Patents

Literature

399results about How to "Improve signal transmission performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

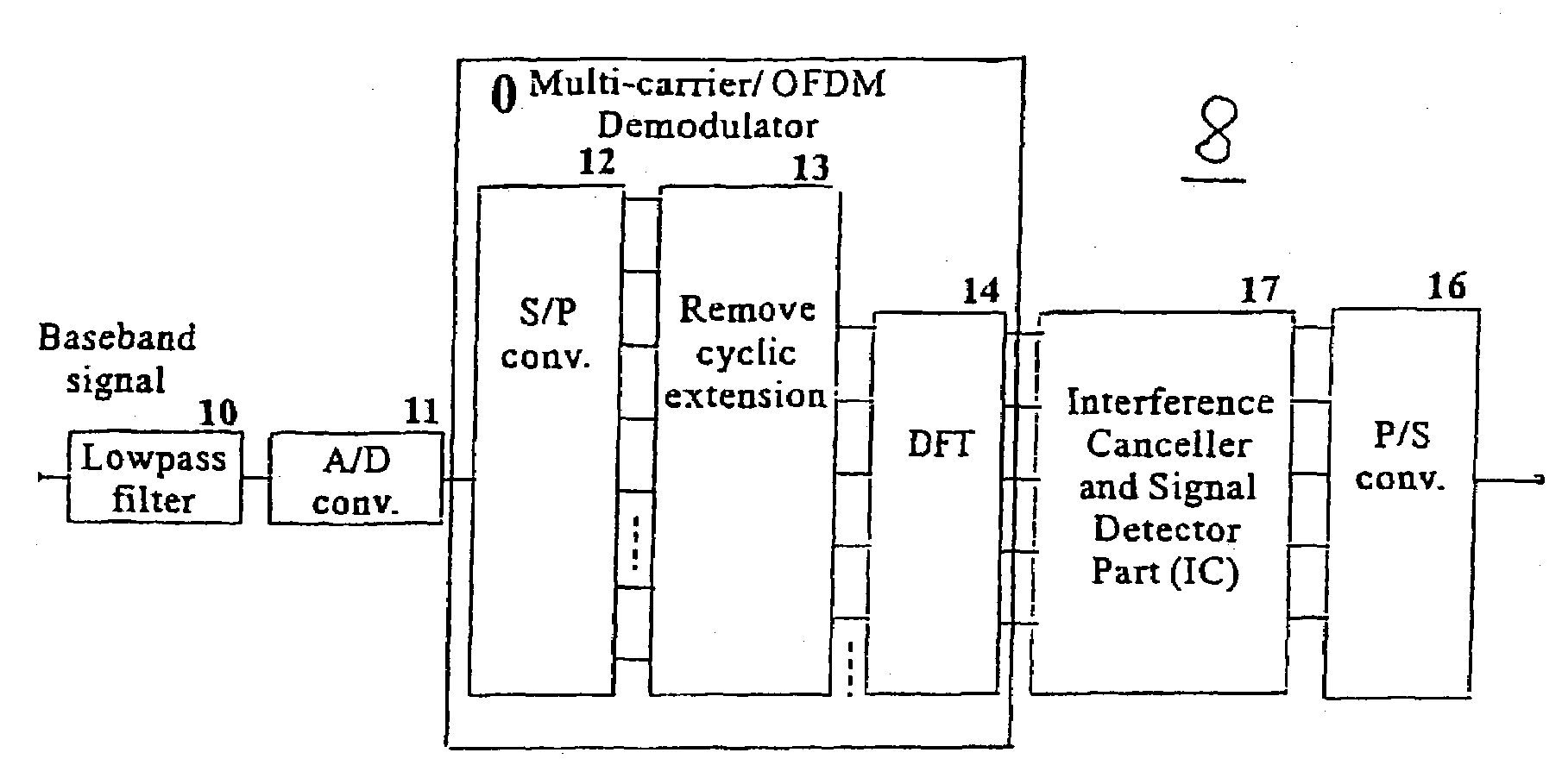

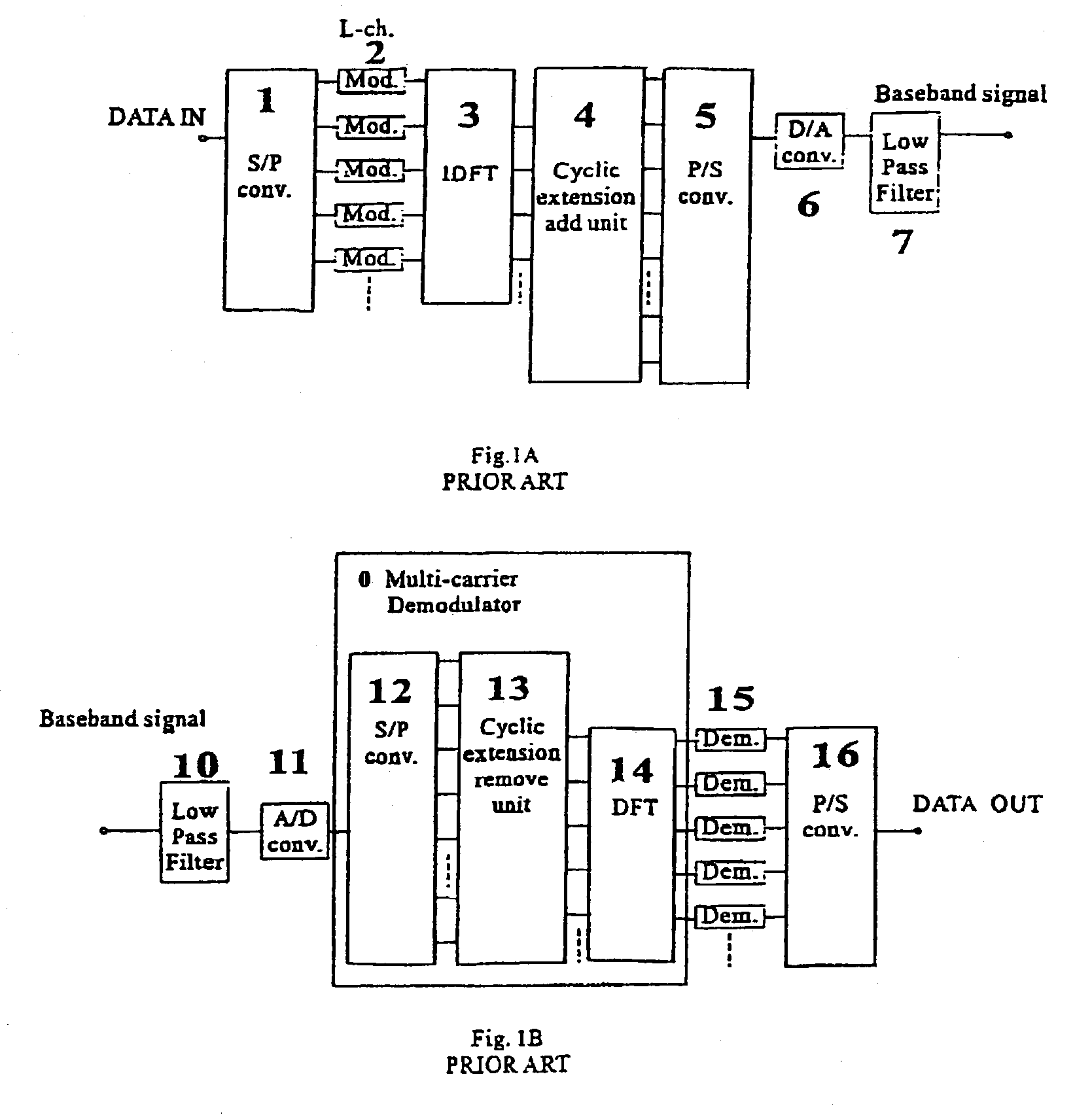

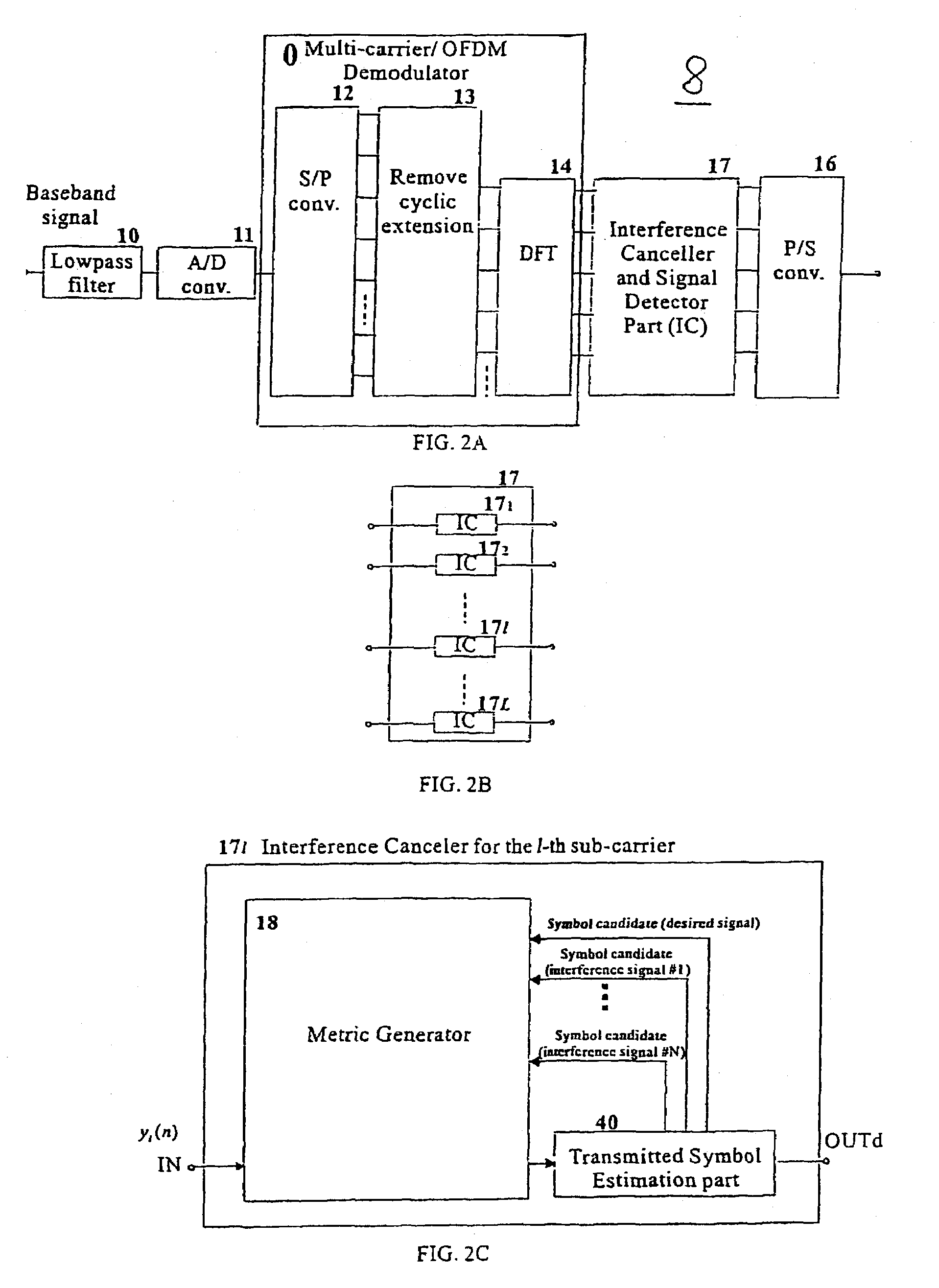

Method for co-channel interference cancellation in a multicarrier communication system

InactiveUS7324437B1Excellent performanceInhibitionSpatial transmit diversityTransmission control/equalisingCarrier signalSubcarrier

A method for cancelling co-channel interference in a multi-carrier communication system includes receiving a serial baseband multi-carrier signal including at least one desired signal and at least one interference signal over at least one receiving branch, and converting the received multi-carrier signal into a plurality of baseband sub-carrier signals. Co-channel interference in each sub-carrier signal is cancelled by subtracting an estimated desired received sub-carrier signal and an estimated interference sub-carrier signal from a received sub-carrier signal. The sub-carrier signals are converted to a multi-carrier output signal comprising the desired signal.

Owner:DEUTSCHE TELEKOM AG

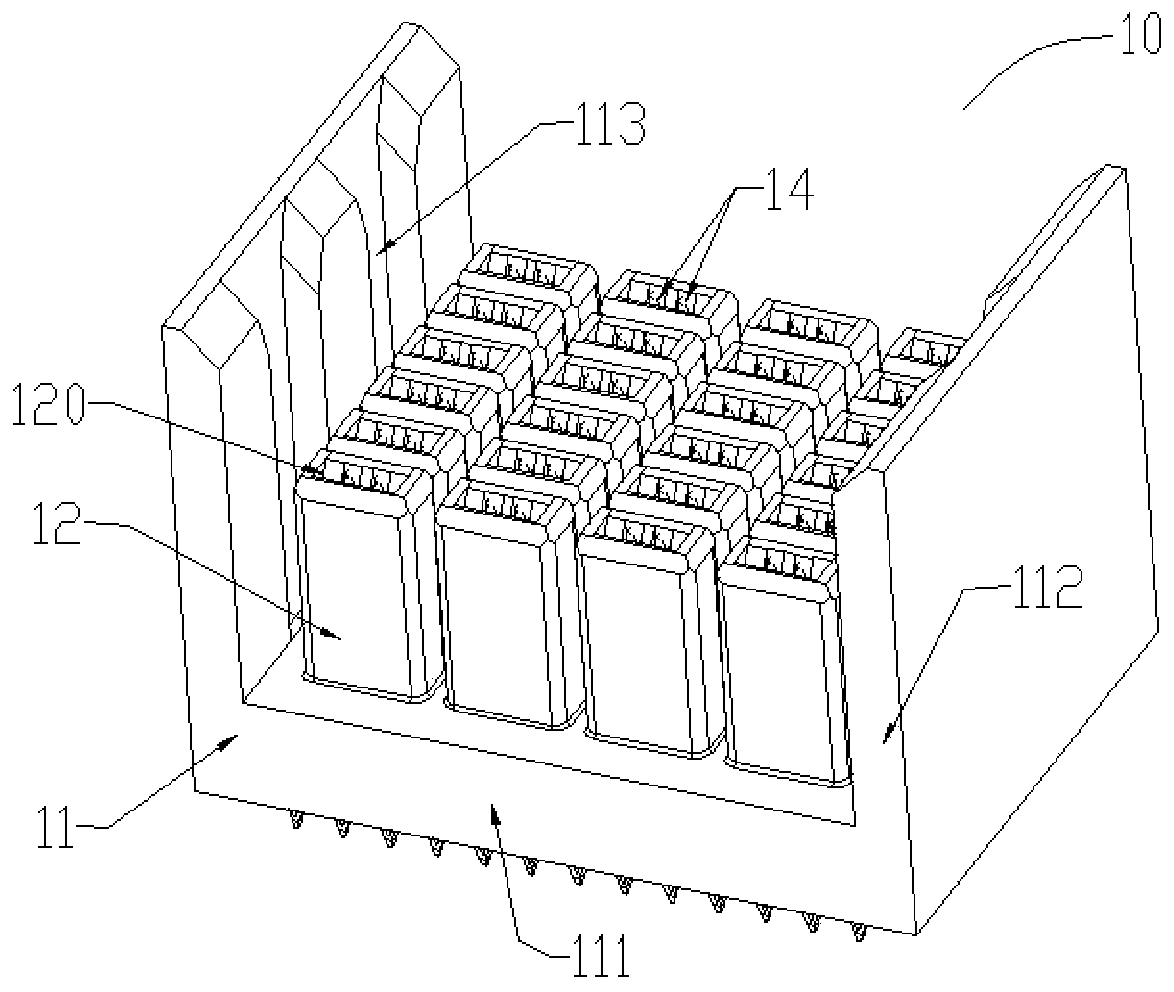

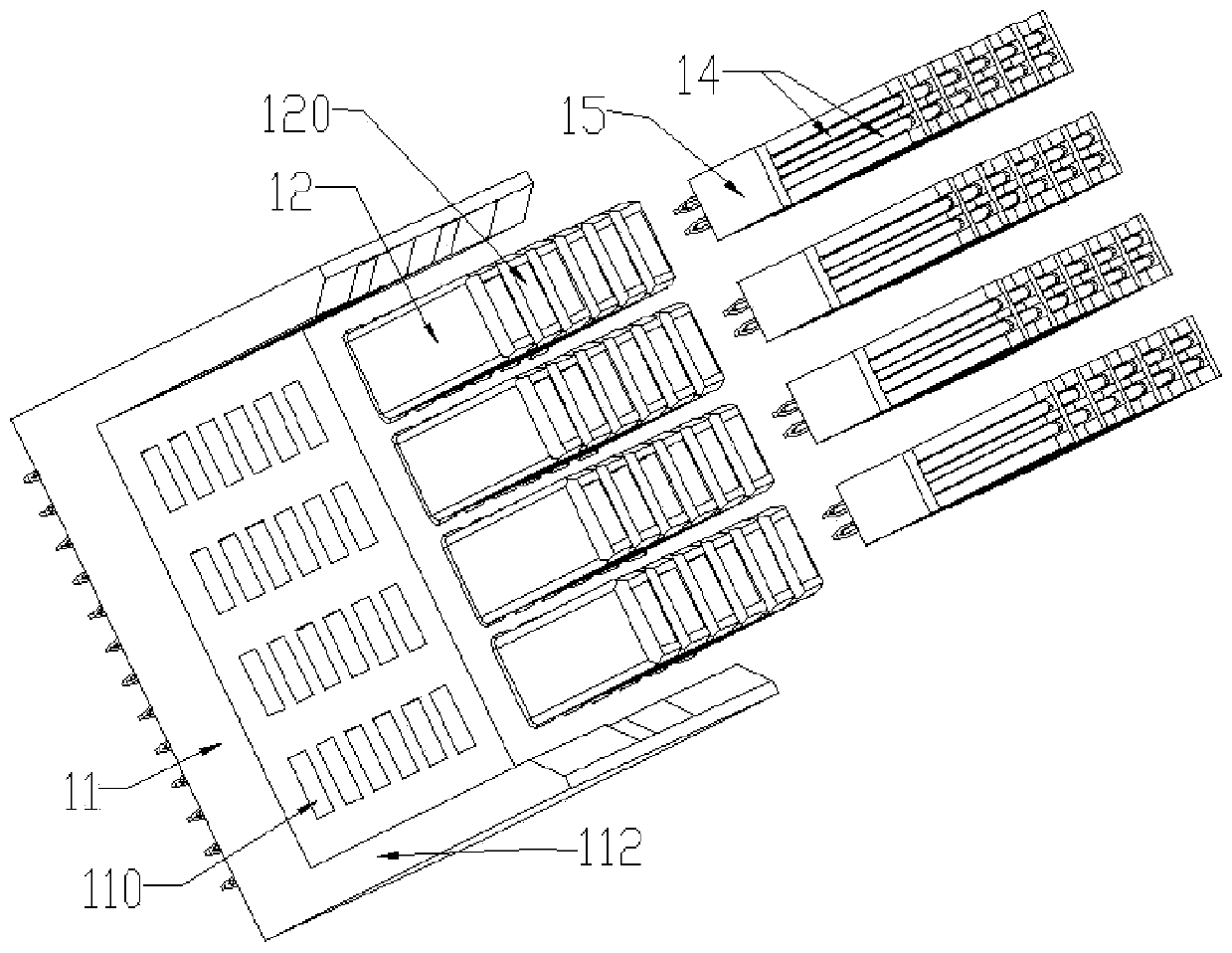

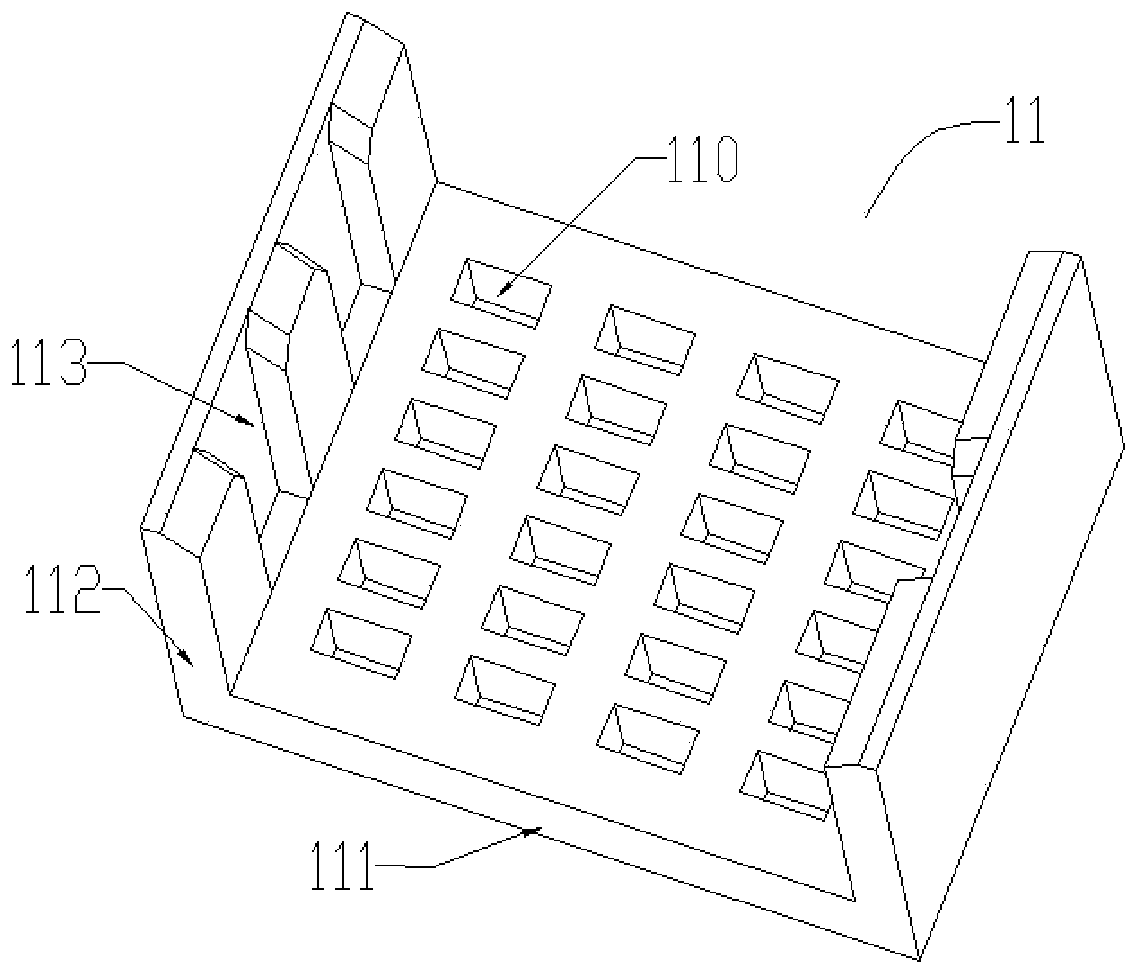

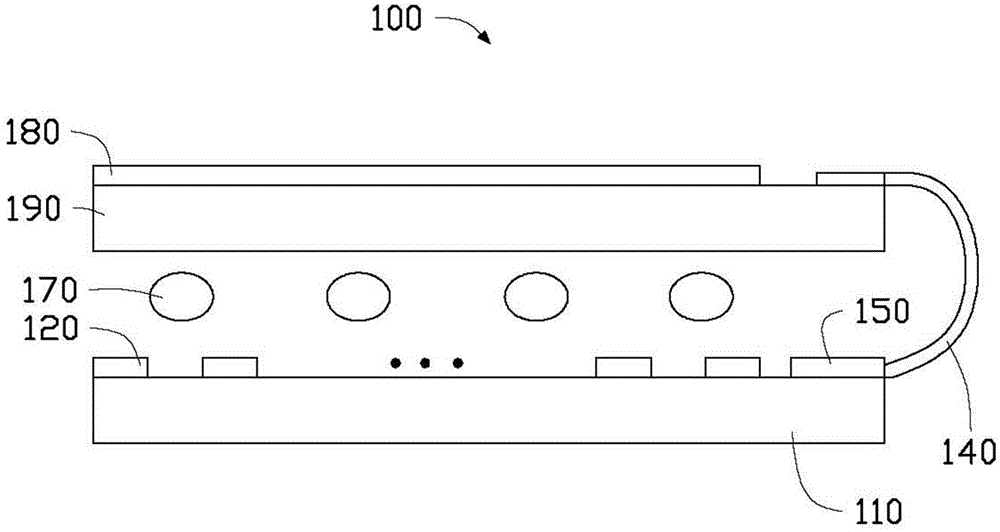

Male connector, female connector, connector assembly and communication equipment

ActiveCN110808499AEasy to processHigh mechanical strengthCoupling device detailsNetwork connectorsAnatomyElectrical connection

The present application provides a male connector, a female connector, a connector assembly and a communication equipment. The male connector comprises a male conductive base, wherein a plurality of first through holes are arranged on the male conductive base; a plurality of shielding sleeves which are fixed on the male conductive base and electrically connected with the male conductive base, theshielding sleeves have a sleeve structure, a front-back through shielding cavity is formed in the shielding sleeves, a plurality of the shielding sleeves are corresponding to a plurality of first through holes in a one-to-one way and the shielding cavity is communicated with the corresponding first through holes; and a plurality of male differential pairs, wherein a plurality of male differentialpairs are corresponding to a plurality of shielding sleeves in a one-to-one way, the male differential pairs are fixed in the shielding cavity by penetrating through the first through holes and the male differential pairs are electrically insulated from the male conductive base and the shielding sleeves. Compared with the connectors in the prior art, the connector has the advantages of convenientprocessing, high mechanical strength and good shielding effect.

Owner:HUAWEI MACHINERY

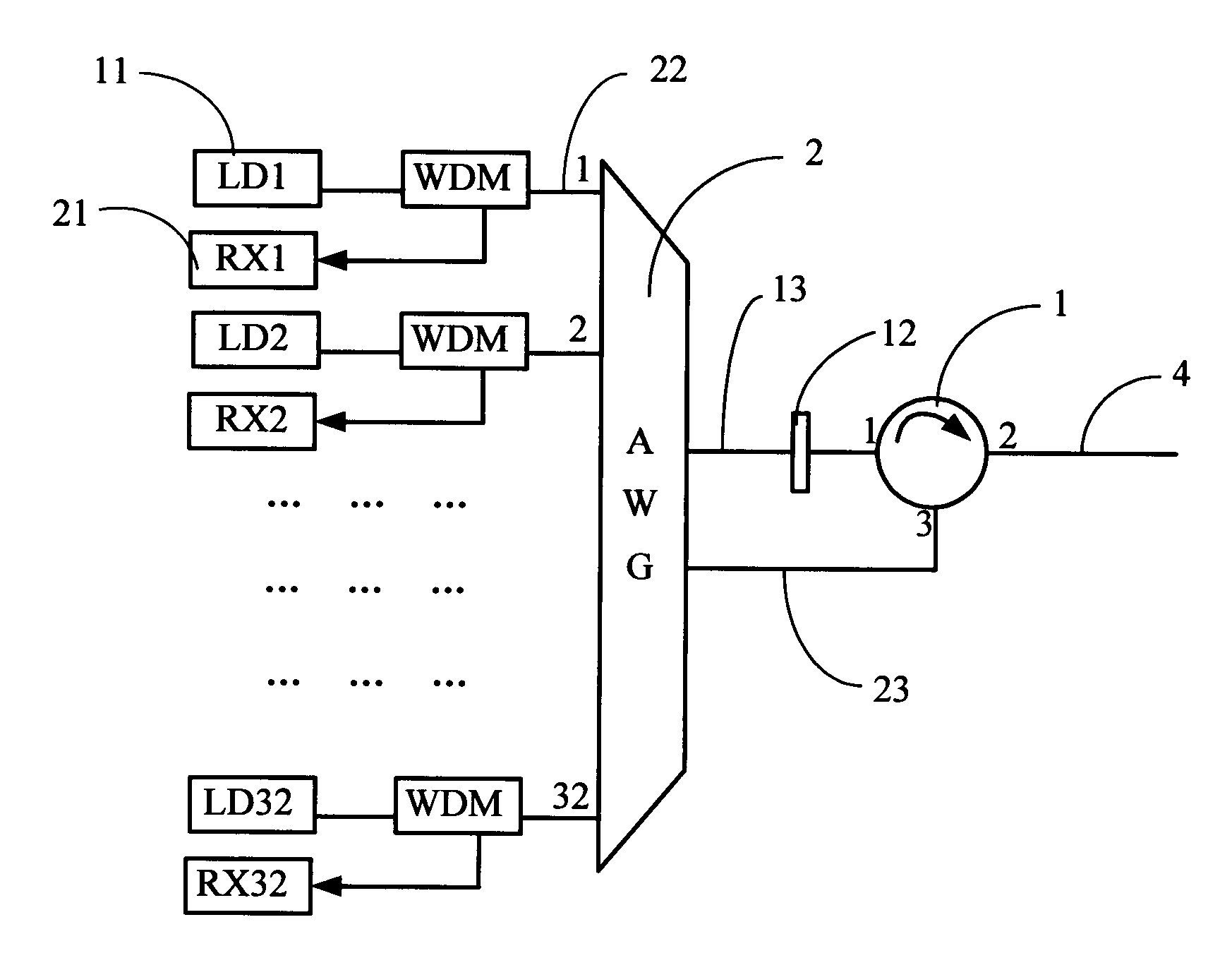

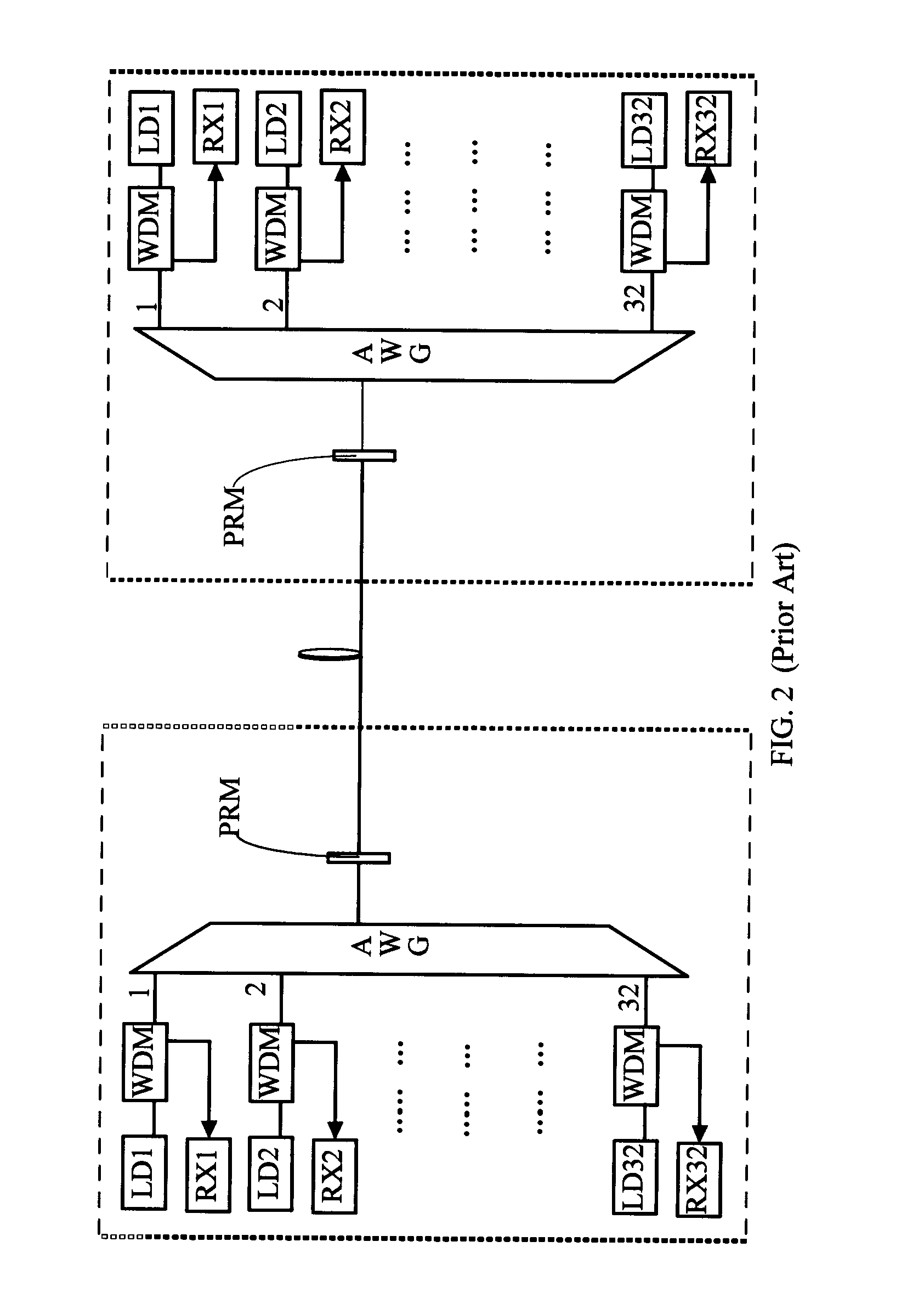

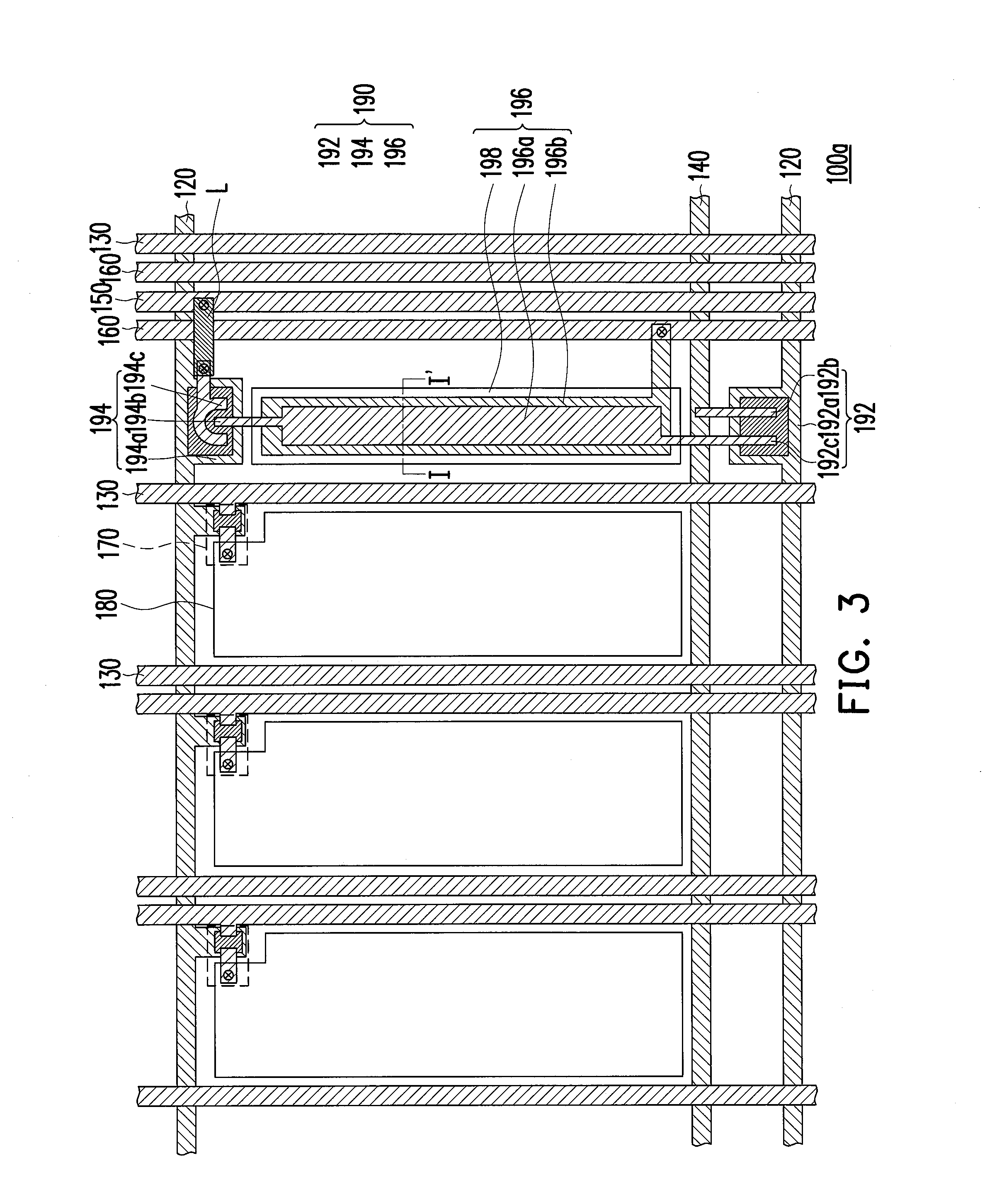

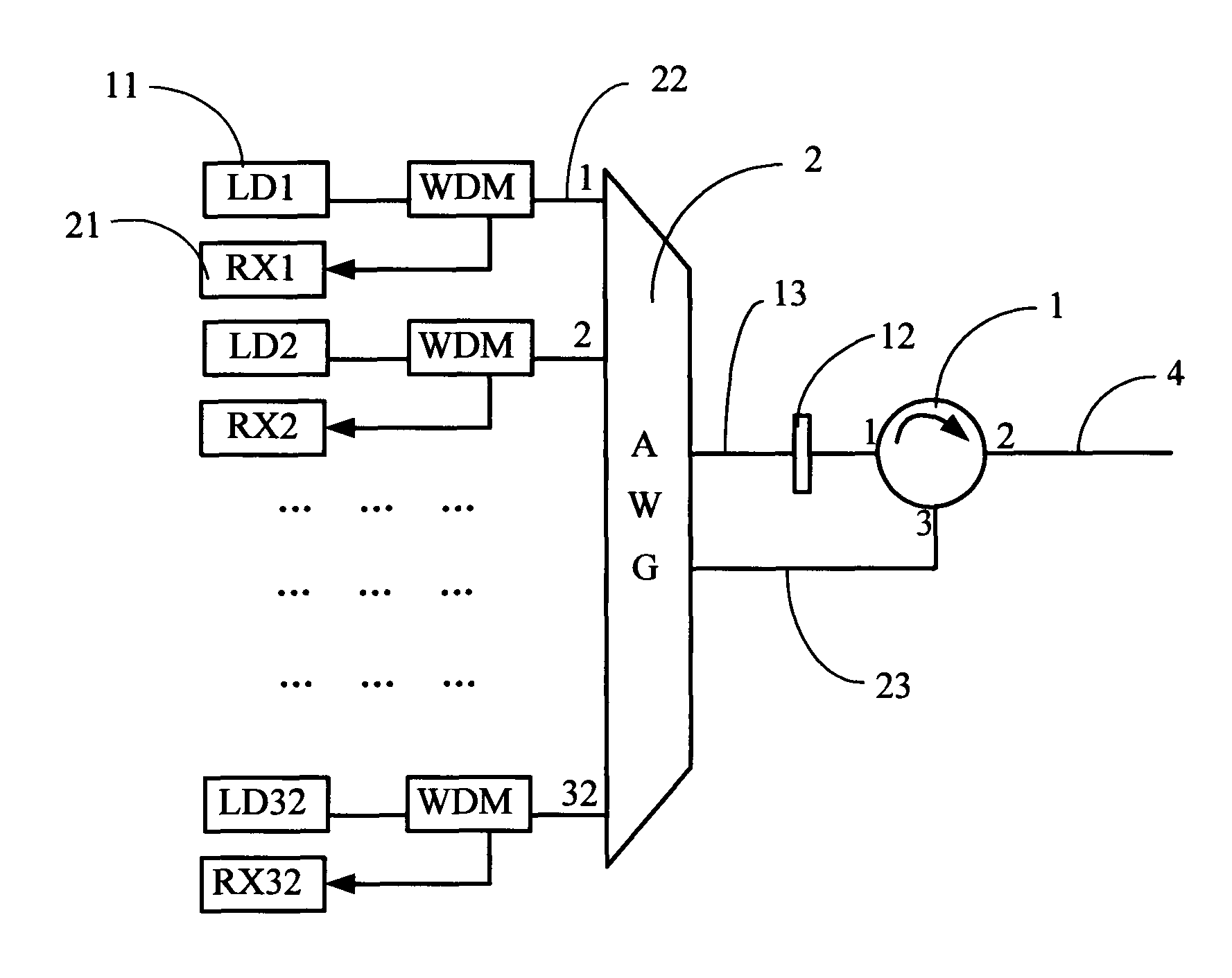

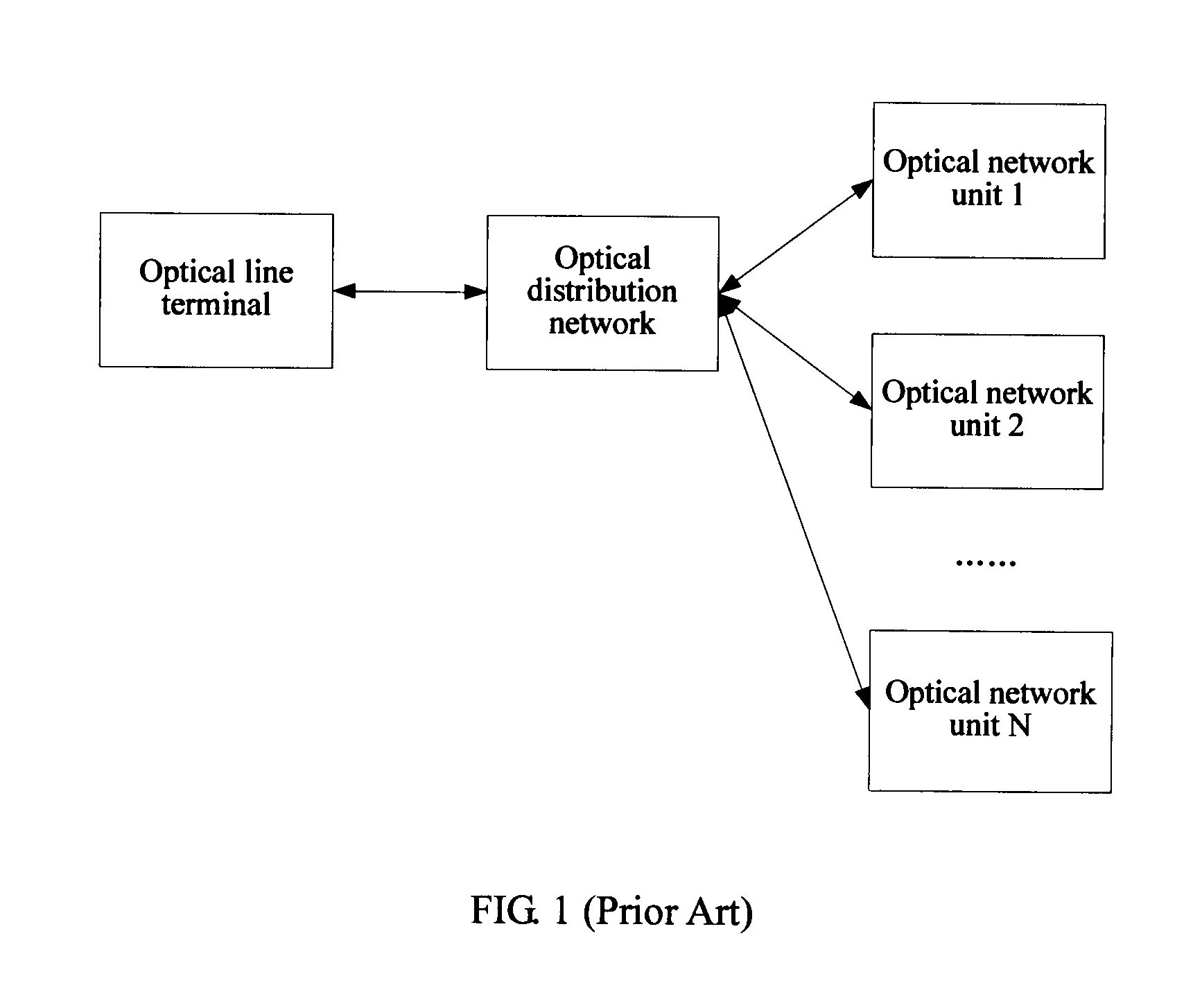

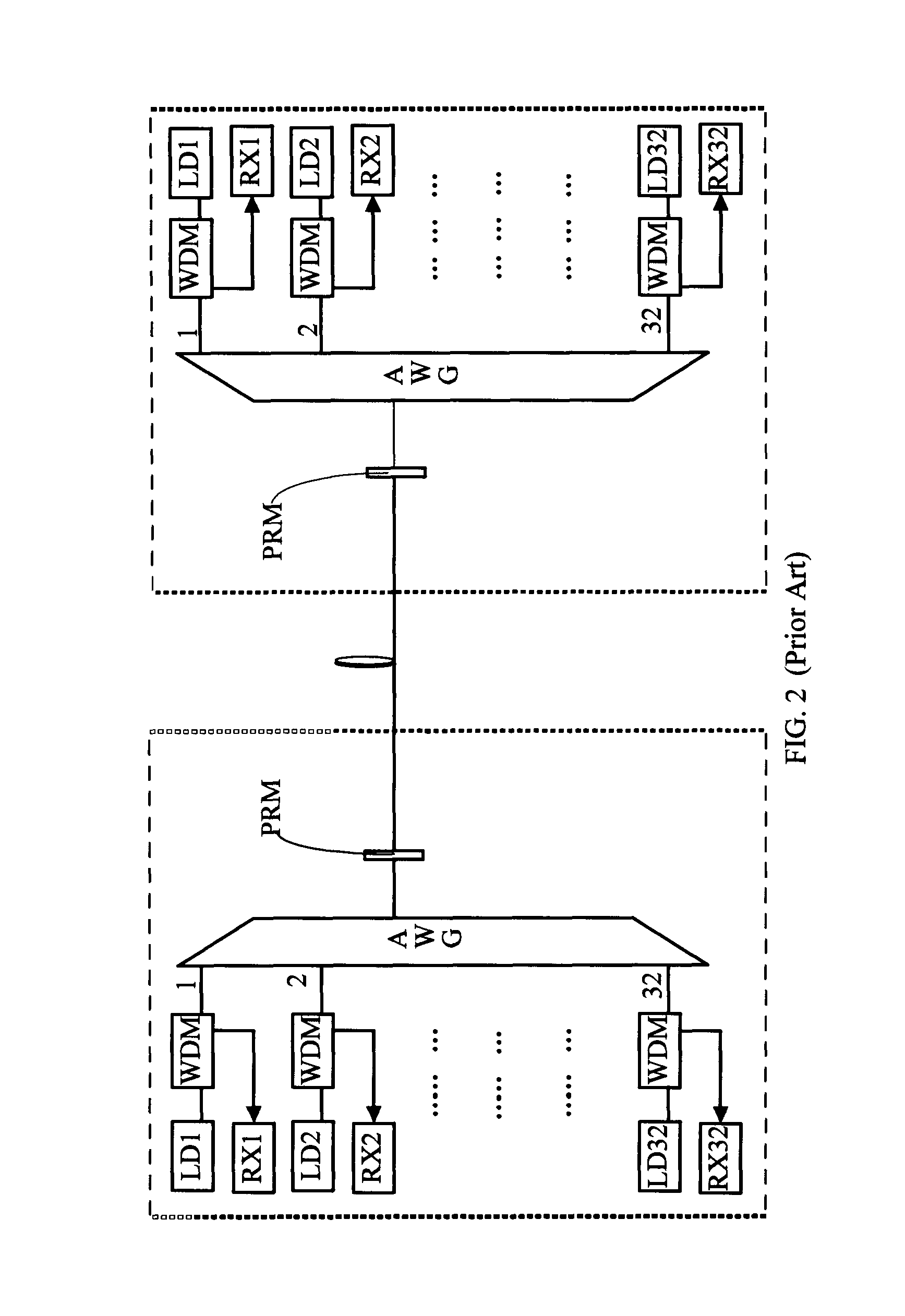

Optical transceiver apparatus and wavelength division multiplexing passive optical network system

InactiveUS20120269516A1Improve signal transmission performanceImprove signal qualityWavelength-division multiplex systemsElectromagnetic transmittersTransceiverLength wave

An optical transceiver apparatus includes a gain medium, a photoelectric converter, at least one AWG, and a partial reflection mirror. The at least one AWG includes two common ports and multiple branch ports. One of the two common ports functions as a signal sending port, and the other functions as a signal receiving port, where bandwidth of the signal sending port is less than that of the signal receiving port. The gain medium and the photoelectric converter are connected to one of the branch ports of the AWG. The AWG and the partial reflection mirror are configured to cooperatively perform wavelength self-injection locking on an optical signal provided by the gain medium, and output the optical signal through the signal sending port. The AWG is further configured to demultiplex an optical signal received by the signal receiving port to a branch port. A WDM-PON system is also provided.

Owner:HUAWEI TECH CO LTD

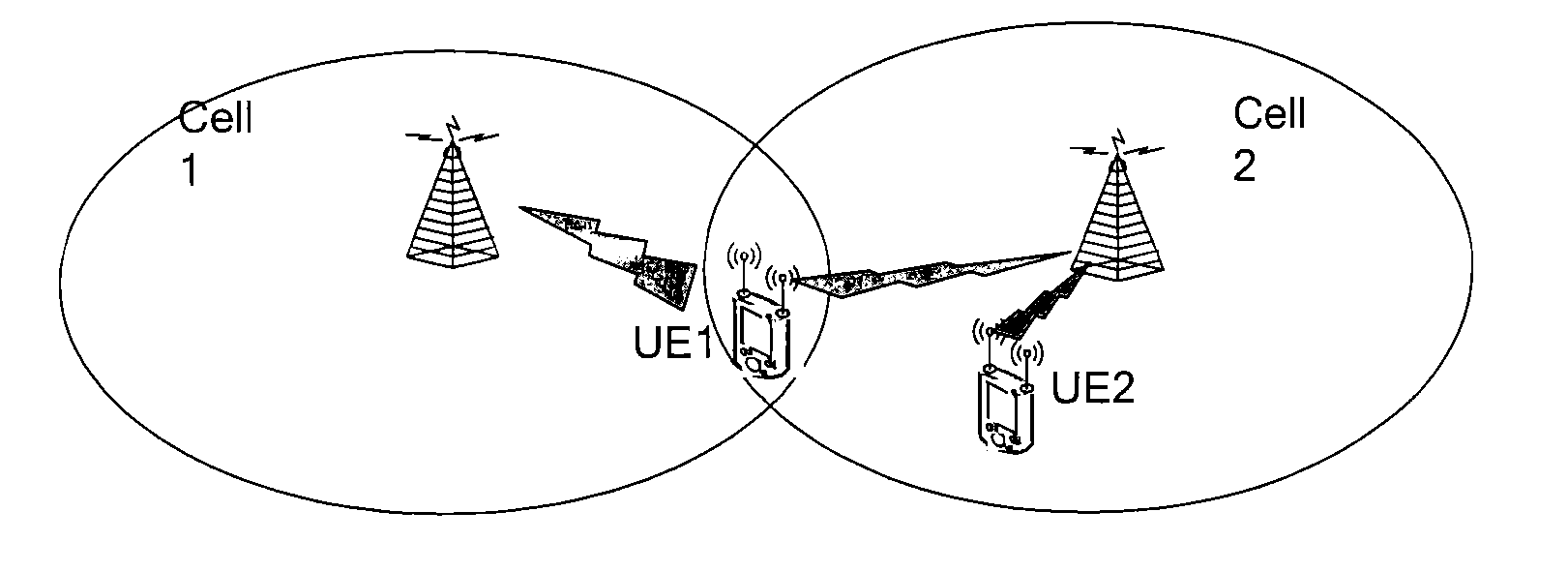

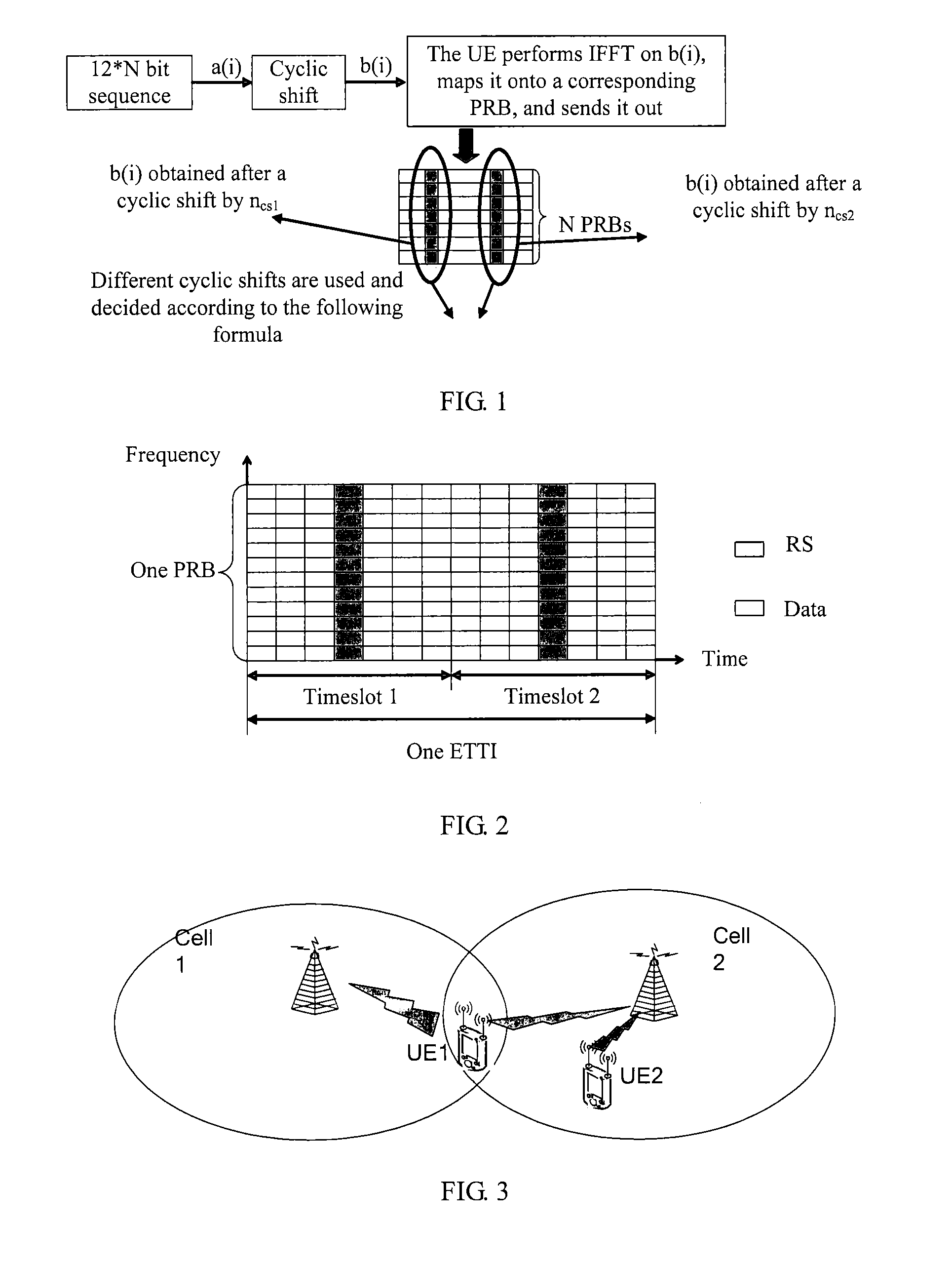

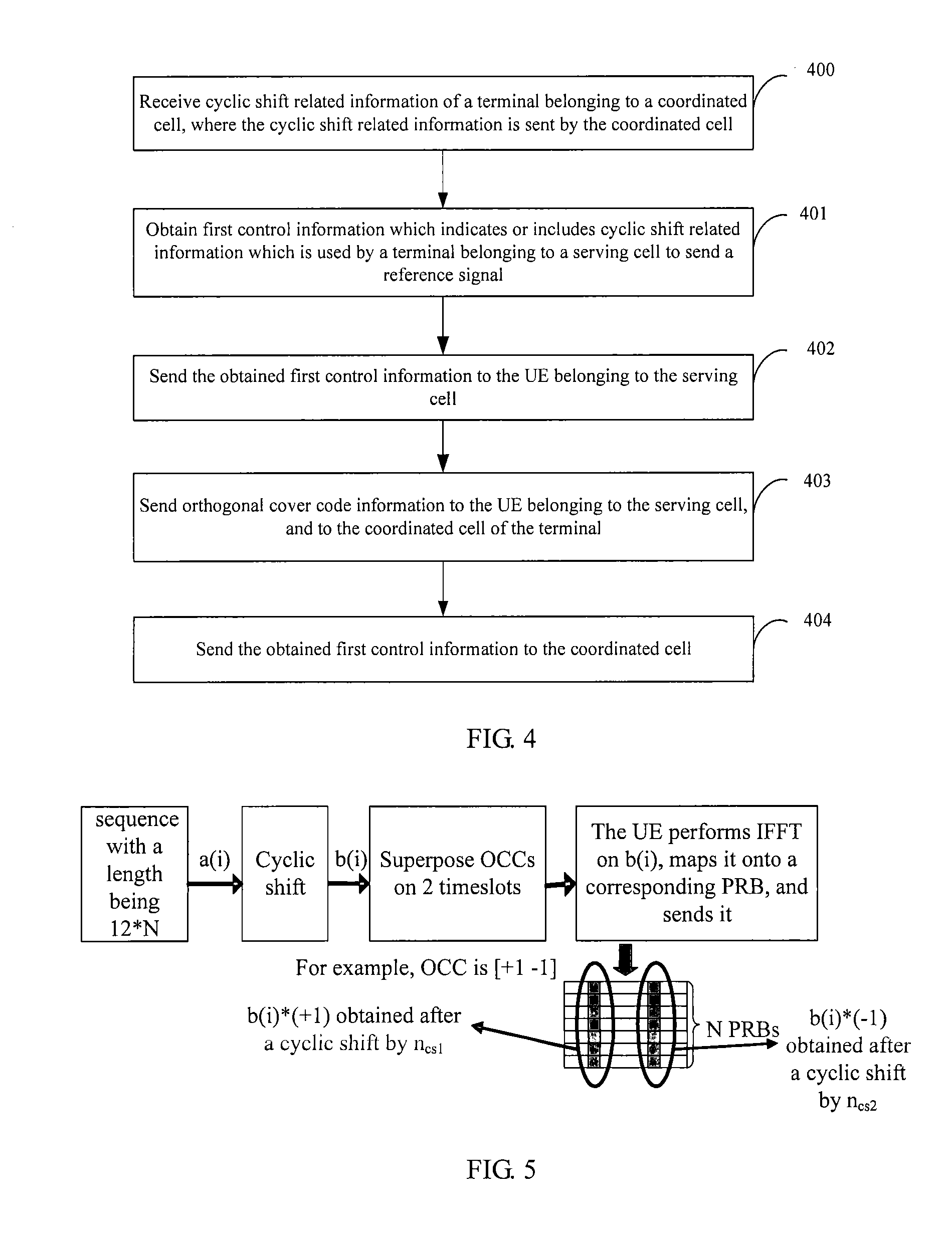

Method, base station, and terminal for generating reference signal

ActiveUS20120307868A1Good orthogonalityAccurate signalModulated-carrier systemsSignal allocationComputer terminalComputer science

The present invention relates to a method for generating a reference signal, including: obtaining first control information, where the first control information indicates or includes cyclic shift related information which is used by a terminal belonging to a serving cell to send a reference signal; and sending the first control information to the terminal belonging to the serving cell, so that the terminal belonging to the serving cell generates the reference signal according to the cyclic shift related information which is indicated or included by the first control information and used by the terminal to send the reference signal, where a variation rule of a cyclic shift which the terminal belonging to the serving cell uses to generate the reference signal is the same as that of a cyclic shift which a terminal belonging to a coordinated cell uses to generate the reference signal.

Owner:HUAWEI TECH CO LTD

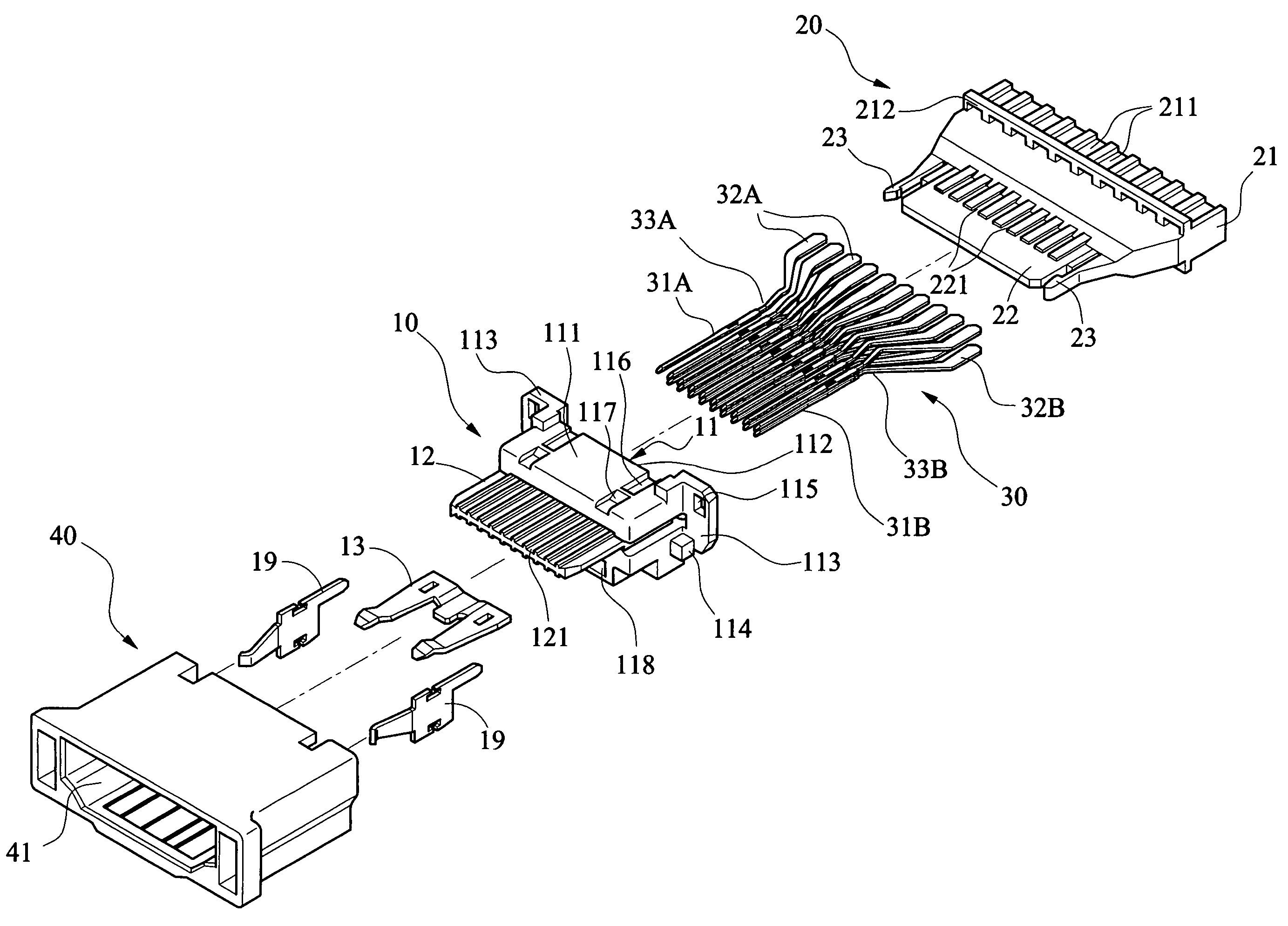

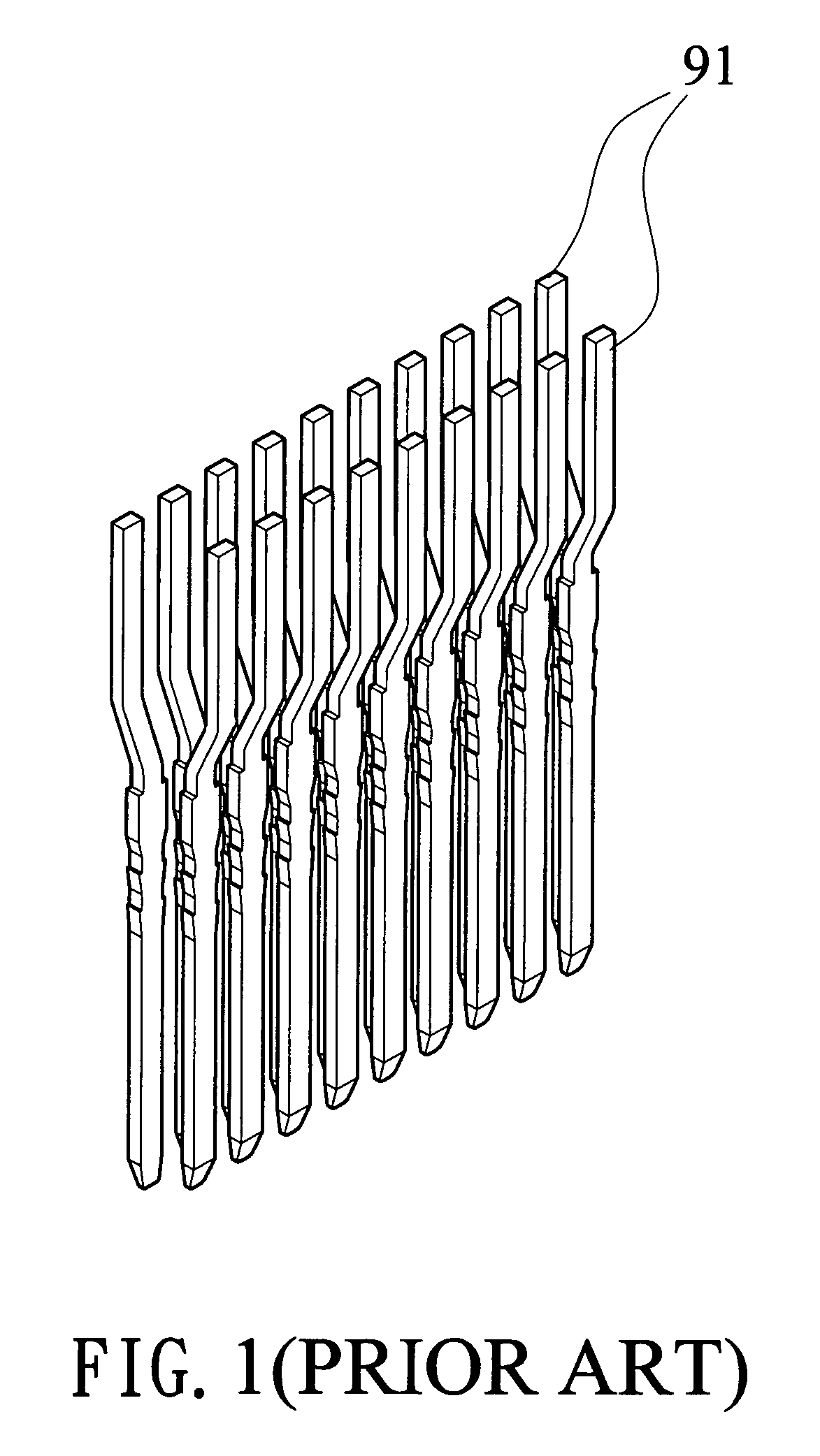

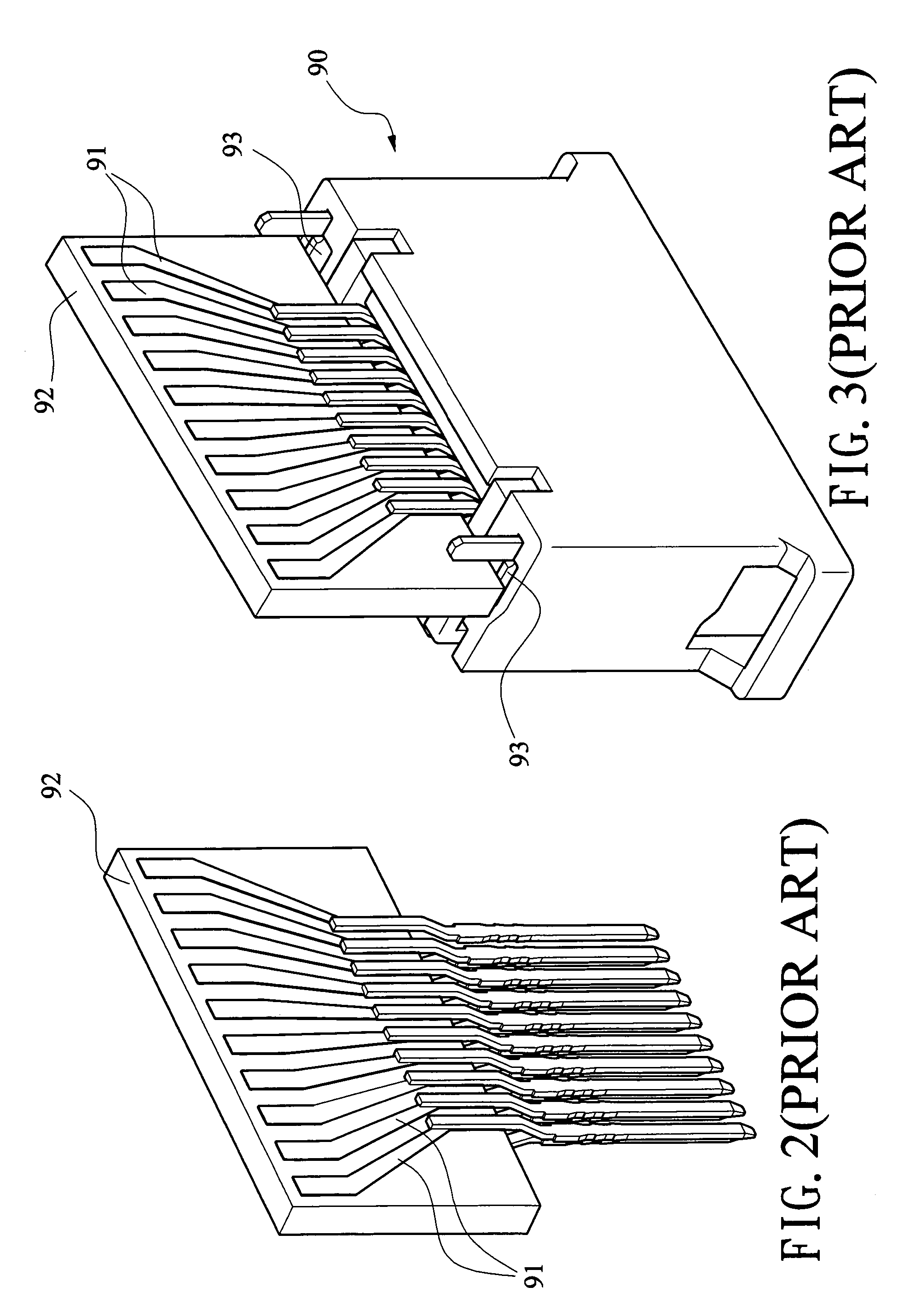

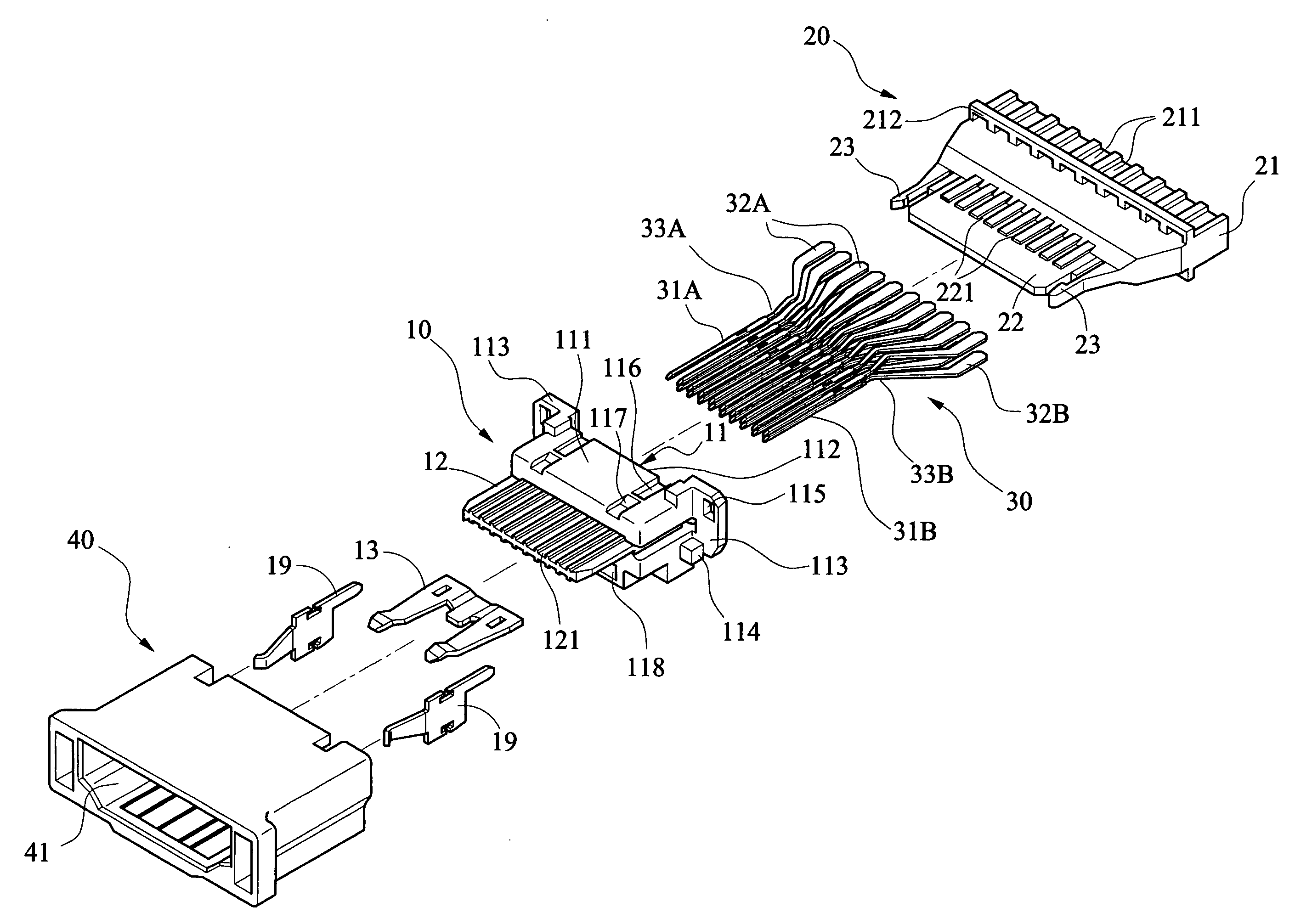

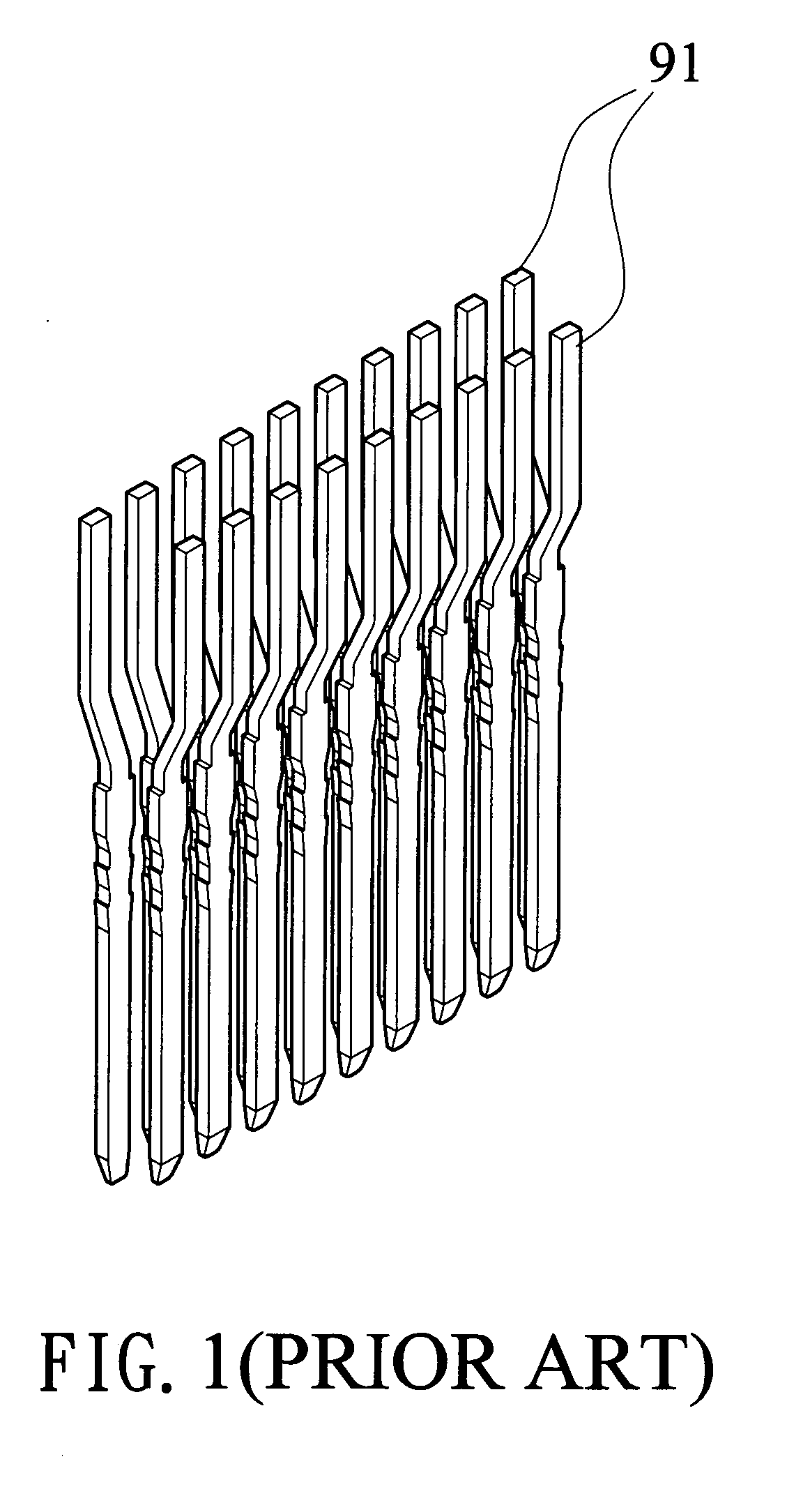

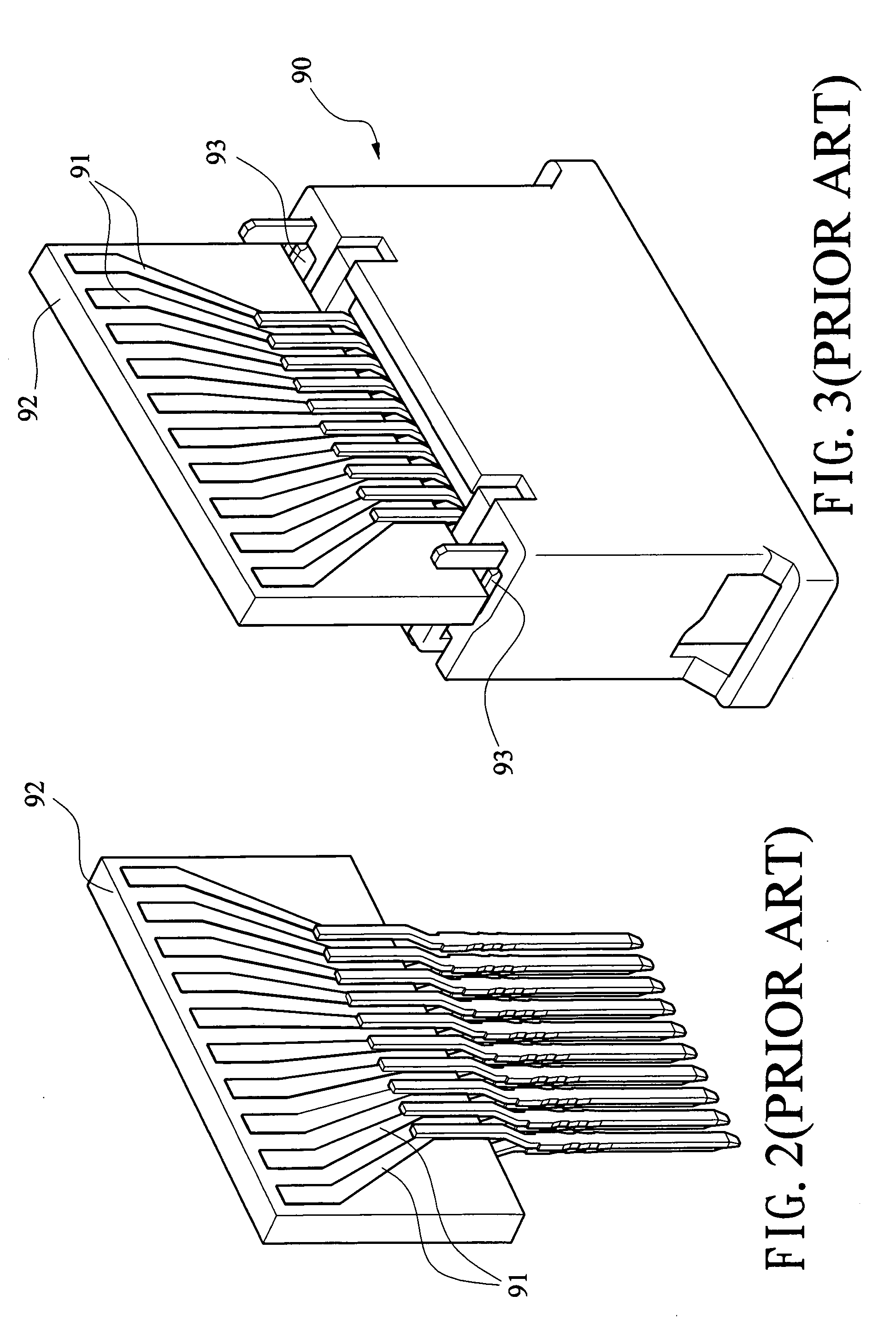

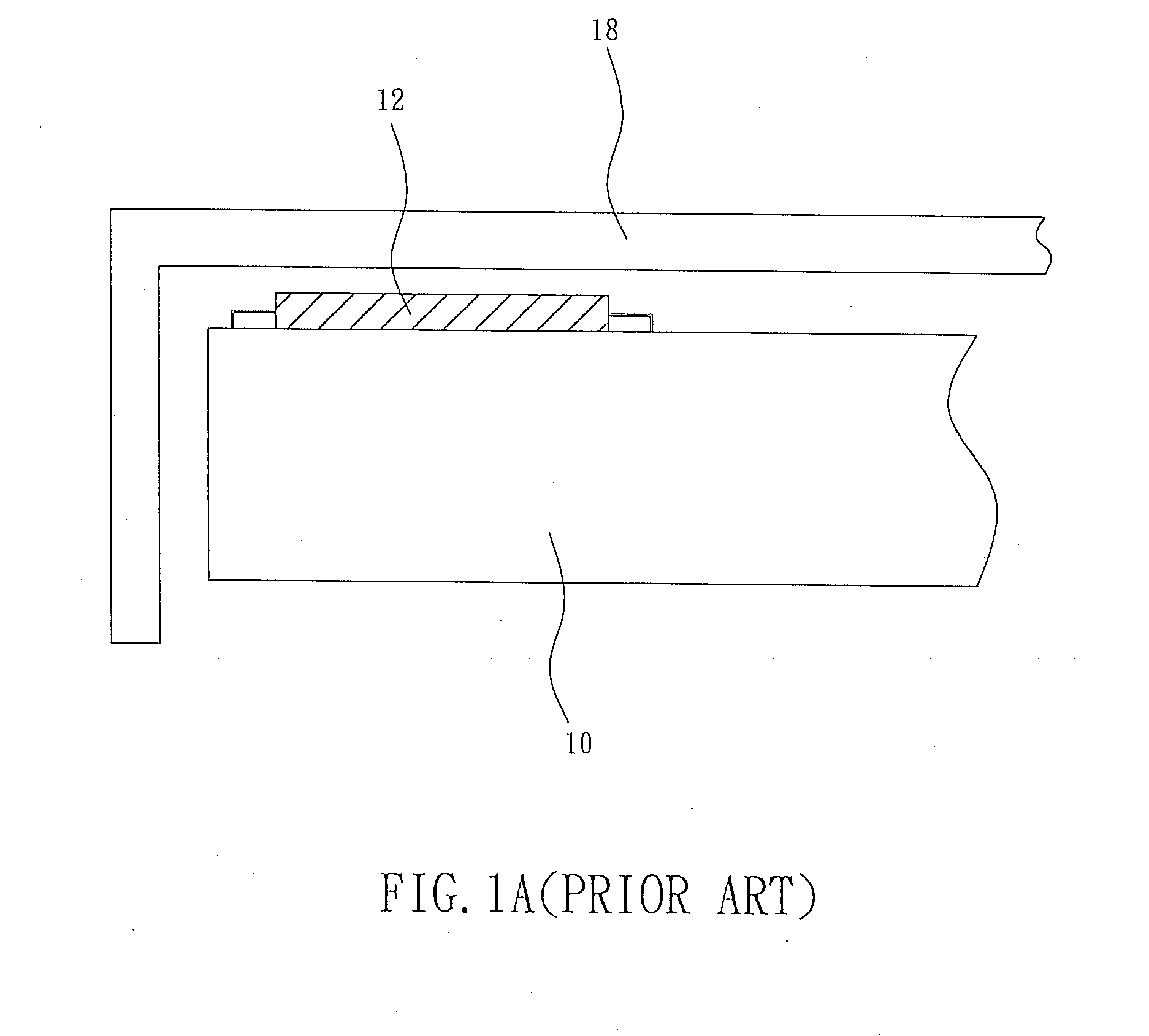

HDMI connector assembly

InactiveUS7210945B1Solder quality be increaseHigh yieldCoupling device detailsPrinted circuitsTransmission performanceHDMI

A HDMI connector assembly includes an insulative body including a body member including a central channel therethrough and parallel grooves on top and bottom of the channel, and a plate including two rows of parallel terminal cavities aligned with the grooves; an insulative seat provided in the channel and including a rear member including parallel furrows on its top and bottom, and a front member including parallel depressions; two rows of conductors provided in the depressions, the furrows, the grooves, and the terminal cavities, each conductor including a front electrical terminal and a rear solder member wherein the solder members of one row and the solder members of the other row are bent in opposite directions; and a housing for receiving the insulative body. The invention has advantages of increased quality and signal transmission performance, and causing no pollution.

Owner:YING WAN FA

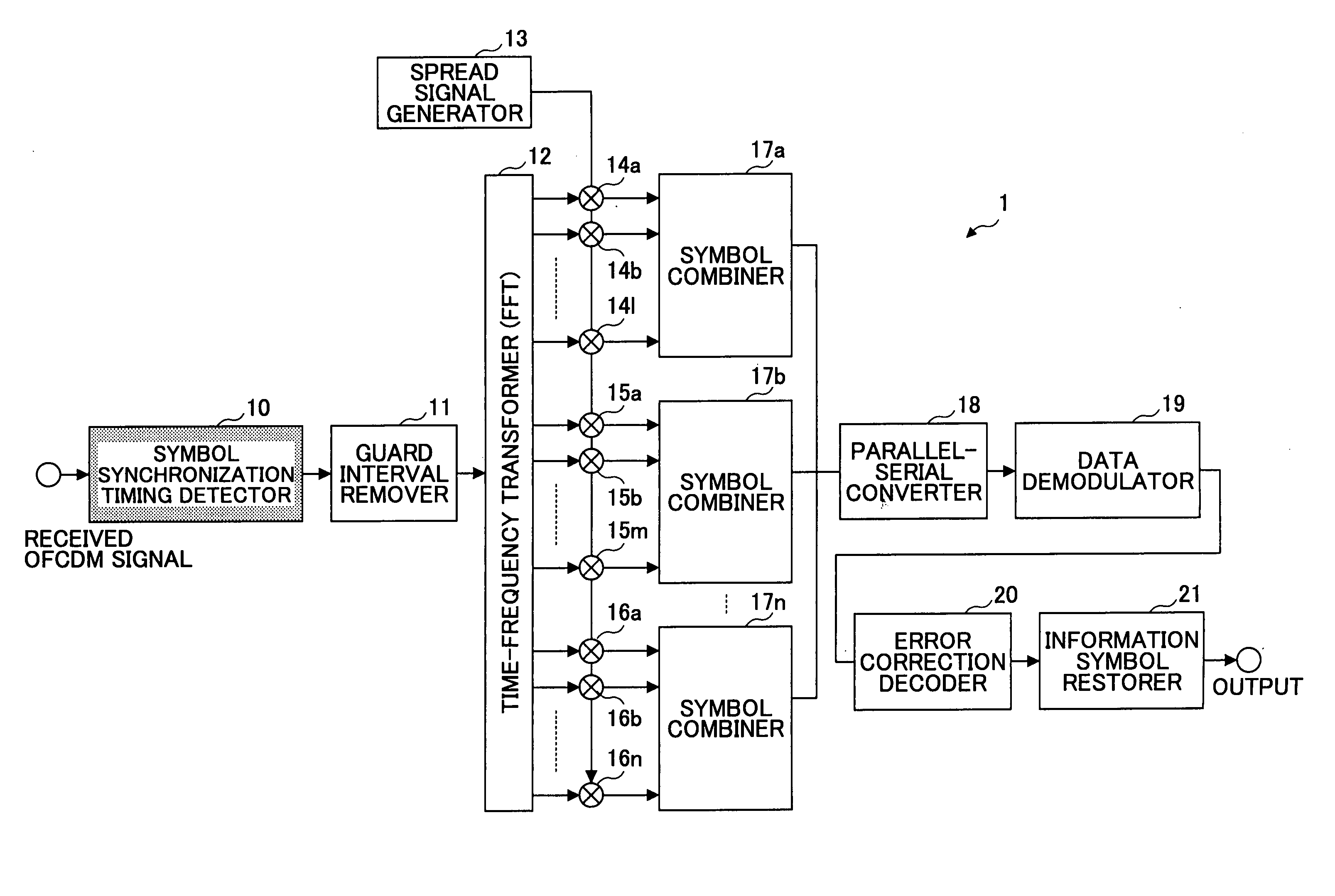

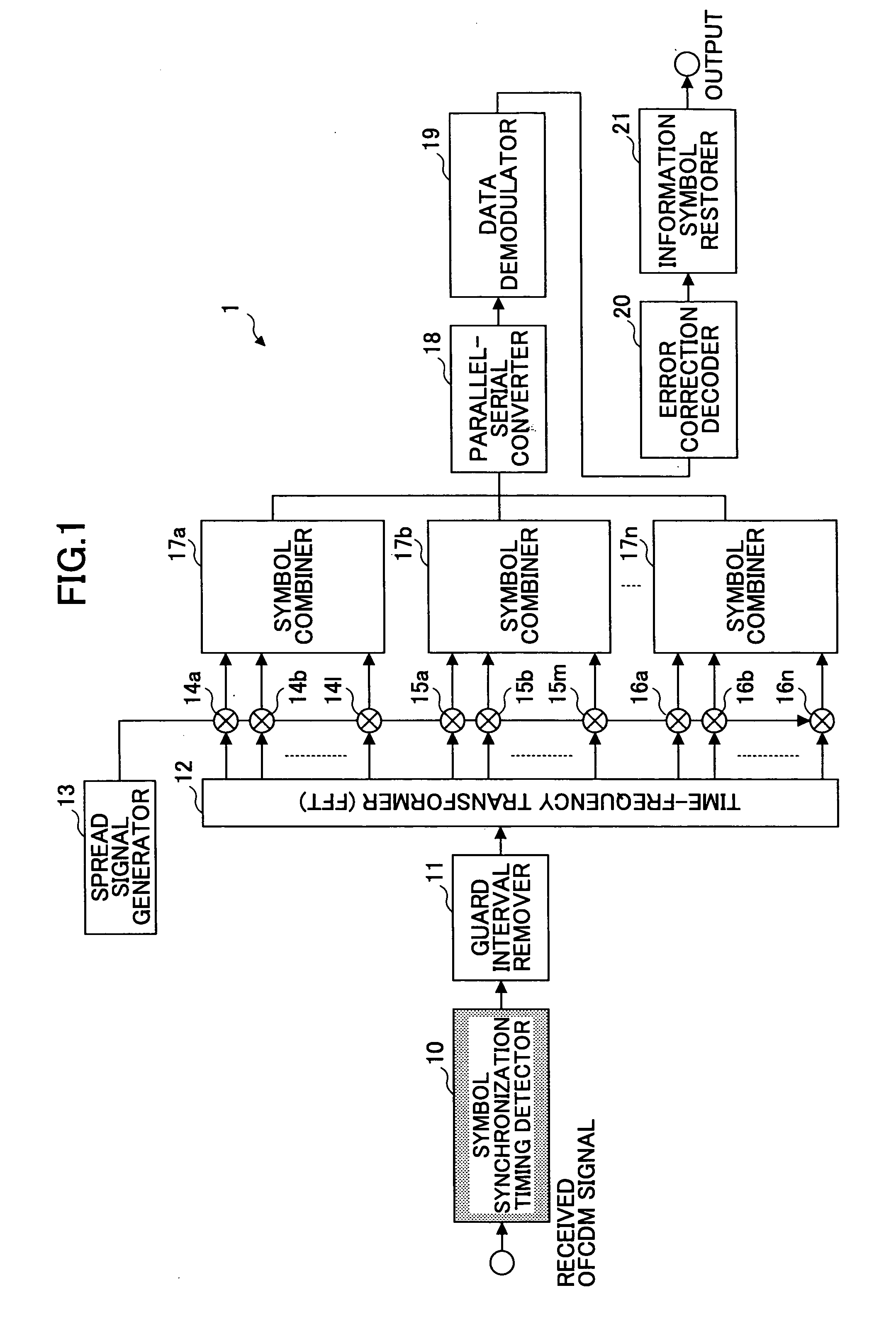

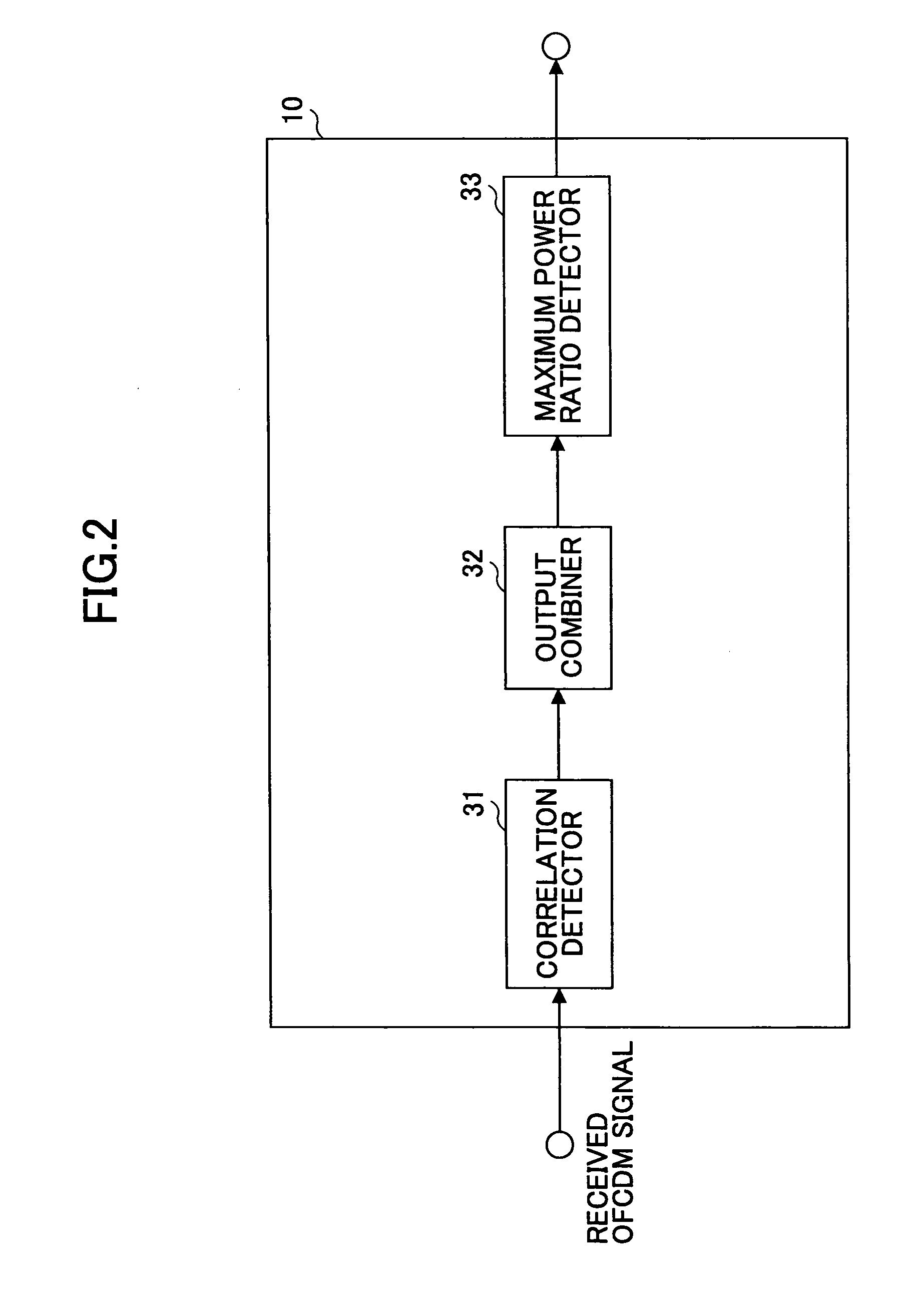

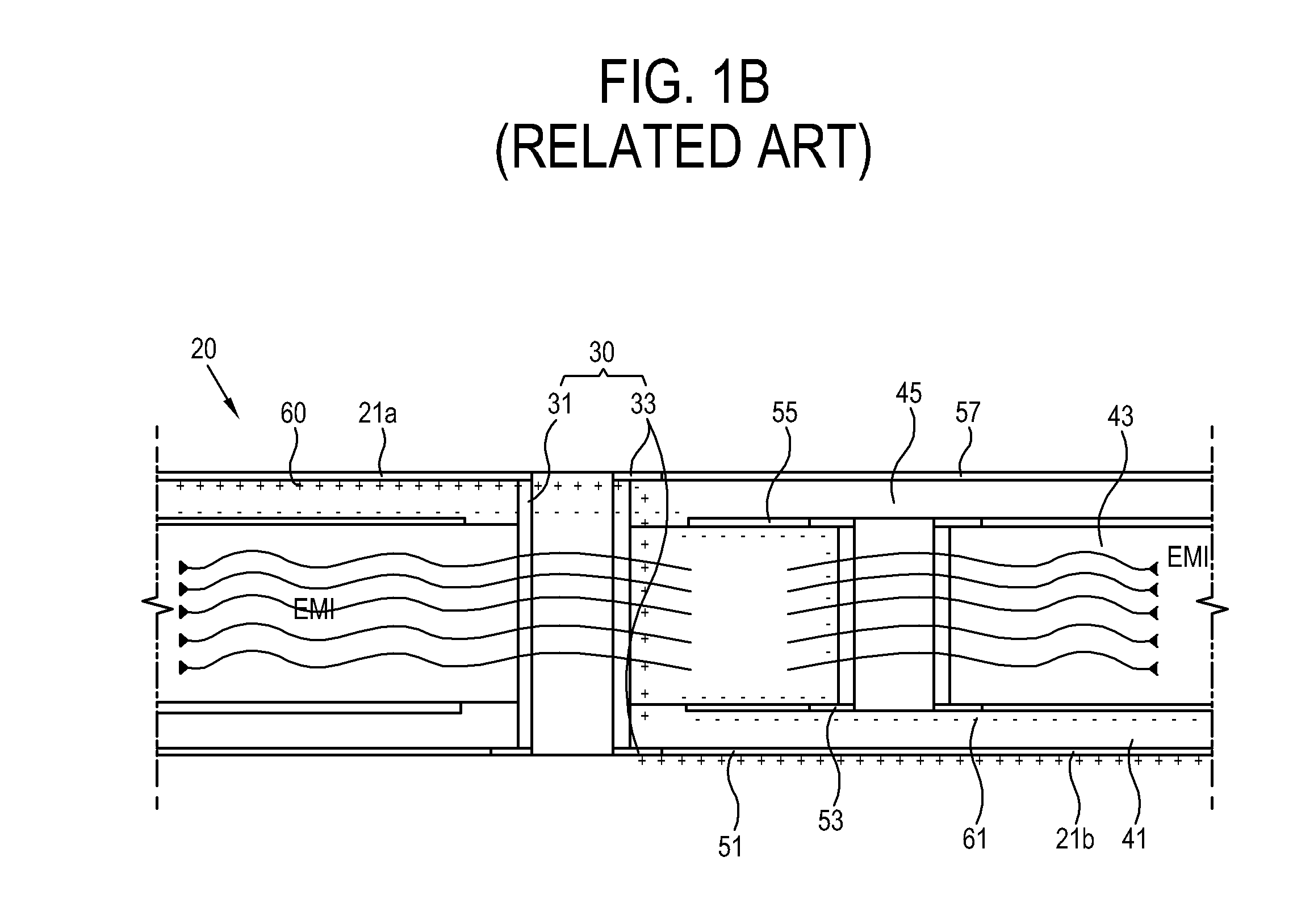

Signal reception device and method of signal reception timing detection

InactiveUS20050100109A1Reduce Intersymbol InterferenceImprove signal transmission performanceElectric pulse generator circuitsSecret communicationCarrier signalEngineering

A signal reception device is disclosed that is capable of detecting symbol synchronization timing with high precision in accordance with a condition of a propagation path even in an environment involving multi-path interference. The signal reception device adopts an OFCDM transmission scheme or a multi-carrier transmission scheme. The signal reception device includes a received signal information calculation unit to calculate received signal information representing a signal reception condition of a received signal; an output combination unit to combine correlation values in a predetermined section obtained by correlation detection based on the received signal information; and a symbol timing detection unit to detect a symbol synchronization timing based on the combined value.

Owner:NTT DOCOMO INC

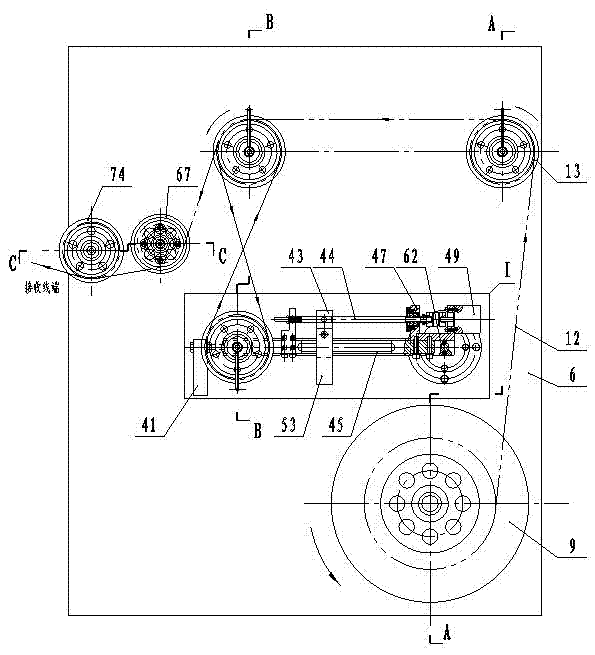

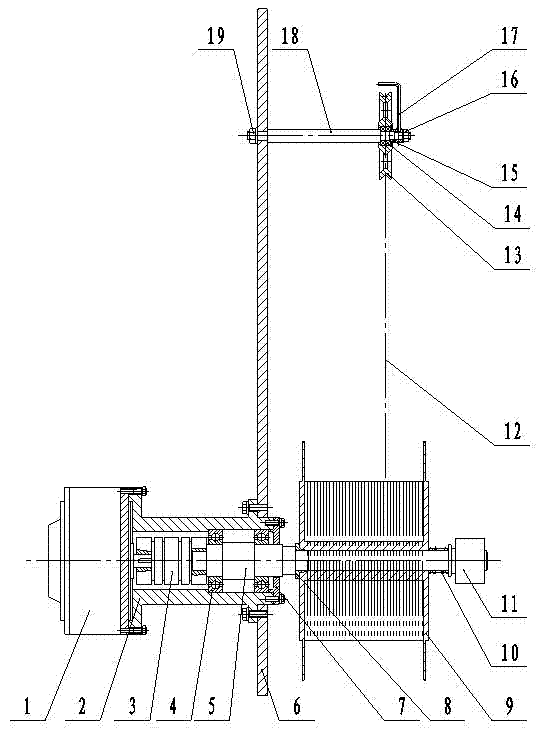

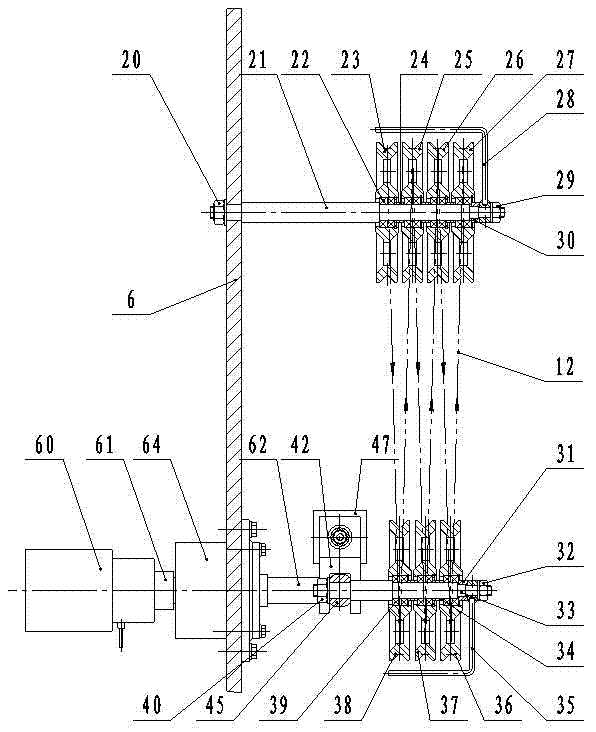

Variable tension adjustment and control device capable of being used for precision winding of optical fiber

The invention discloses a variable tension adjustment and control device capable of being used for precision winding of an optical fiber. The device comprises a releasing mechanism, a dance wheel adjusting mechanism, a tension detection mechanism and a panel, wherein a printed winding motor is used as a releasing motor of the variable tension adjustment and control device; a micro ball screw transmission pair is driven through a step motor to accurately change a rider position in the length direction of a swing rod; the position of the swing rod is detected by using an angle sensor, so that the swing rod is kept at a horizontal position in a moment balance state; the optical fiber tension after layer replacement winding achieves a new stable value requirement by changing the rider position, and precision detection and control of the horizontal balance position of the swing rod; thus variable tension adjustment and control during layer replacement winding of the optical fiber winding are realized, the inner and outer layer stress and strain differences caused by increase in number of layers of the optical fiber winding can be eliminated, and finally stress winding of inner and outer layers of the optical fiber winding and the like is realized so as to obviously improve the signal transmission performance and stability of the optical fiber winding.

Owner:CHANGCHUN EQUIP TECH RES INST

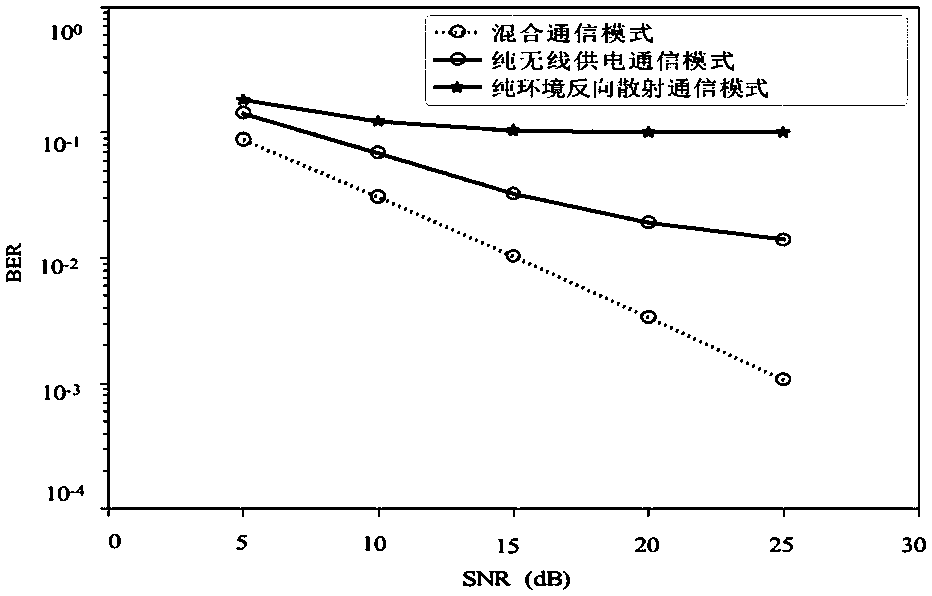

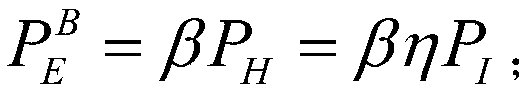

Communication method between communication devices adopting environment RF wireless charging

ActiveCN108964751AImprove communication performanceComplement each other wellCircuit arrangementsScatter propogation systemsTransfer modeData transmission

The invention relates to a communication method between communication devices adopting environment RF wireless charging, and belongs to the technical field of communication adopting the environment RFwireless charging. The technical problem to be solved is to provide the communication method between communication devices adopting environment RF wireless charging. The technical scheme adopted to solve the technical problem is as follows: performing communication by using a transmitter S and a receiver D, wherein the transmitter S is capable of performing an active data transmission mode or a data backscattering transmission mode, and performing RF energy collection; the receiver D can demodulate data from modulated backscattering and active RF transmission; the data transmission mode can be accomplished by the transmitter S by receiving selection signaling; and the communication method provided by the invention is applied to RF wireless charging communication devices.

Owner:TAIYUAN UNIV OF TECH

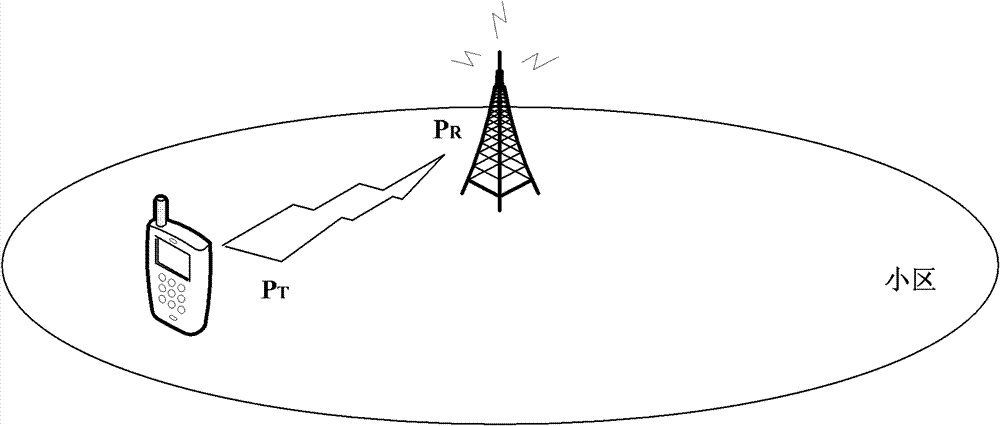

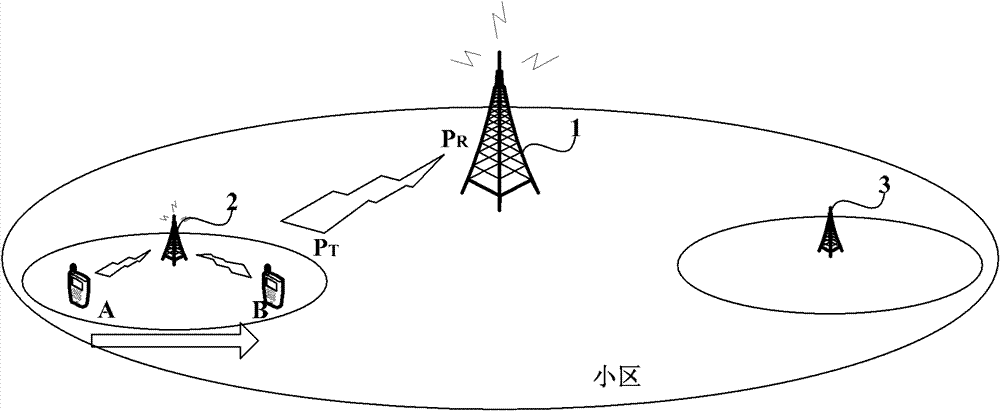

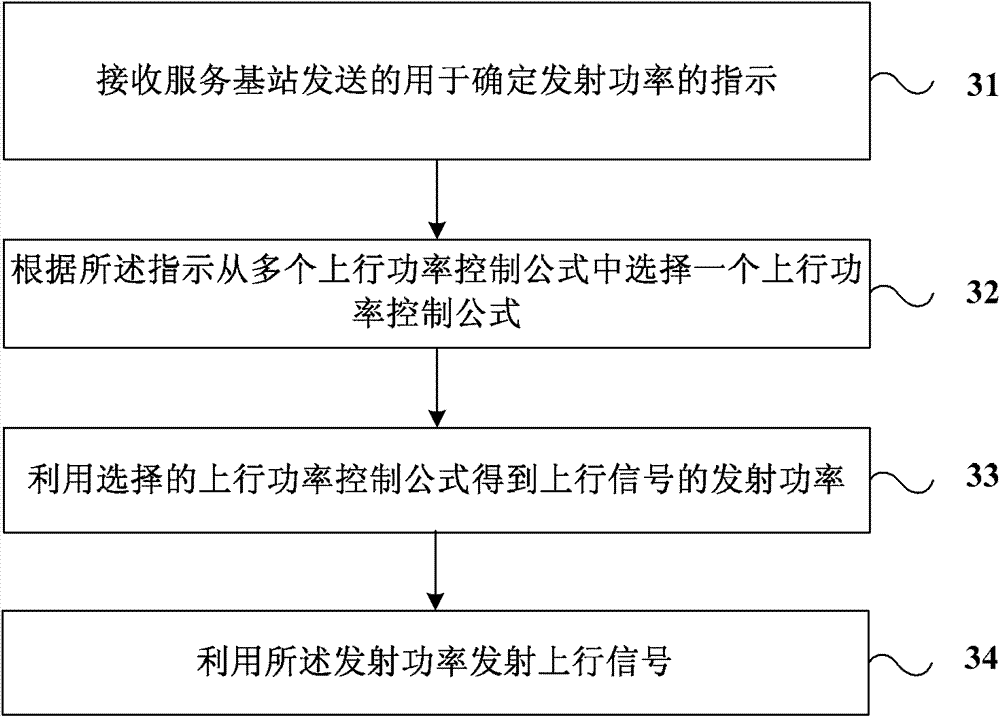

Terminal and method for terminal to transmit uplink signals

ActiveCN102958146AIncrease flexibilityImprove signal transmission performancePower managementSynchronisation arrangementPower controlUplink power control

The invention relates to a terminal and a method for the terminal to transmit uplink signals. The method includes receiving an instruction which is transmitted by a serving base station and is used for determining transmission power; selecting an uplink power control formula from multiple uplink power control formulas according to the instruction; obtaining the transmission power of an uplink signal by the selected uplink power control formula; and transmitting the unlink signal by the transmission power. The uplink power control formula is selected from the multiple uplink power control formulas according to the instruction of the serving base station, so that the terminal can select the corresponding unlink power control formulas to determine the transmitted signals according to receiving modes, power control requirements under the current different receiving modes are met, the corresponding unlink power control formulas can also be used for different configuration parameters of acyclic SRSs (sounding reference signals), the proper transmission power is determined so as to transmit the unlink signals, and the unlink transmission power control flexibility and the signal transmission performance of the terminal are improved.

Owner:HUAWEI TECH CO LTD

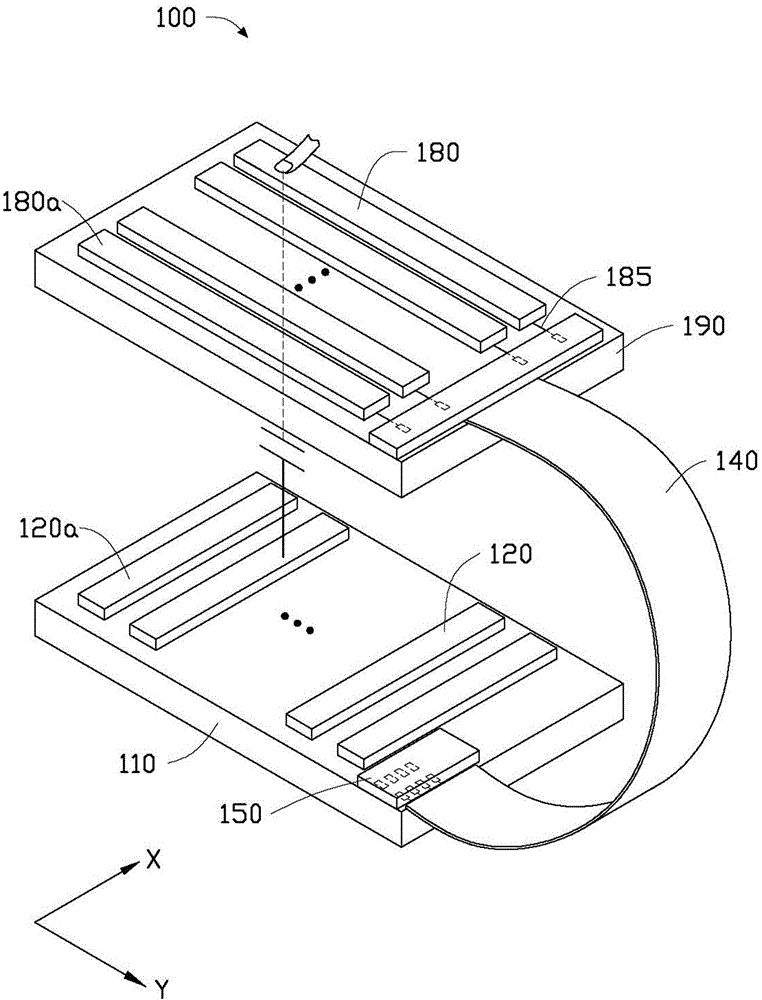

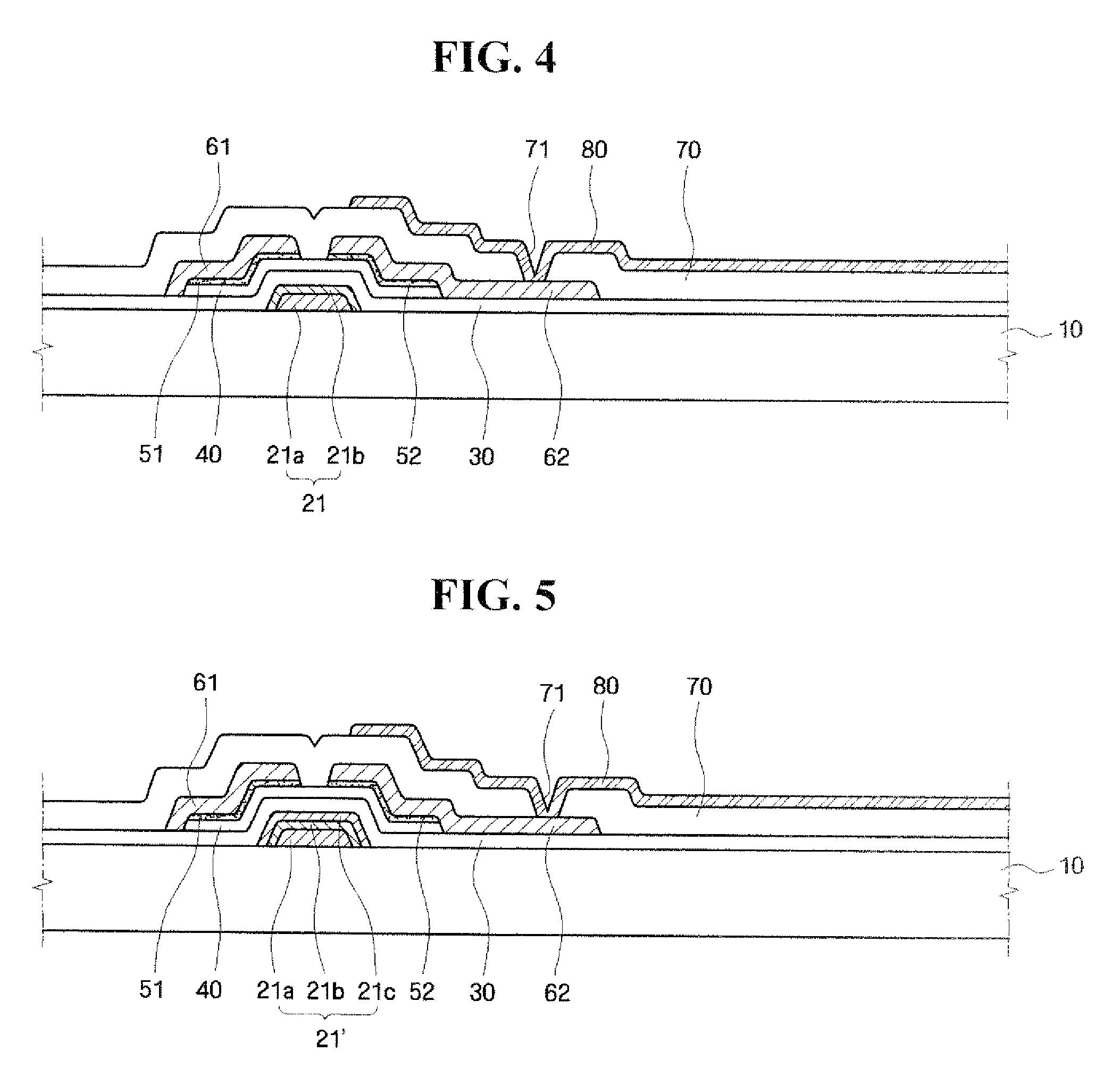

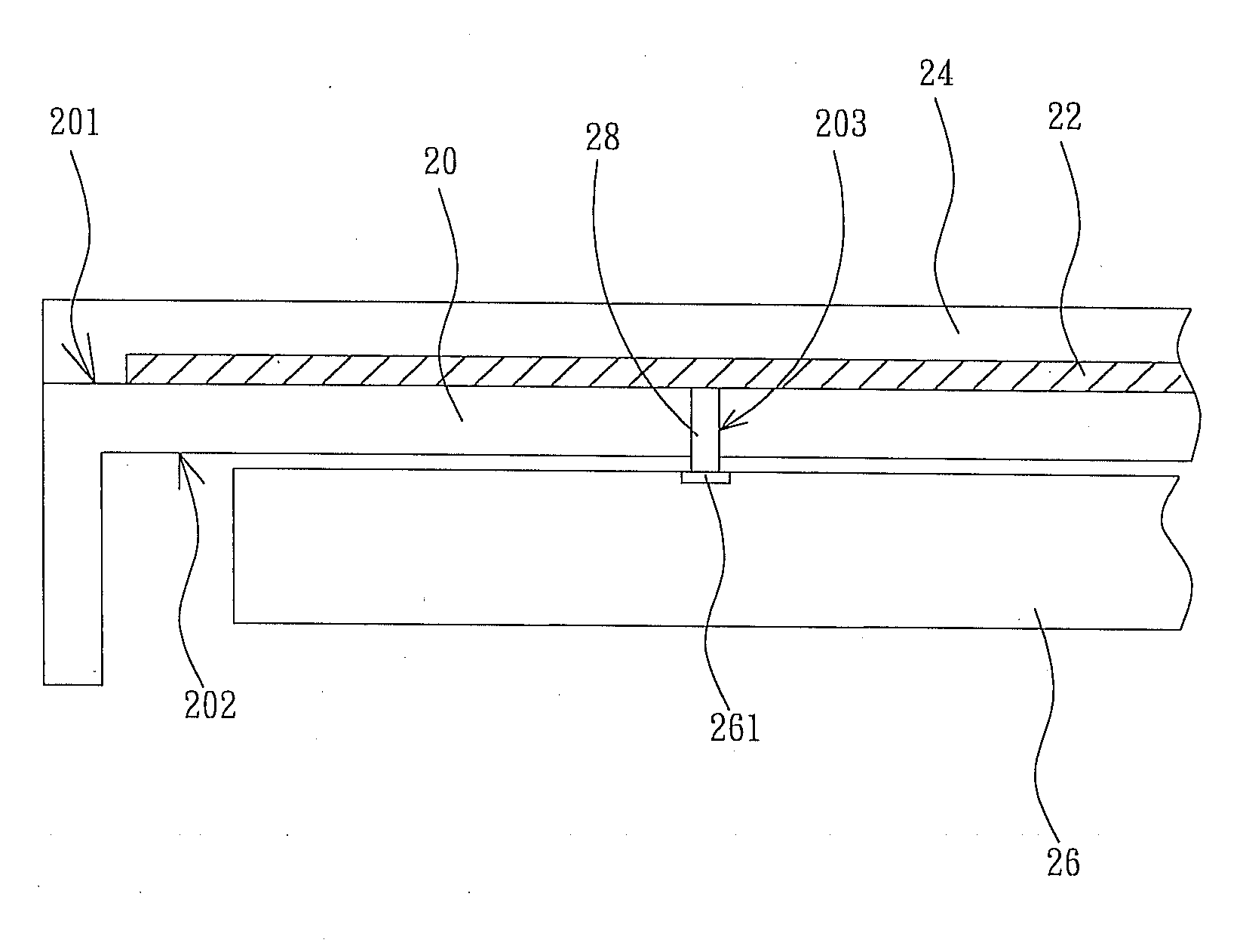

Touch display device

ActiveCN104571655AReduce coupling capacitanceImprove signal transmission performanceNon-linear opticsInput/output processes for data processingTouch SensesDisplay device

The invention relates to a touch display device. The touch display device comprises a first substrate and a second substrate which are oppositely arranged, first sensing electrodes and second sensing electrodes, wherein first pins transmit touch scanning signals, second pins transmit touch sensing signals, and the first substrate defines a touch display region and a non-touch display region; corresponding to the periphery of the non-touch display region, the first substrate is provided with the first pins, wires and the second pins; the first pins transmit the touch scanning signals and the second pins transmit the touch sensing signals; the wires are electrically connected with the corresponding sensing electrodes and the corresponding first pins, the second sensing electrodes are electrically connected with the corresponding second pins, the wires and the second pins are mutually insulated, a conductive layer is arranged at a part, close to the second pins, of the wires, and is located in a layer between the part, close to the second pins, of the wires and the second pins, and the conductive layer is grounded or is in direct electric signal connection with a constant potential. The touch display device is relatively high in touch precision.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

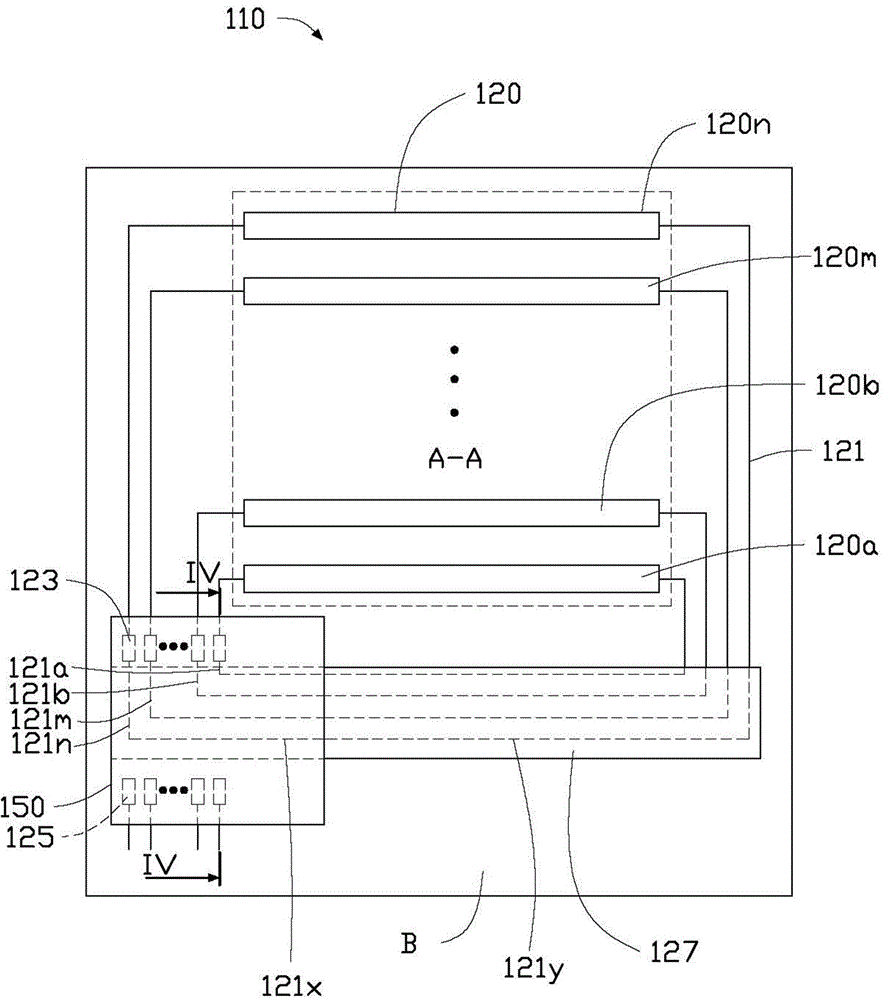

Touch pixel structure, touch pixel array substrate and touch display panel

ActiveUS20130155024A1Improve reliabilityImprove signal transmission performanceInput/output processes for data processingElectricityScan line

A touch pixel array substrate suitable for a touch display panel includes a first substrate, scan lines, data lines, signal-control lines, read-out lines, voltage-shielding lines, active devices, pixel electrodes, and photo-sensing units. The scan lines, the data lines, the signal-control lines, the read-out lines, and the voltage-shielding lines are located on the first substrate. Each of the read-out lines is located between two adjacent data lines. Each of the voltage-shielding lines is located between one of the read-out lines and one of the data lines. Both sides of each of the read-out lines are adjacent to two voltage-shielding lines. The photo-sensing units are located on the first substrate and electrically connected to the scan lines, the signal-control lines, and the read-out lines correspondingly. A touch display panel and a touch pixel structure are also provided.

Owner:AU OPTRONICS CORP

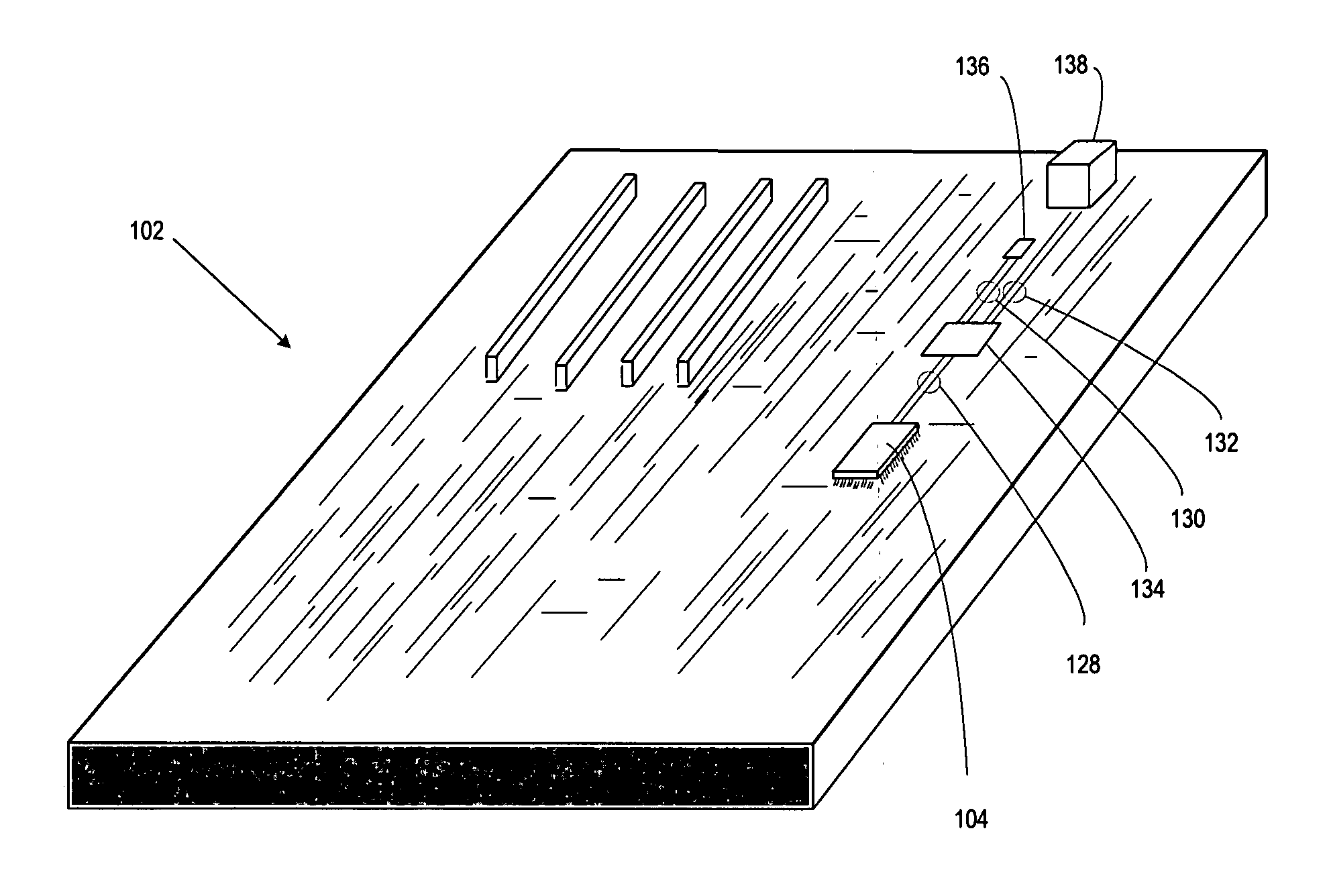

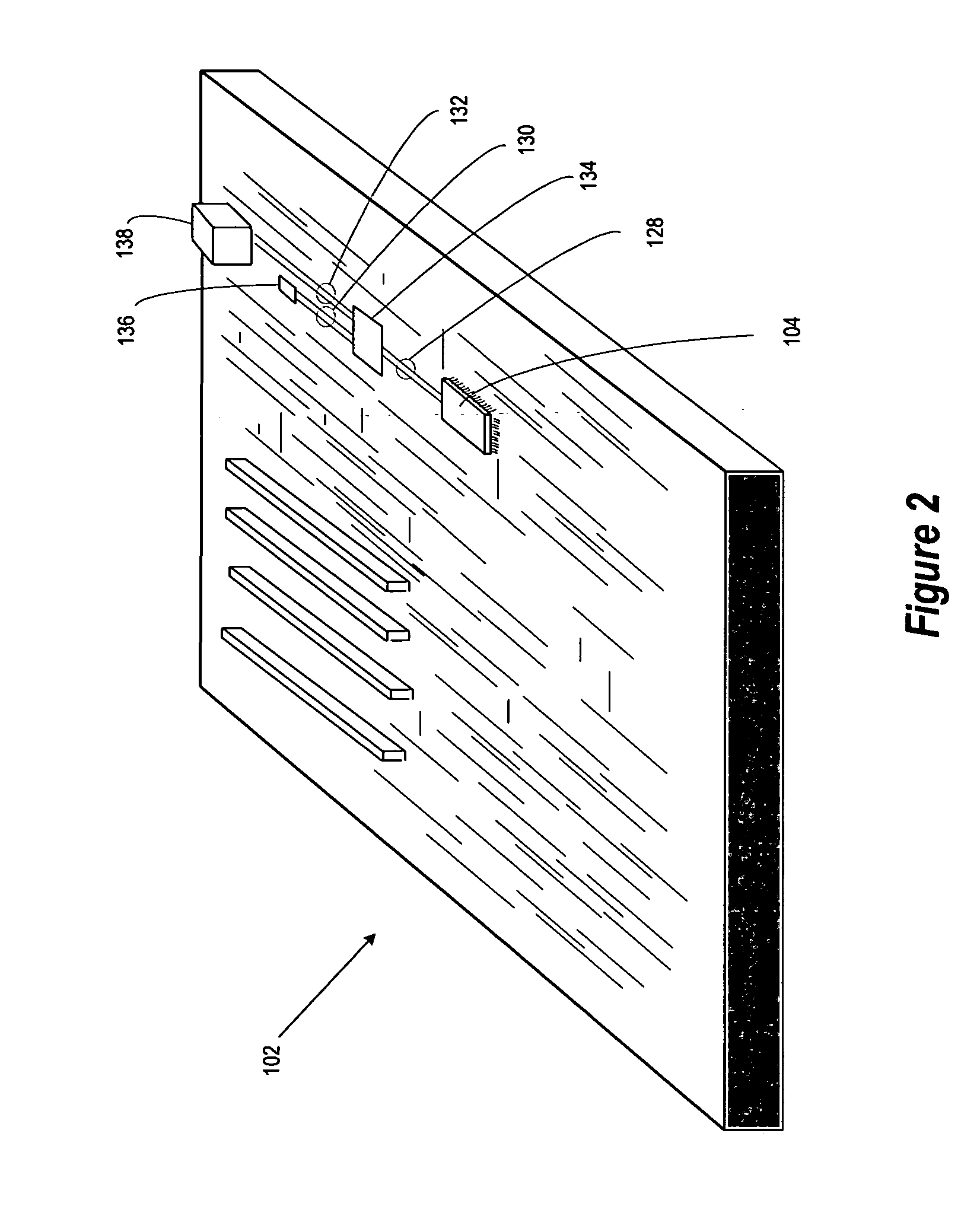

Matched-impedance high-bandwidth configuration jumper

ActiveUS20060272852A1Improve signal transmission performanceAvoid Impedance DiscontinuitiesMultiple-port networksPrinted circuit aspectsHigh bandwidthElectrical conductor

The present invention provides a matched-impedance jumper that is operable to connect pairs of differential signal conductors to provide improved signal transmission characteristics. In an embodiment of the invention, the impedance-matched jumper is used to connect a first pair of differential signal conductors to a selected pair of differential signal conductors selected from a plurality of second pairs of differential signal conductors. The impedance-matched jumper comprises a plurality of input pins that are operable to connect with a plurality of connection pads on the first pair of differential signal conductors and a plurality of output pins operable to connect with a plurality of connection pads on the predetermined second pair of differential signal conductors. A plurality of internal conductors are operably connected to the input pins and the output pins to define a signal path therebetween. The signal path defined by the input pins, the output pins, and the internal conductors provides an impedance-matched passthrough for differential signals.

Owner:DELL PROD LP

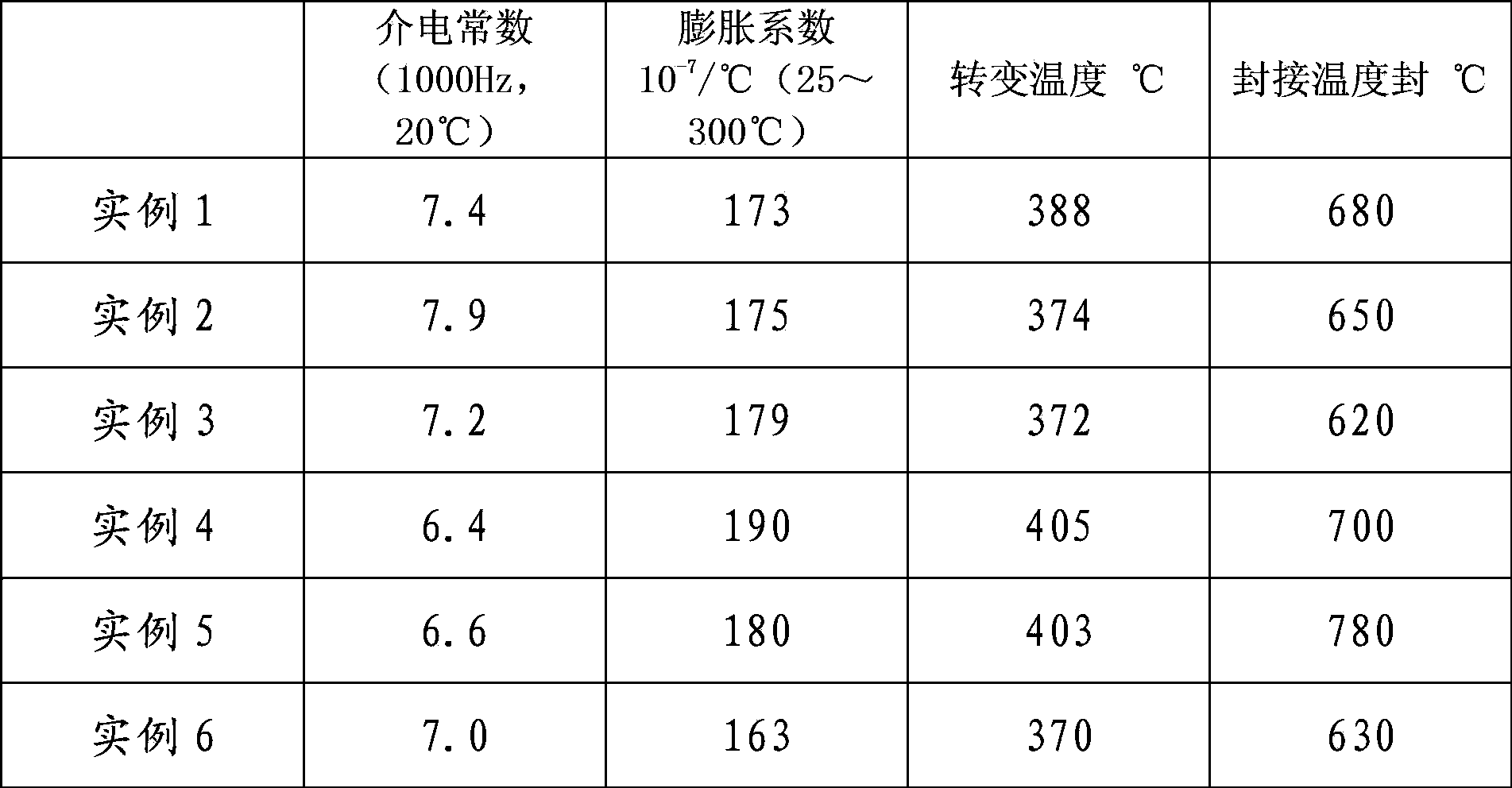

Preparation method and application of high expansion coefficient copper sealing glass powder

ActiveCN103880290AHigh expansion coefficientImprove mechanical propertiesCouplings bases/casesThermal insulationHigh resistivity

The invention relates to a preparation method and an application of high expansion coefficient copper sealing glass powder, wherein the technical difficult problems of high cost, long production period, high use environment requirements and the like of the existing copper seal electrical connector are solved. The high expansion coefficient copper sealing glass powder adopts a phosphate glass system and comprises the following components by mole: 45-65% of P205, 10-15% of B203, 4-15% of Al2O3, 5-20% of Na2O, 8-22% of K2O, and 0-12% of PbO+BaO+CaO+MgO. The application comprises: carrying out mixing, heating, stirring, molding, drying and other steps on the glass powder and a paraffin thin sheet, assembling a sealing copper shell and a glass billet, placing on a graphite mold, placing into a nitrogen atmosphere furnace or vacuum furnace, carrying out thermal insulation for 30 min at a temperature of 600-780 DEG C, and cooling to a room temperature to obtain the electrical connector with characteristics of high temperature resistance, high resistivity and high air-tightness. According to the present invention, the glass powder can match to the copper alloy shell expansion coefficient, the produced copper alloy electrical connector can achieve good electrical property, the preparation method is suitable for industrial production, and the economic benefits can be increased.

Owner:LIAONING SILICATE RES INST

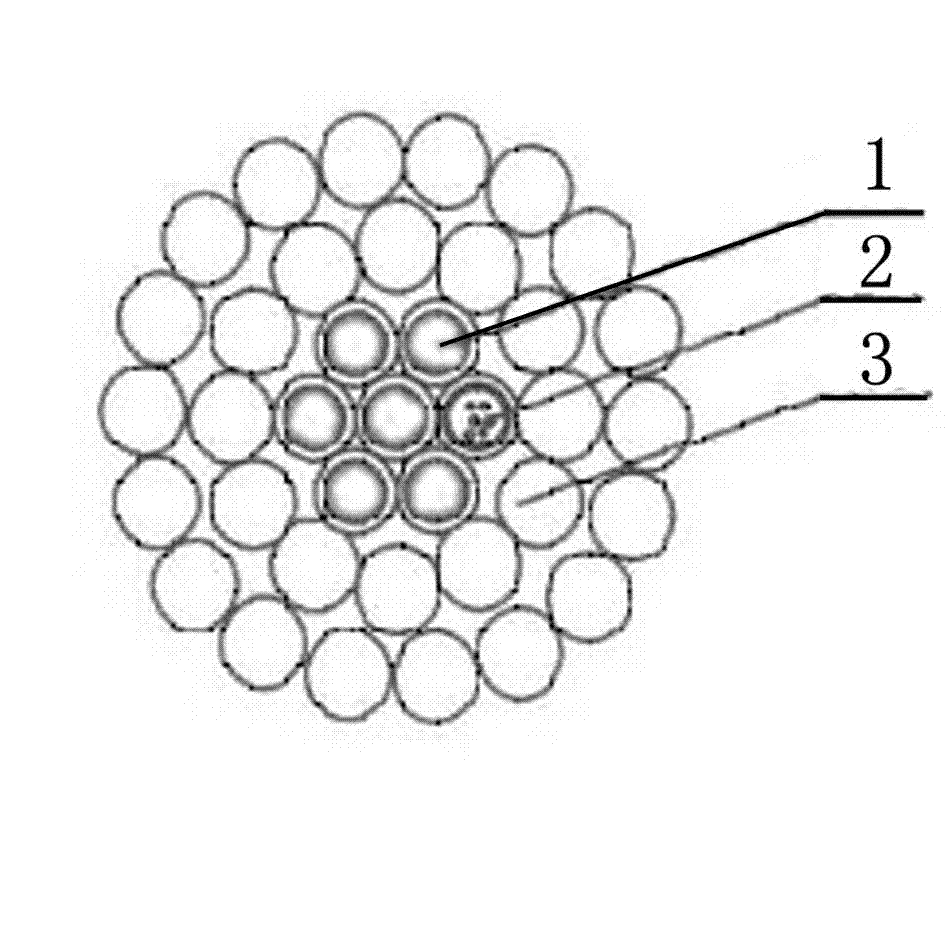

Large-section optical fiber composite overhead phase line and manufacturing method thereof

InactiveCN102930934AImprove tensile propertiesImprove powerPower cablesFibre mechanical structuresEngineeringTower

The invention relates to an optical cable and a manufacturing method, and the high-voltage optical cable is suitable for long-distance, larger-capacity and low-loss long-distance power transmission, in particular to a large-section optical fiber composite overhead phase line and a manufacturing method thereof. The large-section optical fiber composite overhead phase line comprises an optical fiber unit, aluminium-covered steel wires and aluminium wires, the large-section optical fiber composite overhead phase line is at least five layers, the center line of the first layer is one aluminium-covered steel wire, the optical fiber unit is twisted with a plurality of aluminium-covered steel wires to form the second layer, and then the outer layer is twisted with a plurality of aluminium wires to form an aluminium twisting layer. The manufacturing method of the large-section optical fiber composite overhead phase line includes two processes of optical fiber manufacture and cabling manufacture. The large-section optical fiber composite overhead phase line is strong in tension resistant performance, is suitable for a mountainous area and the like which have high requirements for tower distances and sag, and has doubles functions of phase cable power transmission and optical fiber signal transmission. In addition, the large-section optical fiber composite overhead phase line is suitable for direct current based deicing technique, in an ice rain prevalent area, once a conductive wire is covered by ice rain, and the direct current based deicing technique can be used to enable the large-section optical fiber composite overhead phase line to be powered with direct current.

Owner:ZHONGTIAN ELECTRIC POWER OPTICAL CABLES CO LTD

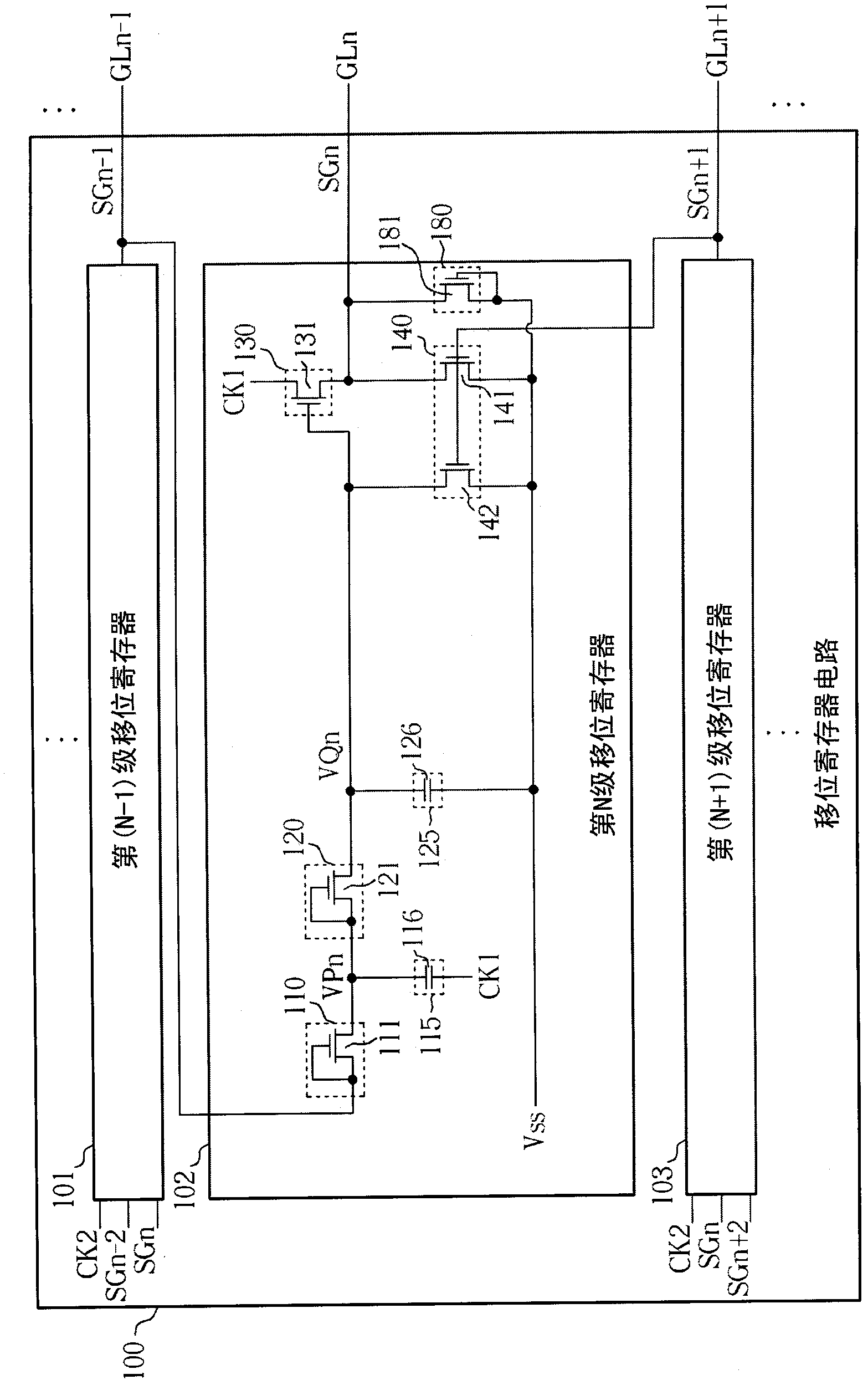

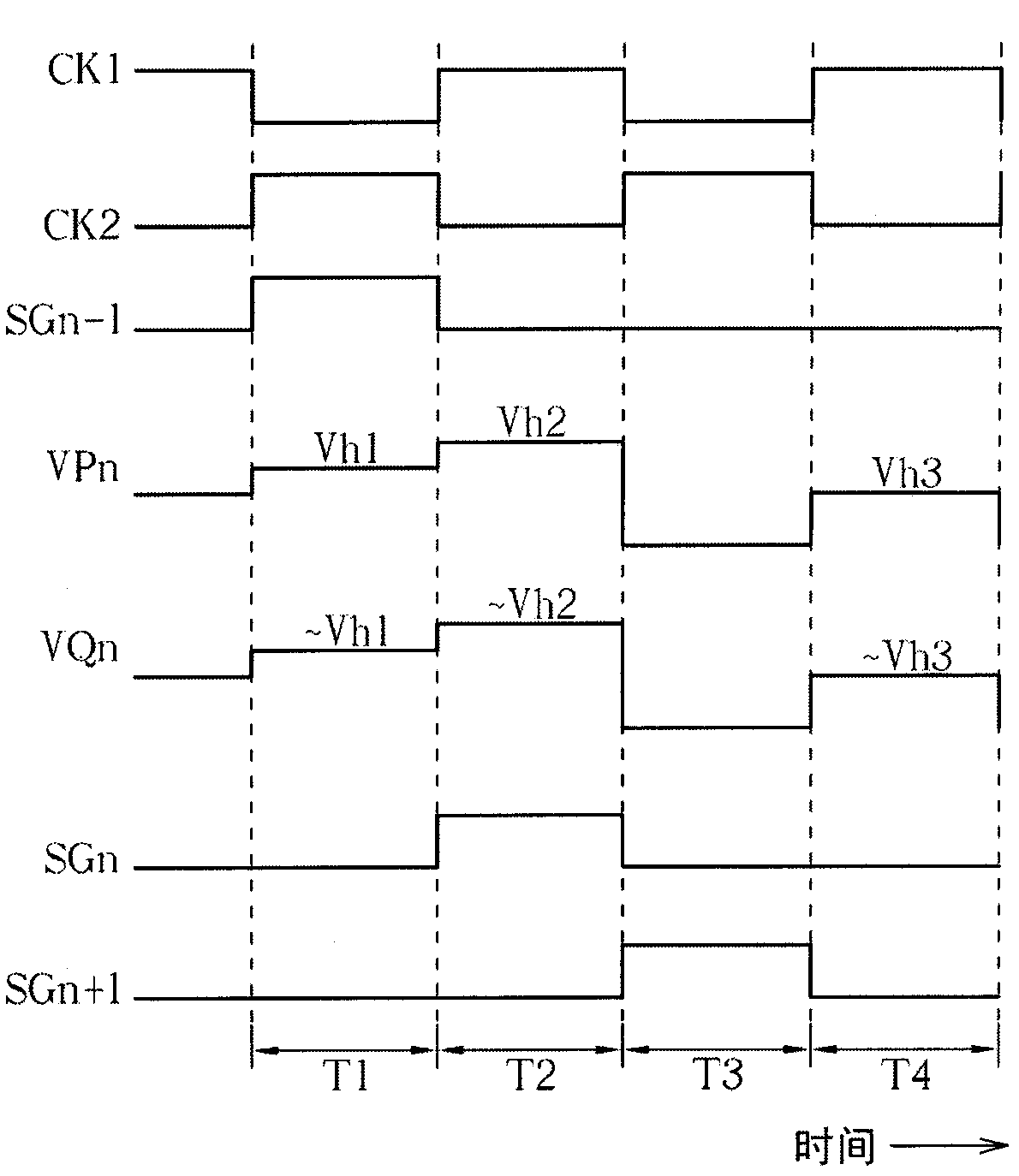

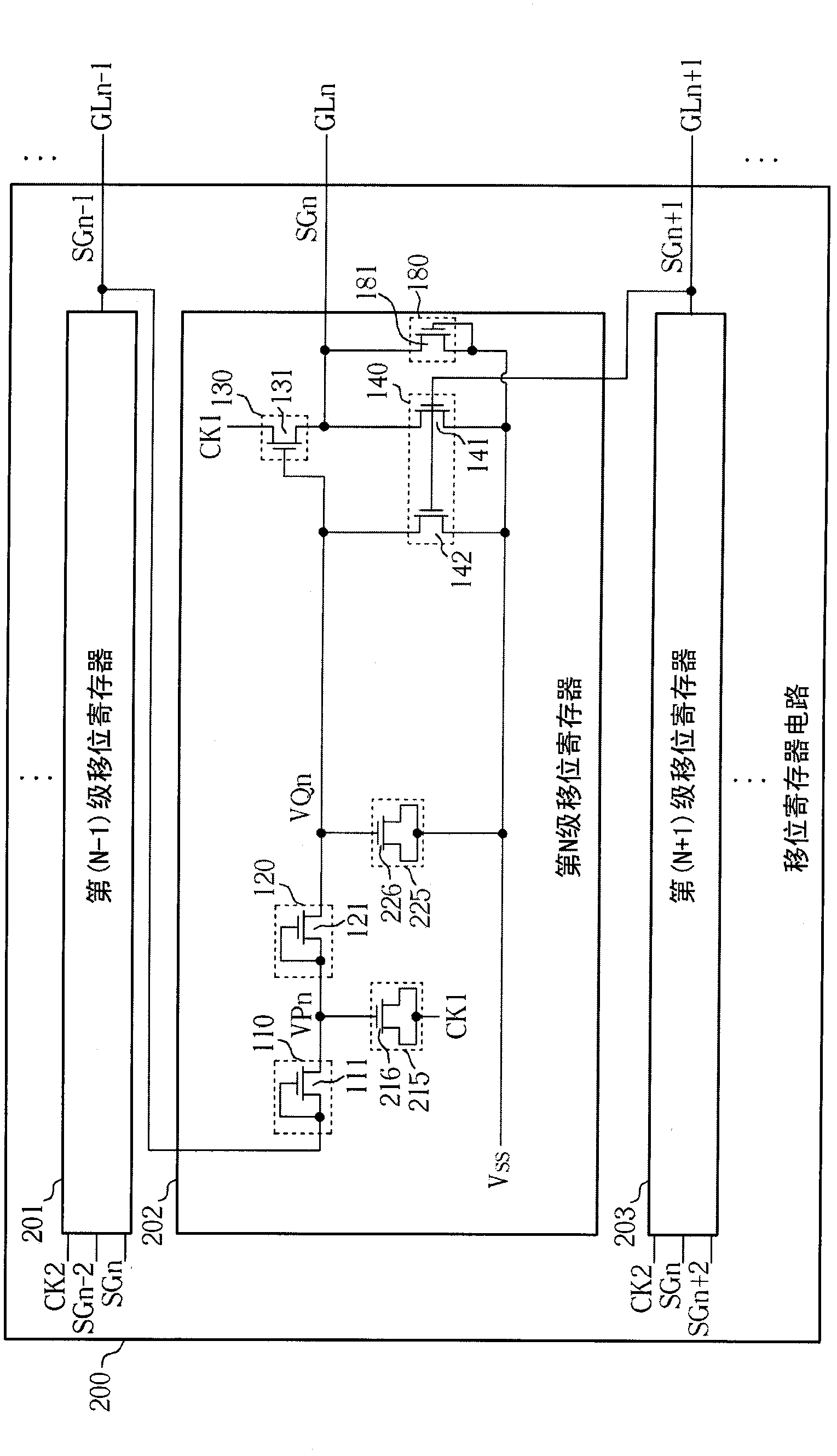

Shift register circuit

InactiveCN102426817AImprove driving abilityImprove signal transmission performanceStatic indicating devicesShift registerVoltage

The invention discloses a shift register circuit comprising multi-stage shift registers for providing a plurality of grid signals. Each stage shift register comprises an input unit, a voltage increasing unit, a unidirectional conducting unit, a driving unit and a pull-down unit, wherein the input unit outputs a front drive control voltage according to a first input signal, the voltage increasing unit increases the front drive control voltage as the increase of a system clock, the unidirectional conducting unit executes unidirectional conduction for the front drive control voltage to output drive control voltage, the driving unit outputs a grid signal based on the drive control voltage and the system clock, and the pull-down unit pulls down the corresponding grid signal, drive control voltage and the front drive control voltage according to a second input signal.

Owner:AU OPTRONICS CORP

HDMI connector assembly

InactiveUS20070111564A1Improve solder qualityHigh yieldCoupling device detailsPrinted circuitsElectrical conductorHDMI

A HDMI connector assembly includes an insulative body including a body member including a central channel therethrough and parallel grooves on top and bottom of the channel, and a plate including two rows of parallel terminal cavities aligned with the grooves; an insulative seat provided in the channel and including a rear member including parallel furrows on its top and bottom, and a front member including parallel depressions; two rows of conductors provided in the depressions, the furrows, the grooves, and the terminal cavities, each conductor including a front electrical terminal and a rear solder member wherein the solder members of one row and the solder members of the other row are bent in opposite directions; and a housing for receiving the insulative body. The invention has advantages of increased quality and signal transmission performance, and causing no pollution.

Owner:YING WAN FA

Optical transceiver apparatus and wavelength division multiplexing passive optical network system

InactiveUS8971709B2Improve signal transmission performanceImprove signal qualityWavelength-division multiplex systemsElectromagnetic transmittersTransceiverInjection locking

Owner:HUAWEI TECH CO LTD

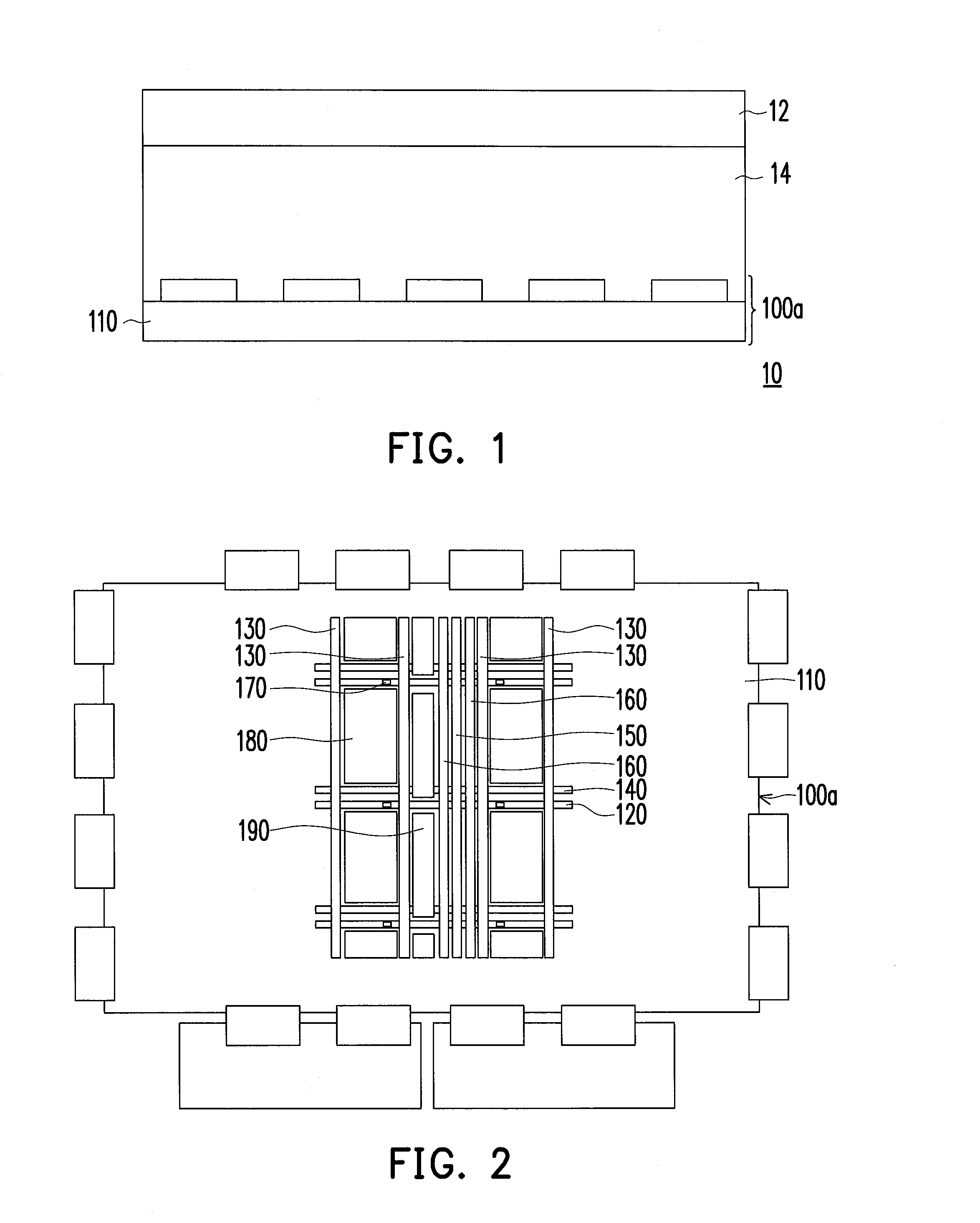

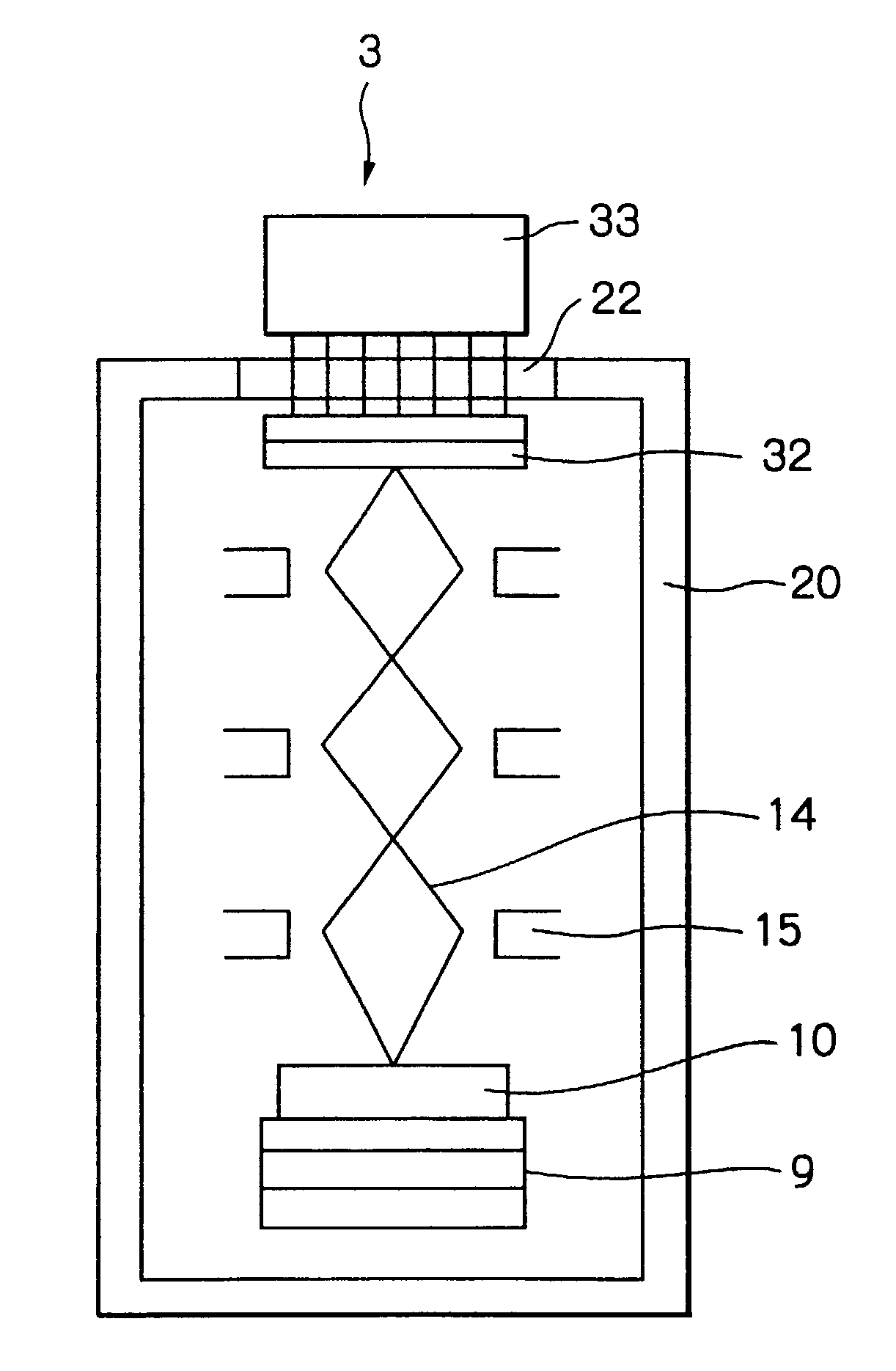

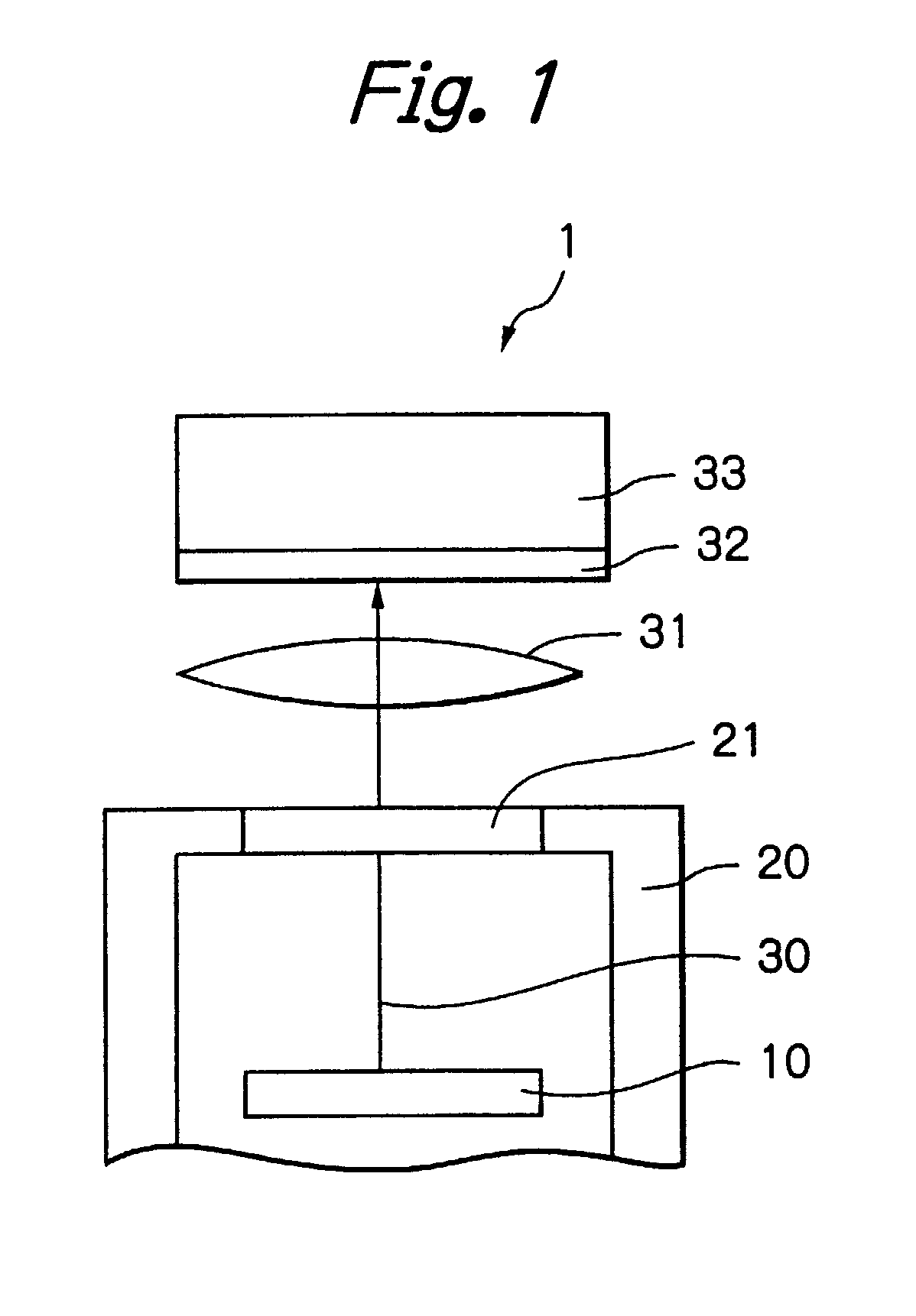

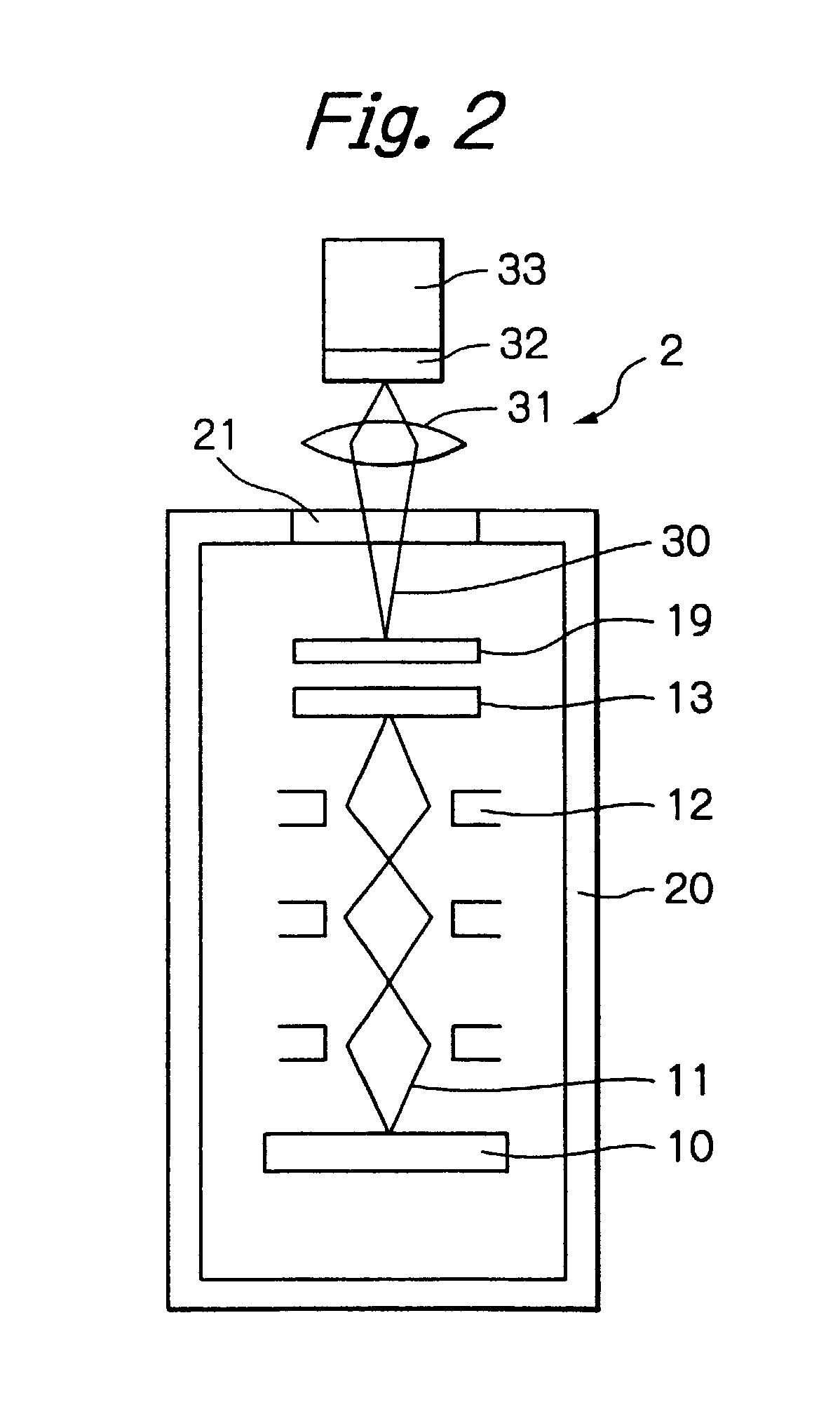

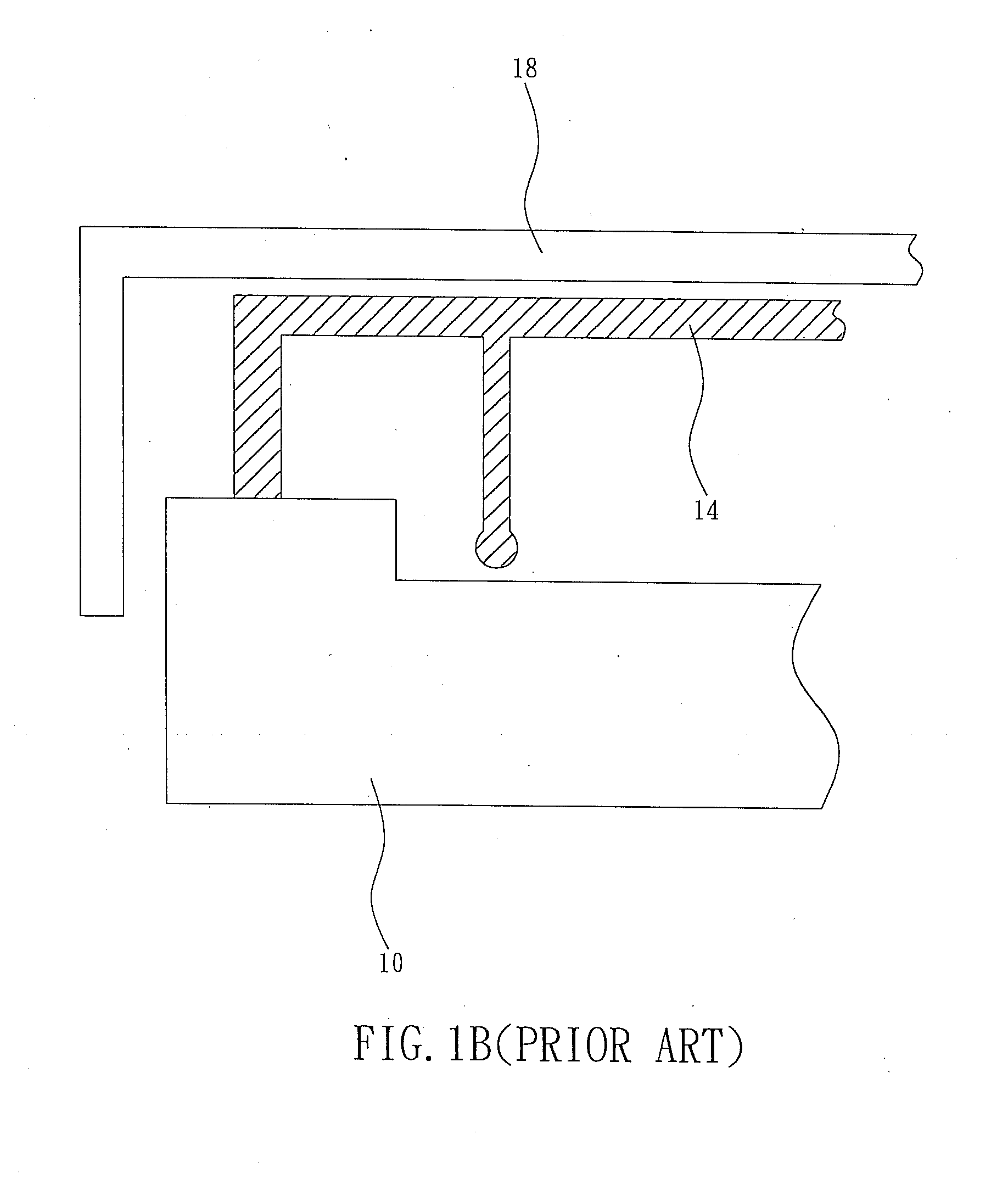

Detecting apparatus and device manufacturing method

InactiveUS7075072B2Low costHigh positioning accuracyMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementSecondary radiationIrradiation

A detecting apparatus for detecting a fine geometry on a surface of a sample, wherein an irradiation beam is irradiated against the sample placed in a different environment different from an atmosphere and a secondary radiation emanated from the sample is detected by a sensor, and wherein the sensor is disposed at an inside of the different environment, a processing device to process detection signals from the sensor is disposed at an outside of the different environment, and a transmission means transmits detection signals from the sensor to the processing device.

Owner:EBARA CORP +1

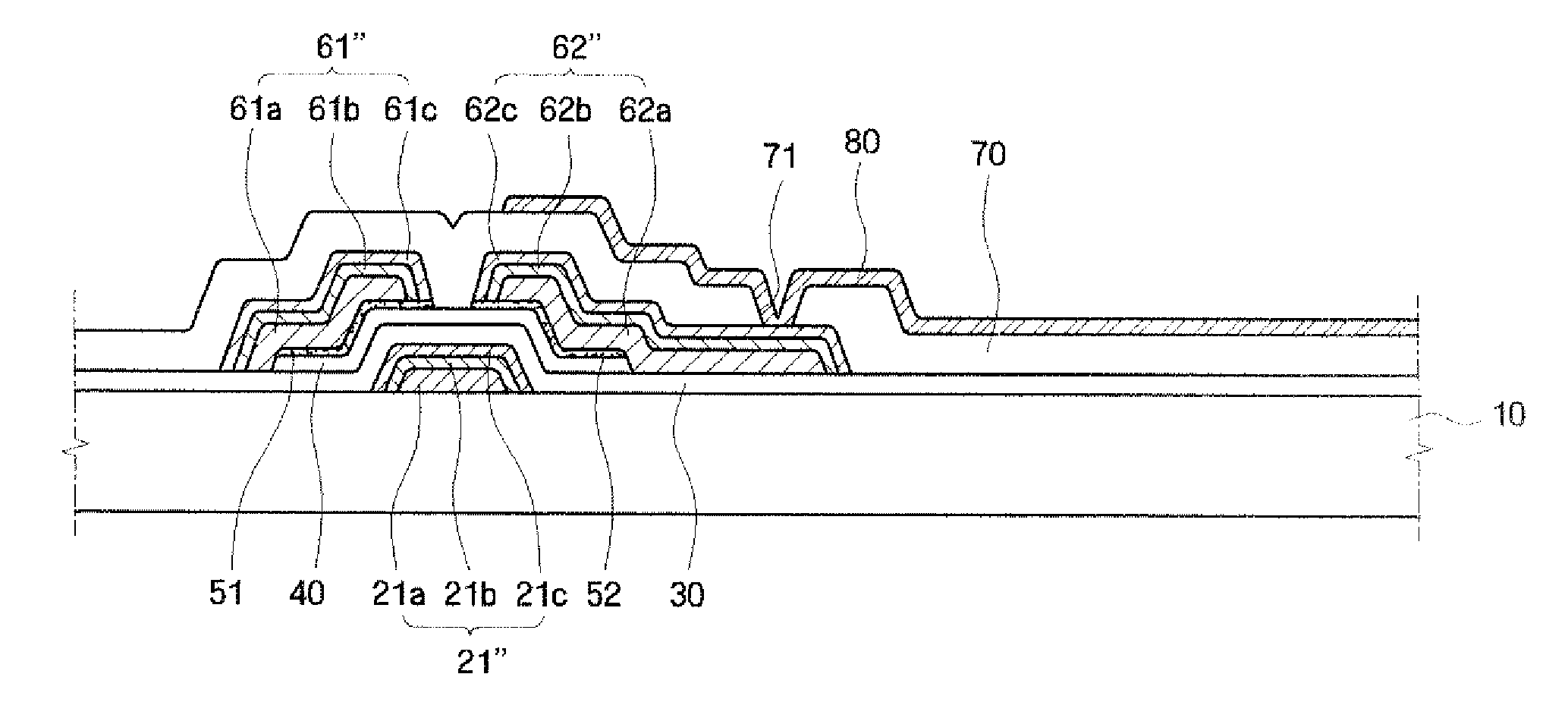

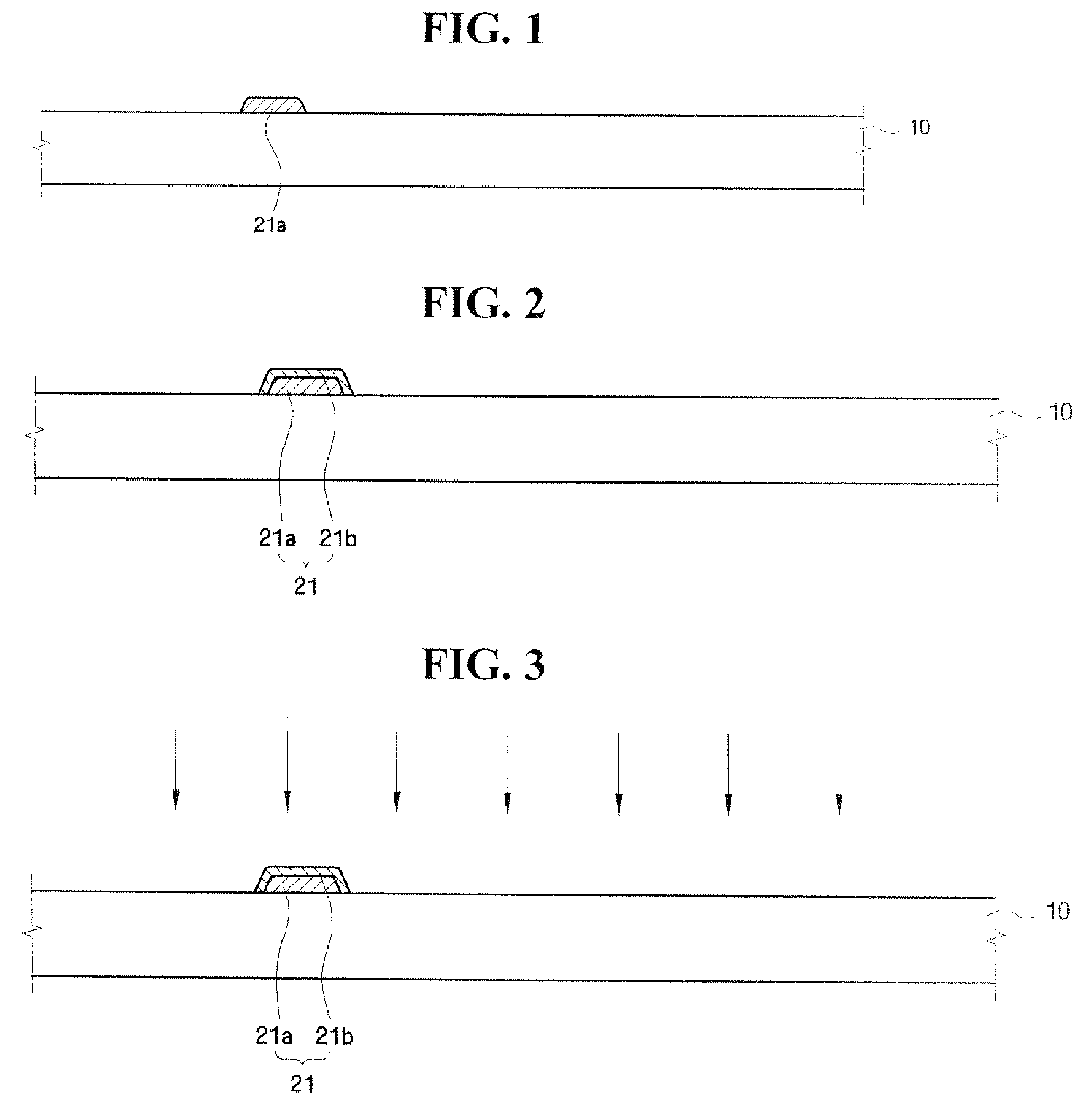

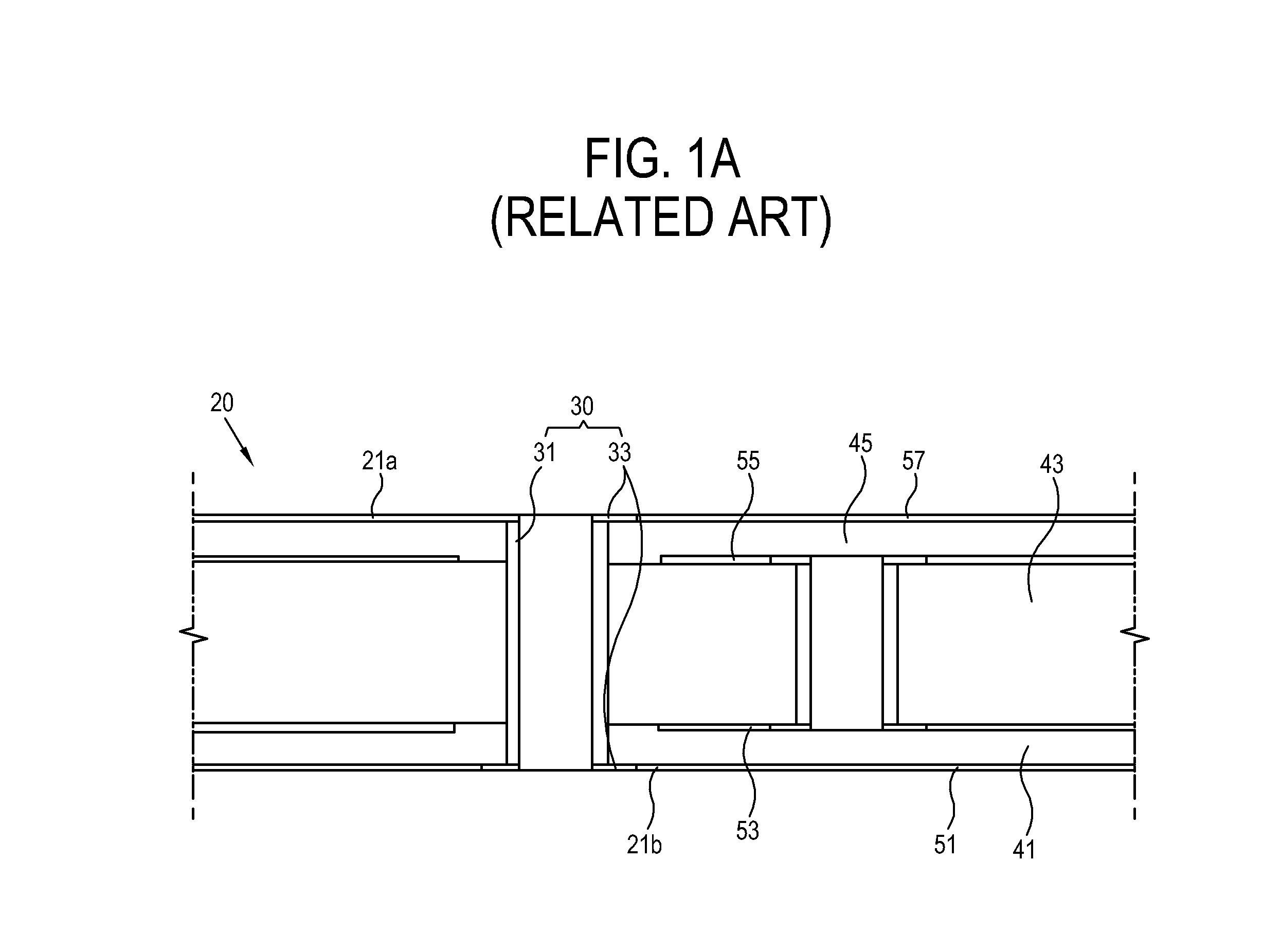

Thin film transistor substrate and method of fabricating the same

InactiveUS20070236641A1Improve signal transmission performanceNon-linear opticsSemiconductor devicesElectroless platingTransistor

A method of fabricating a thin film transistor (TFT) substrate includes forming a gate line and a data line on an insulating substrate. The data line crosses the gate line and is insulated from the gate line. The formation of the gate line, the data line, or both the gate line and the data line includes forming a low-resistive conductive pattern on a base pattern using an electroless plating method.

Owner:SAMSUNG DISPLAY CO LTD

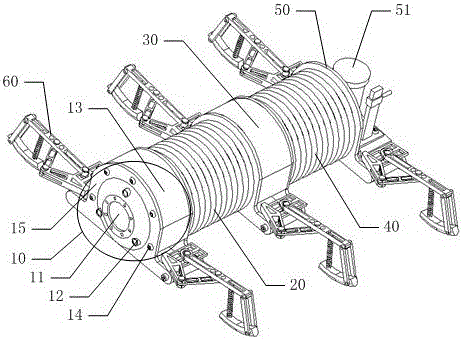

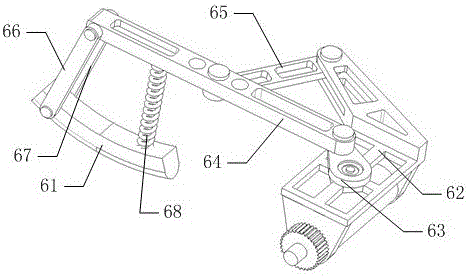

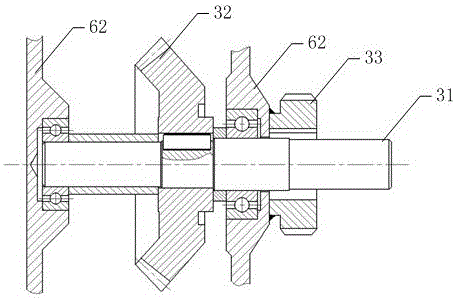

Pipeline detection robot

The invention discloses a pipeline detection robot. The pipeline detection robot comprises a robot head, a robot middle portion connected with the robot head through a first elastic connecting body and a robot tail connected with the robot middle portion through a second elastic connecting body. A bionic leg for traveling is arranged on each of the left sides and the right sides of the robot head, the robot middle portion and the robot tail. A camera for camera-shooting and multiple ultrasonic sensors for detecting obstacles are arranged on the robot head. A circuit control board for controlling the traveling gait of the robot and receiving detection signals is arranged on the robot middle portion. A winder for take-up and pay-off of cables is arranged at the robot tail. According to the pipeline detection robot, a body of the pipeline detection robot has certain scalability and flexibility, meanwhile has flexible gait planning capability and can adapt to the application needs of cornering, crawling, obstacle avoidance and detection in different pipeline environments; and due to the fact that detection signal transmission is stable and reliable, the pipeline failure detection efficiency of the robot is higher.

Owner:FOSHAN UNIVERSITY

Wireless communication device

InactiveUS20090115669A1Improve performanceUse minimizedAntenna supports/mountingsProtective material radiating elementsEngineeringCommunication device

A wireless communication device includes a housing and an antenna unit. The antenna unit is disposed on the outer or inner surface of the housing. A protective layer is optionally disposed to cover the outer surface of the antenna unit and, even more, at least a portion of the housing. Thus, the antenna unit separated from the circuit board does not occupy the layout region of the circuit board, so that the layout region of the circuit board can be used for other purposes. Moreover, the antenna unit formed on the housing can enhance the performance of the wireless communication device for transceiving signals.

Owner:DELTA ELECTRONICS INC

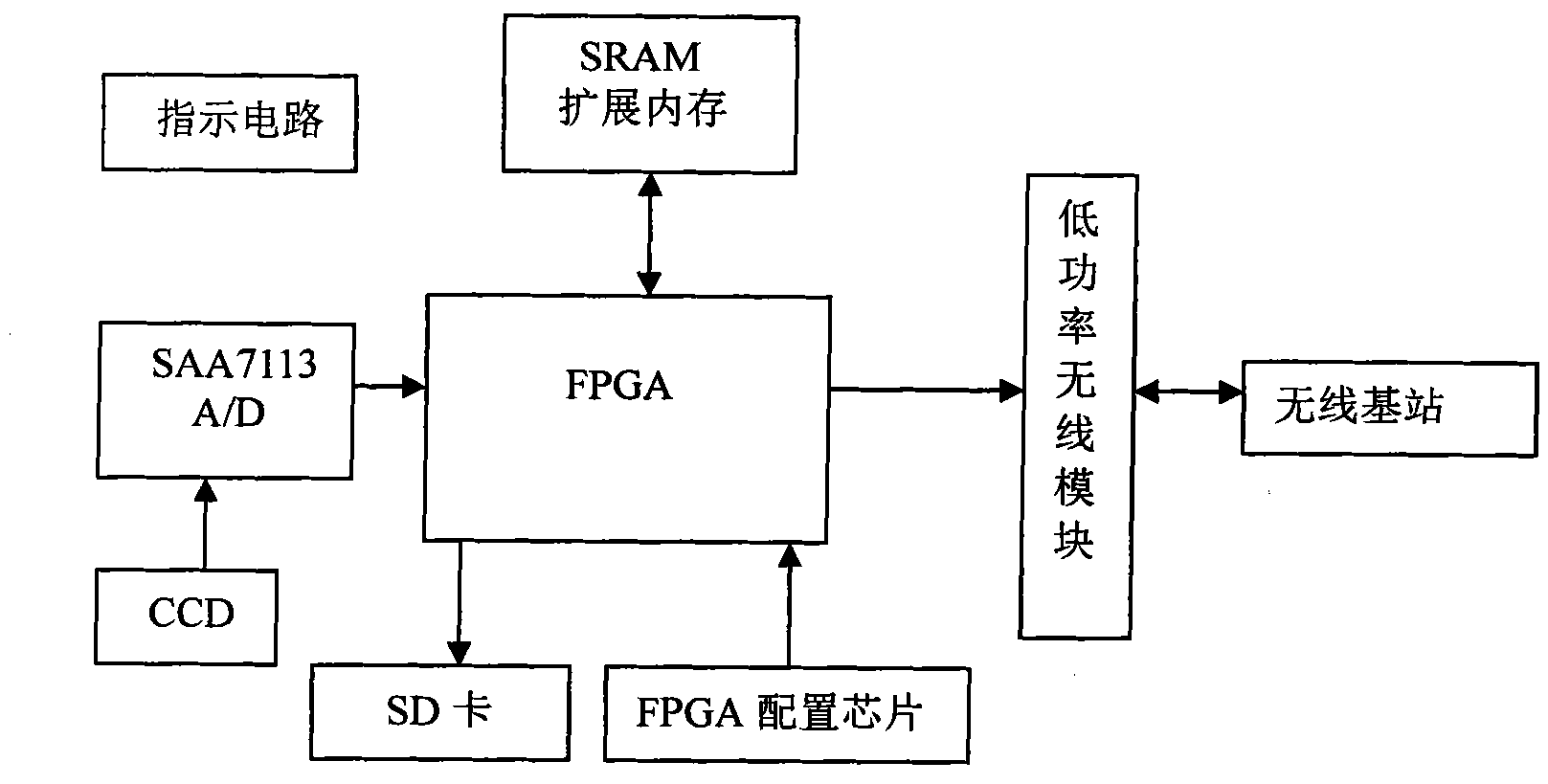

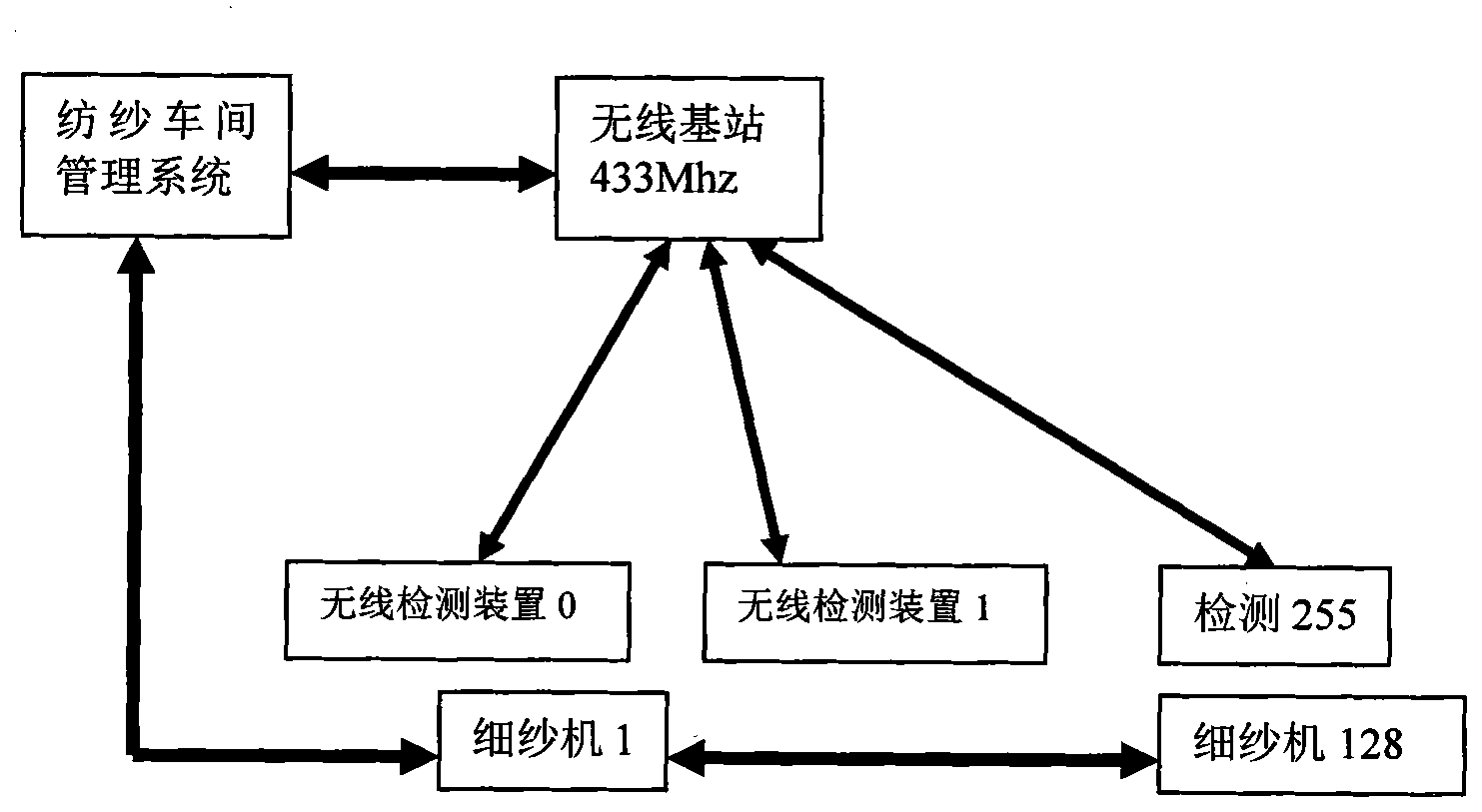

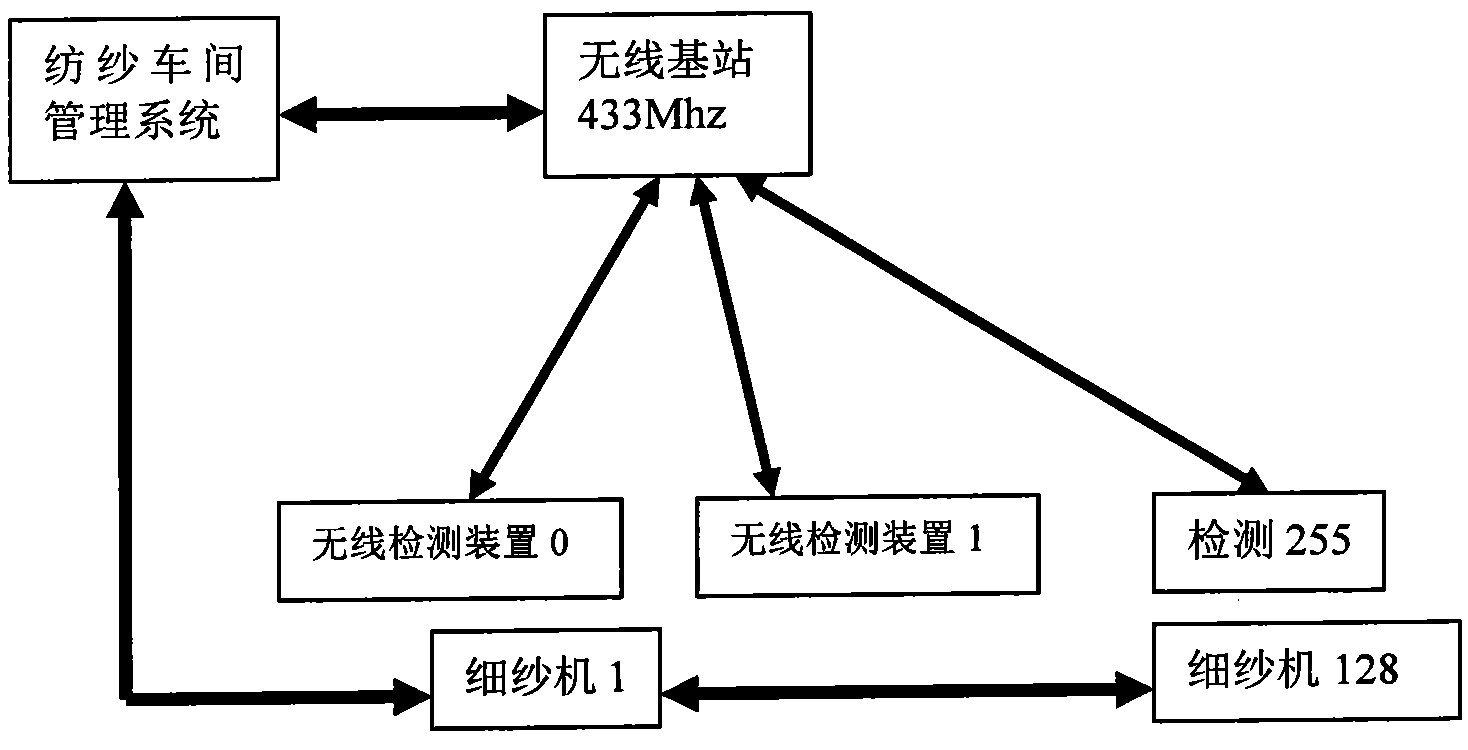

Wireless management system for yarn breakage detection of spinning frame and management method thereof

The invention provides a wireless management system for yarn breakage detection of a spinning frame and a management method thereof, which save a lot of cables and avoid occurrence of accidents. The wireless management system for yarn breakage detection of the spinning frame comprises a yarn breakage detector, a wireless module located on the yarn breakage detector, a battery located on the yarn breakage detector and used for supplying power for the yarn breakage detector and the wireless module, and a wireless base station in wireless connection with the wireless module. The wireless base station is connected with a spinning management system. The wireless management system for yarn breakage detection of the spinning frame and the management method thereof realize wireless transmission of yarn breakage detection result, save a lot of cables and effectively avoid fire accidents caused by leakage of electricity of the cables.

Owner:BEIJING JINGWEI TEXTILE MACHINERY NEW TECH

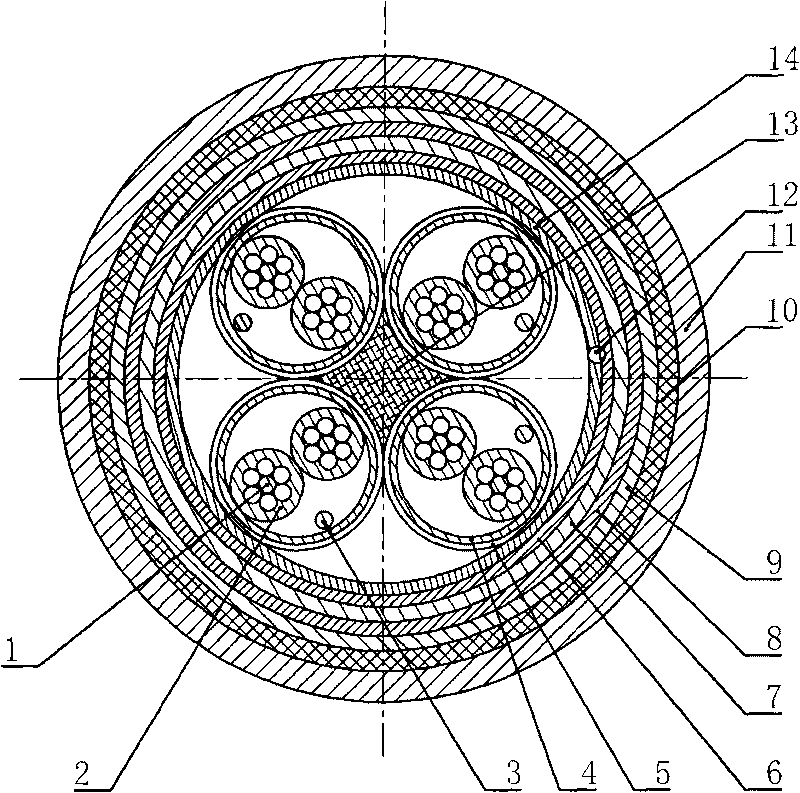

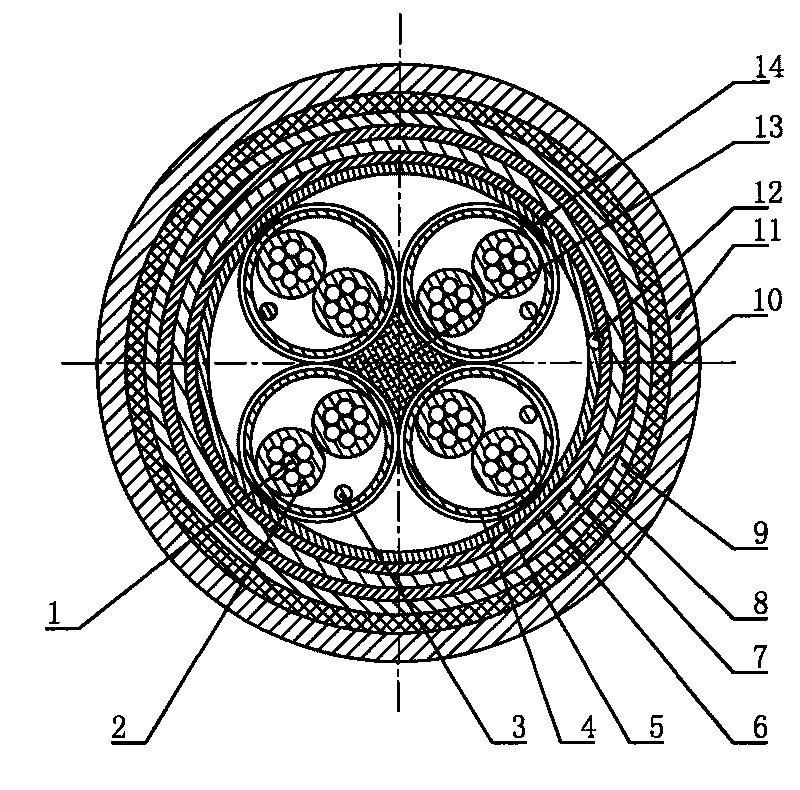

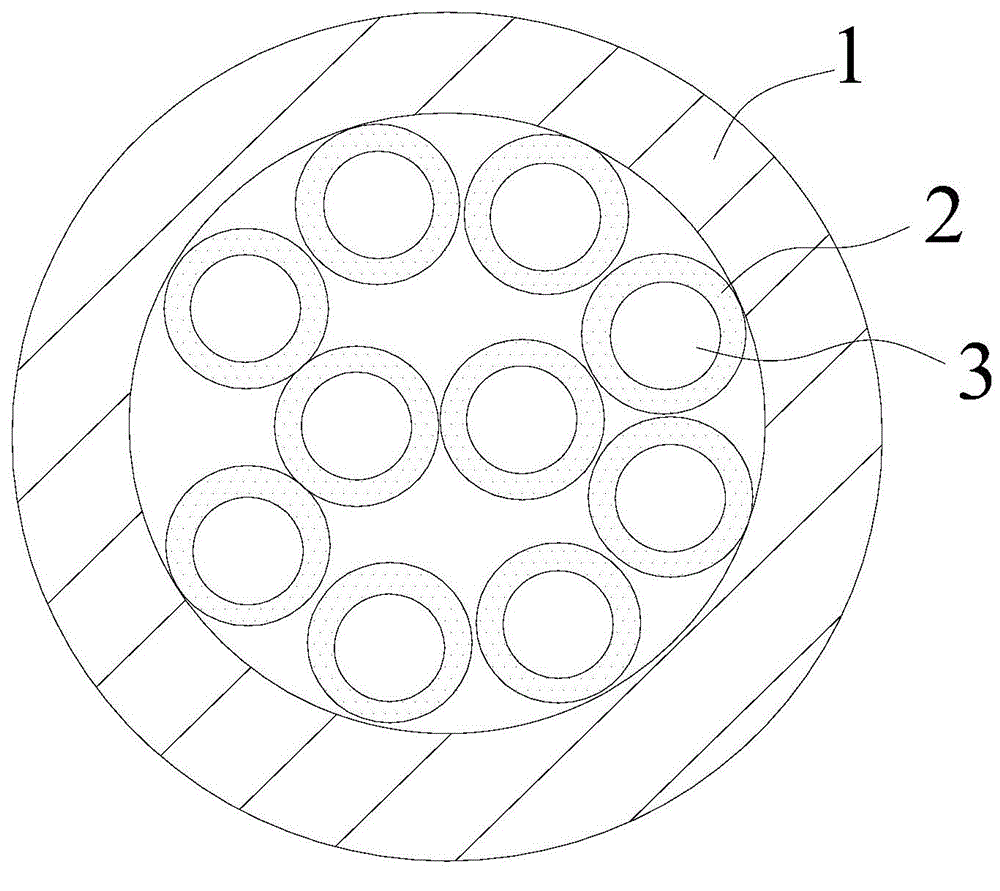

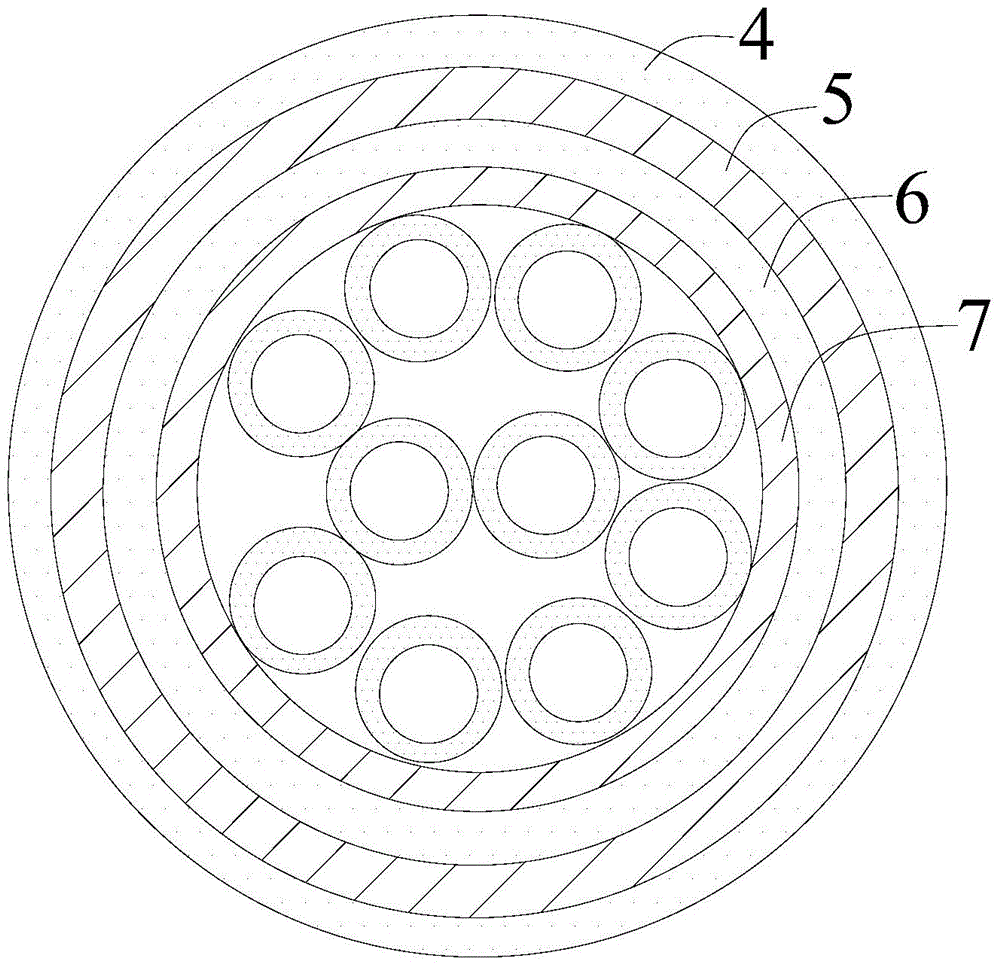

Cat7 soft cable for ocean engineering equipment local area networks and manufacturing method thereof

InactiveCN101707075AHigh strengthStable signal transmission performanceFlexible cablesCable/conductor manufactureElectrical conductorInterference resistance

The invention discloses a Cat7 soft cable for ocean engineering equipment local area networks and a manufacturing method thereof and belongs to the technical field of cables. The cable comprises four twisted pairs, wherein each twisted pair is twisted by two core conductors respectively with an insulating layer; each core conductor is twisted by seven equant tinned wires; a double-layer independent shielding layer is longitudinally wrapped outside each twisted pair, the inner side of the double-layer independent shielding layer is provided with an internal current introducing wire, and the periphery of the double-layer independent shielding layer is provided with an internal wrapping layer; and the four twisted pairs with the internal wrapping layers thereof are twisted into a cable core, an integral wrapping layer is arranged outside the cable core, an integral shielding layer is arranged on the integral wrapping layer, the inner side of the integral shielding layer is provided with an external current introducing wire, an external wrapping layer is arranged outside the integral shielding layer, a knitted shielding layer is arranged outside the external wrapping layer, an internal protective sheath is arranged outside the knitted shielding layer, an armored layer is arranged outside the internal protective sheath, and an external protective sheath is arranged outside the armored layer. The invention has the advantages of favorable insulating property, high strength, soft cable and interference resistance, and can be safely used as a signal transmission cable in construction of ocean engineering equipment local area networks.

Owner:JIANGSU YUANYANG DONGZE CABLE

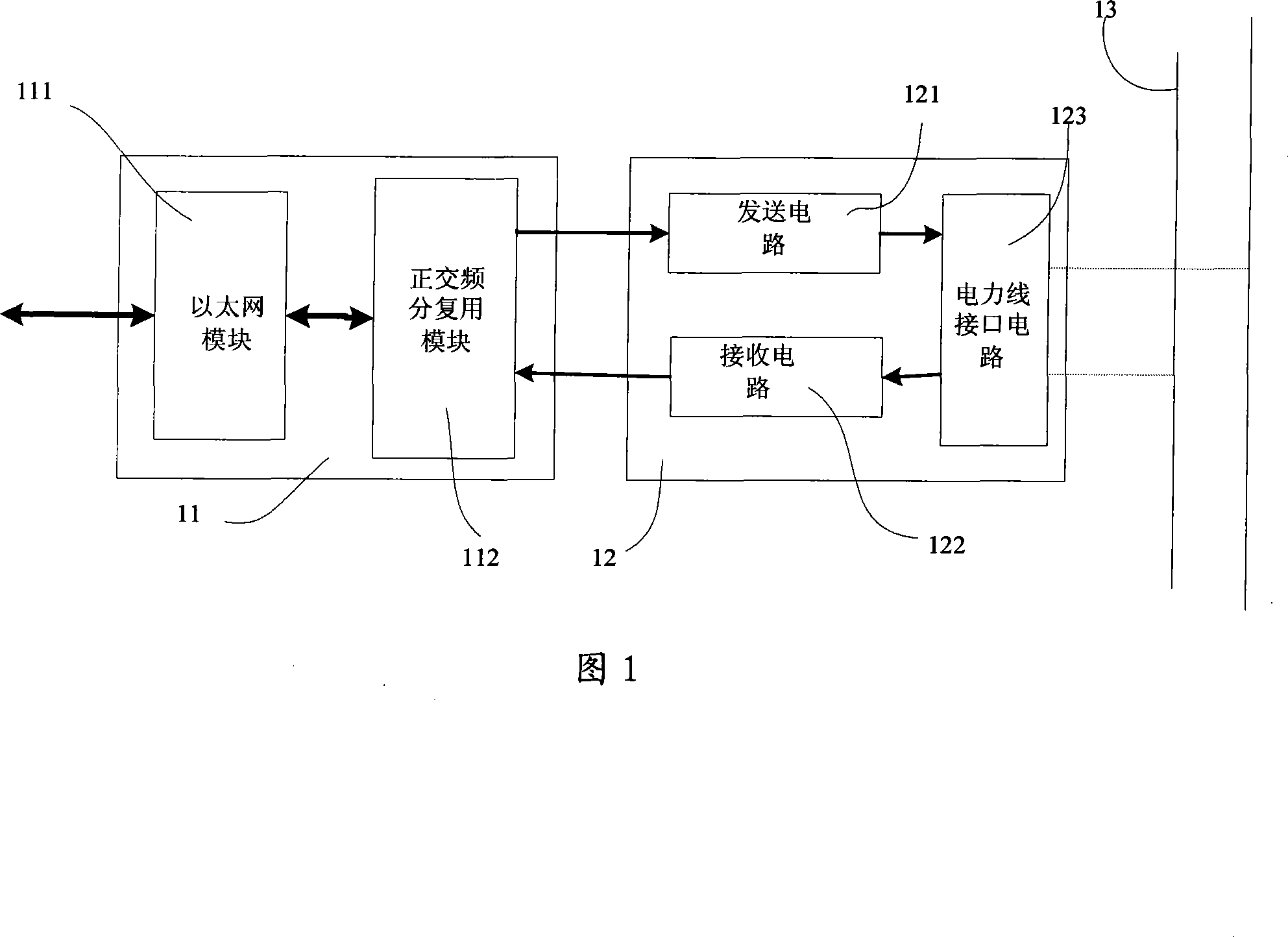

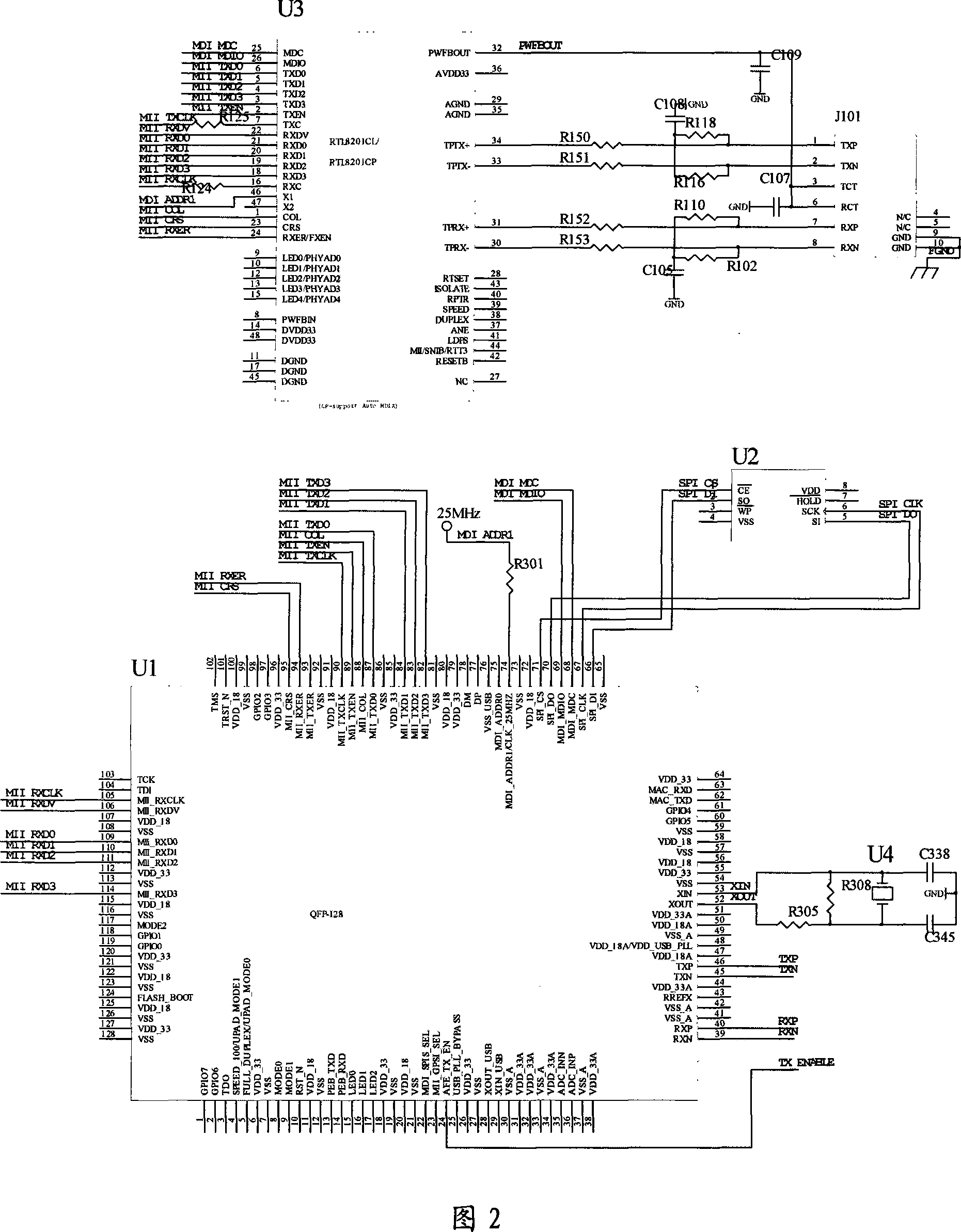

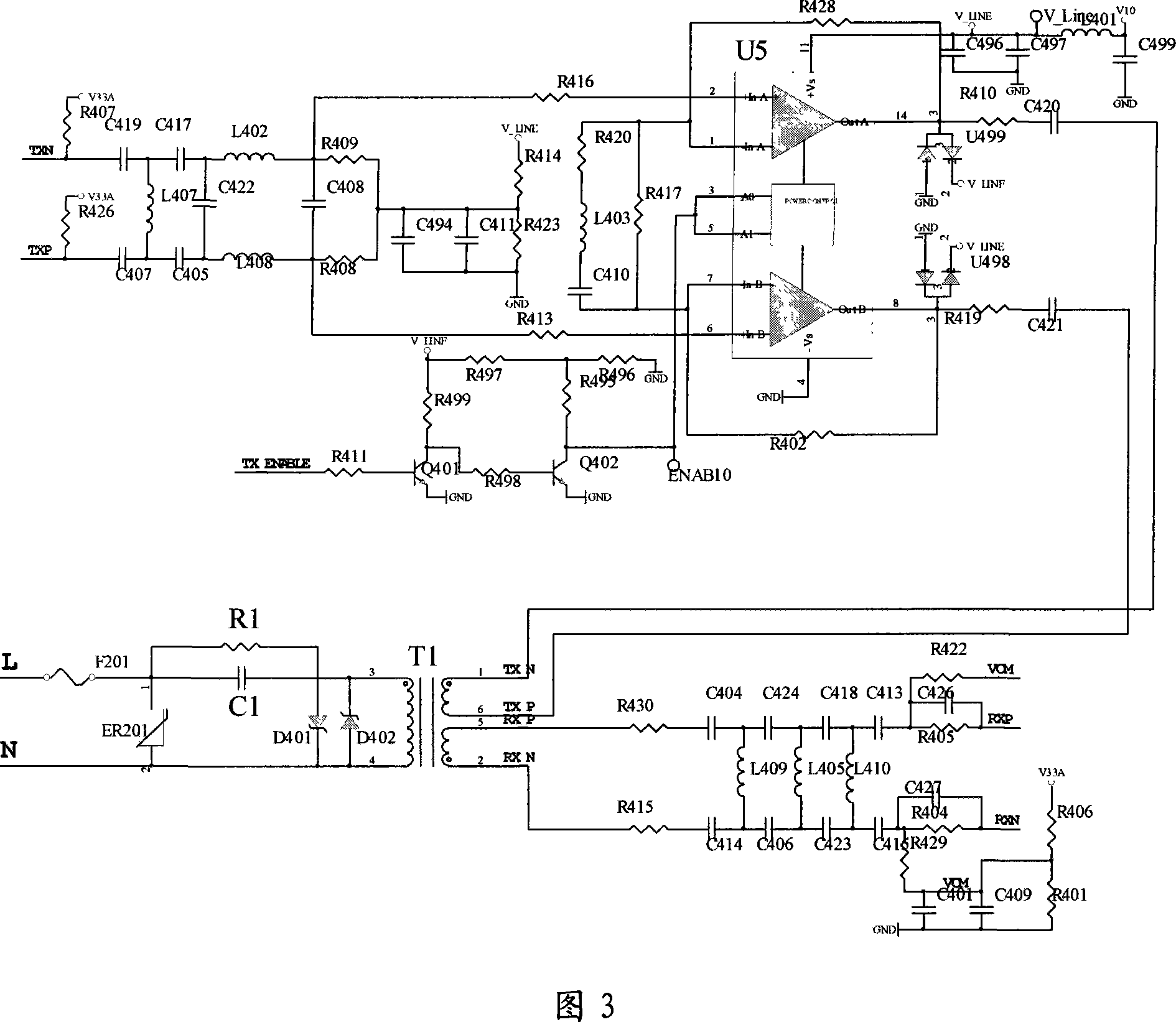

An electric network bridge

InactiveCN101217294AEasy to adjustImprove signal transmission performancePower distribution line transmissionElectricityCommunication unit

The invention relates to an electricity network bridge and comprises a communication unit and a coupling unit, wherein one end of the communication unit is connected with a network, while the other end is connected with the coupling unit which is connected with an electricity wire; the communication unit is used for converting signals between the forms accepted by the network and the coupling unit, and the coupling unit is used for transmitting signals between the communication unit and the electricity wire, and a signal receiving channel and a signal sending channel of the coupling unit are independent with each other. The electricity network bridge of the invention has the following advantages: as the OFDM technique is adopted and the receiving and sending channels of the coupling unit are independent with each other, the invention has simple circuit adjustment and better effect of signal transmission.

Owner:珠海天瑞电力科技有限公司

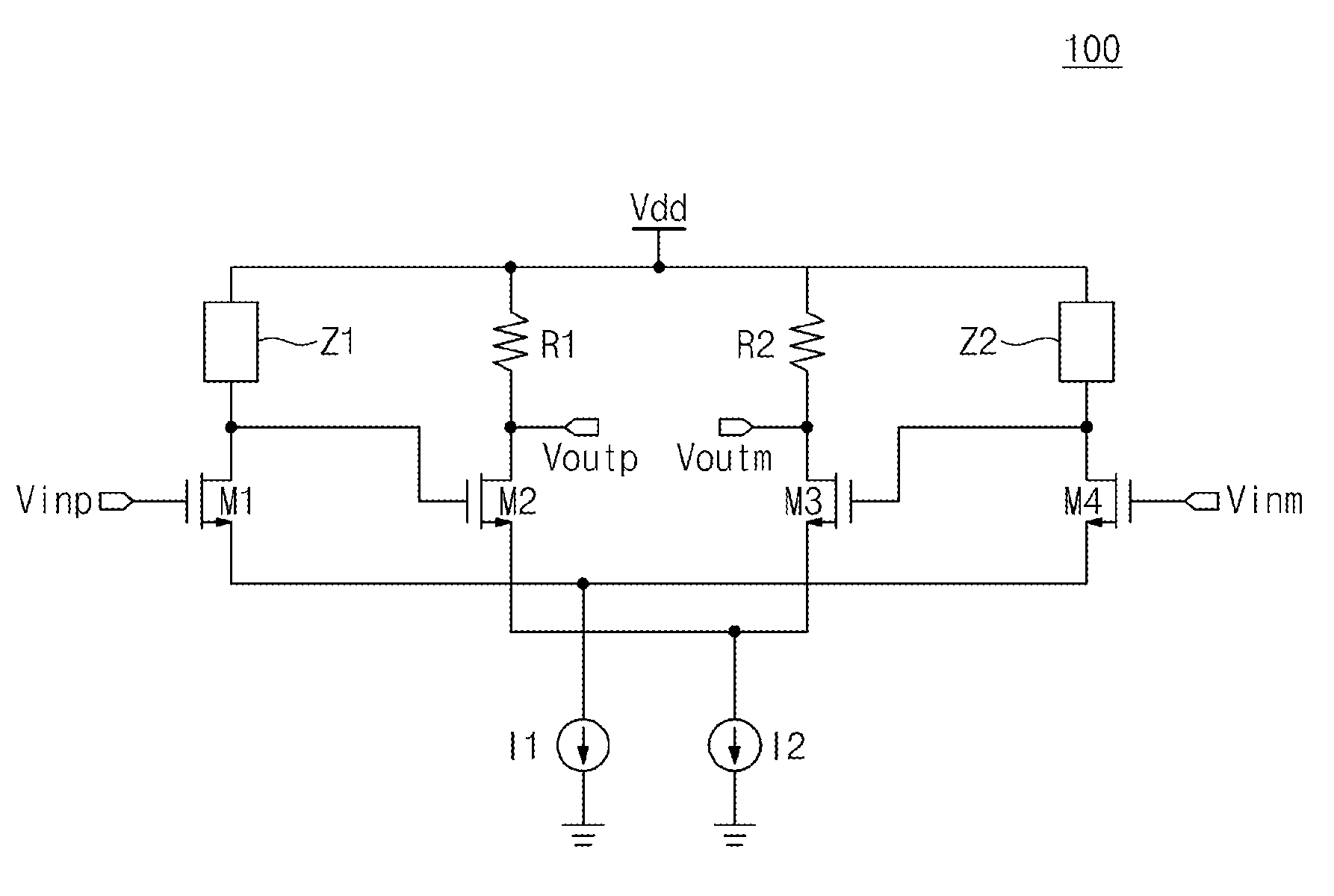

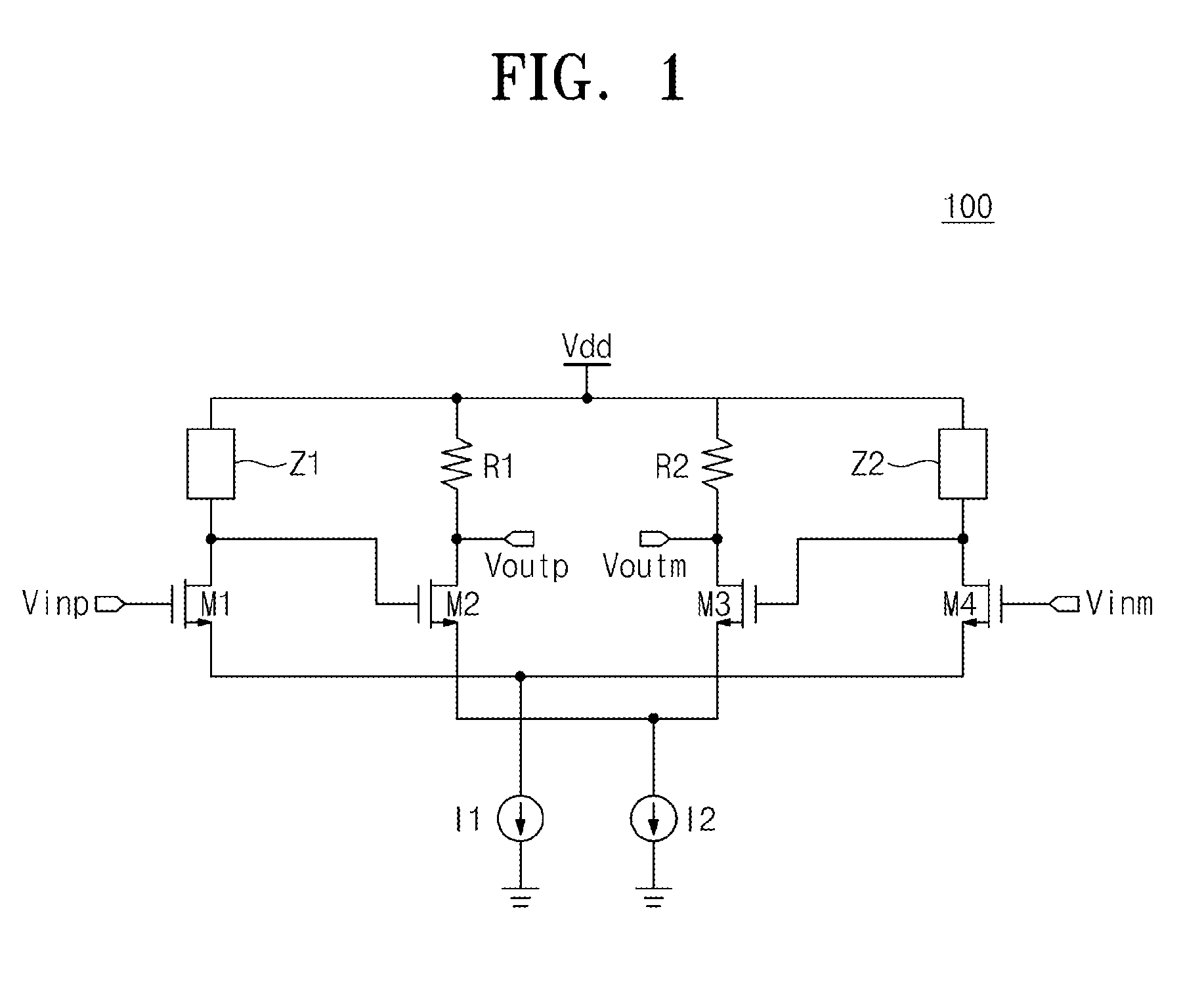

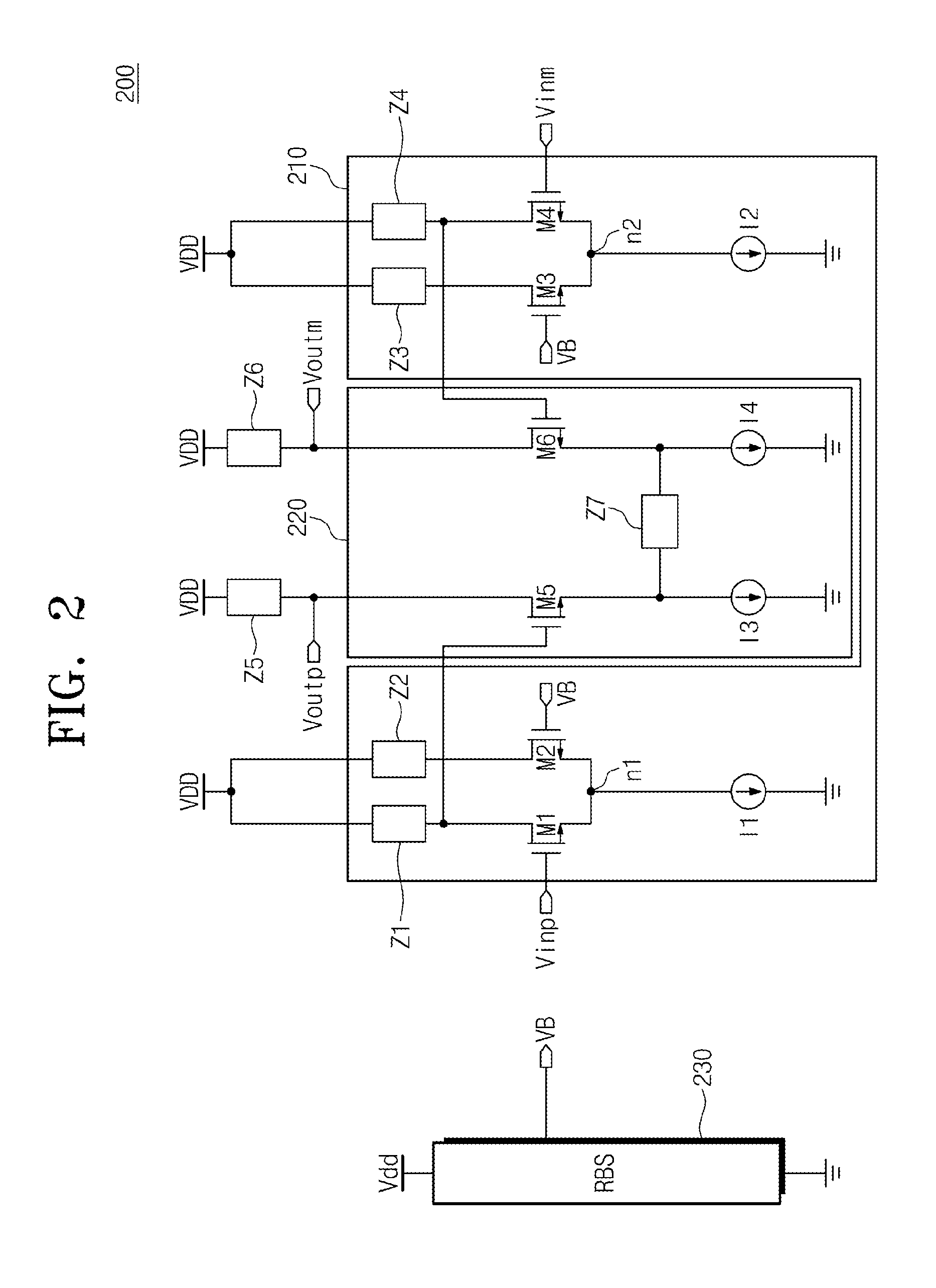

Buffer amplifier and trans-impedance amplifier including the same

ActiveUS20160006395A1Improve signal transmission performanceReduce input capacitanceAmplifier modifications to reduce non-linear distortionAmplifier modifications to raise efficiencyAudio power amplifierEngineering

Provided is a buffer amplifier. The buffer amplifier includes: a replica bias unit dividing an internal power voltage received from an internal power node to generate a bias voltage; an input unit including a first differential amplifier comparing a first differential input signal with the bias voltage to output a first internal signal and a second differential amplifier comparing a second differential input signal with the bias voltage to output a second internal signal; and an output unit including a third differential amplifier comparing the first internal signal with the second internal signal to output a first differential output signal and a second differential output signal.

Owner:ELECTRONICS & TELECOMM RES INST

Multi-layer substrate with a via hole and electronic device having the same

InactiveUS8502085B2Minimizing any discontinuityImprove signal transmission performanceSemiconductor/solid-state device detailsCross-talk/noise/interference reductionSignal lines

A multi-layer substrate includes a plurality of substrate main bodies, a plurality of layers which are alternately layered with the main bodies, a signal via hole which is connected with a signal line and includes a signal column which passes through at least one substrate main body; and a sub via hole which includes a sub column which surrounds the signal column, and a pair of sub pads which extend from end parts of the sub column to be formed to the layers, the layers which are formed with the sub pads being disposed in the same layer as the layers which are formed with the signal line of the signal via hole, or being disposed outside the layers which are formed with the signal line which is connected with the signal via hole.

Owner:SAMSUNG ELECTRONICS CO LTD

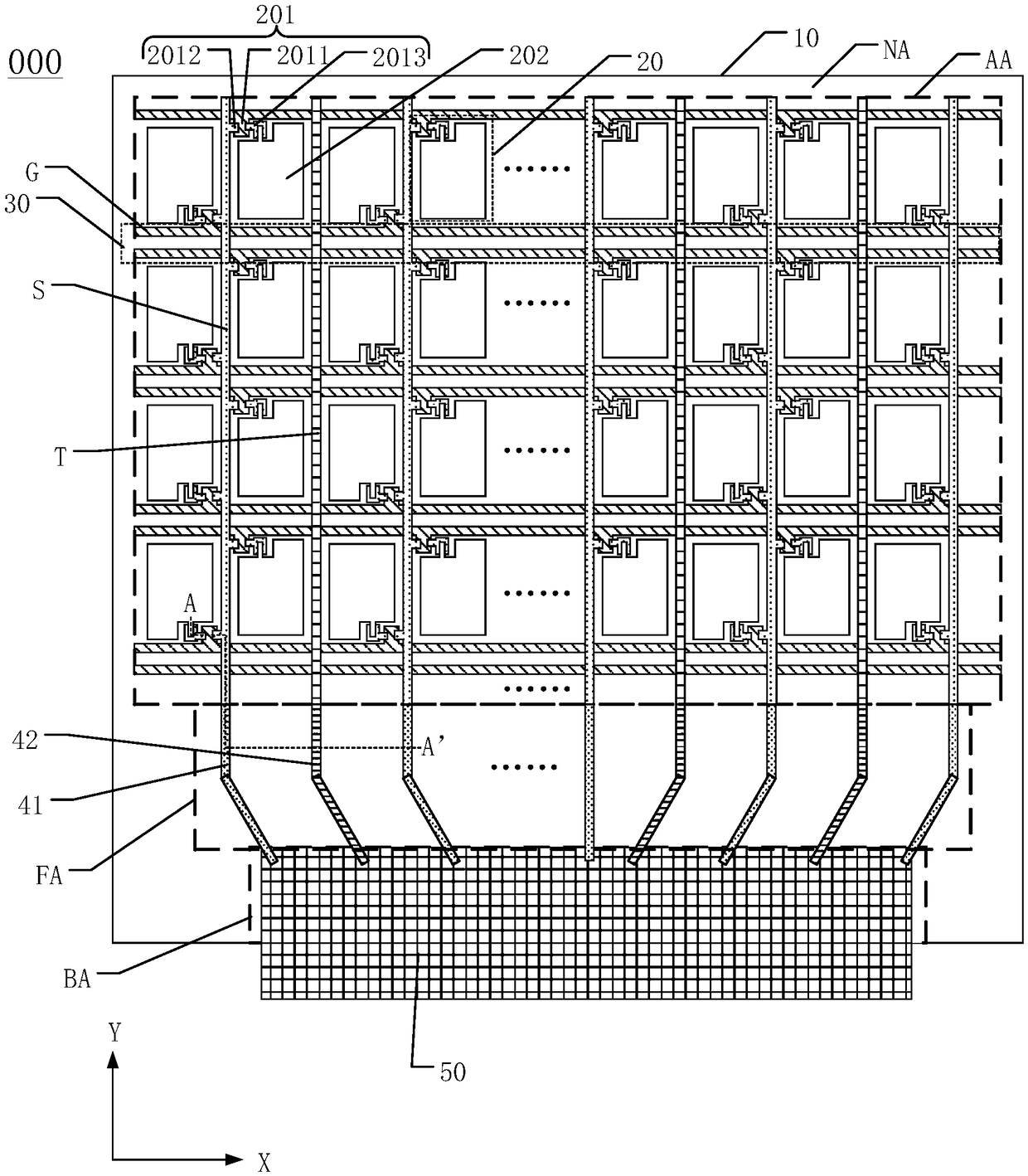

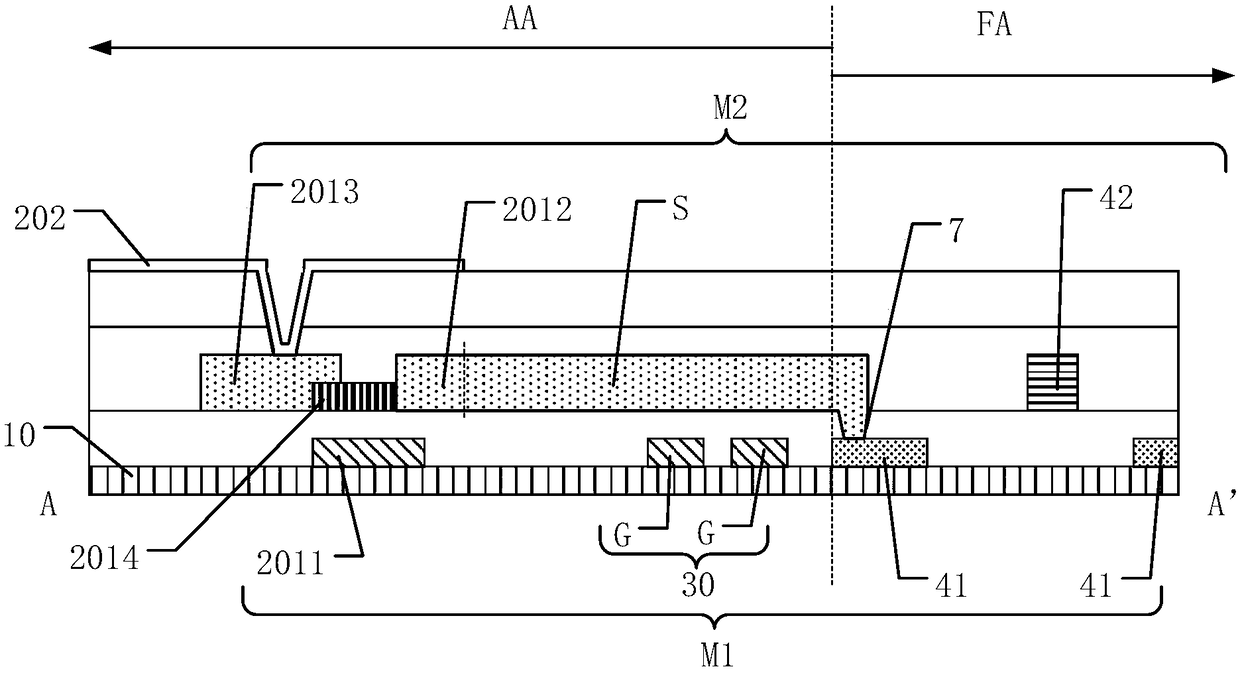

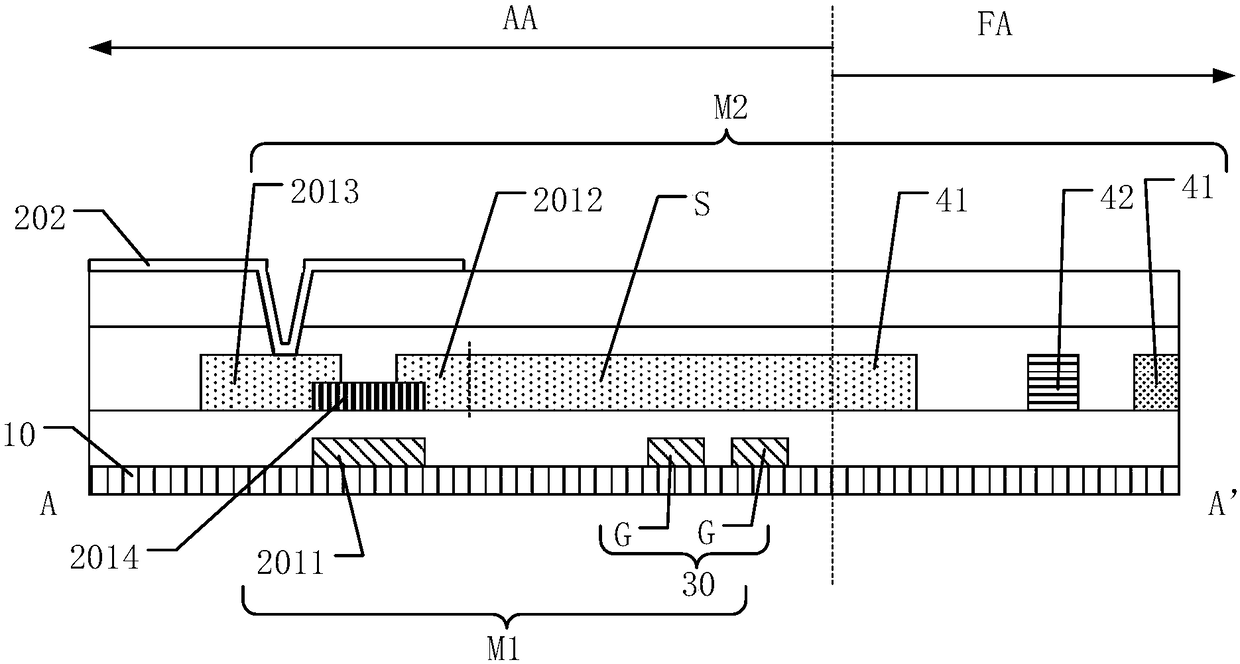

Display panel and display device

ActiveCN109491121ARealize the touch functionAffect display qualitySolid-state devicesNon-linear opticsDisplay deviceComputer science

The invention discloses a display panel and a display device, and belongs to the technical field of display. The display panel comprises a substrate, a display area, a non-display area and a fan-out area. The display area comprises a plurality of pixel units, a plurality of grid line sets, a plurality of data lines and a plurality of touch lines. Each grid line set includes two adjacent grid lineslocated between adjacent two rows of pixel units. The grid lines are located on a grid metal layer, the data lines and the touch lines are all located in a source / drain metal layer. The fan-out areaincludes a plurality of first fan-out lines and a plurality of second fan-out lines, the first fan-out lines are located on the grid metal layer and / or the source / drain metal layer, and each second fan-out line is located on the source / drain metal layer. The display device includes the above display panel. The display panel and the display device can save cost and make the impedance of all the touch lines consistent, thereby improving the display quality of the display panel.

Owner:SHANGHAI AVIC OPTOELECTRONICS

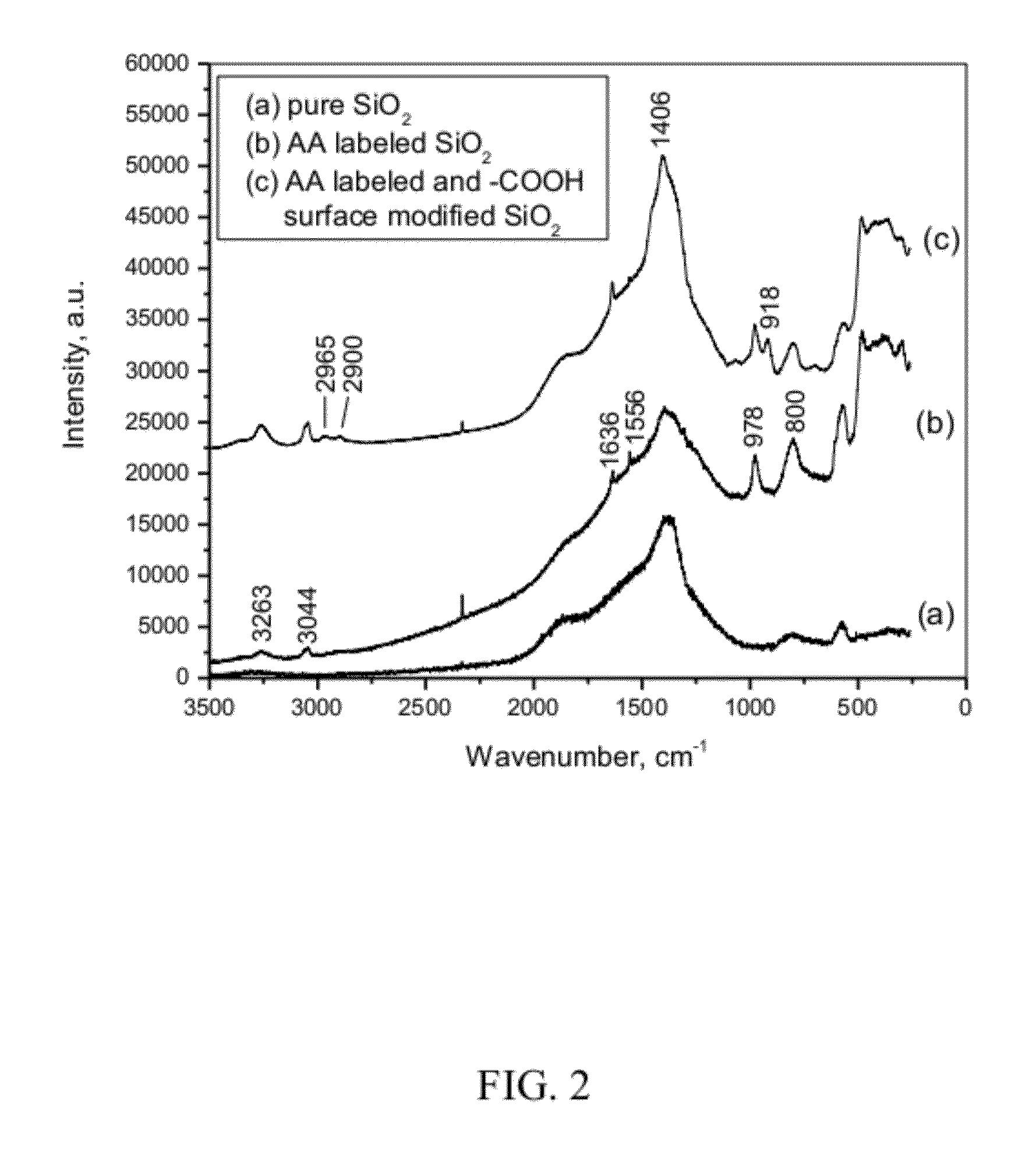

Volume-labeled nanoparticles and methods of preparation

InactiveUS20120267585A1Hinder pH measurementMinimizes sequestrationMaterial nanotechnologyMagnetic materialsCore shell nanoparticlesQuantum dot

Compositions comprising nanosized objects (i.e., nanoparticles) in which at least one observable marker, such as a radioisotope or fluorophore, is incorporated within the nanosized object. The nanosized objects include, for example, metal or semi-metal oxide (e.g., silica), quantum dot, noble metal, magnetic metal oxide, organic polymer, metal salt, and core-shell nanoparticles, wherein the label is incorporated within the nanoparticle or selectively in a metal oxide shell of a core-shell nanoparticle. Methods of preparing the volume-labeled nanoparticles are also described.

Owner:UT BATTELLE LLC

Wire, preparing method and application thereof

InactiveCN104538090AEasy to operateEase of industrial productionInsulated cablesCable/conductor manufactureFiberElectrical performance

The invention discloses a wire, and further discloses a preparing method of the wire and an application thereof. The wire comprises an insulation protecting layer and inner wires located in the insulation protecting layer. Each inner wire comprises at least one conducting element. Each conductive element comprises nonmetal fiber core wires, and a conducting layer arranged on the outside of the nonmetal fiber core wires. Due to the fact that the conducting layer is arranged on the surfaces of the nonmetal fiber core wires, the wire has the advantages of being simple in operation and easy in wide range industrial production The surface of the wire manufactured with the method is even. By further twisting and twining the multiple conducting elements, the structure is more compact, and the electrical performance and the mechanical performance can be further improved.

Owner:J NOVA WORKS CO LTD

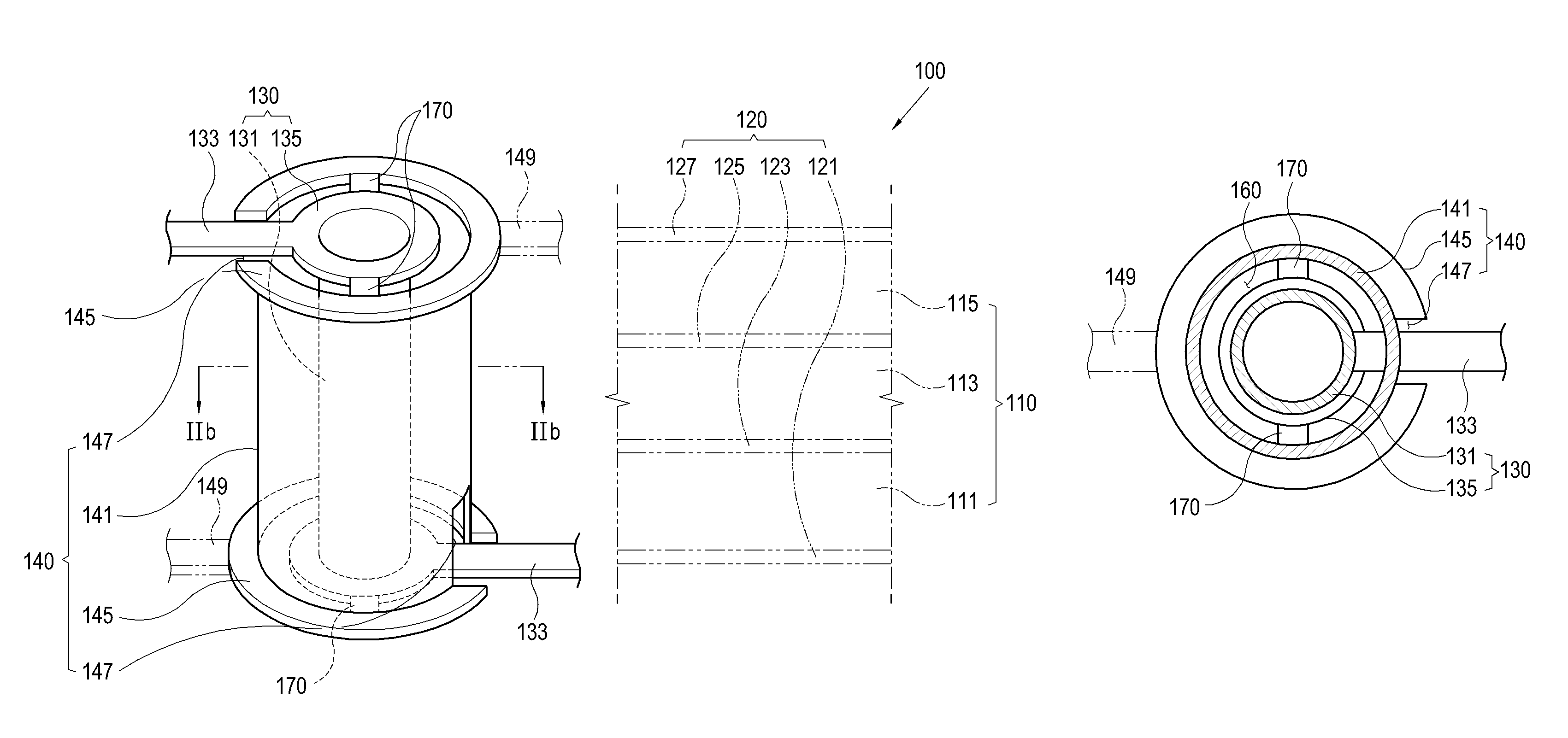

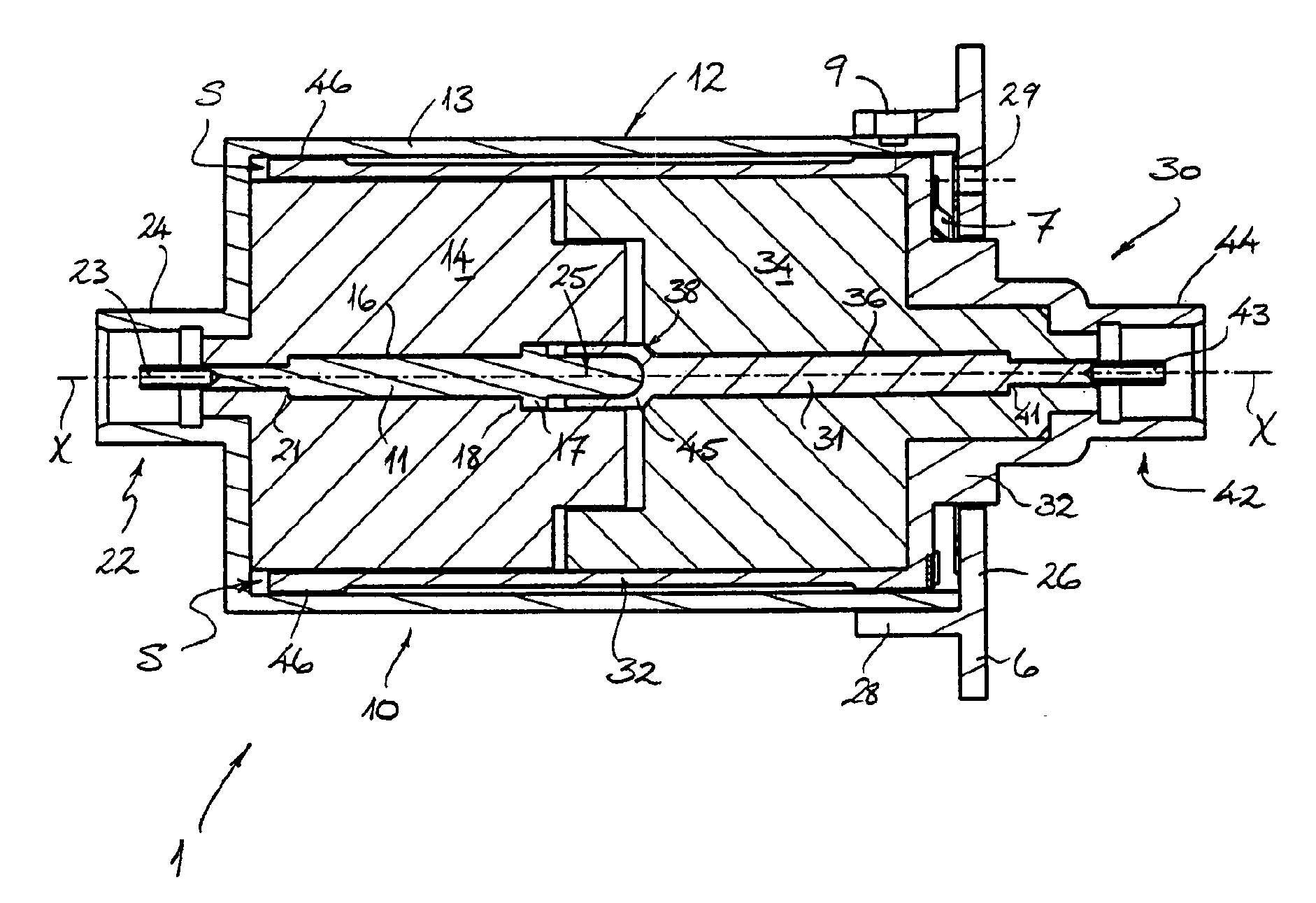

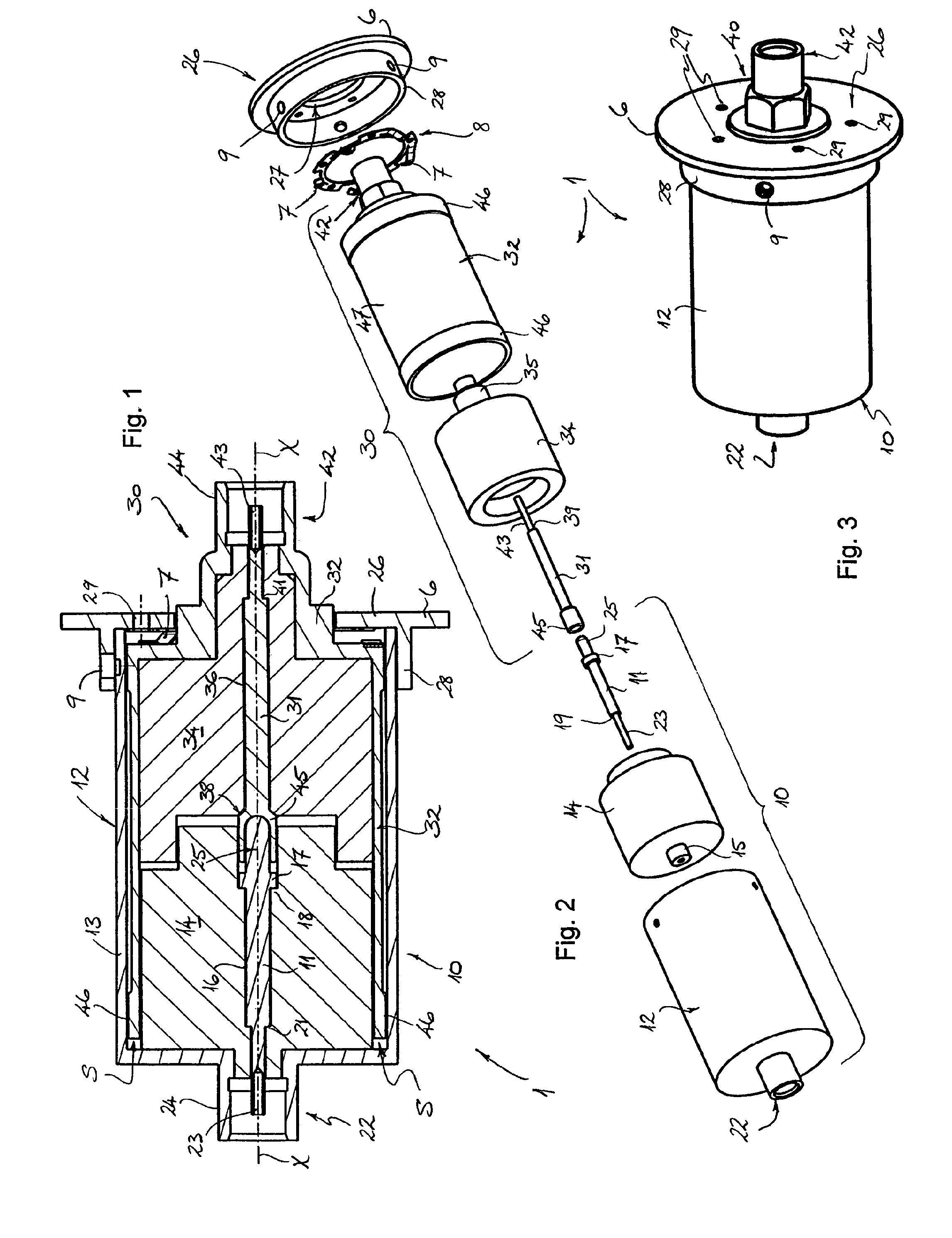

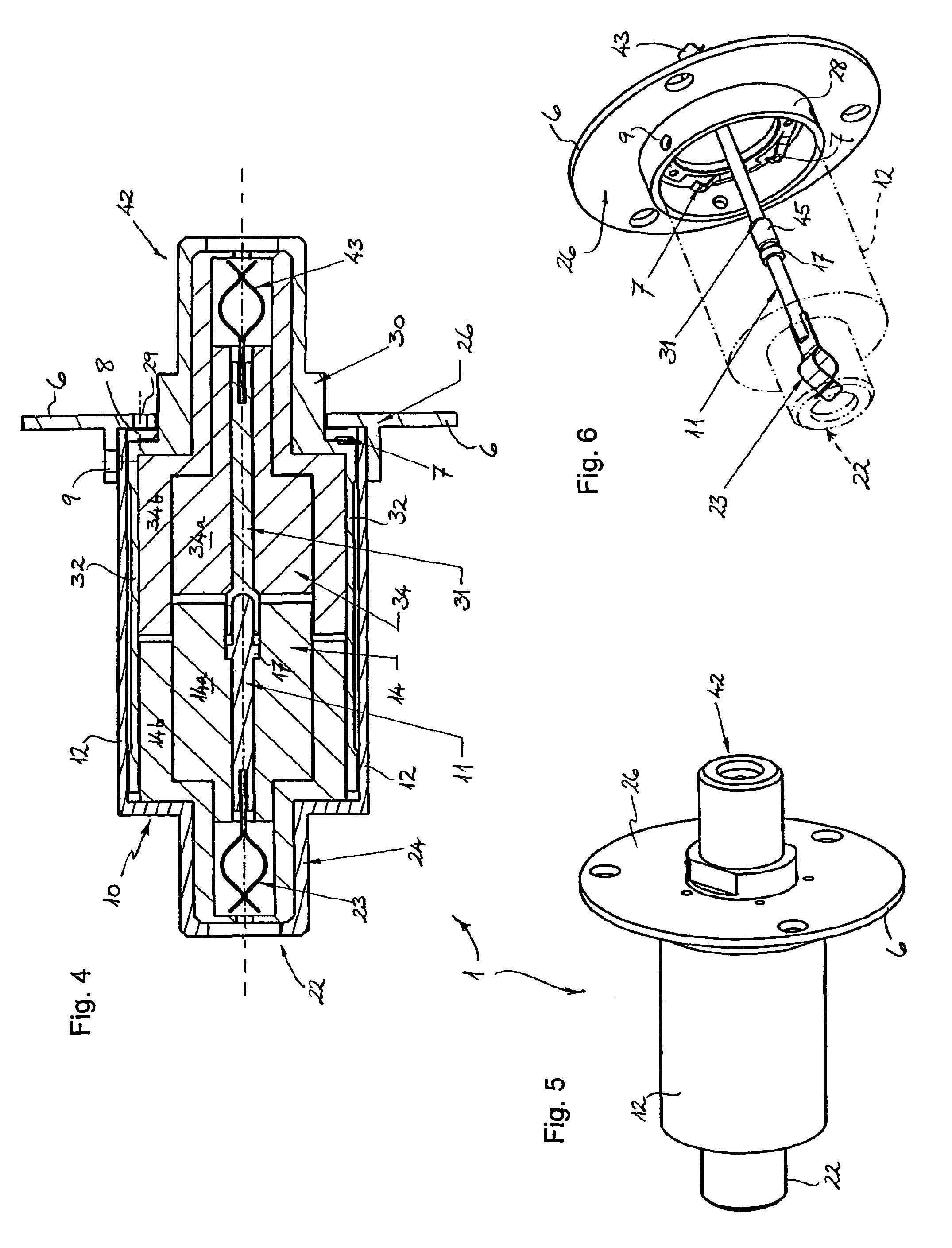

Rotatable electrical coupling device

InactiveUS8926336B2Specific characteristic impedanceImprove signal transmission performanceRotary current collectorElectrically conductive connectionsElectricityCoupling

A rotatable electrical coupling device incorporates a first connector having a first electrical contact member adapted to conduct or transmit a high-frequency and / or high-speed data signal, and a second connector having a second electrical contact member adapted to conduct or transmit a high-frequency and / or high-speed data signal. The second connector is configured to be coupled with the first connector for substantially free or unimpeded rotation about an axis (X) relative to the first connector, the first and second electrical contact members being configured to engage one another and to maintain uninterrupted electrical contact throughout a relative rotational movement between the first and second connectors in a coupled state.

Owner:ONDAL MEDICAL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com