Method for laminating cover film in flexible board

A cover film and middle layer technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of glue overflow, achieve the effect of strengthening, preventing glue overflow, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

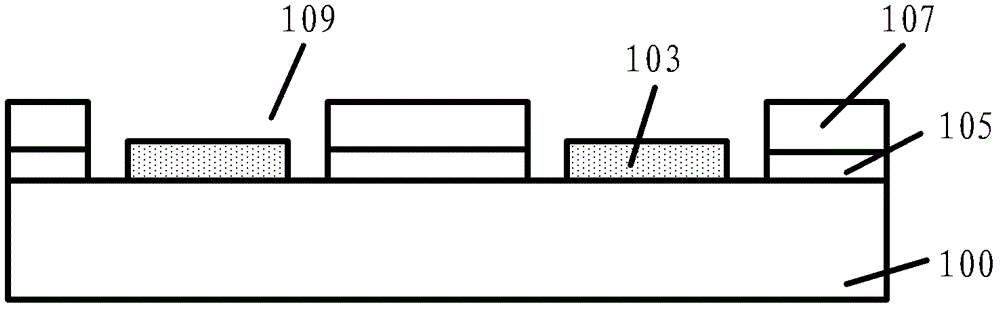

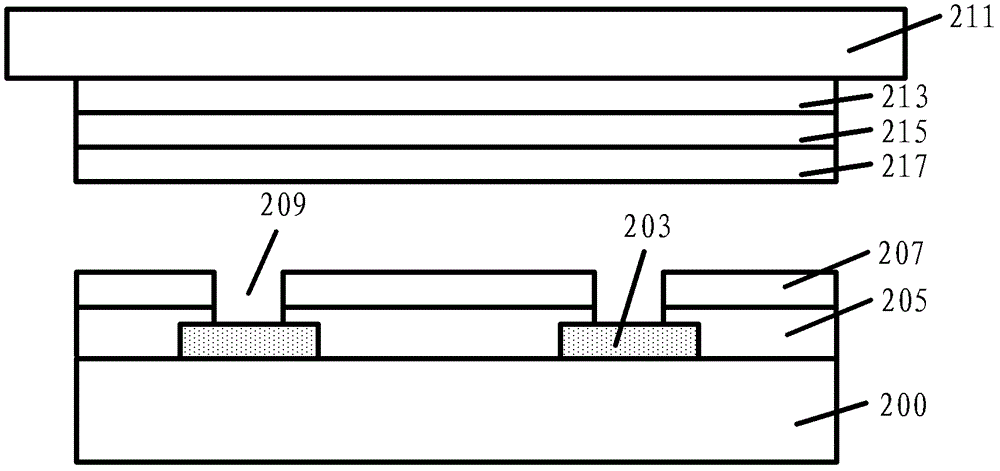

[0033] As described in the background technology, when using the prior art flexible board forming method to form a soft board whose window size of the cover film is smaller than the size of the pad, glue overflow when laminating the cover film and the flexible copper foil substrate The phenomenon is serious, which seriously affects the signal transmission of the subsequently formed PCB soft board.

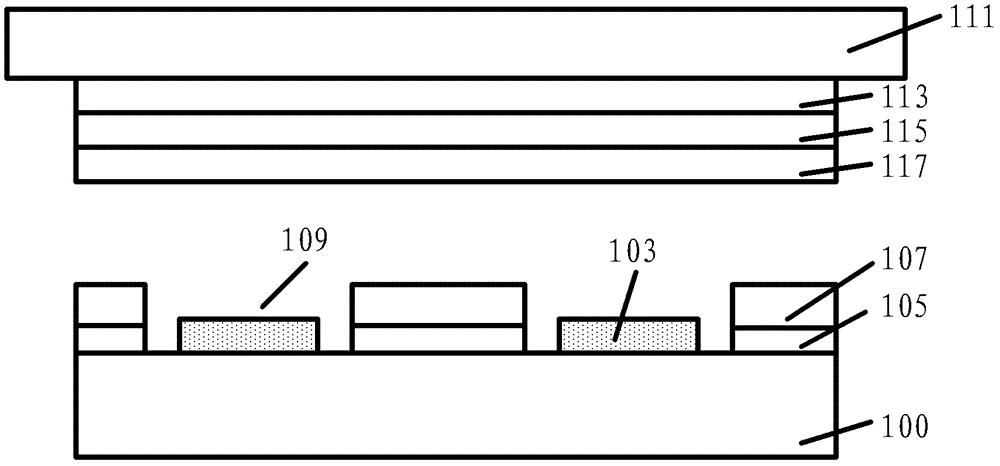

[0034] After research, the inventors of the present invention have found that when using the prior art to form a common soft board, since the size of the window of the cover film is larger than the size of the pad, there is a gap between the cover film and the pad, and there is a gap between the layers. When the covering film is pressed, the part overflowing after the adhesive melts will first overflow into the gap, and will not overflow to the pad, which will affect the signal transmission of the subsequently formed PCB soft board. and please refer to figure 2 The surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com