Preparation method and application of high expansion coefficient copper sealing glass powder

A technology for sealing glass and high expansion, which is applied to the preparation of high-expansion coefficient copper sealing glass powder and the preparation of glass powder required for the sealing of copper electrical connectors, and can solve the problem of high cost and use of copper-sealed electrical connectors. High environmental requirements, long production cycle and other problems, to achieve the effect of good chemical stability, low cost, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Molar percentage P 2 0 5 55%, B 2 0 3 6%, Al 2 o 3 7.5%,Na 2 O15.5%, K 2 O16%, use phosphorus pentoxide, boric acid, aluminum oxide, sodium carbonate, and potassium carbonate to introduce the feed respectively, mix the ingredients 400-500g evenly and add them to a dry 800ml alumina dry pot, heat the glass liquid at 1200°C for 2 hours Pour into cold water to quench the desired glass, then put it in a 150°C oven to dry for 3 hours, take it out and use an alumina ball mill jar to add alcohol to ball mill for 35 minutes, take it out and put it in a 60°C oven to dry for 12 hours, pass through a 200-mesh sieve and add The wax is granulated, and the required copper sealing glass powder is obtained by passing through a 40-mesh sieve.

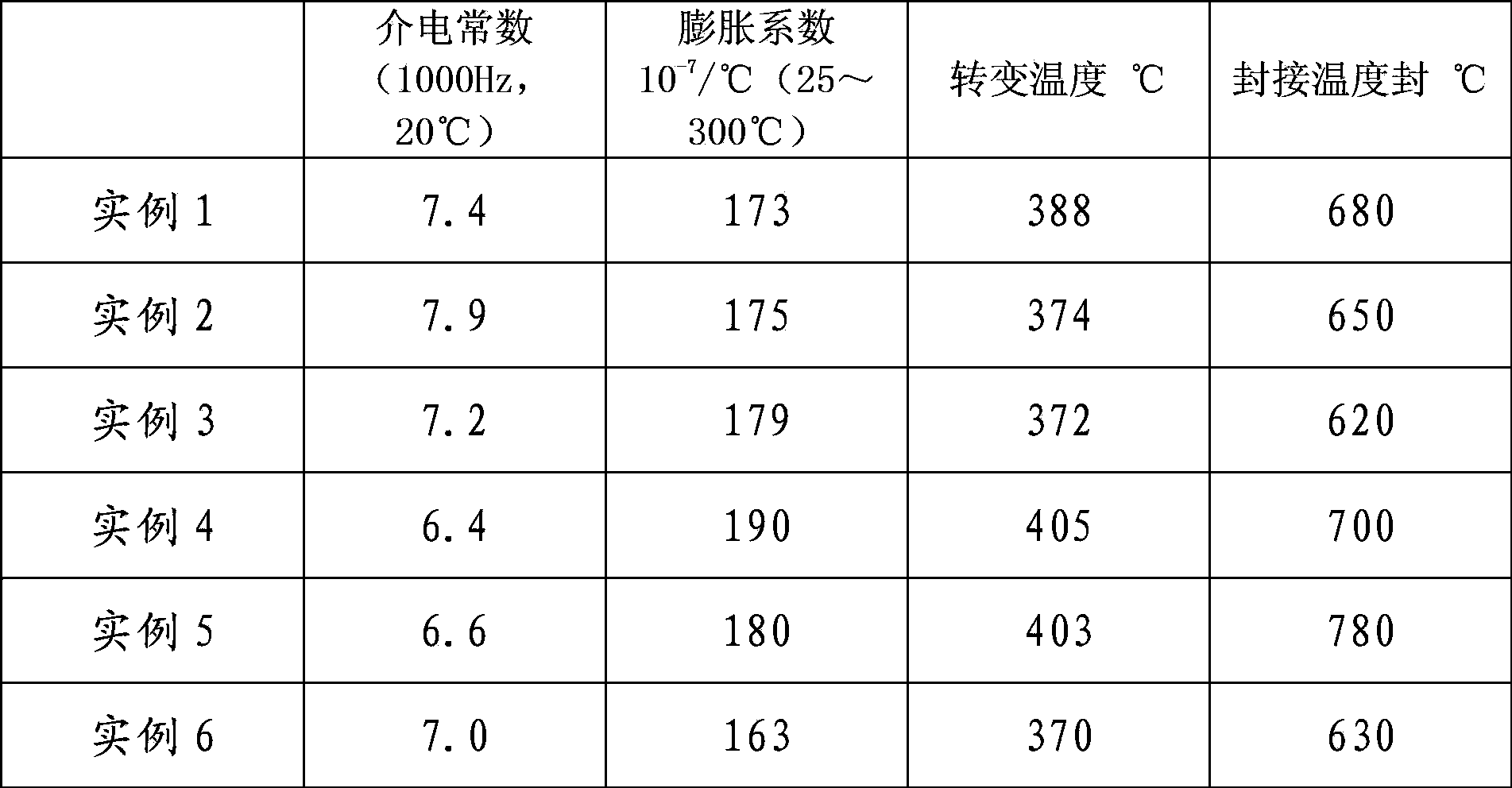

[0017] The dielectric constant of the obtained copper-sealed glass is 7.4 (1000Hz, 20°C), and the expansion coefficient is 173×10 -7 / °C (25~300°C), the transition temperature is 388°C, the sealing temperature is 680°C, and ...

Embodiment 2

[0018] Embodiment 2: P by molar percentage 2 0 5 50%, B 2 0 3 5%, Al 2 o 3 15%,Na 2 O9%,K 2 O11%, PbO10% respectively use phosphorus pentoxide, aluminum oxide, boric acid, sodium carbonate, potassium carbonate, lead oxide to introduce and feed, mix 400-450g of materials evenly, add them to a dry 800ml alumina dry pot, and keep warm at 1050°C After 2 hours, pour the molten glass into cold water to obtain the desired glass, then put it in an oven at 150°C and dry it for 3 hours, take it out and use an alumina ball mill jar to add alcohol for ball milling for 30 minutes, take it out and put it in an oven at 60°C to dry for 12 hours, After 200-mesh sieve, add wax to granulate, pass through 40-mesh sieve to obtain the required copper sealing glass powder.

[0019] The dielectric constant of the obtained copper-sealed glass is 7.9 (1000Hz, 20°C), and the expansion coefficient is 175×10 -7 / °C (25~300°C), the transition temperature is 374°C, the sealing temperature is 650°C, ...

Embodiment 3

[0020] Embodiment 3: P by molar percentage 2 0 5 55%, B 2 0 3 6%, Al 2 o 3 10%,Na 2 O 10%, K 2 O16% and BaO 3% are introduced and fed with phosphorus pentoxide, aluminum oxide, boric acid sodium carbonate, potassium carbonate, and barium carbonate respectively, and the proportion of 400-450g is mixed evenly and added to a dry 800ml alumina dry pot, and kept at 1150°C After 2 hours, pour the molten glass into cold water to obtain the desired glass, then put it in an oven at 150°C and dry it for 3 hours, take it out and use an alumina ball mill jar to add alcohol for ball milling for 30 minutes, take it out and put it in an oven at 60°C to dry for 12 hours, After 200-mesh sieve, add wax to granulate, pass through 40-mesh sieve to obtain the required copper sealing glass powder.

[0021] The resulting copper-sealed glass has a dielectric constant of 7.23 (1000Hz, 20°C) and an expansion coefficient of 179×10 -7 / ° C (25 ~ 300 ° C), the transition temperature is 372 ° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com