Large-section optical fiber composite overhead phase line and manufacturing method thereof

A technology of optical fiber compounding and production methods, applied in the direction of fiber mechanical structures, power cables, electrical components, etc., can solve the problems of high transmission pressure and high pollution, achieve strong tensile capacity, and avoid the effects of disconnection accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

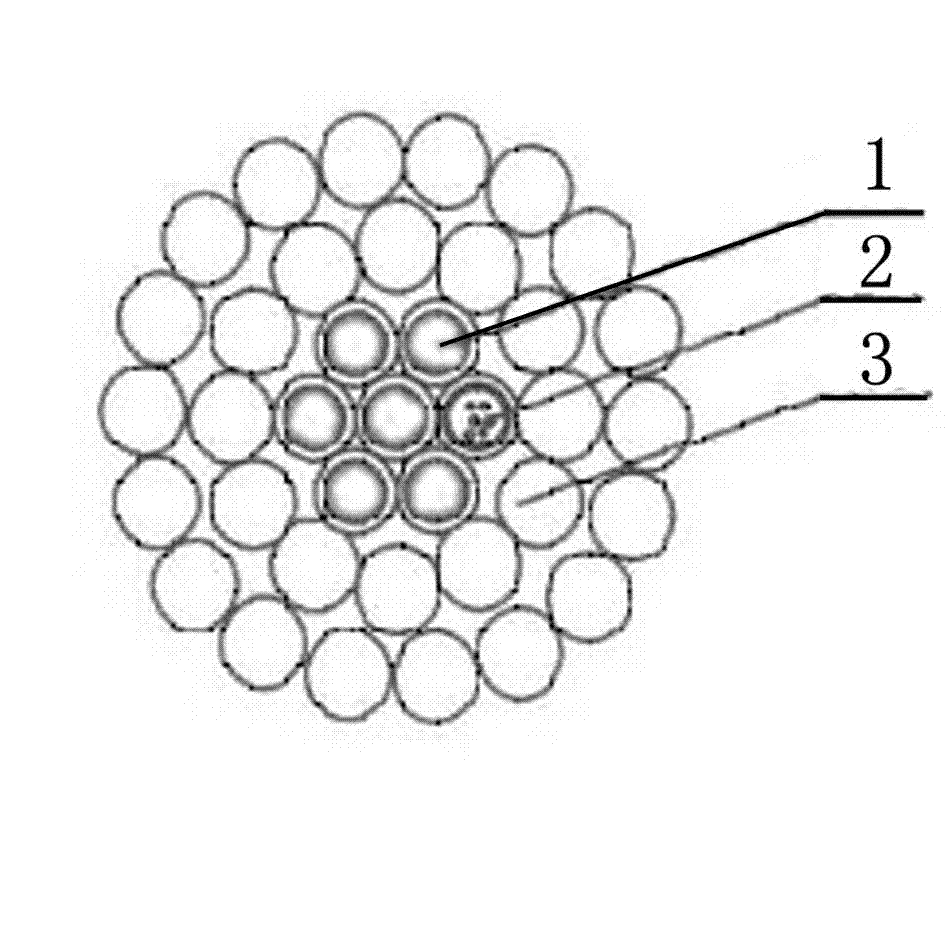

[0028] Refer to attached figure 1 , the large cross-section optical fiber composite overhead phase wire of the present invention includes an optical fiber unit, an aluminum-clad steel wire and an aluminum wire, the large cross-section optical fiber composite overhead phase wire has at least five layers, the center line is an aluminum-clad steel wire, the optical fiber unit and several aluminum The clad steel wires are twisted together to form the second layer, and the outer layer is twisted with several aluminum wires to form the aluminum wire twisted layer.

[0029] The aluminum wire twisted layer is at least 3 layers.

[0030] The cross-sectional area of the large cross-section optical fiber composite overhead phase line ranges from 40 to 45mm 2 .

[0031] The production method of the large cross-section optical fiber composite overhead phase line includes two processes of optical fiber unit production and cable production. The specific steps are as follows:

[0032] 1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com