Antibacterial ceramic coating layer for non-stick pan and preparation method thereof, and non-stick pan

A technology of antibacterial ceramics and non-stick pans, applied in the direction of special materials for cooking utensils, etc., to achieve the effect of increasing the expansion coefficient, enhancing the toughness and improving the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

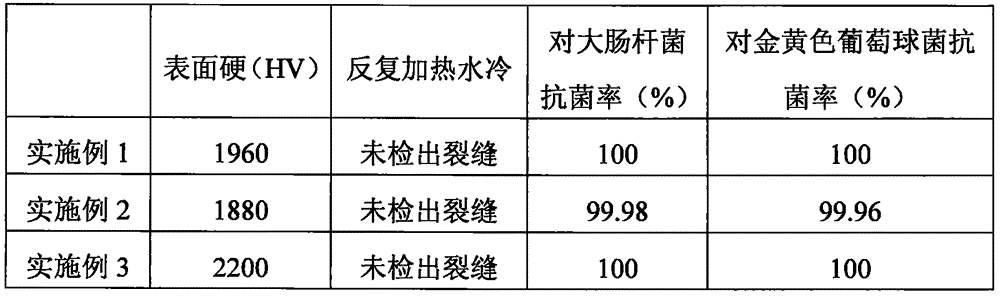

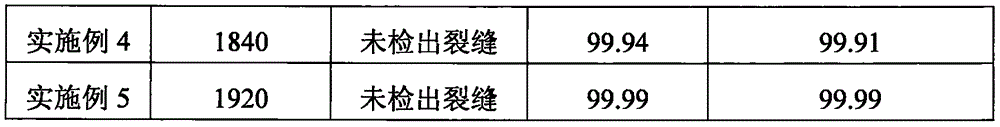

Examples

preparation example Construction

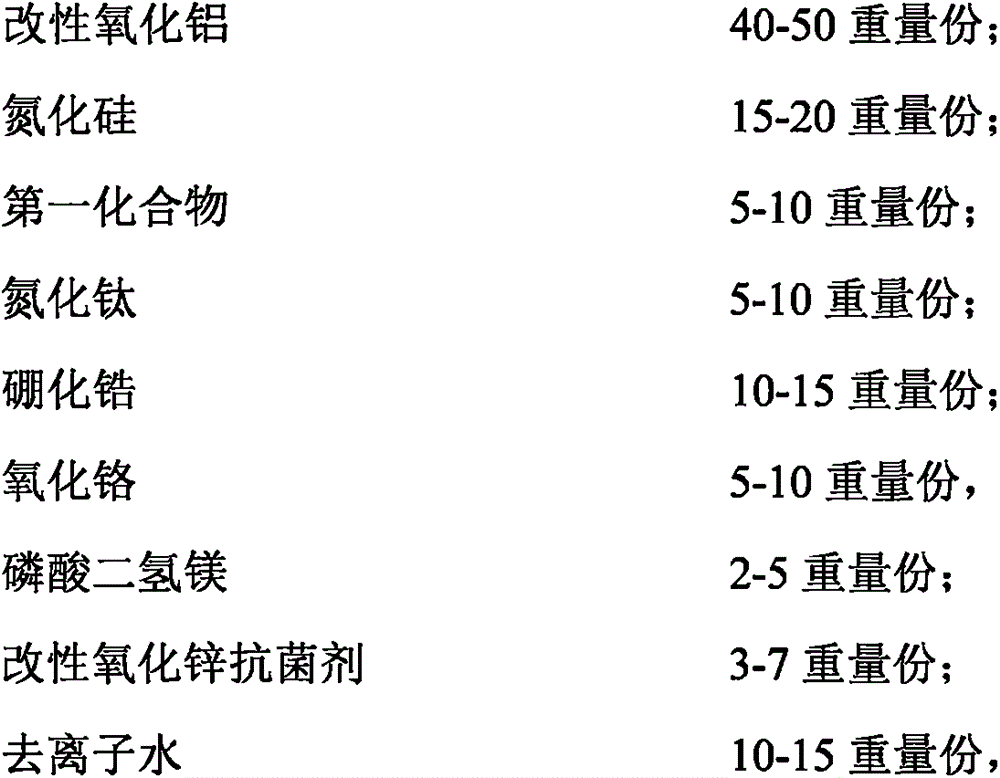

[0033] Correspondingly, the present invention also provides a preparation method of the antibacterial ceramic coating for non-stick pans, comprising the following steps: 40-50 parts by weight of modified alumina, 15-20 parts by weight of silicon nitride, 5-10 parts by weight of The first compound, 5-10 parts by weight of titanium nitride, 10-15 parts by weight of zirconium boride, 5-10 parts by weight of chromium oxide and 3-7 parts by weight of modified zinc oxide antibacterial agent are mixed, pulverized, and 500-1000r Stir at a speed of 40-60 minutes per minute to obtain the first mixture, the first compound being silicon dioxide or titanium dioxide; adding 2-5 parts by weight of magnesium dihydrogen phosphate and 10-15 parts by weight of Deionized water, stirred to obtain ceramic slurry; after aging the ceramic slurry for 24-48h, apply it on the inner surface of the pot base, keep it at 600-800°C for 3-8h, and then anneal at 350-500°C , get an antibacterial ceramic coating...

Embodiment 1

[0057] An antibacterial ceramic coating for a non-stick pan, the ceramic coating is prepared from the following raw materials in parts by weight:

[0058] 45 parts of modified alumina,

[0059] 20 parts of silicon nitride,

[0060] 6 parts of silicon dioxide,

[0061] Titanium nitride 6 parts,

[0062] 10 parts of zirconium boride,

[0063] 5 parts of chromium oxide,

[0064] 3 parts of magnesium dihydrogen phosphate,

[0065] 7 parts of modified zinc oxide antibacterial agent,

[0066] 15 parts of deionized water.

[0067] Wherein, the modified alumina is prepared according to the following method: 100 g of dihydroxy oligodimethylsiloxane is added to the 22 o 3 In chloroform (800 g of chloroform quality) of 400 g of nanoparticles, under a nitrogen atmosphere, reflux and stir at 90 ° C for 24 h, centrifuge the resulting product, and wash the separated solid repeatedly with chloroform, then place it in a vacuum oven at 80 ° C Drying at low temperature for 20h to obtain...

Embodiment 2

[0078] An antibacterial ceramic coating for a non-stick pan, the ceramic coating is prepared from the following raw materials in parts by weight:

[0079] 40 parts of modified alumina,

[0080] 15 parts of silicon nitride,

[0081] Titanium dioxide 5 parts,

[0082] 5 parts of titanium nitride,

[0083] 10 parts of zirconium boride,

[0084] 5 parts of chromium oxide,

[0085] 5 parts of magnesium dihydrogen phosphate,

[0086] 5 parts of modified zinc oxide antibacterial agent,

[0087] 10 parts of deionized water.

[0088] Wherein, the preparation method of the modified alumina comprises the following steps: adding 100 g of dihydroxy oligodimethylsiloxane to the 2 o 3Nanoparticles in 400g of chloroform (chloroform mass 600g), under a nitrogen atmosphere, reflux and stir at 100°C for 36h, centrifuge the resulting product, wash the separated solid with chloroform repeatedly, and place it in a vacuum oven at 70°C Dry for 15 hours to obtain modified alumina;

[0089] W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com