Oil reservoir three-dimensional gas injection method and well pattern structure

A technology of gas injection wells and network structure, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problem that thick oil reservoirs cannot replenish oil reservoir energy well, and can not well suppress bottom water coning , gas injection mode and insufficient recovery effect, etc., to achieve the effect of improving development effect, increasing microscopic sweep coefficient, and increasing oil production rate and recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a three-dimensional gas injection method and a well pattern structure for a reservoir. The Xinggu Block 7 in the Xinggu buried hill oil reservoir of the Liaohe Oilfield was carried out. The reservoir is ancient, complex in structure and diverse in lithology. It is a buried-hill reservoir of fractured massive bottom-water metamorphic rock with extremely thick reservoirs. The area of the experimental area is 9.77km 2 , reservoir thickness 2335m, geological reserves 3537×10 4 t, matrix reserves accounted for 65%, macro fracture reserves accounted for 12%, micro fracture reserves accounted for 23%, reservoir matrix permeability was 0.47mD, fracture permeability was 140mD, formation crude oil viscosity was 0.527MPa·s.

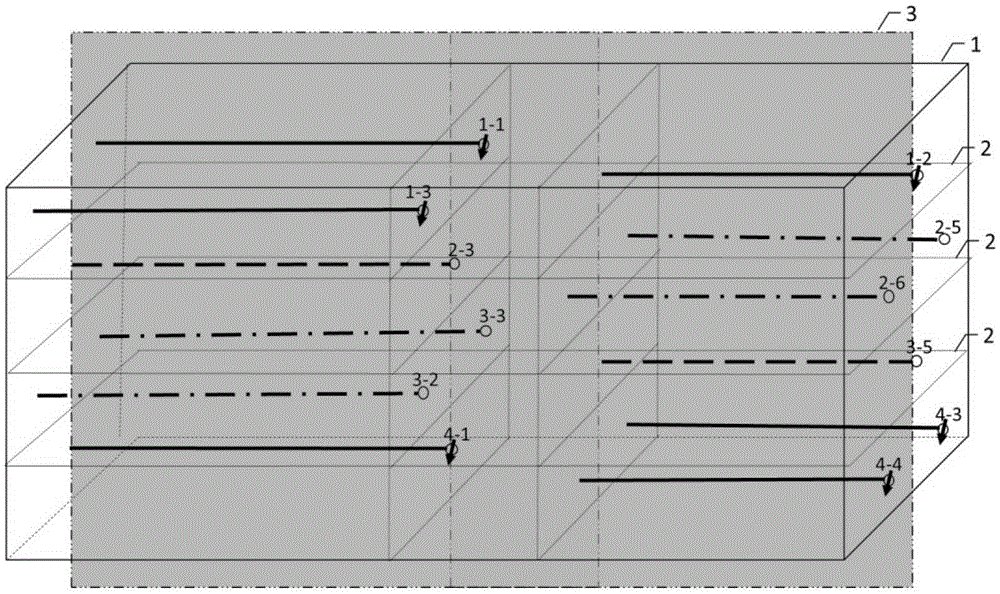

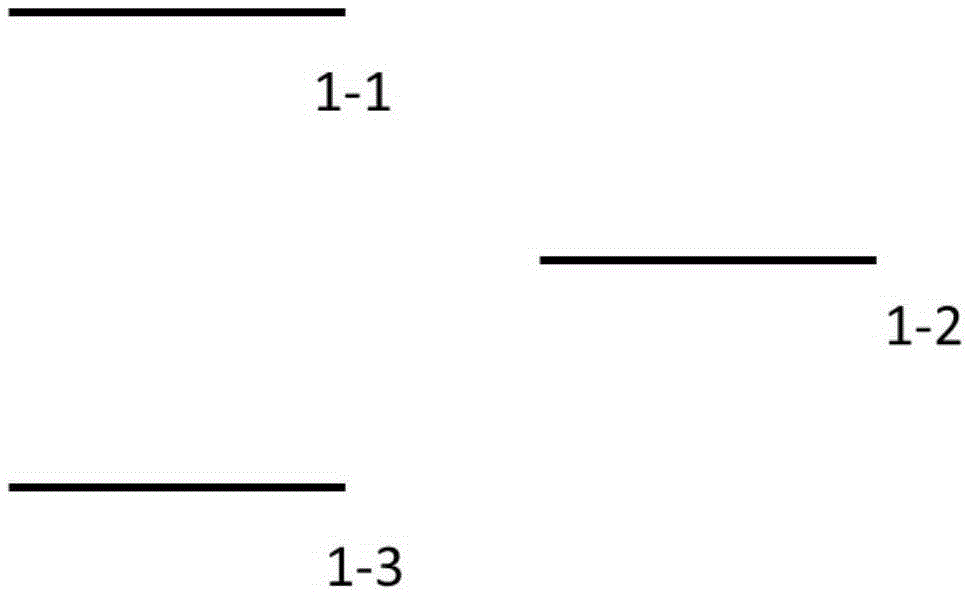

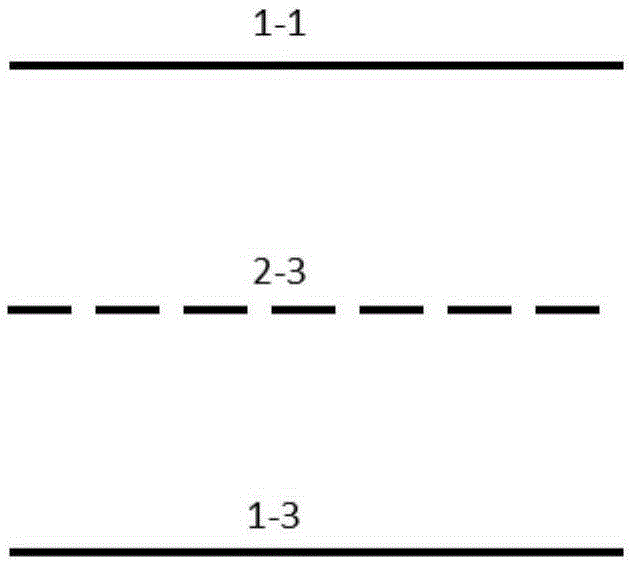

[0045] A three-dimensional injection-production well pattern with four sections and seven layers vertically stacked and staggered is selected and formed with a horizontal injection-production well spacing of 300m and a vertical le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com