of the ultra-thin quantum dot film to be prepared and dissolving them in a quantum dot stabilizer to obtain a quantum dot solution; The solution is uniformly mixed with the matrix resin 107, the scattering particles 106, the photoinitiator and the diluent to obtain the quantum dot glue; 2) The quantum dot glue is coated on the first barrier film 102 and the second barrier film 103 using a roll-to-roll process In between, the first barrier film 102 is bonded to the second barrier film 103 through the quantum dot glue layer, and the first quantum dot film is obtained after coating by the roll-to-roll process; the first barrier film 102 in the first quantum dot film and the sides away from each other on the second barrier film 103 are respectively attached with a protective film 101; 3) in the first quantum dot film, ...

Embodiment 1

[0055] (1) Preparation of quantum dot glue

[0056] Green and red CdSe quantum dots with an average particle size of 3 nm and 7 nm dissolved in n-hexane with a mass fraction of 1.5% were mixed with a matrix resin acrylic resin and scattering particles TiO 2 , photoinitiator 819 and diluent acetic acid are mixed; after vacuum deoxygenation and nitrogen protection, after stirring at a speed of 50-300rpm for 1-3 hours, the quantum dot glue liquid is obtained;

[0057] (2) Preparation of ultra-thin quantum dot film

[0058] The first barrier film 102 and the second barrier film 103 with the protective film 101 attached to one side are respectively unwound by the first unwinding shaft 201 and the second unwinding shaft 202, wherein the thickness of the protective film is 75 μm, the first barrier film and The thickness of the second barrier film layer is 25 μm; under the traction of the tractor, the prepared quantum dot glue solution is passed through the upper metering roller 211 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com