Pipeline detection robot

A robot and pipeline technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of insufficient curve traffic capacity, poor signal transmission effect, weak autonomous obstacle avoidance and crawling functions, etc., to improve fault detection efficiency, The effect of simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a pipeline detection robot. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

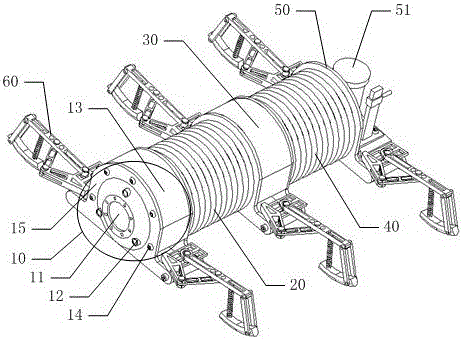

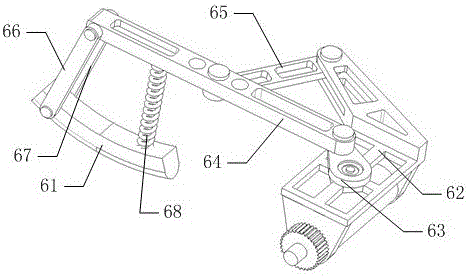

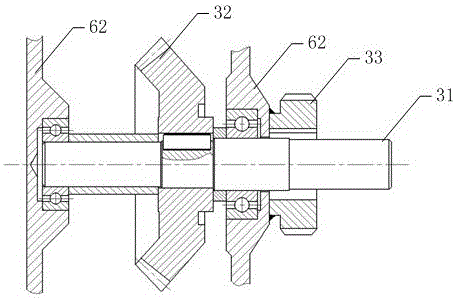

[0022] see figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of a pipeline detection robot in the present invention, a pipeline detection robot, which includes a robot head 10, a robot middle part 30 connected to the robot head 10 through a first elastic connecting body 20, and The robot tail 50 connected with the robot middle part 30 through the second elastic connector 40, the robot head 10, the robot middle part 30 and the robot tail 50 left and right sides are all provided with a bionic leg 60 for walking, the robot The head 10 is provided with a camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com