Wire, preparing method and application thereof

A technology of wires and inner wires, which is applied in the field of wires, can solve the problems of restricting earphone signal wires, earphones cannot be used continuously, and low flexibility, etc., and achieves easy large-scale industrial production, excellent transmission performance and durability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

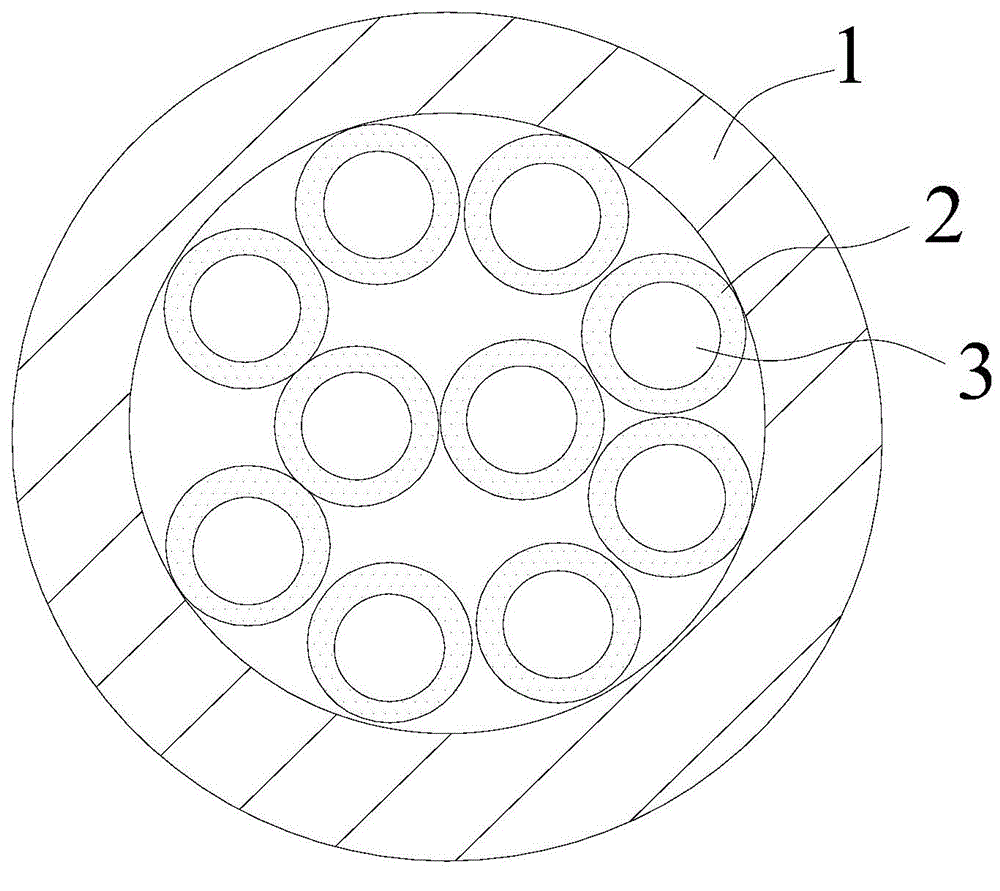

[0033] The wires of this embodiment, such as figure 1 As shown, it includes an insulating protective layer 1 and an inner wire located in the insulating protective layer 1. The inner wire includes at least one conductive unit, and each conductive unit includes a non-metallic fiber core wire 3 and is covered outside the non-metallic fiber core wire 3. The conductive layer 2.

[0034] Among them, the non-metallic fiber core wire 3 is a carbon nanotube fiber core wire composed of carbon nanotube fibers, and the diameter of each carbon nanotube fiber core wire is 100 μm; the conductive layer 2 is specifically a copper-plated layer, and its thickness is 20 μm ; The insulating protective layer 1 is a polyimide insulating protective layer 1 .

[0035] The inner wire of this embodiment is formed by intertwining 10 conductive units in order to enhance its signal transmission capability.

[0036] The preparation method of the wire of the present embodiment comprises the following step...

Embodiment 2

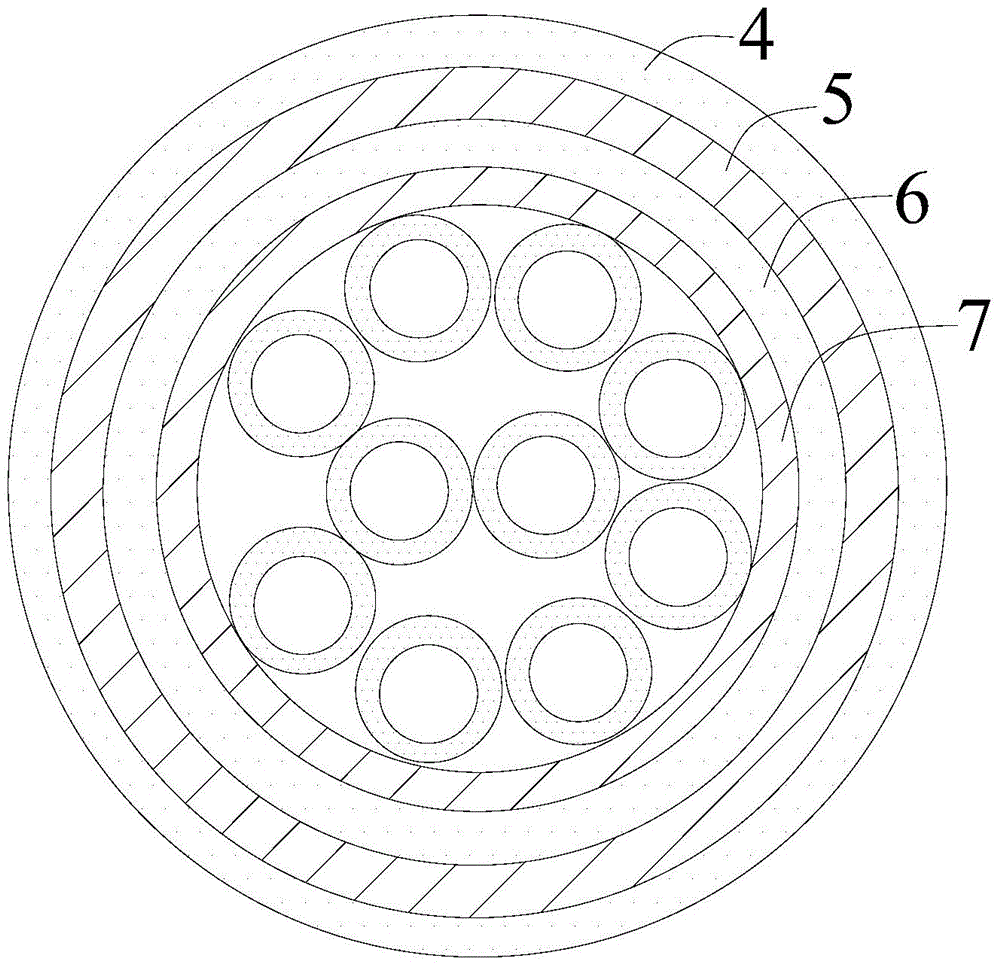

[0044] The wire of this embodiment differs from that of Embodiment 1 in that the insulating protective layer is a multilayer structure, such as figure 2 As shown, it includes a conductor shielding layer 7, an insulating layer 6, an insulating shielding layer 5 and an outer protective layer 4 in order from inside to outside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com