Patents

Literature

38results about How to "Won't cure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reversible emulsifier and preparation method thereof, and environment-friendly reversible emulsifying drilling liquid and application

ActiveCN106833556AImprove liquidityWon't cureDrilling compositionCarbon numberVolumetric Mass Density

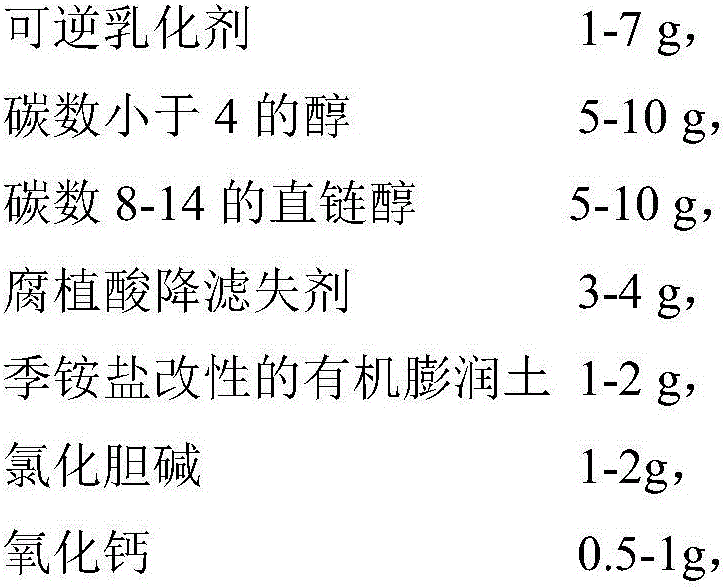

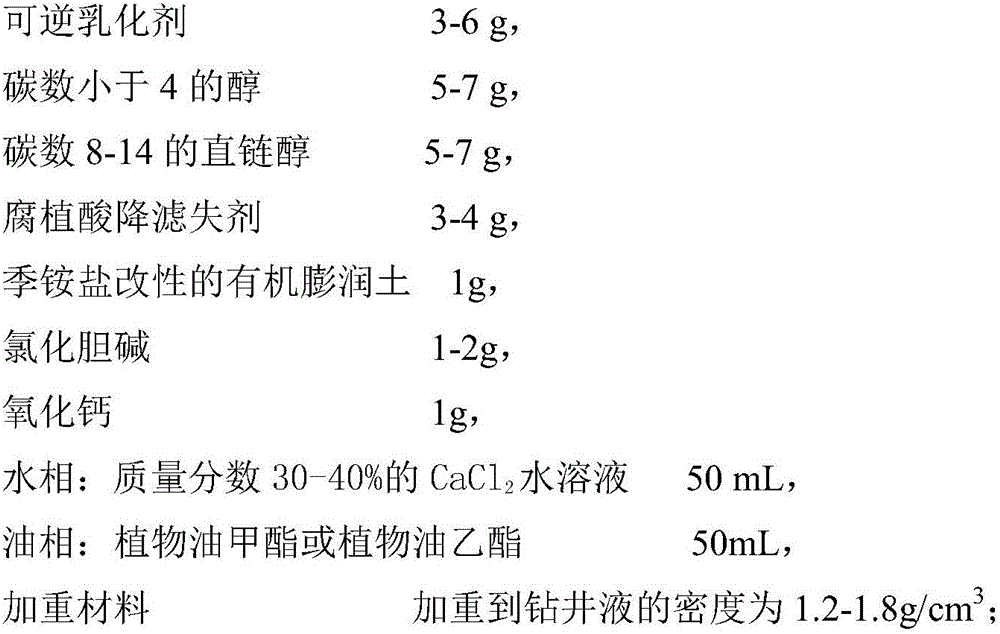

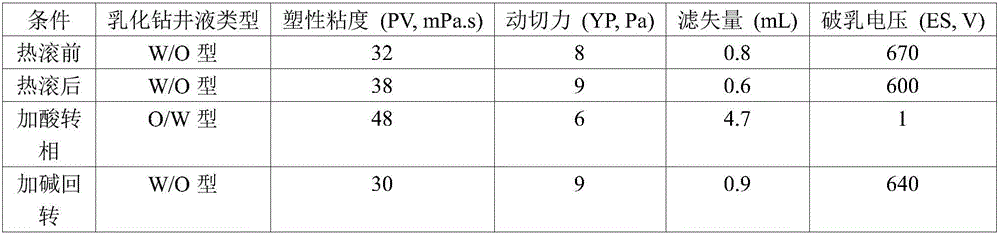

The invention relates to a reversible emulsifier and a preparation method thereof, and an environment-friendly reversible emulsifying drilling liquid and application. The reversible emulsifier is prepared from the following raw materials: initial raw materials: C10-C20 alkyl primary amine, C10-C20 alkyl sulfonic acid, perfluorooctane sulfonate and chloroacetic acid; additives: isopropanol, peregal O-15, and peregal O-8. The environment-friendly reversible emulsifying drilling liquid is prepared by the following steps of stirring an oil phase, the reversible emulsifier and a water phase at high speed, adding alcohols with carbon number less than 4, straight-chain alcohols with carbon number of 8 to 14, quaternary ammonium salt-modified organobentonite, humic acid filtrate loss reducer, calcium oxide and choline chloride, and then adding weighing material, so as to reach the required density of the drilling liquid. The invention also provides a phase transfer method of the reversible emulsifying drilling liquid. The phase transfer method has the advantages that according to production requirements, the phases of the drilling liquid can be conveniently transferred, and the drilling liquid is stable under the two states of W / O (water / oil), and O / W (oil / water), and can be repeatedly used.

Owner:中石化石油工程技术服务有限公司 +2

Treatment method for casing channeling and casing leakage of oil and gas production well

PendingCN108756806AGood sealingConducive to anti-channelingDrilling compositionSealing/packingOil wellWellbore

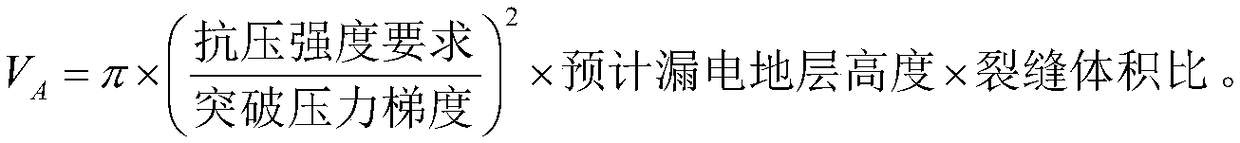

The invention discloses a treatment method for casing channeling and casing leakage of an oil and gas production well. The treatment method comprises the following steps that S1, a first plugging agent, a second plugging agent and a third plugging agent are configured correspondingly; S2, clear water is injected into a casing to measure the water absorbing index, and the using quantity of the plugging agents is predicted preliminarily according to the water absorbing capacity of a stratum; S3, a casing gate is closed, an oil well pipe string or a polished wellbore are trapped in, the first plugging agent and the second plugging agent are extruded and injected into the casing successively, and after injecting is completed, still standing is conducted for four hours; S4, the third plugging agent is injected into the casing, then the clear water is injected into the casing so as to jack the third plugging agent to the leakage point of the casing, and a reserved mortar face is located on the leakage point of the casing; S5, the well is shut down for waiting on cement setting for 72 hours; and S6, after the process of waiting on cement setting is completed, an unloading well opening adopts the pipe string to detect a mortar plugged face, and then plug drilling is conducted. According to the treatment method for casing channeling and casing leakage of the oil and gas production well,the one-time success rate for treatment of casing channeling and casing leakage caused by damage of the oil and gas production well, especially the shallow casing, reaches 90% or above, the types andthe using quantity of treatment agents are less, and the cost is reduced.

Owner:SICHUAN GUANGYA POLYMER CHEM

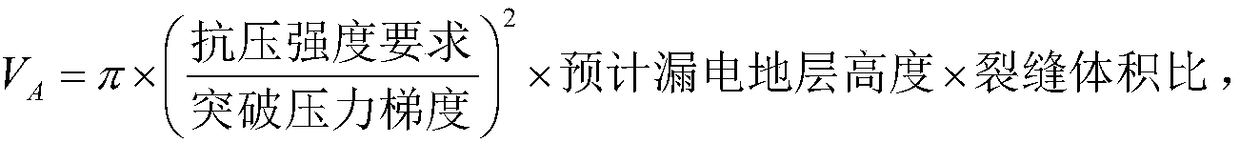

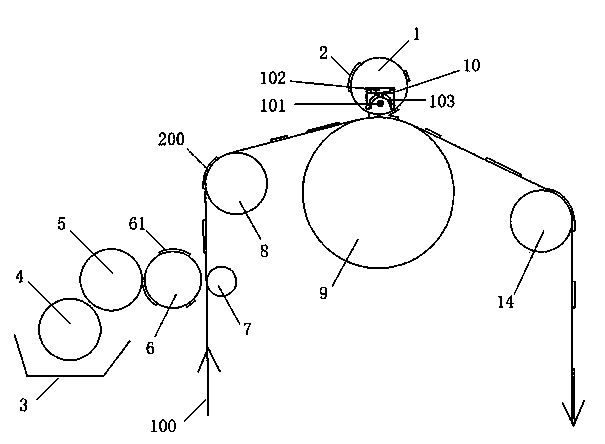

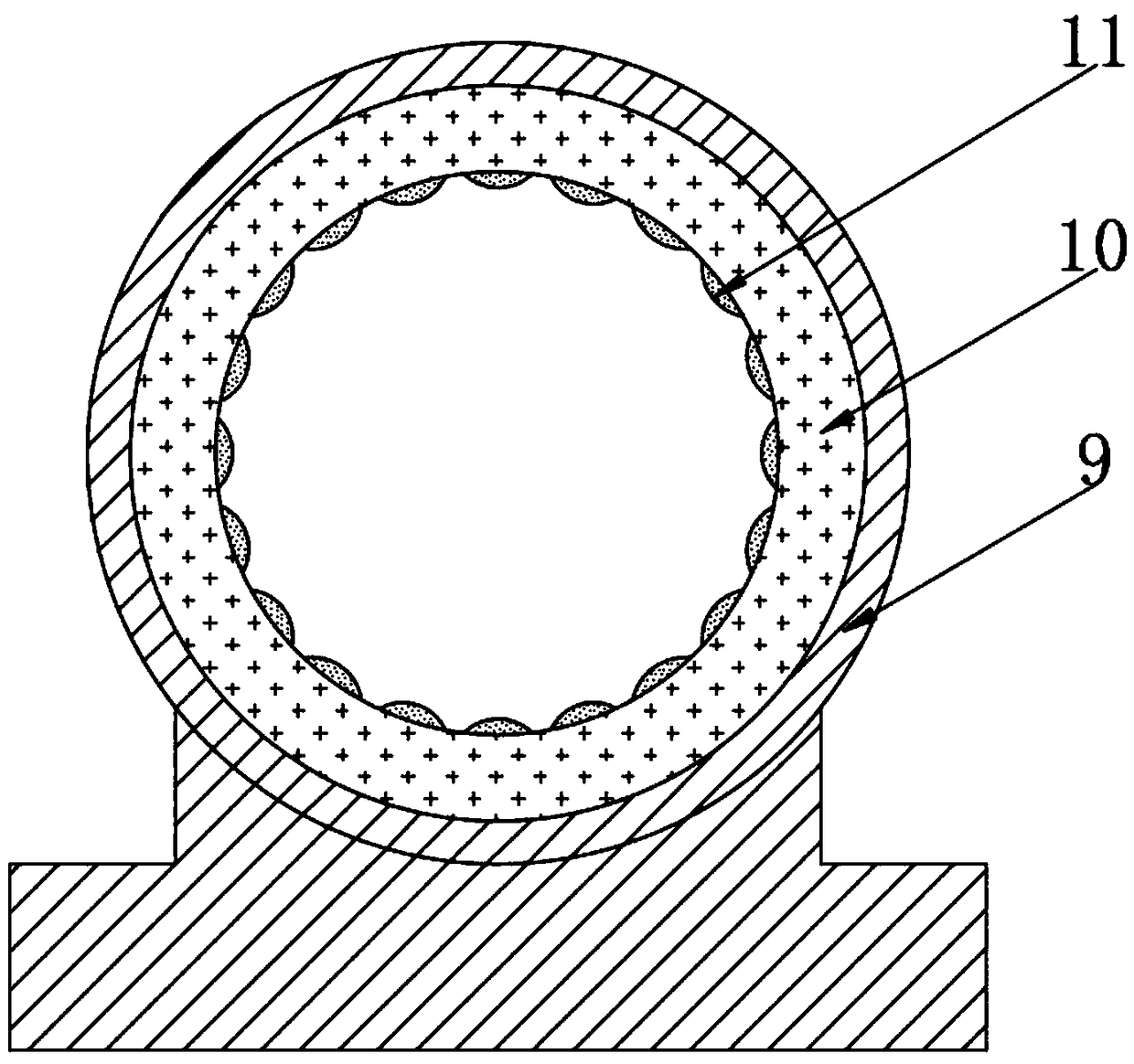

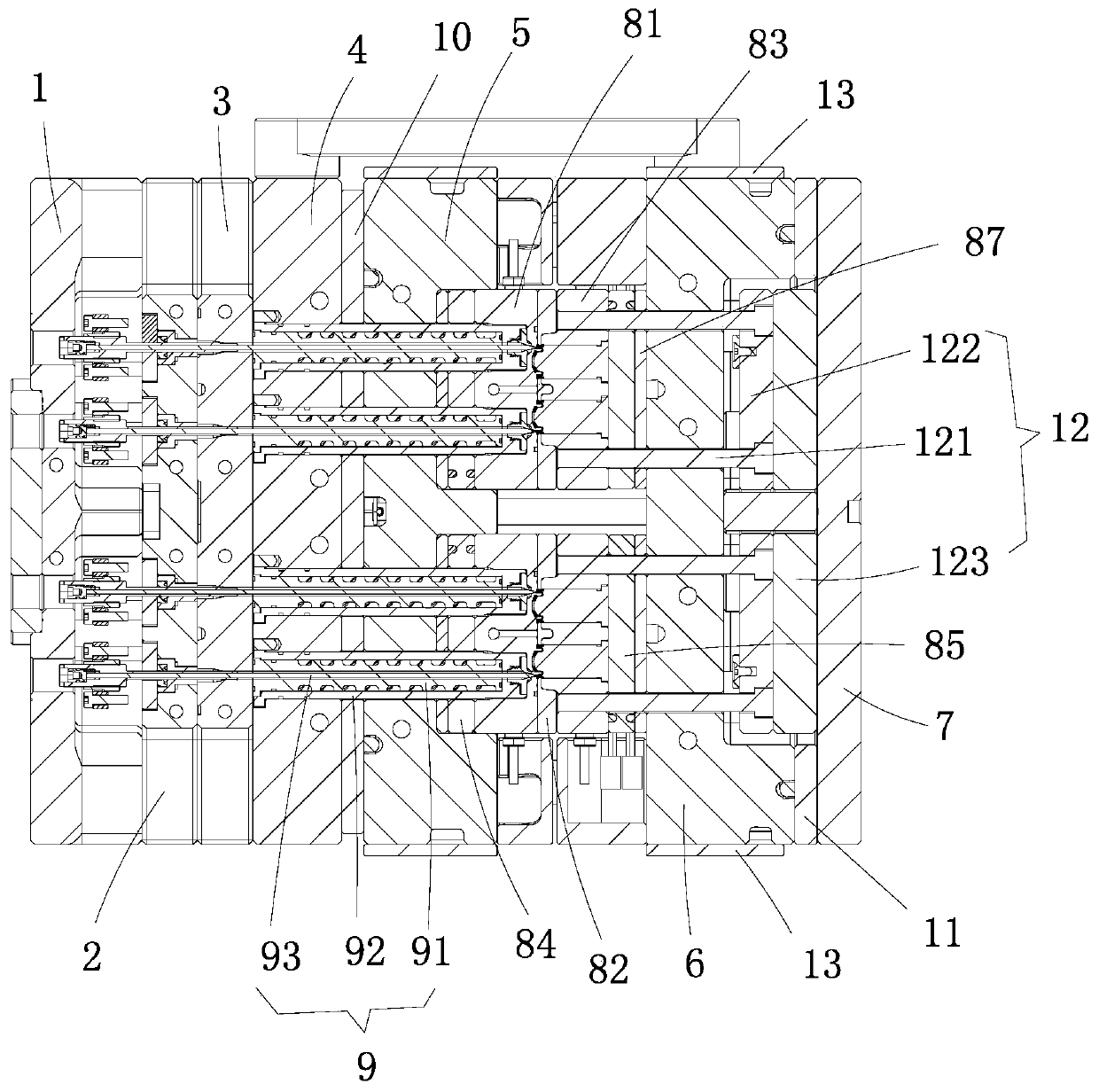

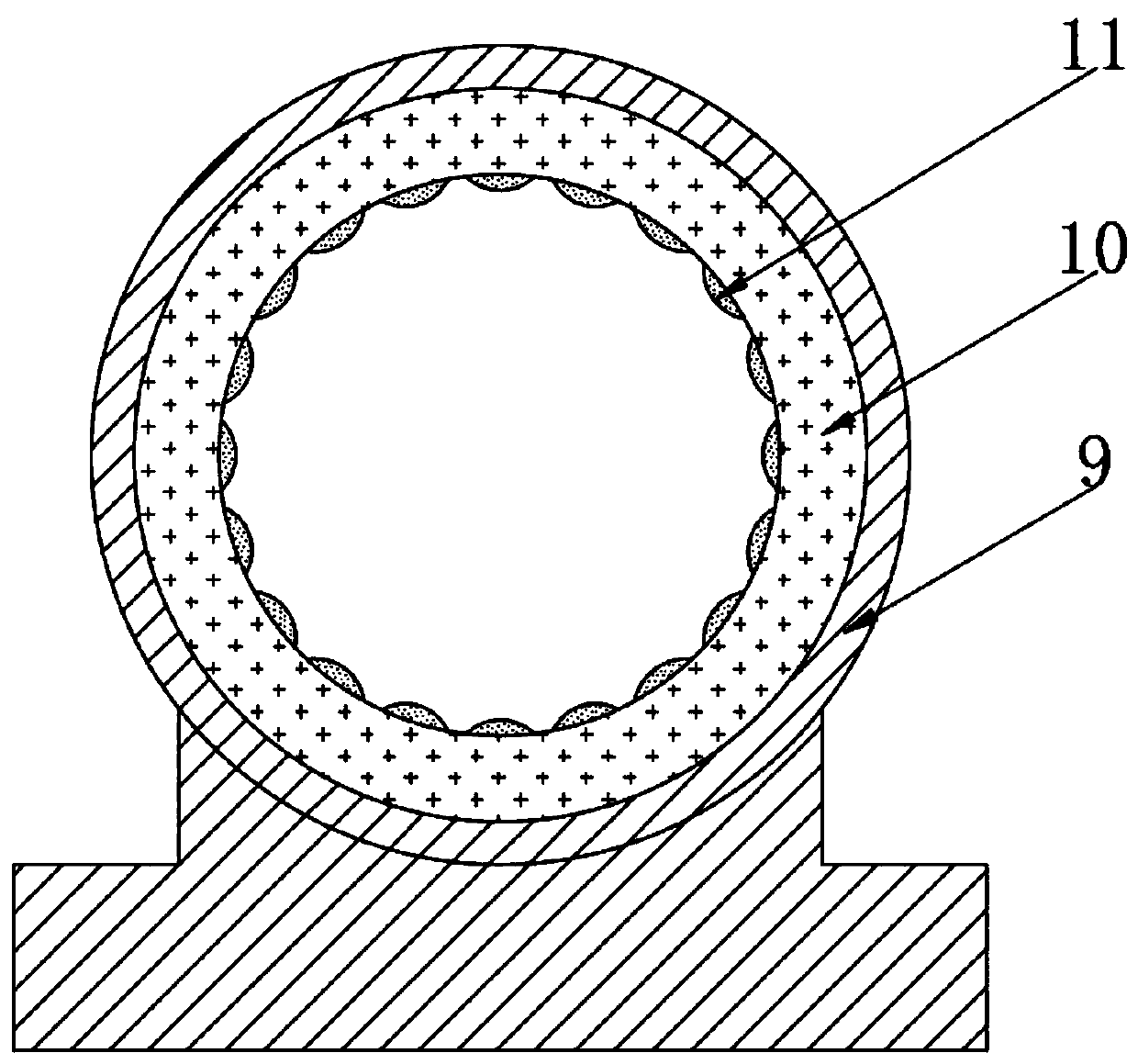

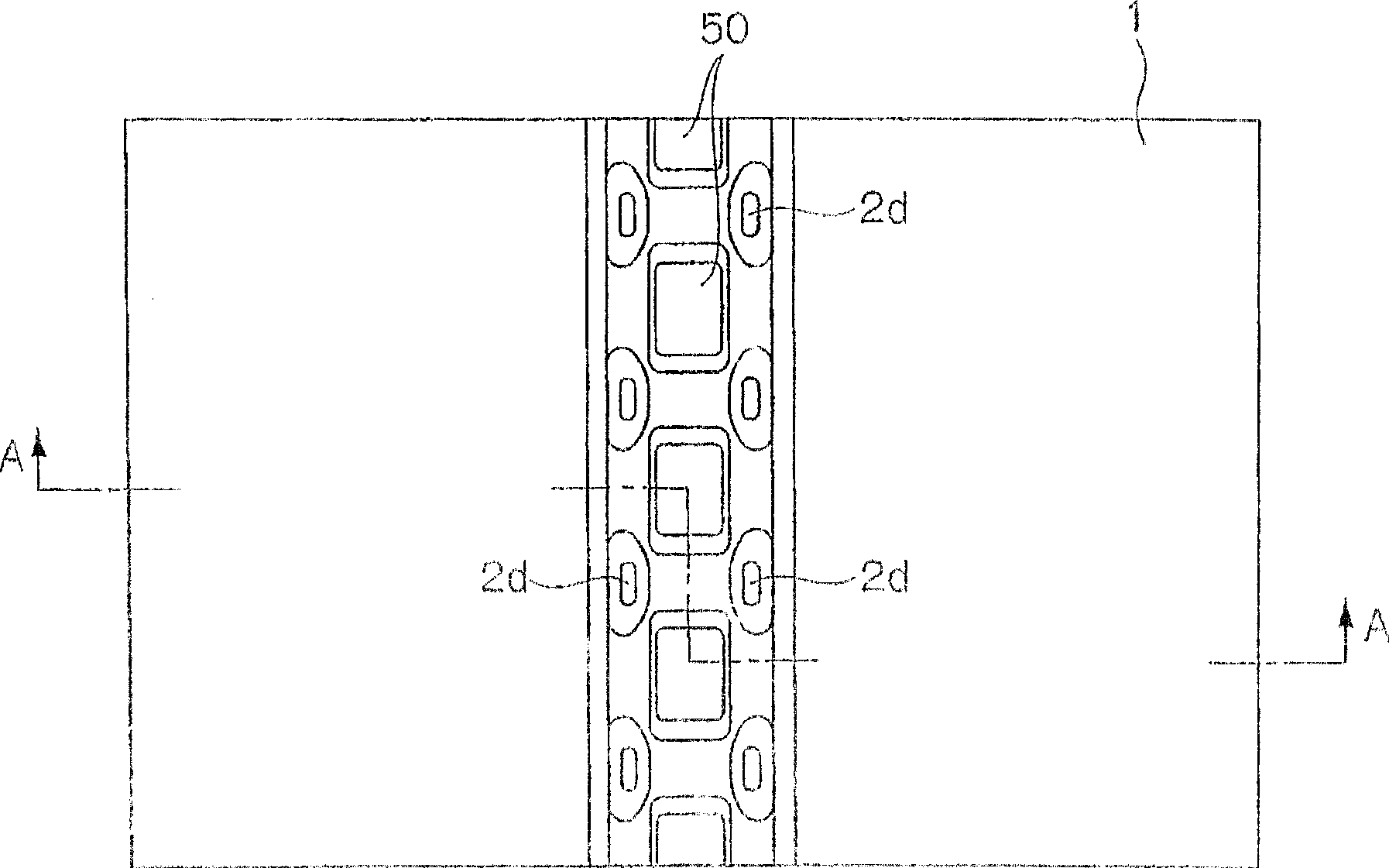

Transparent roller for laser imprinting and laser imprinting device

ActiveCN103722917AImprove surface accuracyImprove heat resistanceStampingLaser patterningEngineering

The invention discloses a transparent roller for laser imprinting. The transparent roller comprises a roller body, a roller hub and a roller shaft. The roller body comprises a quartz glass transparent roller and a plastic transparent roller which is arranged on the quartz glass transparent roller in a sleeved mode and is not in contact with the quartz glass transparent roller. The quartz glass transparent roller and the plastic transparent roller are driven in a synchronous mode through a servo motor. The transparent roller is provided with at least one mother set with an engraved laser pattern. The transparent roller further comprises a shading layer which is arranged above the plastic transparent roller. A light transmitting pattern of the shading layer is matched with the laser pattern of the mother set. Correspondingly, the invention discloses a laser imprinting device used for the transparent roller. Point-to-point location special set pattern imprinting transferring can be achieved, the fringing phenomenon of four sides of a transferred pattern is removed, imprinting transferring pattern accuracy is improved, and pattern surface quality is improved.

Owner:广东依明机械科技有限公司

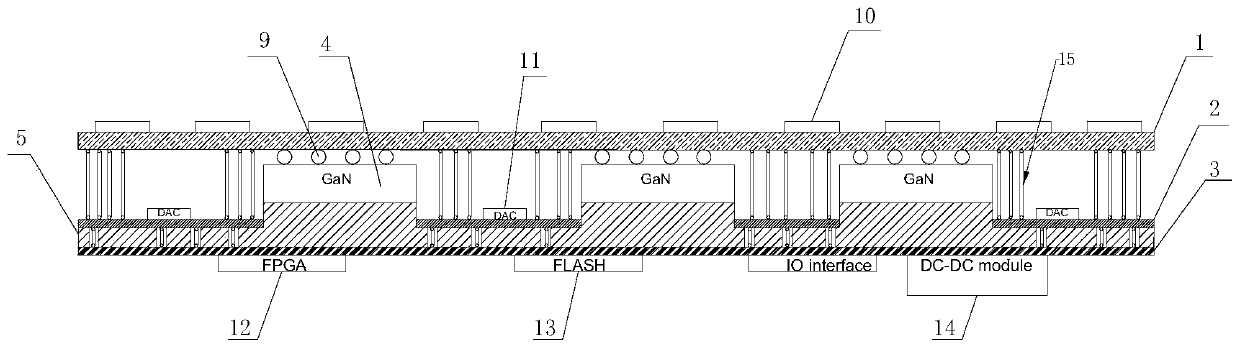

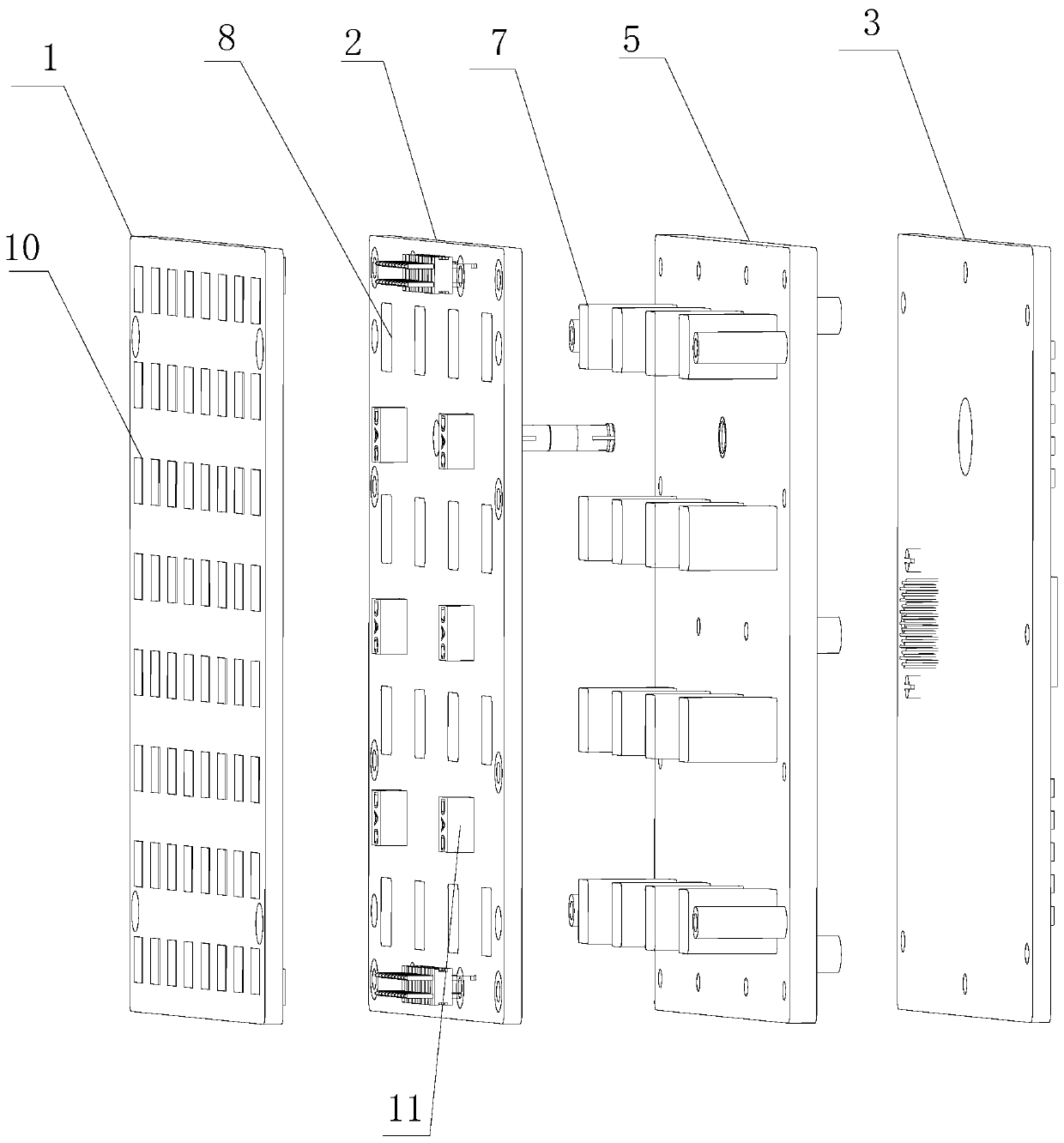

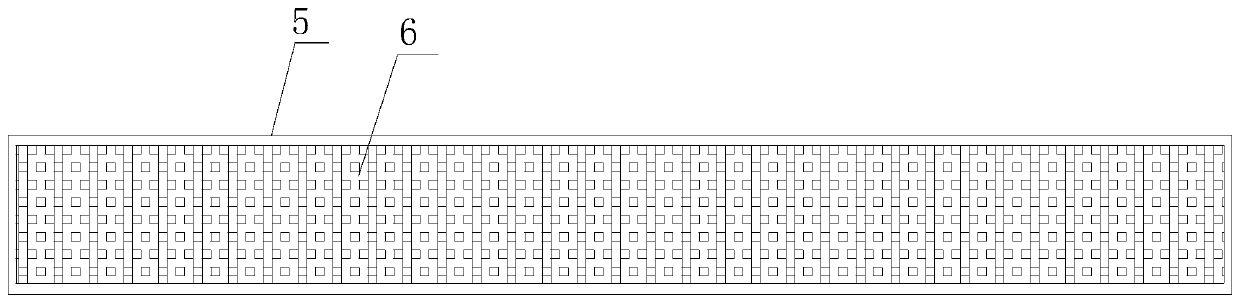

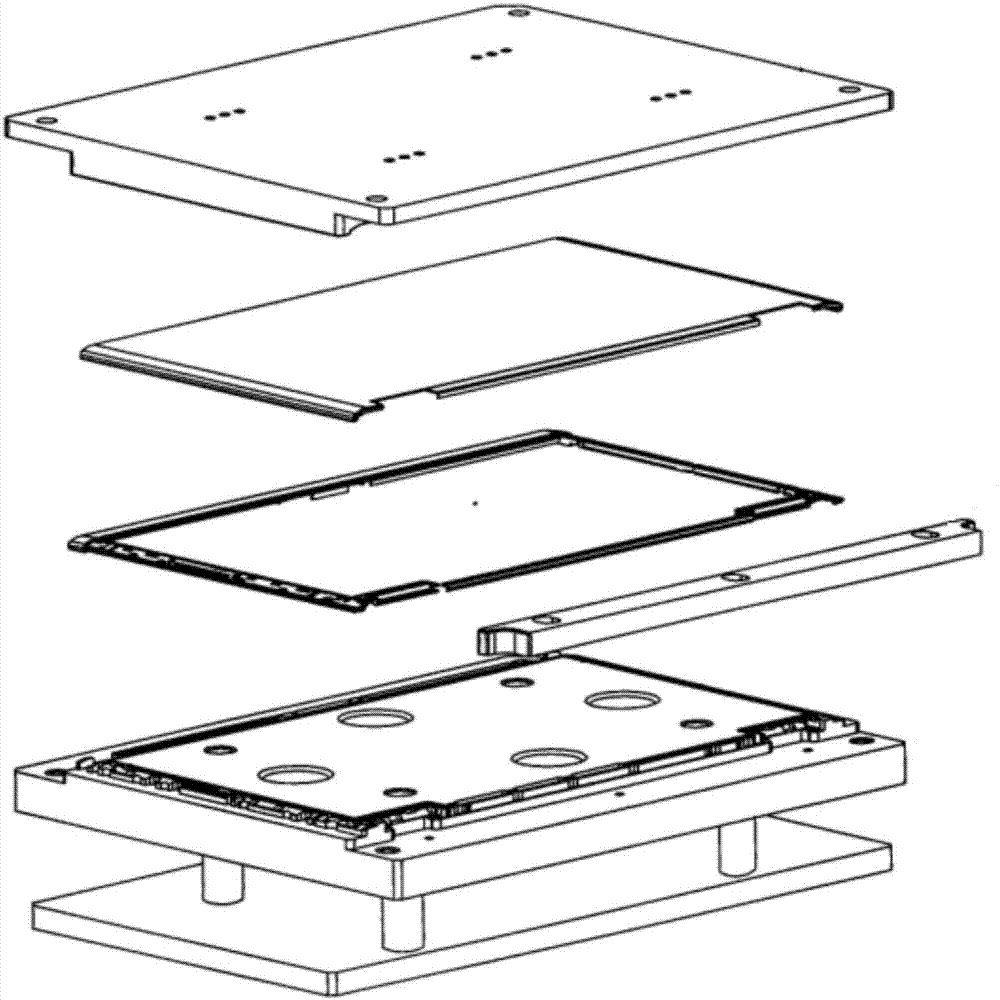

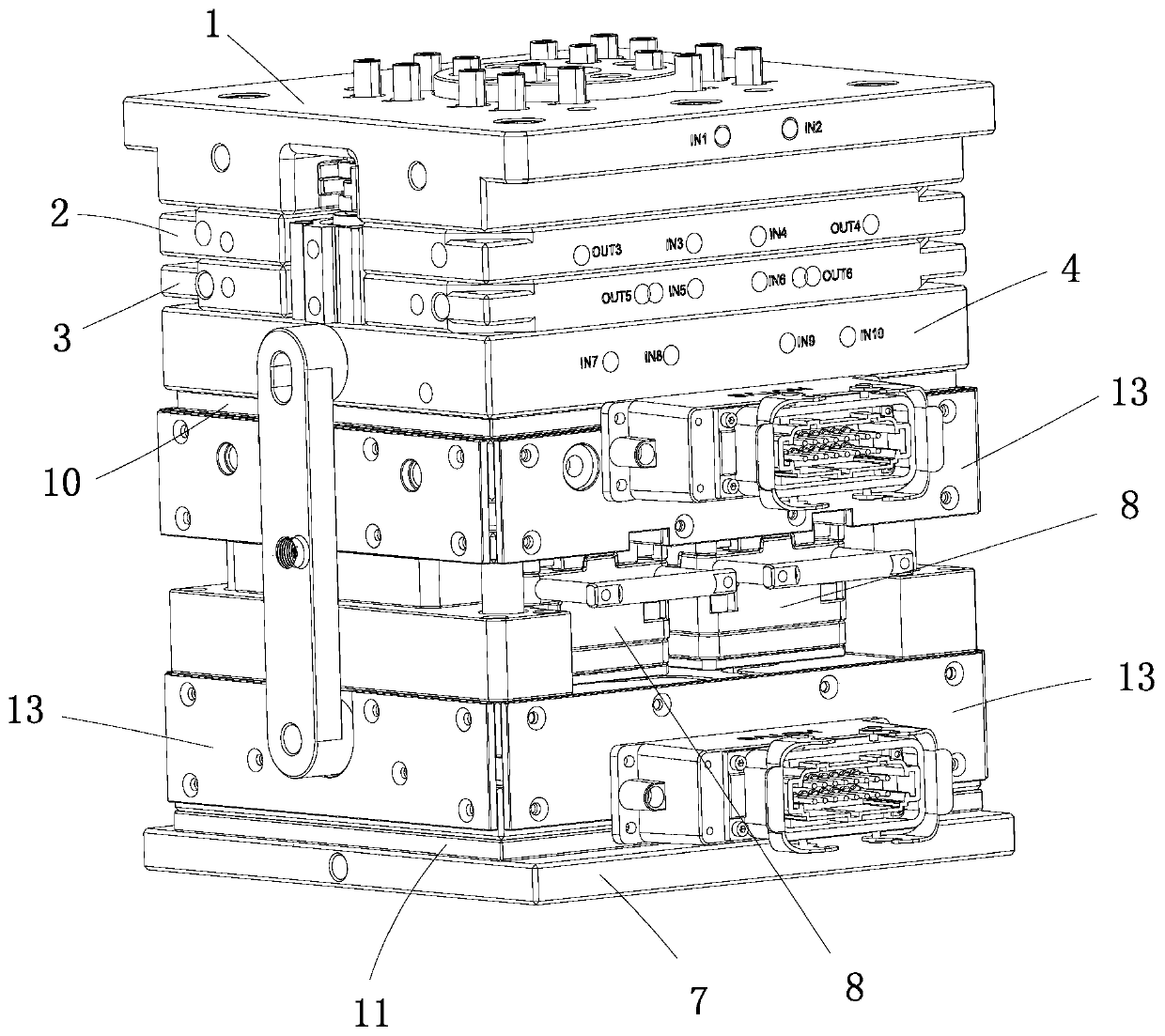

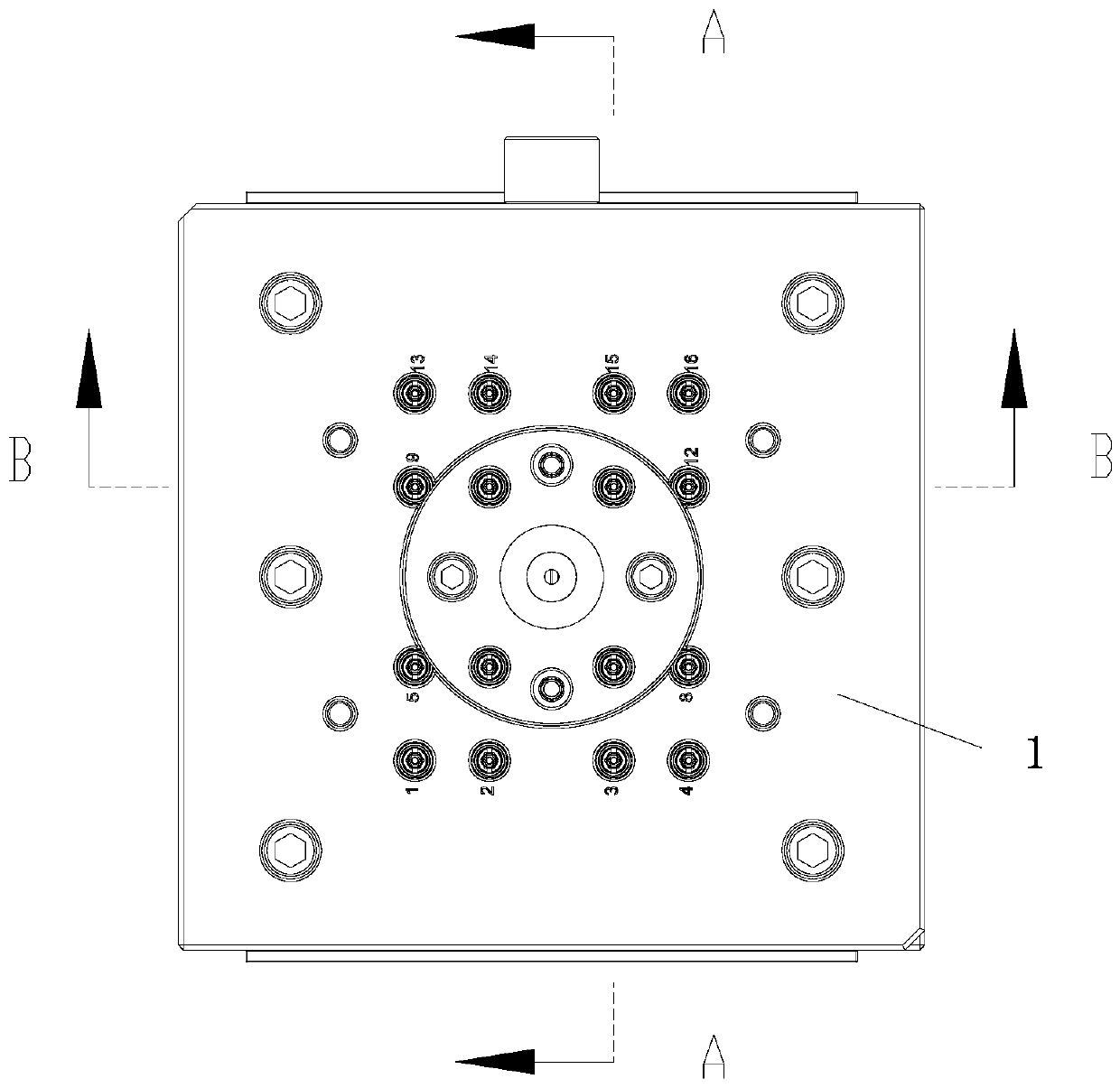

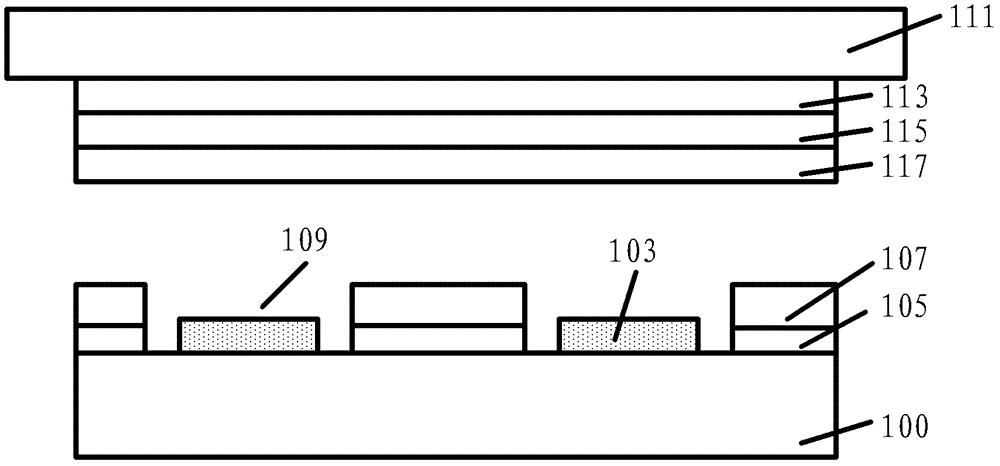

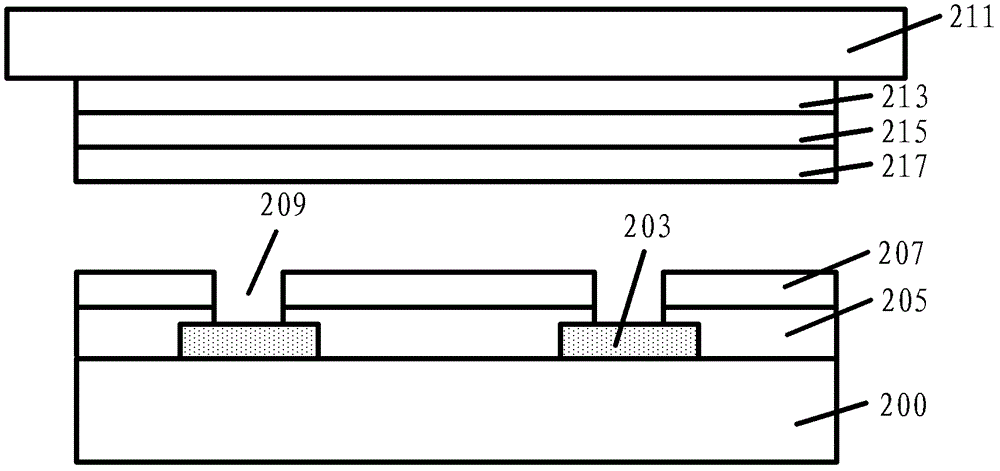

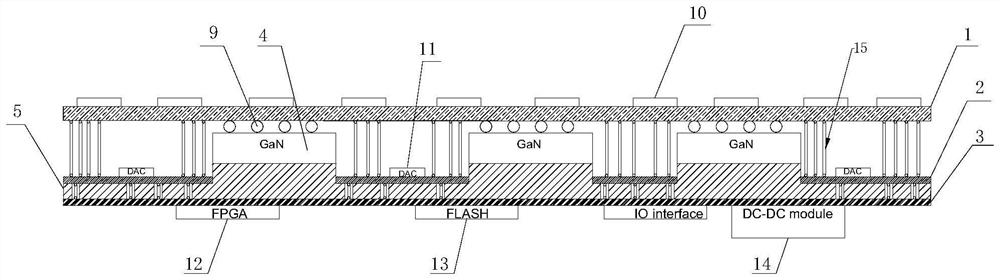

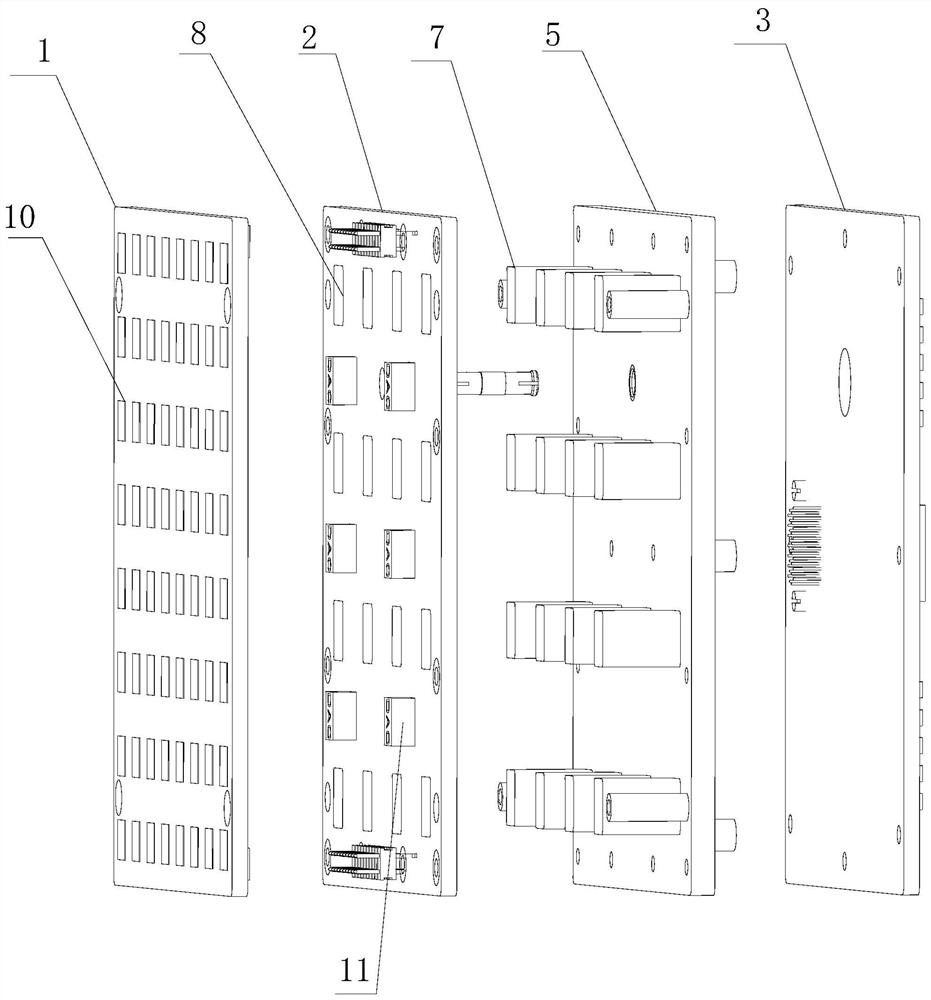

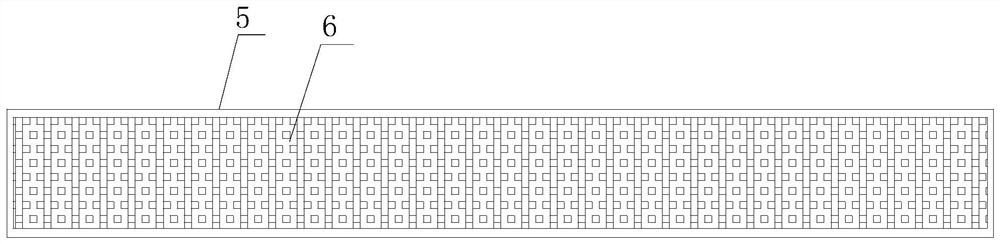

High-power tile type phased-array antenna

ActiveCN110797624AAchieve high power transmissionReal-time heat dissipationParticular array feeding systemsDe-icing/drying-out arrangementsControl signalRadio frequency signal

The invention discloses a high-power tile type phased-array antenna, comprising a first printed circuit board layer, a second printed circuit board layer and a third printed circuit board layer whichare arranged in sequence. The first printed circuit board layer is used for transmitting radio frequency signals and realizing a 64-unit power division network. The second printed circuit board layeris electrically connected with the first printed circuit board layer and is used for controlling phase shift and attenuation of signals. The third printed circuit board layer is electrically connectedwith the second printed circuit board layer and is used for power supply and signal input control. A plurality of chips for signal output are arranged on the first printed circuit board layer. A heatdissipation cold plate is arranged between the second printed circuit board layer and the third printed circuit board layer, and the heat absorption end of the heat dissipation cold plate is in contact with the chips. According to the invention, the problem of chip heating in the antenna can be solved in real time, and high-power transmission of signals can be truly realized.

Owner:成都华芯天微科技有限公司

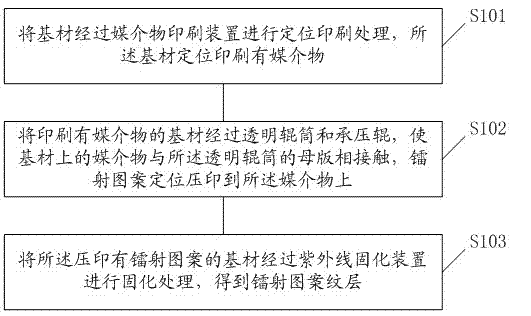

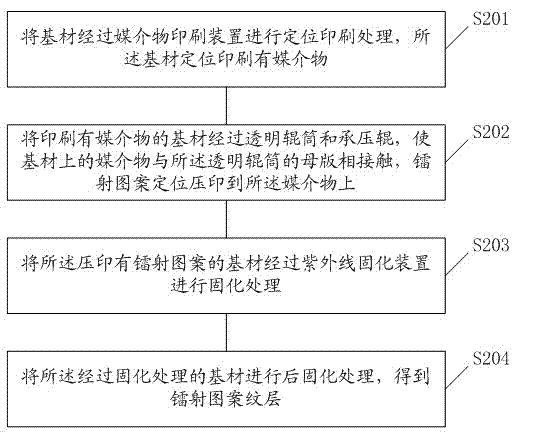

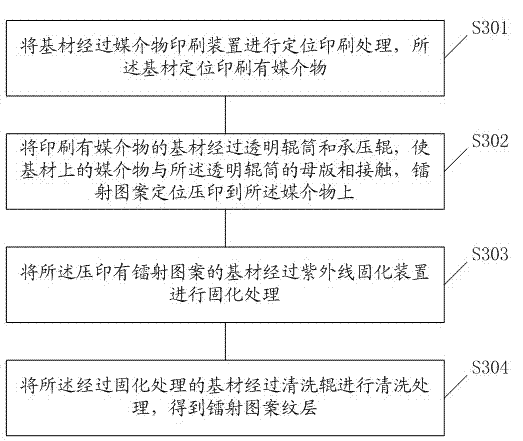

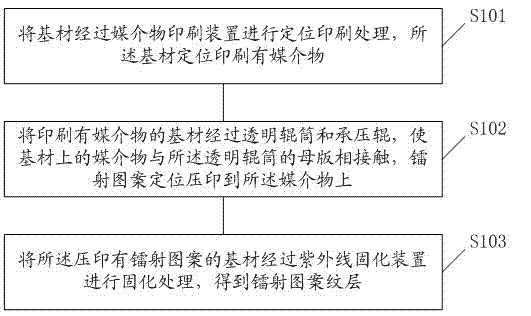

Laser pattern positioning impression transfer method

ActiveCN103707670AQuality improvementSimplify process production routePrinting after-treatmentInk transfer from master sheetUV curingLaser patterning

The invention discloses a laser pattern positioning impression transfer method. The method comprises the following steps: carrying out positioning printing treatment of a substrate through an intermedium printing device to obtain an intermedium position-printed substrate; allowing the intermedium position-printed substrate to go through a transparent roller and a bearing roller to make the intermedium on the substrate contact with a mother matrix of the transparent roller in order to impress a laser pattern on the medium in a positioning manner; and curing the substrate impressed with the laser pattern through an ultraviolet curing device to obtain a laser pattern laminae. The method has the advantages of realization of the point-to-point position special edition pattern impression transfer, elimination of the ghost phenomena of four edges of the transferred pattern, increase of the impression transferred pattern precision, and improvement of the surface quality of the pattern.

Owner:广东依明机械科技有限公司

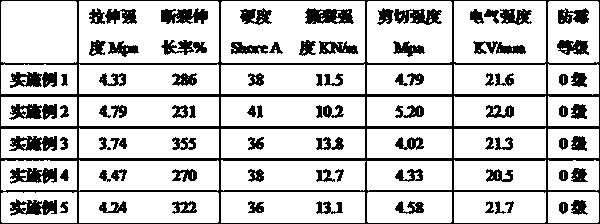

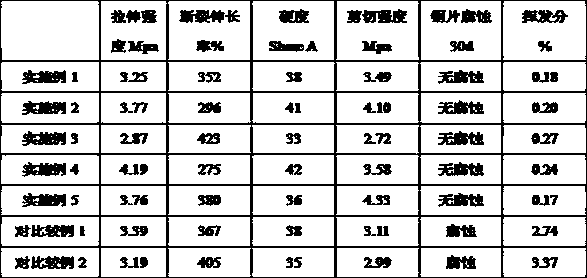

Organosilicon coating rubber for rail transit, and preparation method thereof

The invention discloses an organosilicon coating rubber for rail transit, and a preparation method thereof, and belongs to the technical field of silicone rubber application, wherein the organosiliconcoating rubber comprises: 60-80 parts of hydroxyl-terminated polydimethylsiloxane, 10-20 parts of a reinforcing filler, 10-20 parts of an adhesive film reinforcing agent, 4-8 parts of a cross-linkingagent, 1-5 parts of a chain extender, 0.02-0.5 part of a catalyst, 1-4 parts of a tackifier, and 0.8-3 parts of an antifungal agent, and is prepared through heating drying, vacuum defoaming, vacuum mixing and other steps. According to the present invention, the organosilicon coating rubber is a ketoxime removing type one-component room temperature vulcanized organosilicon elastomer, is used for rail transit, can effectively achieve the effects of water resistance, dust resistance, mildew resistance, insulating protection and the like on the outer layer, can solve the mildew problem of the existing organosilicon coating rubber, can achieve the mildew-resistant grade of 0 grade, does not contain volatile solvents such as petroleum ether, solvent gasoline, toluene and the like, and is safe and environmentally friendly, and the cured rubber layer has good strength and good toughness.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

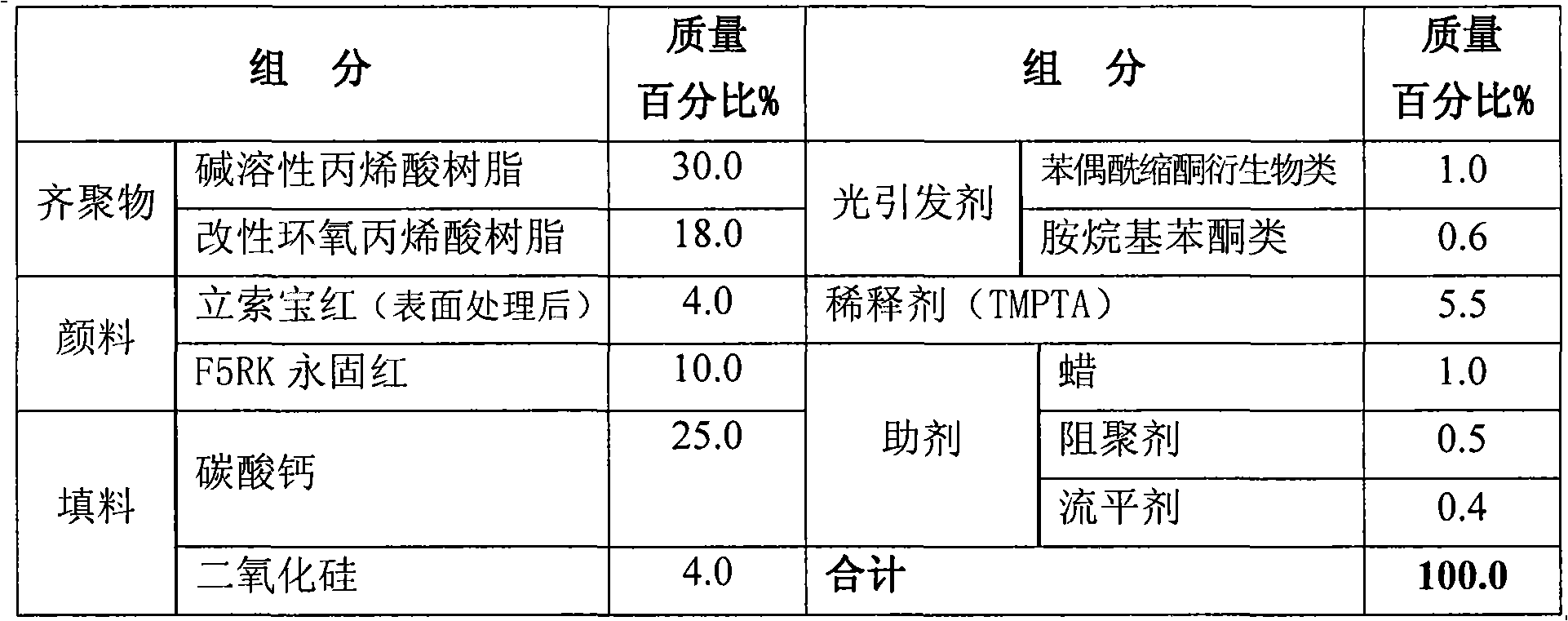

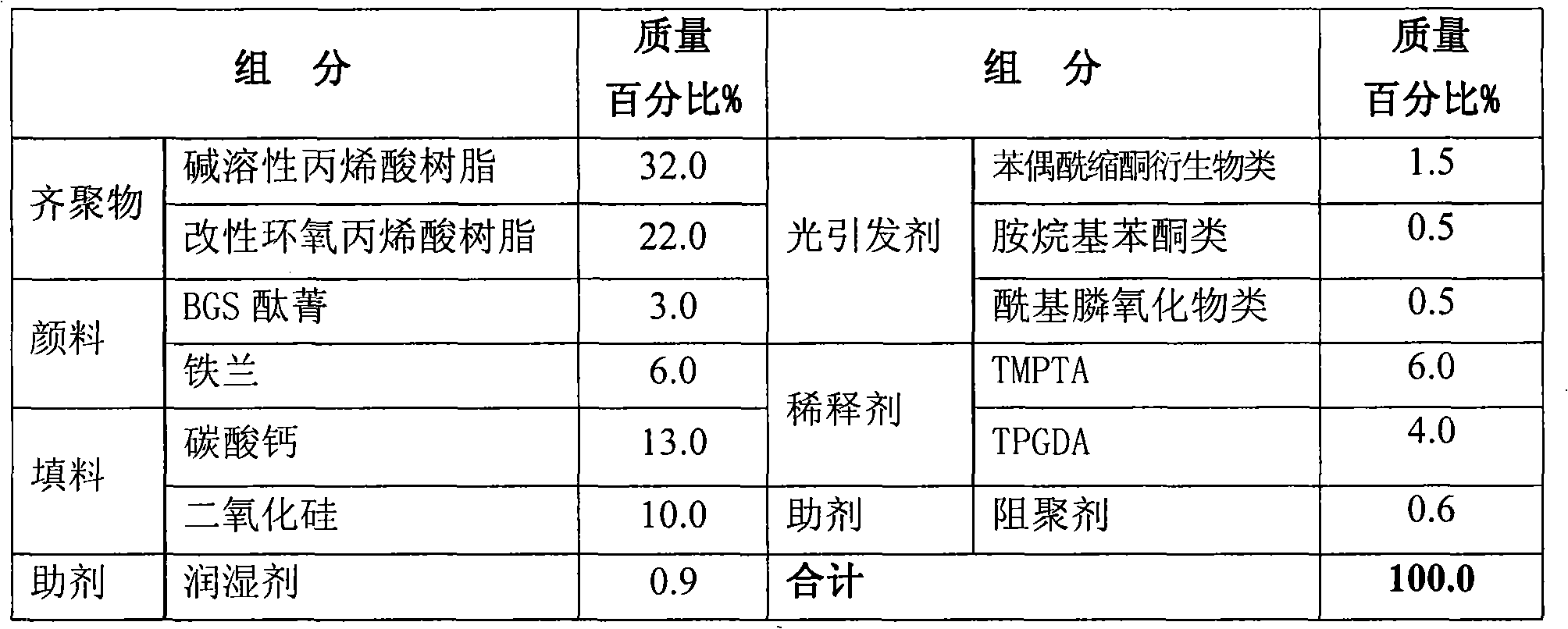

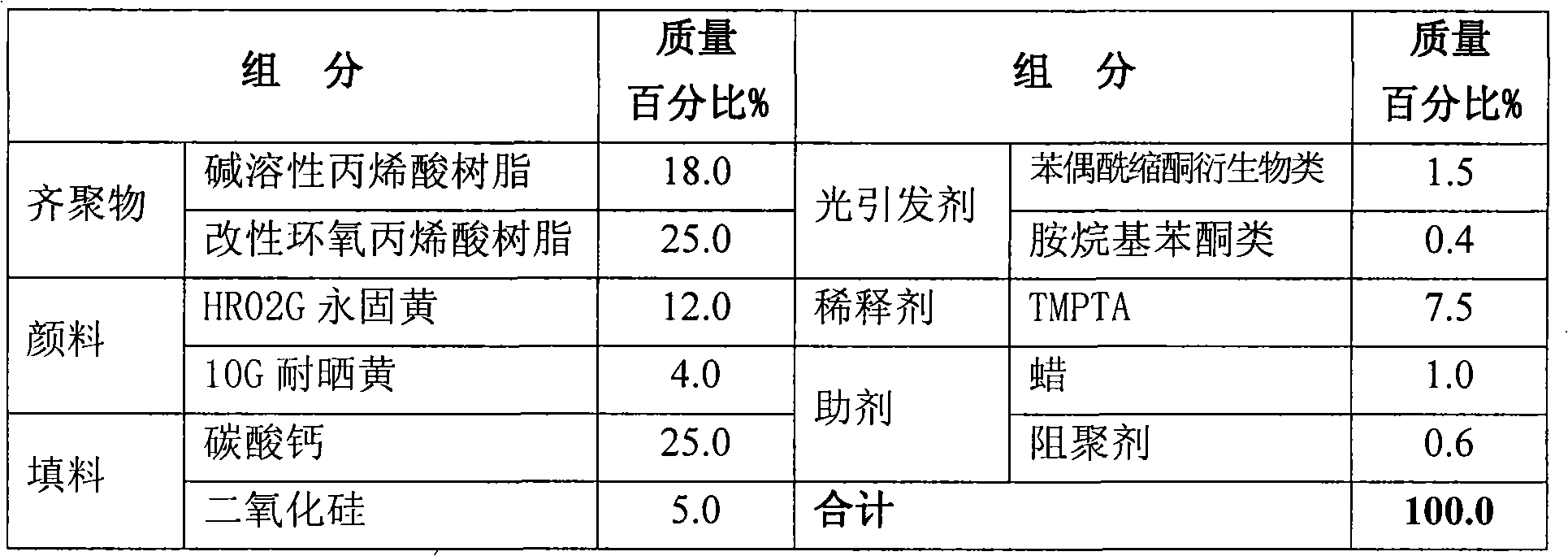

UV curing intaglio printing ink and preparation thereof

UV cured gravure ink and a preparation method thereof relate to UV gravure ink printed adopting engraved intaglio printing and a preparation method thereof in the printing industry and aim at solving the problems of long drying period, easy plate drying, roll drying and poor transitive property in the existing engraved gravure ink. The ink comprises the following components according to mass percent: oligopolymer (30-65 percent), light trigger (1.5-6 percent), pigment (8-15 percent), filler (15-40 percent), diluter (3-15 percent), and addition agent (0.2-5 percent); the preparation method includes the steps of: pre-dispersing 95 percent of the oligopolymer, the pigment and the filler, rolling the components on an ink rolling machine to satisfy specified fineness requirement; putting the rolled components into a stirring bucket so as to be stirred at uniform speed, and adding the remaining 5 percent of the oligopolymer, and the light trigger and the addition agent for uniform mixing; and the diluter is used for adjusting the viscosity of oil. The invention is applicable to engraved intaglio printing.

Owner:CHINA BANKNOTE PRINTING & MINTING

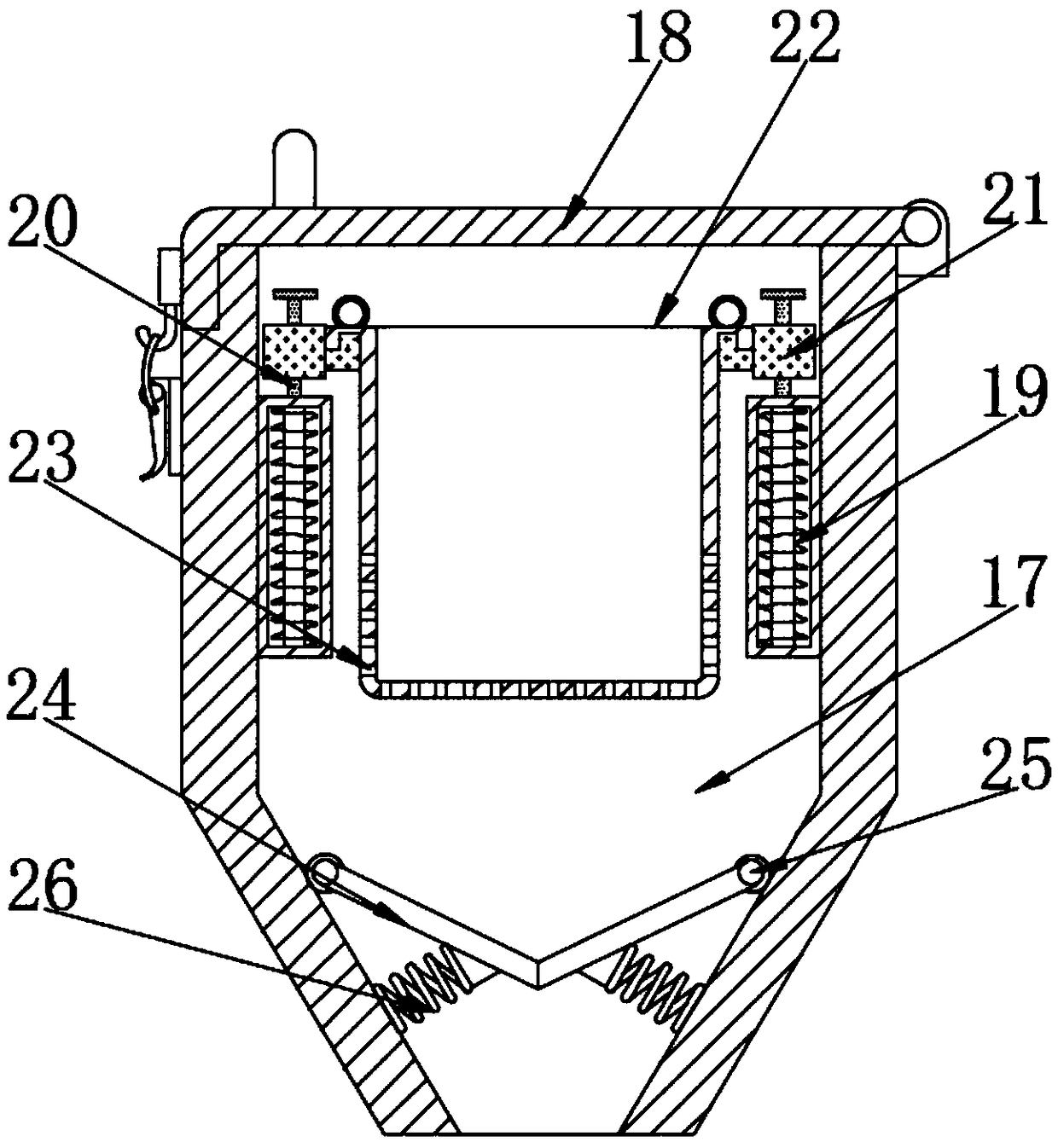

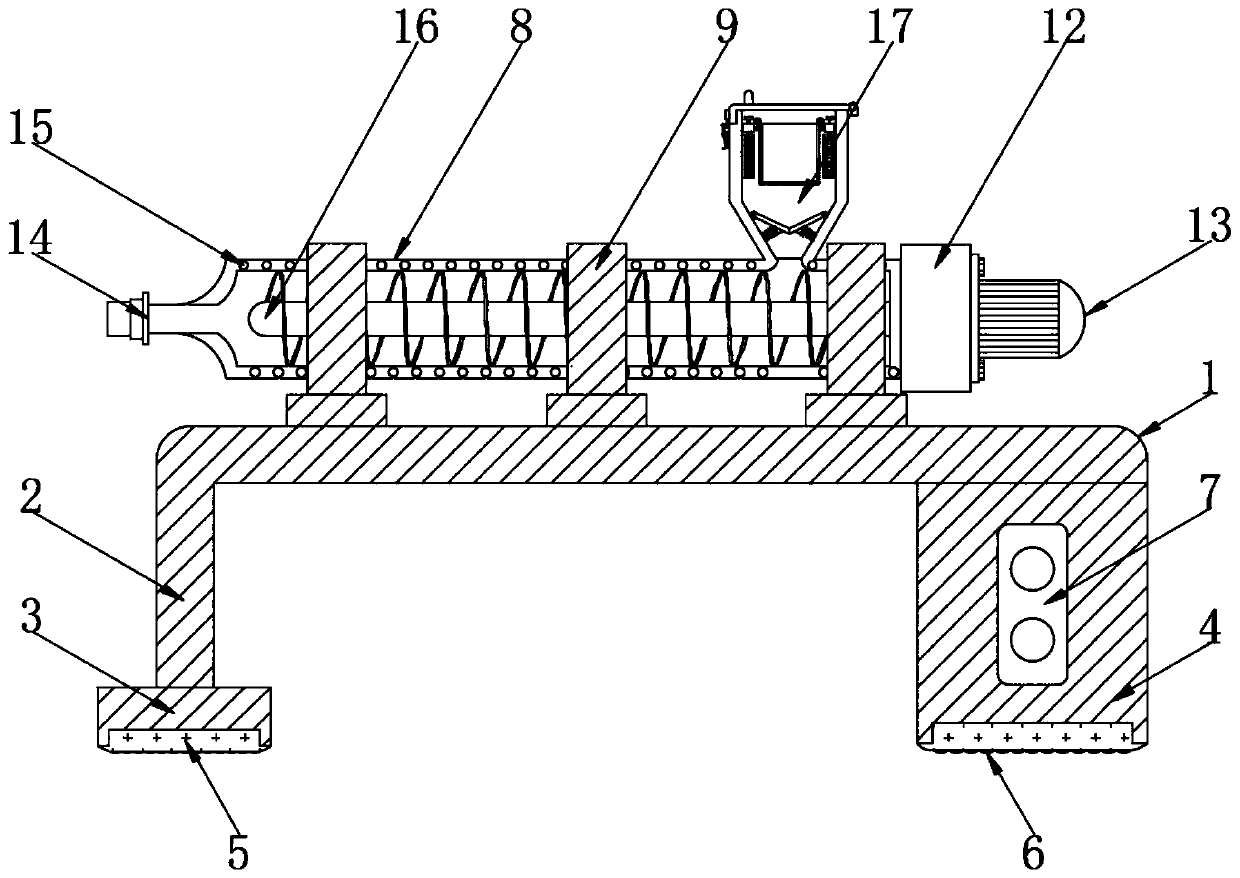

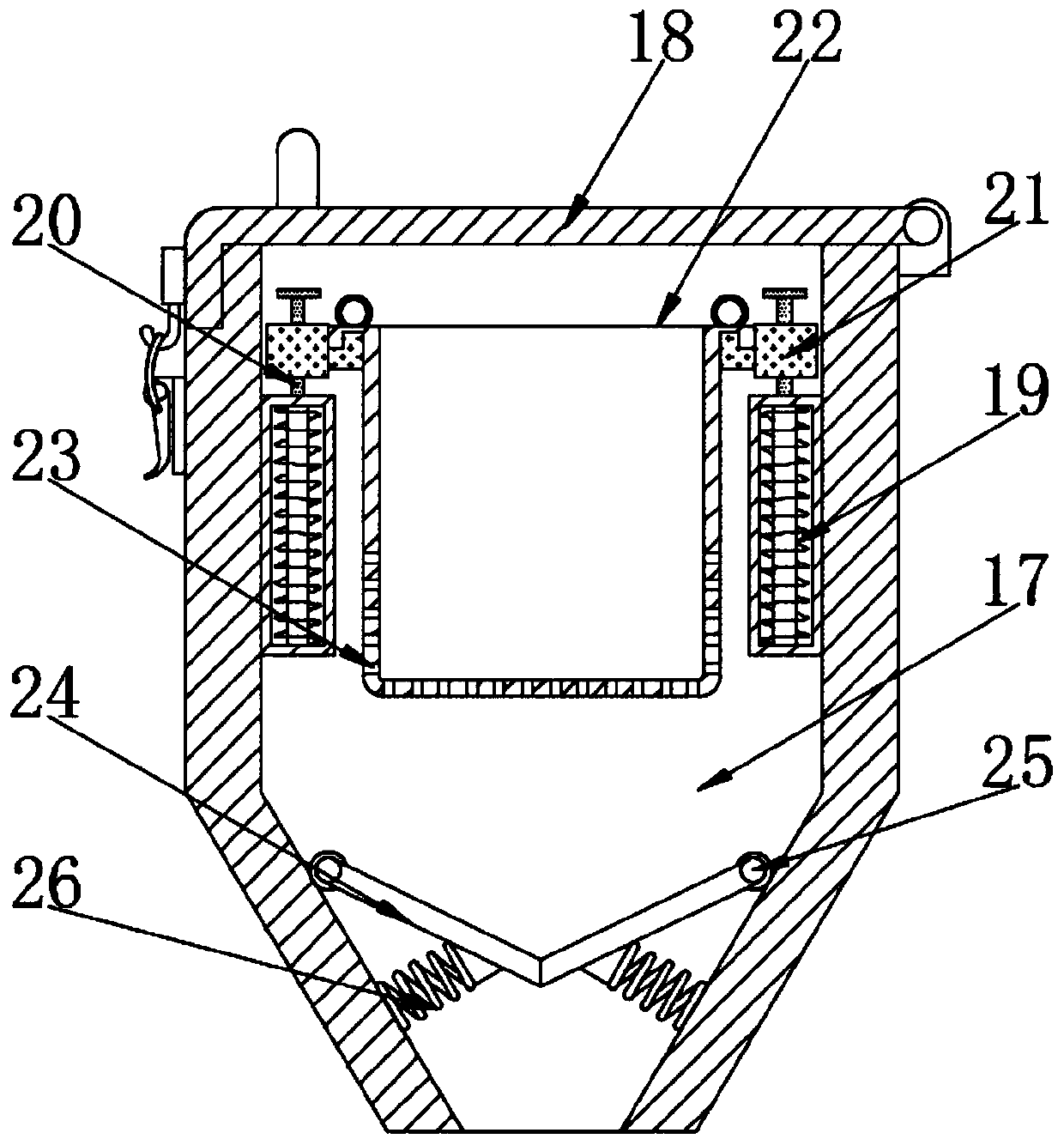

High-stability injection molding machine for plastic shoes

ActiveCN109177029AScientific and reasonable structureEasy to useDomestic articlesPower flowEngineering

The invention discloses a high-stability injection molding machine for plastic shoes. The injection molding machine comprises a feeding hole, electromagnets, sliding rods, magnets, a screening basketand screening holes, wherein the electromagnets are mounted on the inner wall in the feeding hole, the sliding rods are mounted at the top ends of the electromagnets and are externally sleeved with the magnets, a screening screen is fixedly mounted on one sides of the magnets through buckles, and the screening holes are formed in the bottom end and bottom of the screening screen. The injection molding machine is scientific and reasonable in structure and safe and convenient to use; by arranging the electromagnets, the sliding rods, the magnets, the screening basket and the screening holes, alternating current in the electromagnets is continuously changed so as to change the magnetism of the electromagnets constantly, the to-and-fro shaking of the screening basket is effectively realized through the cooperation with the magnets, and the automatic screening of the raw materials in the feeding process can be realized through the cooperation with the screening holes, so that the raw material screening time is saved, the working efficiency of the injection molding machine is improved, and the injection molding quality of the injection molding machine is improved.

Owner:揭阳市新华龙机械设备有限公司

Medical one-component room temperature vulcanization silicone rubber and preparation method thereof

InactiveCN109929505AReduce contentSmall smellNon-macromolecular adhesive additivesCross-linkVulcanization

The invention discloses a medical one-component room temperature vulcanization silicone rubber and a preparation method thereof, and belongs to the technical field of silicone rubber application, wherein the raw materials of the medical one-component room temperature vulcanization silicone rubber comprises, by mass, 100 parts of low volatile hydroxyl-terminated polydimethylsiloxane, 15-25 parts ofa reinforcing filler, 4-10 parts of a cross-linking agent, 1-3 parts of a tackifier, and 0.1-1 part of a catalyst, and is prepared through heating drying, vacuum defoaming, vacuum mixing and other steps. According to the present invention, the medical one-component room temperature vulcanization silicone rubber can greatly reduce the volatilization amount of D3-D10 small molecules; by using the ethyl lactate-based cross-linking agent, the odor during the silicone rubber vulcanization process is reduced, and no corrosion is generated to the metal material; and by using the novel catalyst, thesafety is further improved compared with the ordinary one-component room temperature vulcanized silicone rubber.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Simple hot pressing method

The invention belongs to the field of automatic mechanical equipment, and in particular, relates to a simple hot pressing method. The simple hot pressing method comprises the following steps: (1) an iron piece is put in a groove of a fixed base; (2) the iron piece is glued; and a plastic part is put on the iron piece; (3) relative positions of a rotating shaft and the fixed base are adjusted; (4) a rotating rod is driven to rotate under the effect of external force; (5) the rotating rod is continuously rotated; and meanwhile, the position of a sleeve on the rotating rod is adjusted; (6) the rotating rod is continuously rotated until the plastic part and the iron piece are totally glued in a gluing position on the iron piece; (5) the rotating rod is continuously rotated; and the position of the sleeve can guarantee the acting force of a pressure applying piece on the upper surface of the plastic part; and (6) the rotating rod is continuously rotated until the plastic part and the iron piece are totally glued. The simple hot pressing method can effectively realize accurate positioning and gluing of the plastic part and the iron piece.

Owner:WUXI HOUFA AUTOMATIC EQUIP CO LTD

Liquid butyl rubber asphalt waterproof coating and preparation method

InactiveCN104974665AGuaranteed performanceExtend your lifeInksBituminous coatingsPolymer sciencePetroleum resin

The invention discloses liquid butyl rubber asphalt waterproof coating and a preparation method. According to the invention, a used additive has long chain and low molecular weight, can ensure that the asphalt can be mutually mixed and dissolved with various high polymer materials in the production process, so that steady combination is formed, respective characteristics take effect under the most steady state in the application process, and thus the asphalt never can be cured. The preparation method of the waterproof coating disclosed by the invention comprises the following steps of heating the asphalt in formula weight to 130-180 DEG C, then, adding liquid butyl rubber, SBS, naphthenic oil and petroleum resin into the asphalt in formula weight, stirring at 175-180 DEG C for 1-2h, finally, decreasing the temperature to 160 DEG C, adding reclaimed rubber in formula weight, stirring for 1-1.5h till the mixture is uniform and does not contain particles, and discharging after the mixture is molten. The waterproof coating disclosed by the invention has the advantages that the waterproof coating is difficult to crystallize at low temperature; the waterproof coating cannot be cured even though placed for a long time after construction; the original property of the waterproof material is kept; and furthermore, the service life of the waterproof coating is greatly increased.

Owner:北京世纪洪雨科技有限公司

Liquid silica gel cold-runner mould

PendingCN110076964AAvoid quality defects such as lack of glueImprove cooling effectRubber materialManufacturing technology

The invention discloses a liquid silica gel cold-runner mould, and relates to the technical field of silica gel mould manufacturing. The liquid silica gel cold-runner mould is provided with mould cores; each mould core comprises a concave mould plate, a stripper plate and a convex mould plate which are arranged in a stacked manner; exhaust holes are formed in the parts, corresponding to the ends of material flows of cavities, of the concave mould plates; the ends of the exhaust holes communicate with a vacuum pump; sealing rings are arranged between the concave mould plates and the stripper plates; and the cavities and the exhaust holes are positioned in sealing areas enclosed by the sealing rings. The sealing rings are arranged in the mould cores, so that the cavities are positioned in sealed environments; and the cavities communicate with the exhaust holes, after the liquid silica gel cold-runner mould is closed, the cavities are rapidly vacuumized by the vacuum pump, and a rubber material is injected after the vacuum degree reaches a rated degree, so that the situation that the quality defects such as hungry joint and the like of silica gel products are caused since a serious air entrapment phenomenon occurs is avoided.

Owner:厦门豪特维思科技有限公司

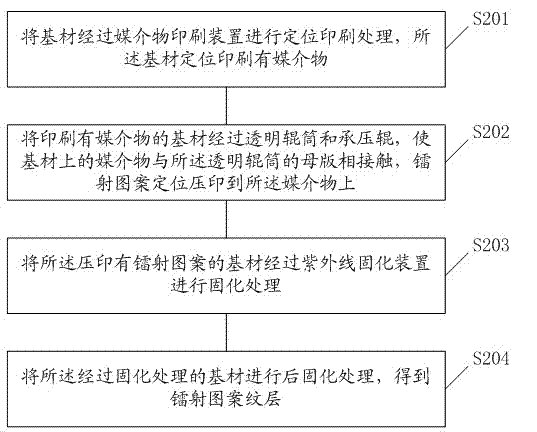

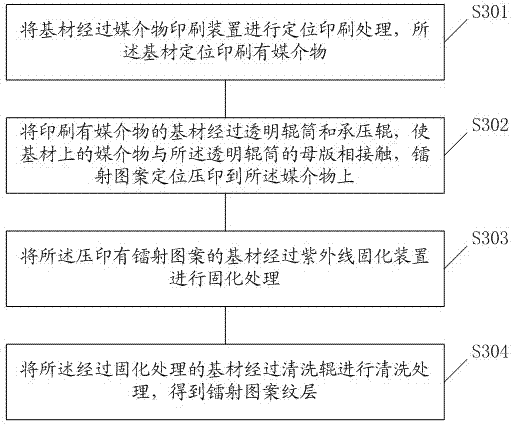

Laser pattern positioning impression transfer method

ActiveCN103707670BQuality improvementSimplify process production routePrinting after-treatmentInk transfer from master sheetUV curingLaser patterning

The invention discloses a laser pattern positioning impression transfer method. The method comprises the following steps: carrying out positioning printing treatment of a substrate through an intermedium printing device to obtain an intermedium position-printed substrate; allowing the intermedium position-printed substrate to go through a transparent roller and a bearing roller to make the intermedium on the substrate contact with a mother matrix of the transparent roller in order to impress a laser pattern on the medium in a positioning manner; and curing the substrate impressed with the laser pattern through an ultraviolet curing device to obtain a laser pattern laminae. The method has the advantages of realization of the point-to-point position special edition pattern impression transfer, elimination of the ghost phenomena of four edges of the transferred pattern, increase of the impression transferred pattern precision, and improvement of the surface quality of the pattern.

Owner:广东依明机械科技有限公司

3d printing method for manufacturing metal part or ceramic part through resin

PendingCN112439901AIncrease contentHigh viscosityAdditive manufacturing apparatusTransportation and packagingSlurryCeramic particle

The invention discloses a 3d printing method for manufacturing a metal part or a ceramic part through resin. The 3d printing method comprises the following steps that S1, a photosensitive resin preparation process is conducted; S2, nano metal particles can be pretreated or not pretreated, and nano ceramic particles must be pretreated; S3, slurry is prepared; S4, FDM printing is carried out; S5, the printed object is cleaned; S6, supports are removed, wherein redundant supports on the printed object are removed; S7, degreasing is carried out; S8, sintering is conducted, wherein some metals needto be sintered in a specific atmosphere or vacuum. As an FDM method needs high-viscosity resin, the sedimentation problem of particles does not need to be considered. Compared with the prior art, a resin material with metal particles or ceramic particles having a volume fraction of 60%-95% can be prepared.

Owner:杜晖

A plastic shoe injection molding machine with strong stability

ActiveCN109177029BScientific and reasonable structureEasy to useDomestic articlesInjection molding machineAlternate current

Owner:揭阳市新华龙机械设备有限公司

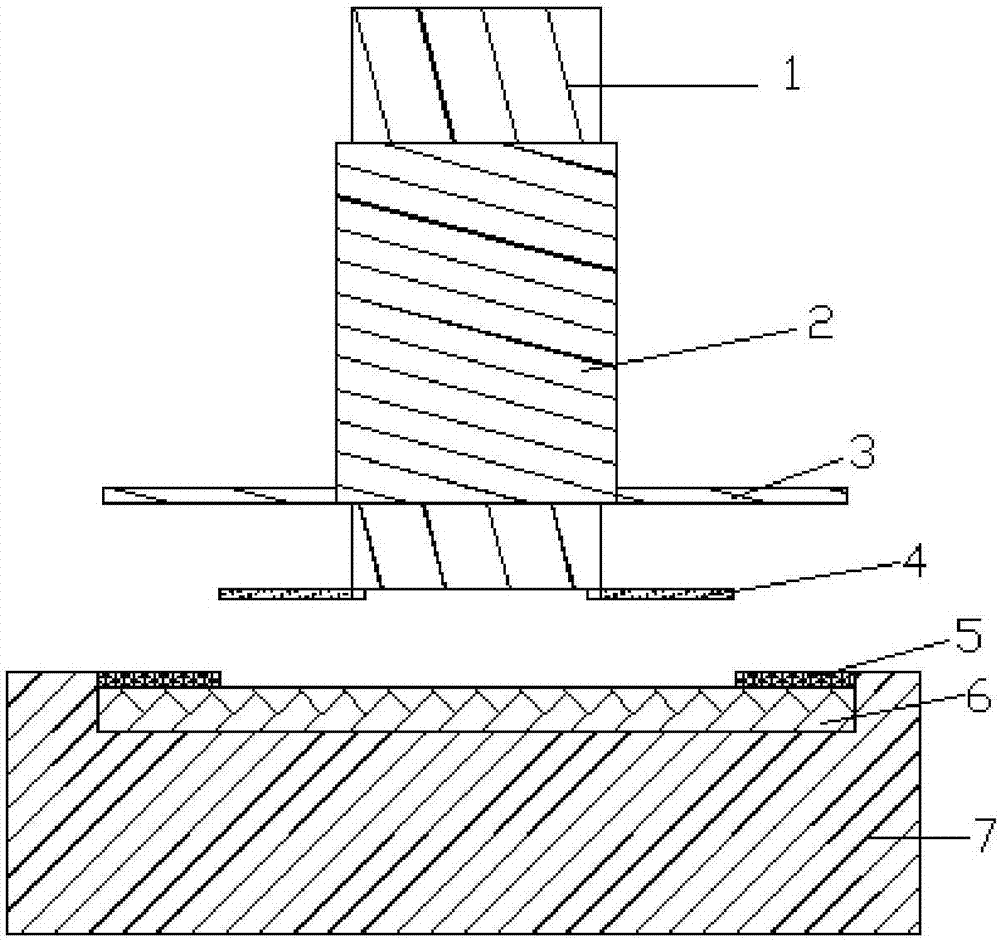

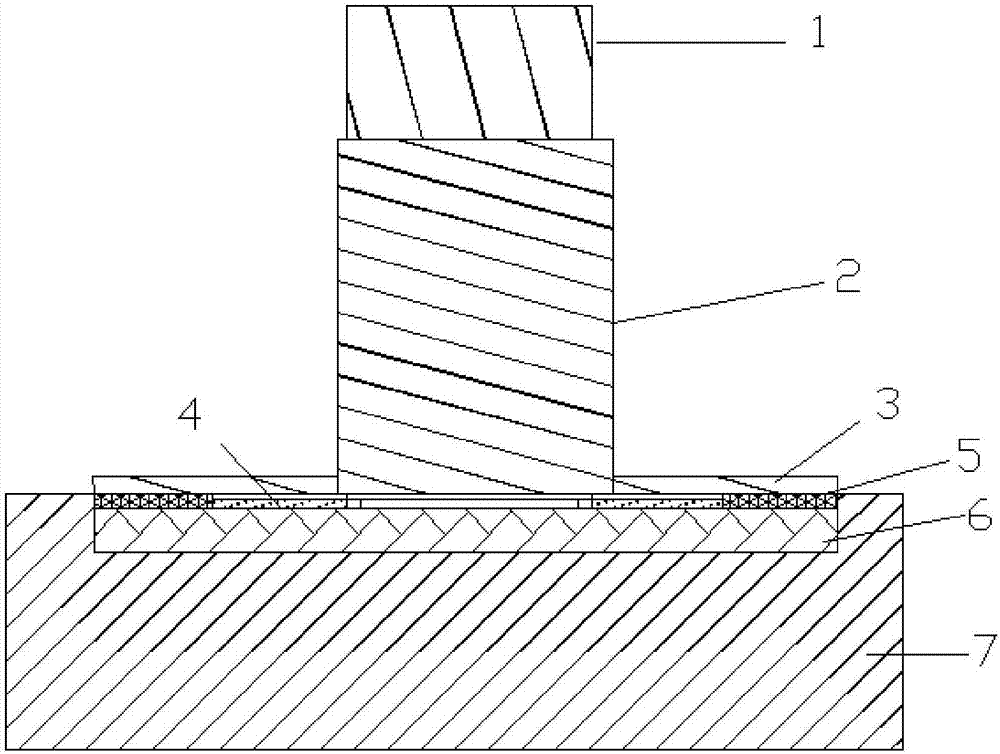

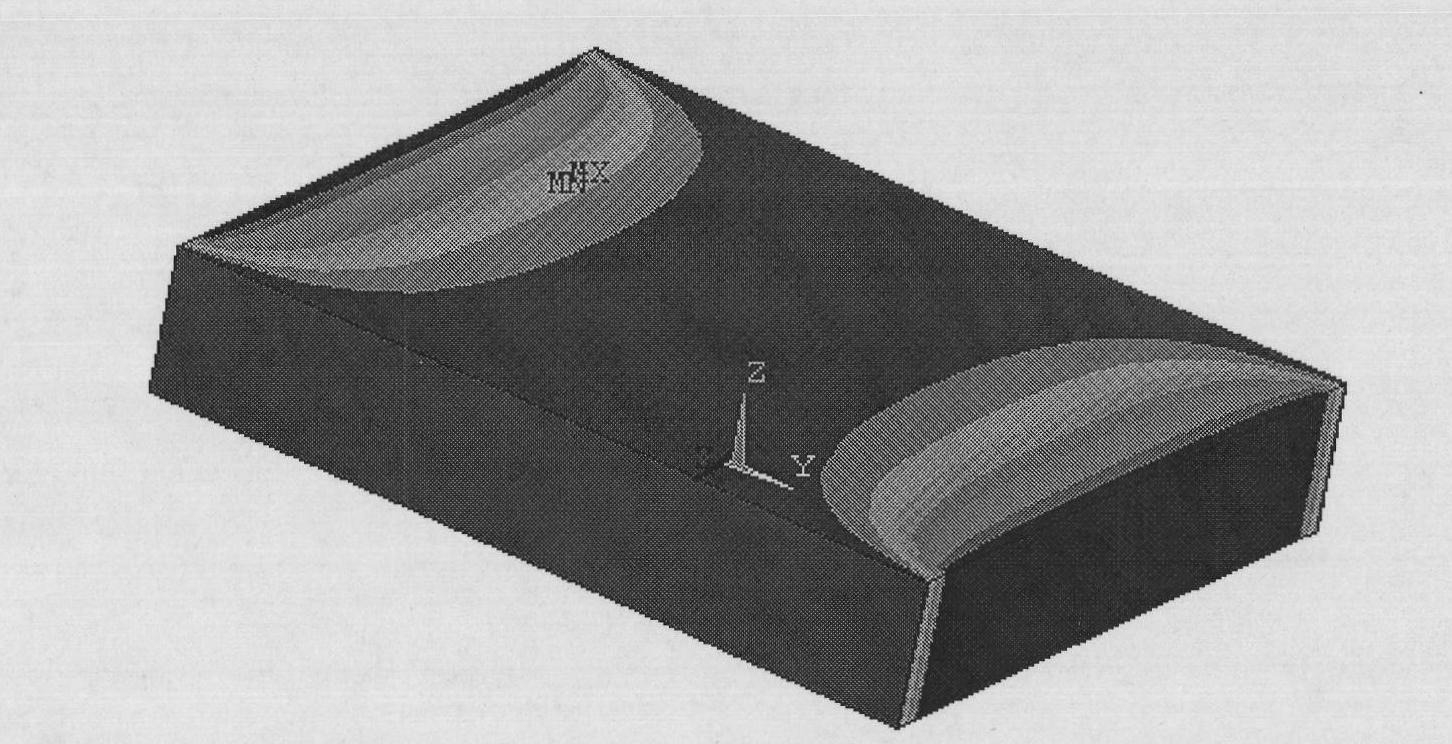

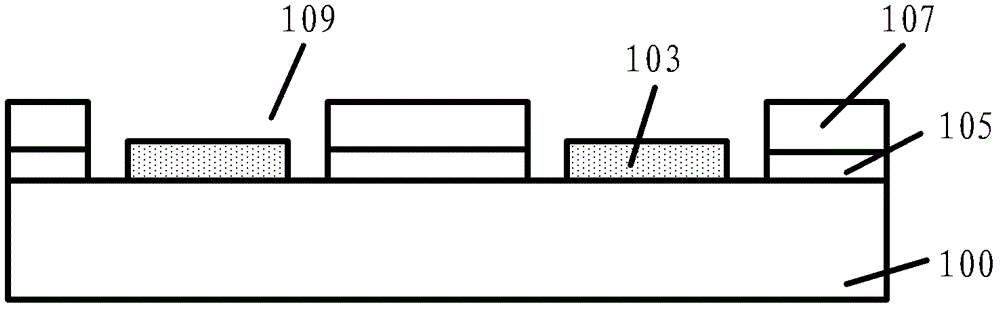

Temperature field simulation device with substrate micro/nano film

InactiveCN101799384AImprove the heating effectFast heatingPreparing sample for investigationOhmic-resistance heatingTemperature controlAdhesive

The invention relates to the fields of nano material force and heat property researches and MEMS (Micro-electromechanical Systems) micro / nano film device experiments and tests, in particular to a temperature field simulation device with a substrate micro / nano film. In order to scientifically and reasonably simulate a temperature field of an MEMS micro / nano film device in a working environment and provide a new method for heating a film substrate structure test piece, the invention adopts the technical scheme that the a temperature field simulation device with a substrate micro / nano film comprises a clamp, a heat conductive adhesive, a foil-type resistor used as a heating source, a thermoelectric couple used for measuring the temperature of the test piece and a temperature controller for controlling the foil type resistor according to the output of the thermoelectric couple; the front surface, the back surface and the lower surface of the test piece are set to be heating surfaces, the left surface and the right surface are set to be clamping surfaces of the clamp, and the top surface is set to be a film plating surface; the clamp is made of metal; the foil type resistor forms an electric heating piece; the heat conductive adhesive is coated on the electric heating piece; and the front surface, the back surface and the lower surface of the test piece are pasted on the electric heating piece through the heat conductive adhesive. The invention is mainly applied to the force and heat property researches of nano materials.

Owner:TIANJIN UNIV

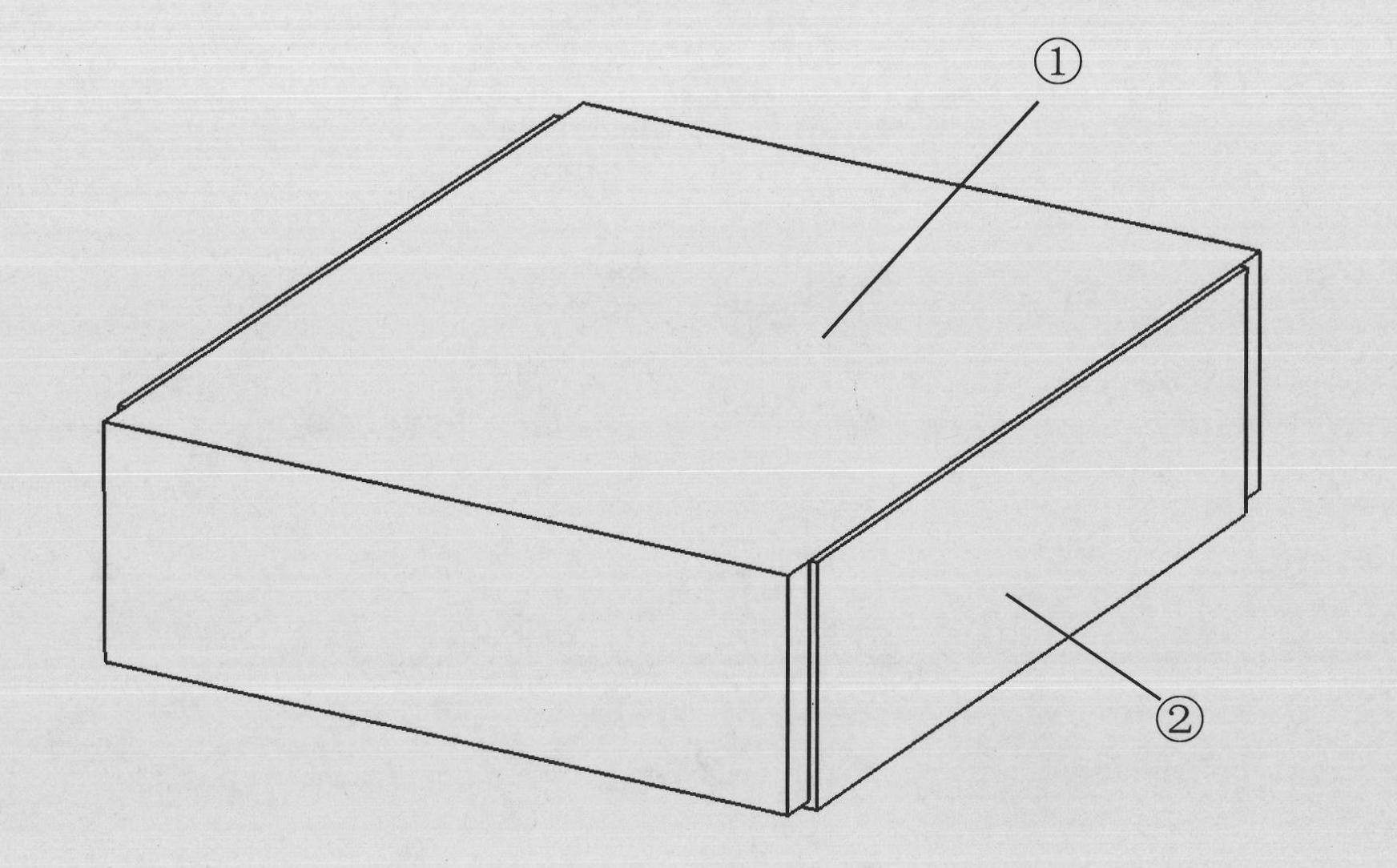

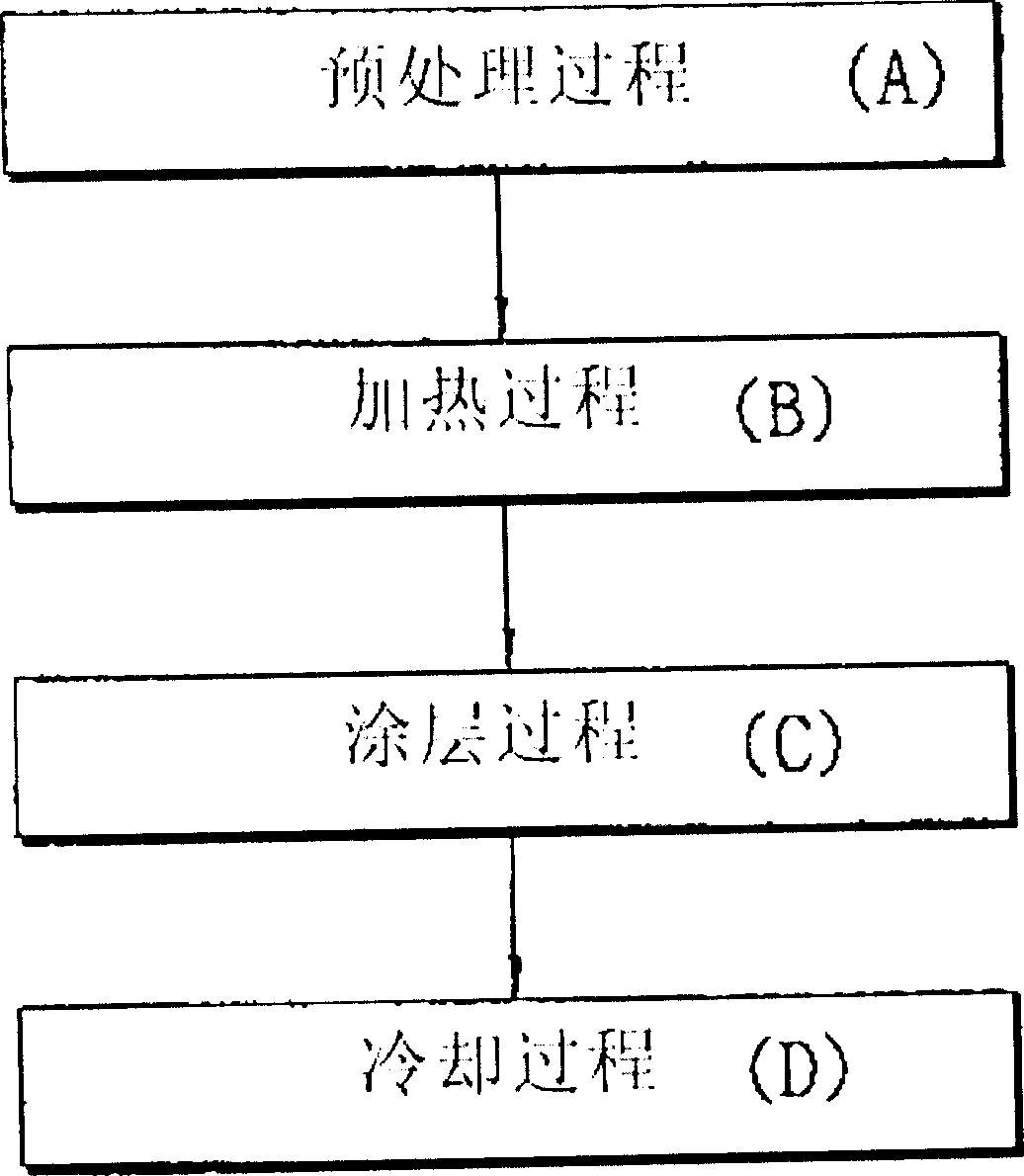

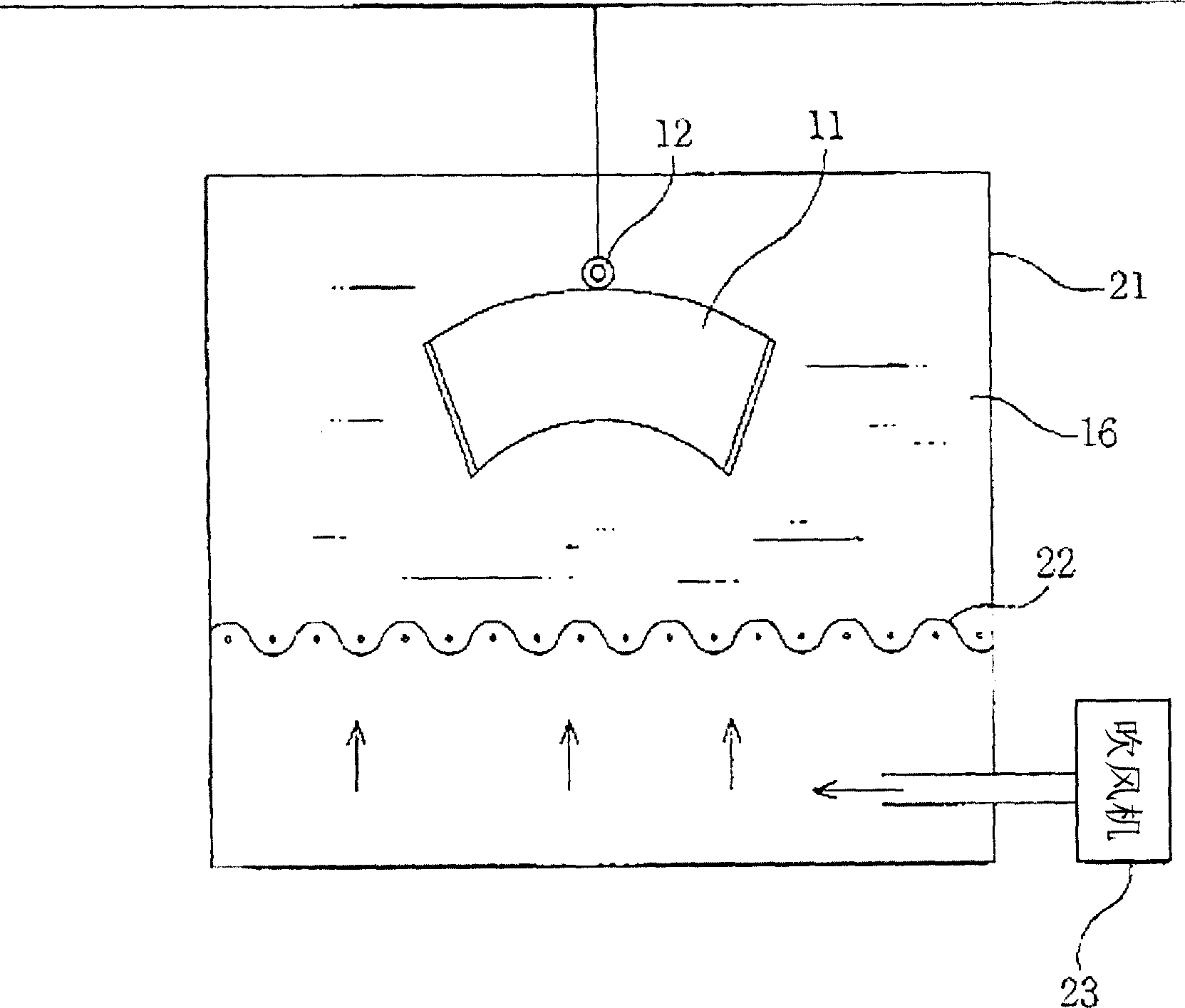

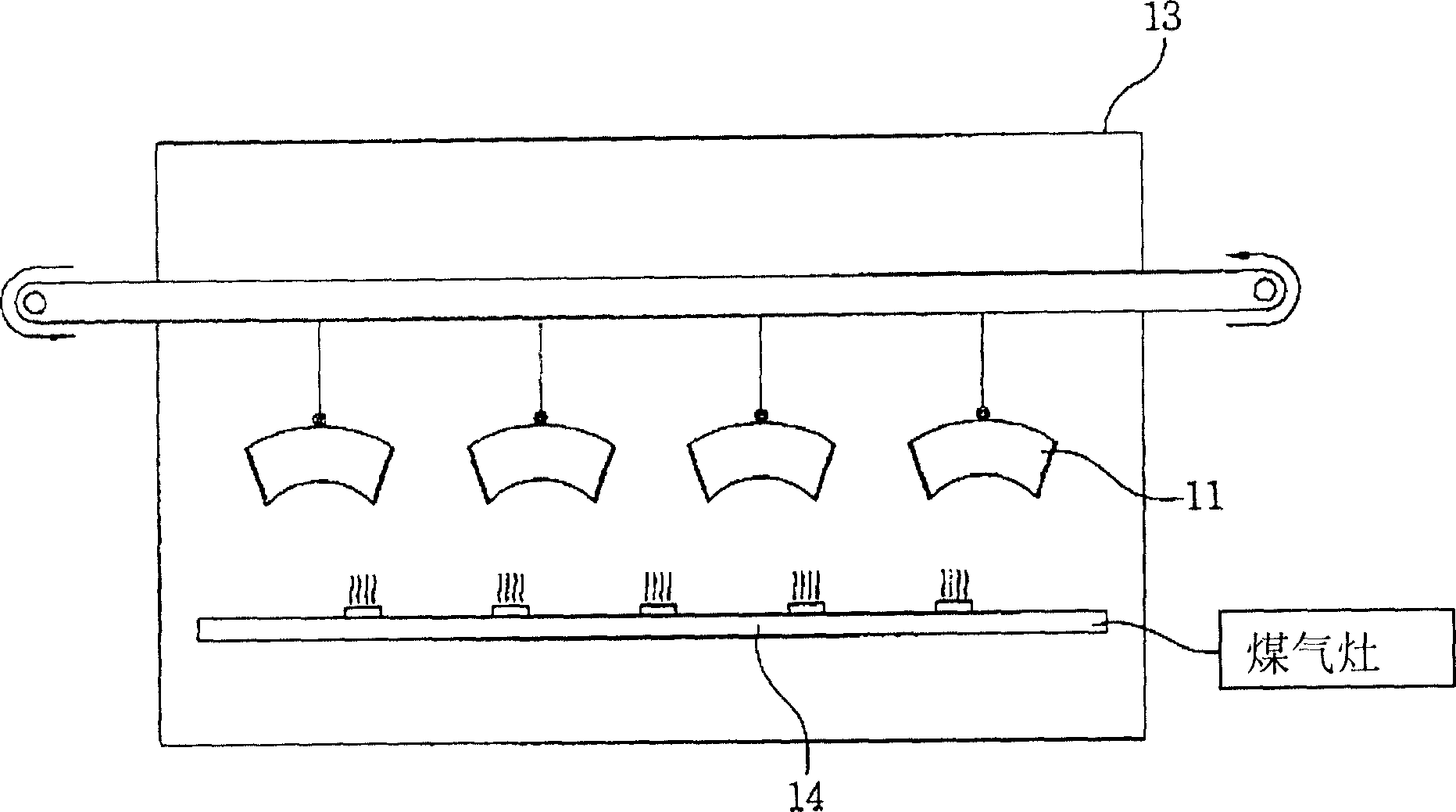

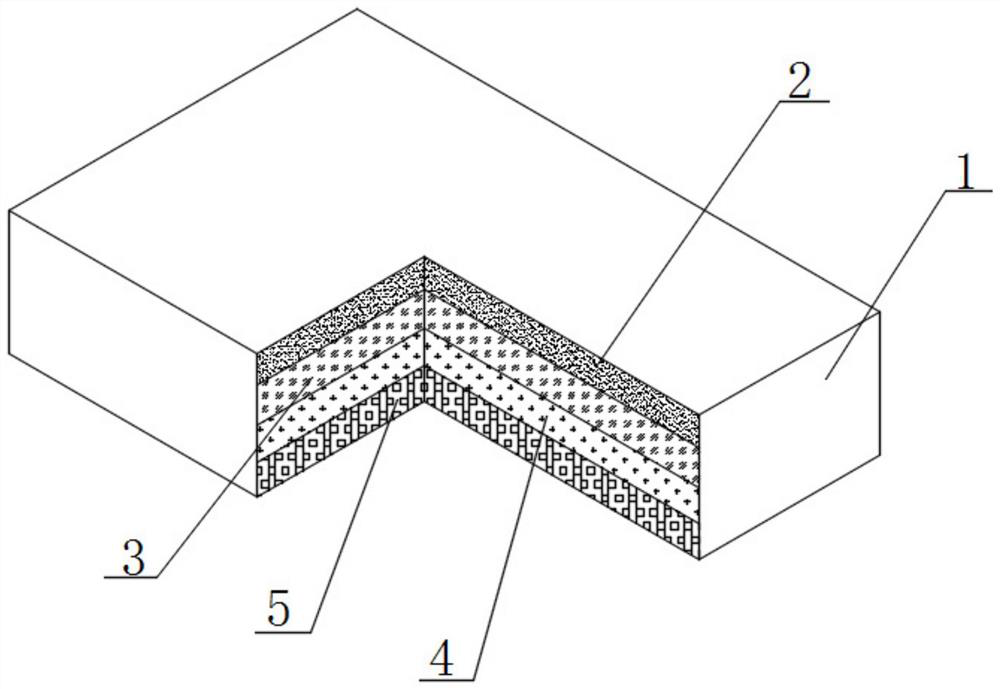

Coating method for cast iron pipe fitting joint and the coated castiron pipe joint by polyethyene

InactiveCN1905956AEnhanced adhesionWon't be cleared easilyPretreated surfacesCoatingsEngineeringCast iron pipe

Disclosed is a pipe joint for connecting pipes in order to form a pipeline such as a water supply pipeline and a sewerage pipeline, and more particularly to a cast-iron pipe joint in which the inner and outer surfaces thereof are coated with a polyethylene resin. The present invention relates to a cast-iron pipe joint such as L bends, T branches, Y branches, an increaser connecting pipes of different diameters, for connecting pipes in order to form a pipeline. The inner and outer surfaces of the cast-iron pipe joint are coated with a polyethylene resin through a preprocessing process, a heating process, a coating process, and a cooling process. In the coating process, air is blown through a filtering net from the lower side of a coating tank containing polyethylene resin powder, in order to float the polyethylene resin powder. The heated cast-iron pipe joint is introduced into the coating tank, and is rotated so that the polyethylene resin is adhered to the pipe joint. Thereafter, the pipe joint is cooled in cooling water to contract the coating film and gloss the surfaces of the pipe joint.

Owner:KOREA WATER PIPE TECH

Glycerin containing anti-freezing solution

The invention discloses a glycerin containing anti-freezing solution and relates to the field of automobile anti-freezing solutions. The glycerin containing anti-freezing solution is prepared by mixing a glycerin containing solution A with a mixed solution B taking water as the main component; the anti-freezing solution does not contain ethylene glycol; the solution A accounts for 1-99% of totalweight of the anti-freezing solution; the mixed solution A is prepared from water, dicarboxylic acid, a metal hydroxide aqueous solution and one or more substances of triazole, chelating agent, saturated fatty acid and unsaturated fatty acid. With a freezing point of -20 DEG C, the anti-freezing solution disclosed by the invention is not solidified when cooled to -20 DEG C or lower temperature, and thus has a good anti-freezing effect at low temperature.

Owner:芜湖清柏白露智能信息科技有限公司

A kind of preparation method of self-healing multifunctional glass

The invention relates to a preparation method of self-preparing multifunctional glass, in particular to a preparation method of self-repairing multifunctional glass. The preparation method comprises the following steps: (1) surface treatment of a glass base layer; (2) annealing treatment; (3) preparation of the self-repairing glass; and (4) carrying out surface coating to obtain the self-repairingmultifunctional glass. The preparation method of the self-preparing multifunctional glass has the beneficial effects that (1) after the glass is broken, the broken glass cannot drop; (2) a glass adhesive cannot be cured in advance, and thus, the glass can be repaired in time after being broken; and (3) the self-repairing multifunctional glass is diversified in function and can be used under various conditions.

Owner:ZHEJIANG XIXI GLASS

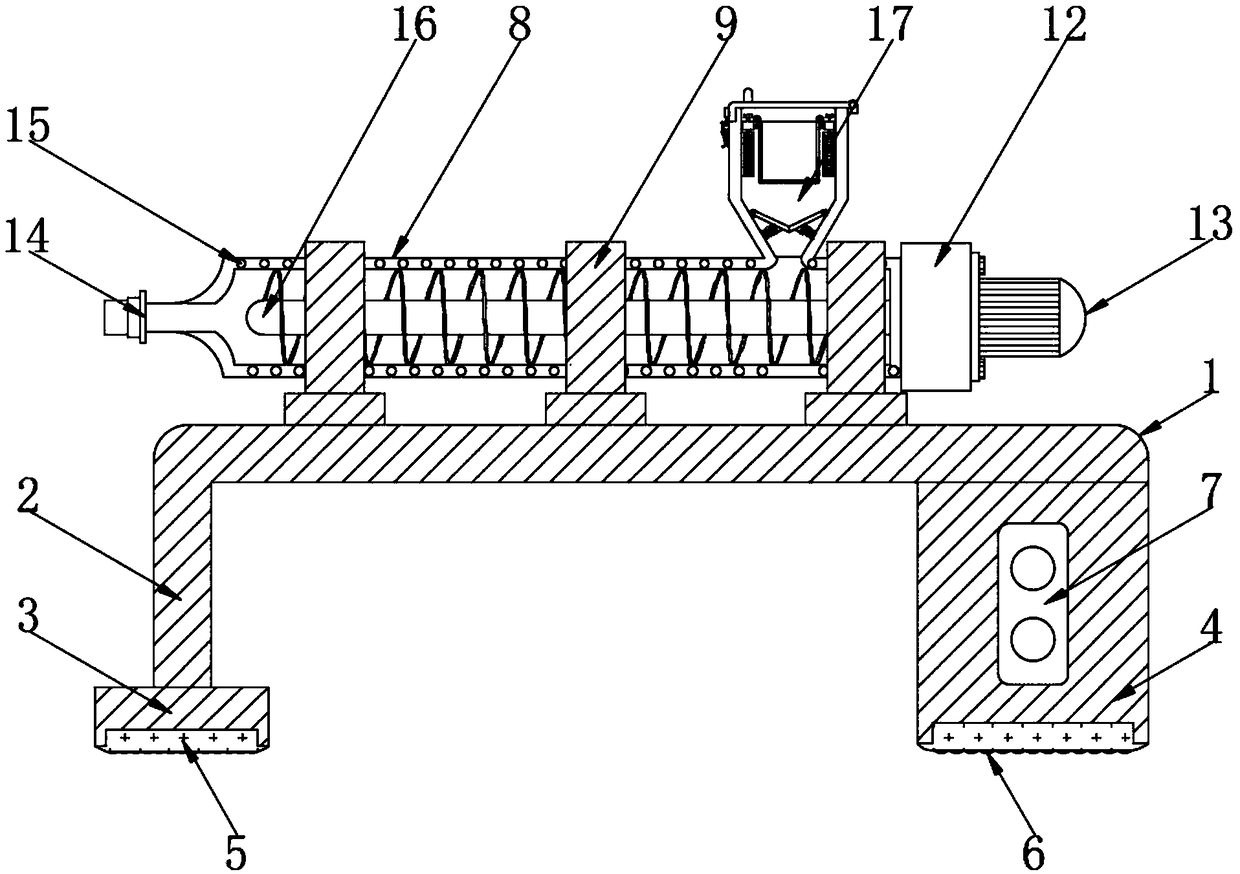

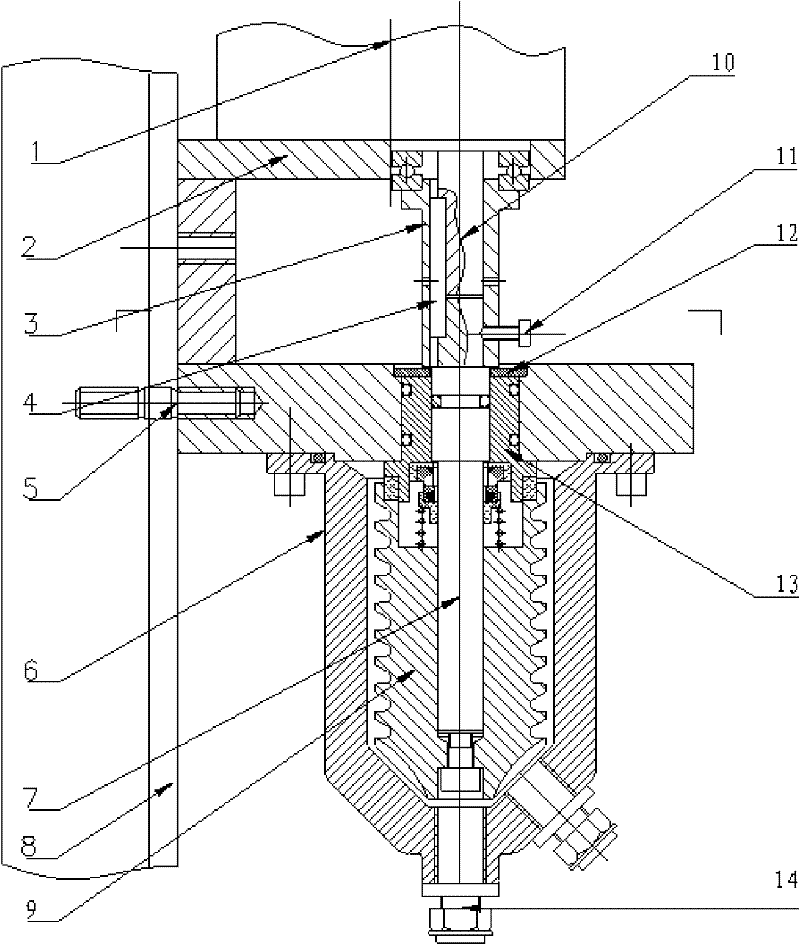

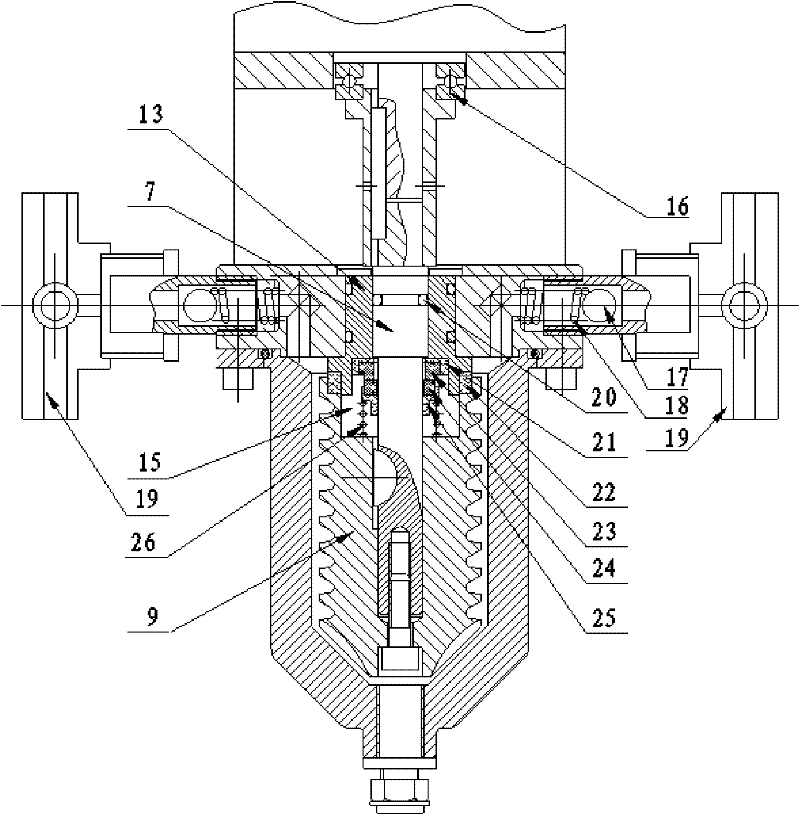

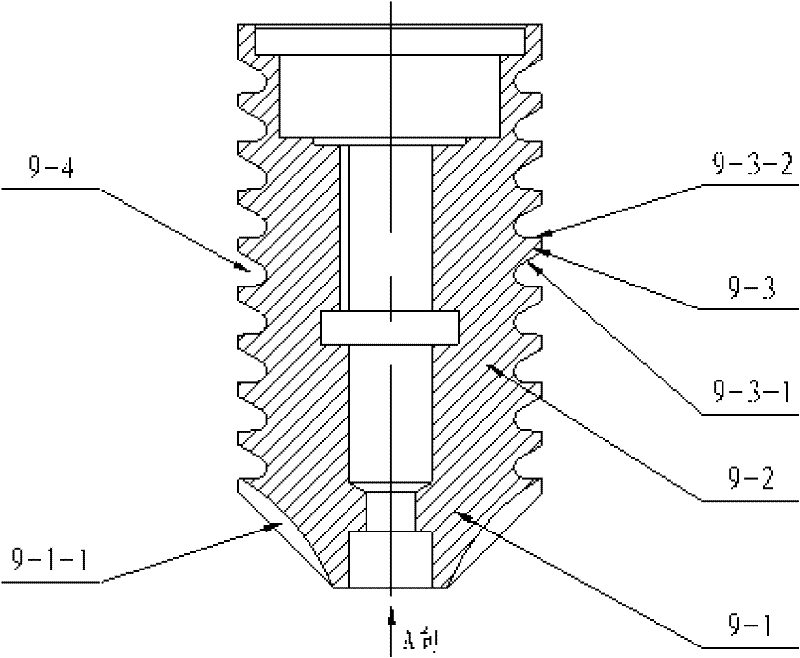

High speed dynamic state on-line mixing device applicable to large-scale mixing

InactiveCN101693171BAvoid strandedPrevent leakageEngine sealsRotary stirring mixersEngineeringFrustum

The invention discloses a high speed dynamic state on-line mixing device applicable to large-scale mixing. The device is characterized in that a stirring component comprises a columnar body, wherein the lower end of the columnar body is provided with a reversed frustum body, a plurality of blades are arranged on the columnar body, each blade comprises a plurality of separate blade bodies, the blade bodies are tilted upwards wholly, the lower edges of the blades are upward arc-shaped surfaces, the upper edges of the blade bodies are upward inclined planes, the width of the blade bodies gradually narrows from roots to top portion, grooves for containing material liquid are formed between neighboring blades, and the surface of the reversed frustum body is provided with vertical backflow grooves which are staggered with the blade bodies on the periphery direction. The device has high mixing efficiency and strong mixing homogeneity, and can effectively prevent the residue of mixed materialliquid in tanks.

Owner:TIANJIN UNIV

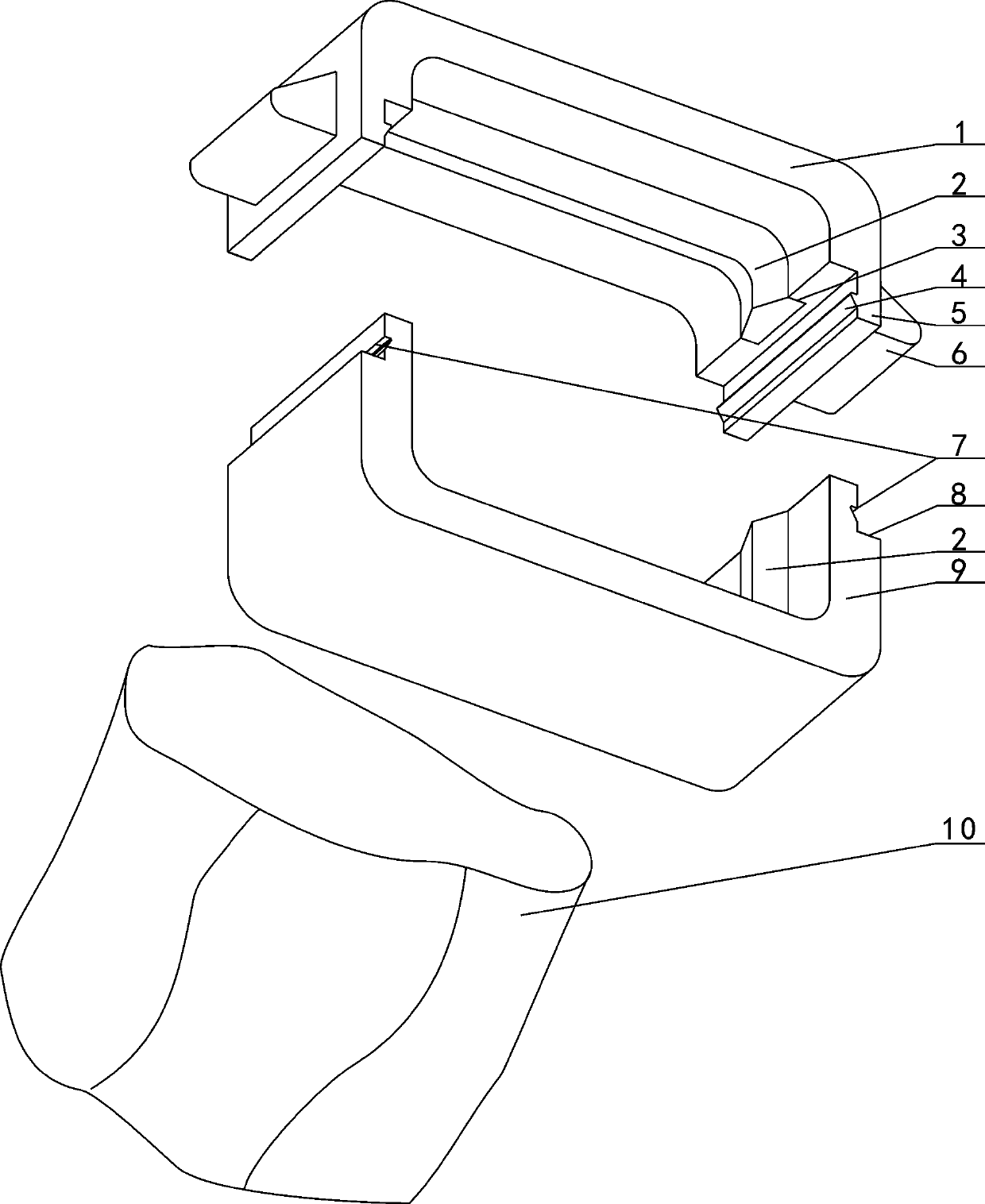

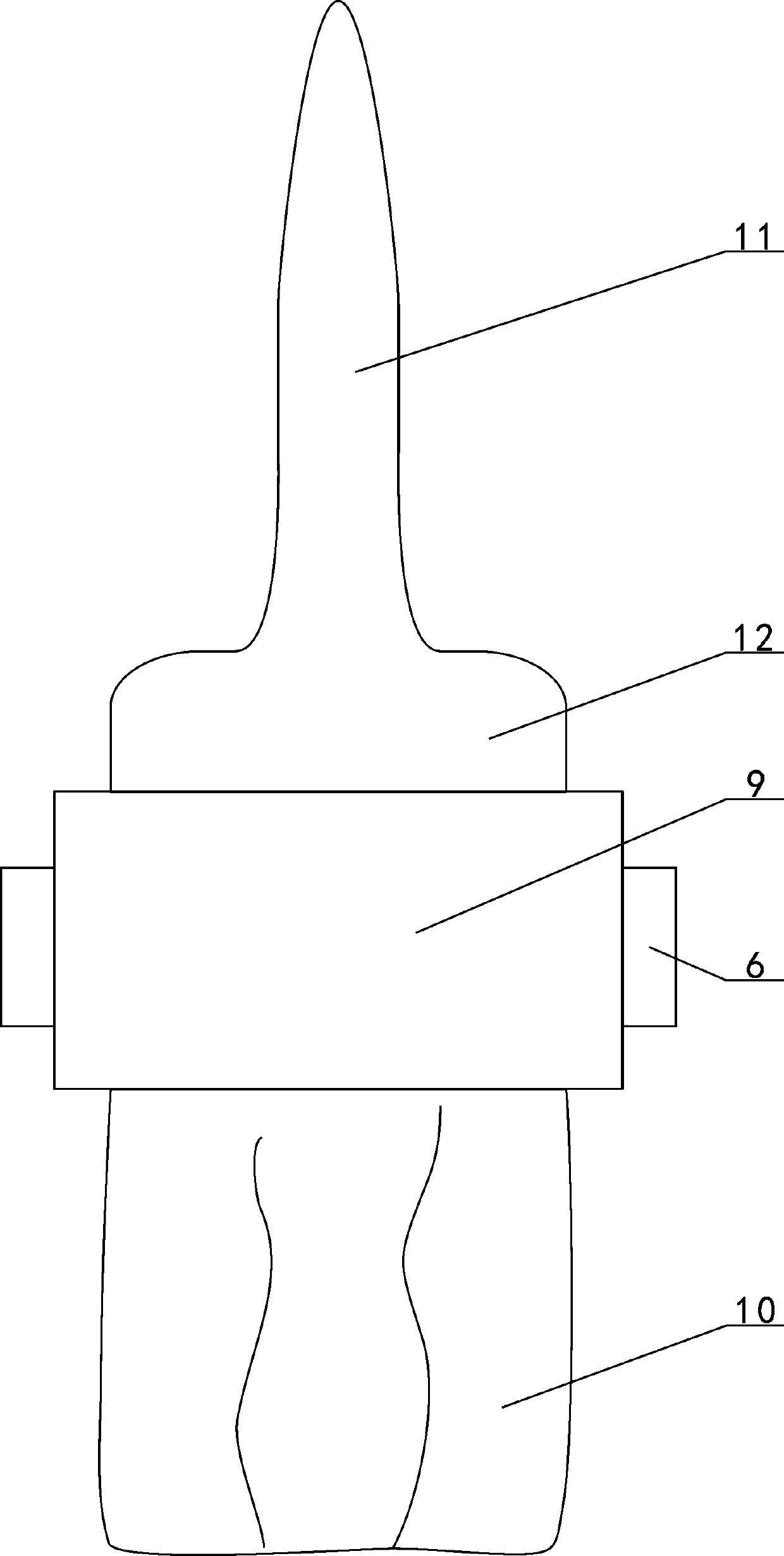

An anti-dry protection clip for paint brushes

An anti-dry protection clip for a paint brush, relating to a brush protection device, in which a rubber protruding strip (2) is provided on the inner surface of an inverted U-shaped clamp (1), and a rubber protruding strip (2) is provided on the inner surface of the U-shaped clamp (9). The strip (2), the plastic bag (10) wraps the bristles of the brush and part of the brush head (12), and the rubber protruding strip (2) in the inverted U-shaped card (1) and the rubber protruding strip (2) in the U-shaped card (9) The rubber protruding strip (2) compacts the mouth of the plastic bag (10) on the brush head (12) to isolate the bristles from the outside air; the invention uses an inverted U-shaped card and a U-shaped card to seal the mouth of the plastic bag , so that the bristles stained with paint are isolated from the outside air, and the purpose of multiple uses of the paint brush is realized.

Owner:徐州金汉鬃刷制品有限公司

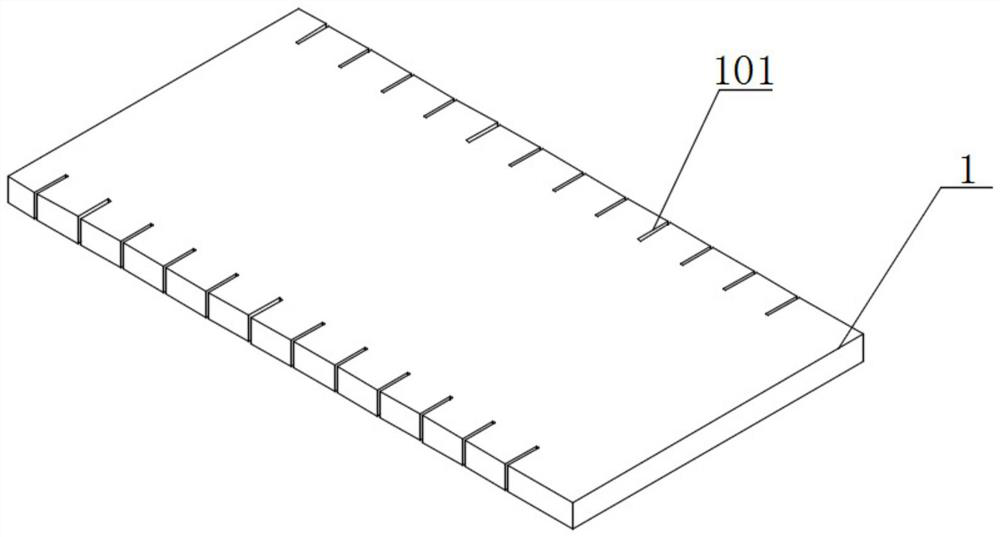

Method for laminating cover film in flexible board

ActiveCN103108502BImprove signal transmission performancePrevent glue overflowMultilayer circuit manufactureEngineeringHigh pressure

The invention provides a method for laminating a cover film in a soft board. The method includes a first step of providing a soft copper clad substrate and the cover film, a welding disc is formed on the soft copper clad substrate, and a window is arranged on the cover film, a second step of enabling the cover film to be covered on the surface of the soft copper clad substrate, and enabling the welding disc to be exposed out of the window, a third step of forming a glue blocking layer corresponding to the window after the cover film is covered on the surface of the soft copper clad substrate, and a fourth step of laminating the soft copper clad substrate and the cover film after the glue blocking layer is formed. The glue blocking layer has good elastic deformation capacity under a high temperature and high pressure environment, can fully fill the window in the laminating process, and avoids glue leakage, so the method improves signal transmission capacity of a follow-up formed printed circuit board (PCB) soft board.

Owner:JIANGNAN INST OF COMPUTING TECH

High-performance adhesive tape without stimulation to human sense organs

PendingCN114106730APrevent slippingGood light transmissionFilm/foil adhesivesHuman bodyAdhesive belt

The high-performance adhesive tape comprises a main body, an anti-skid layer is installed on the inner top wall of the main body, a shielding layer is installed at the bottom of the anti-skid layer, a tough layer is installed at the bottom of the shielding layer, and a bonding layer is installed at the bottom of the tough layer. By installing the multi-layer structure, the adhesive tape is free of irritation and convenient to use, the anti-skid patterns can be tightly attached to the finger part of a worker, the anti-skid effect is enhanced, the frosted sheet can increase the roughness of the anti-skid layer and can also increase friction force, the shielding layer can reduce the light transmission amount of the adhesive tape, and the anti-skid effect is improved. The shielding sheet can further shield sunlight, the dark thin sheet can effectively reduce the light transmission amount and prolong the service life of the adhesive tape, the toughness layer can improve the toughness of the adhesive tape, so that the adhesive tape is not prone to breakage after being bonded, in addition, the anaerobic adhesive is free of irritation and can make contact with the human body, and the practicability of the device is improved.

Owner:苏州灏扬电子材料有限公司

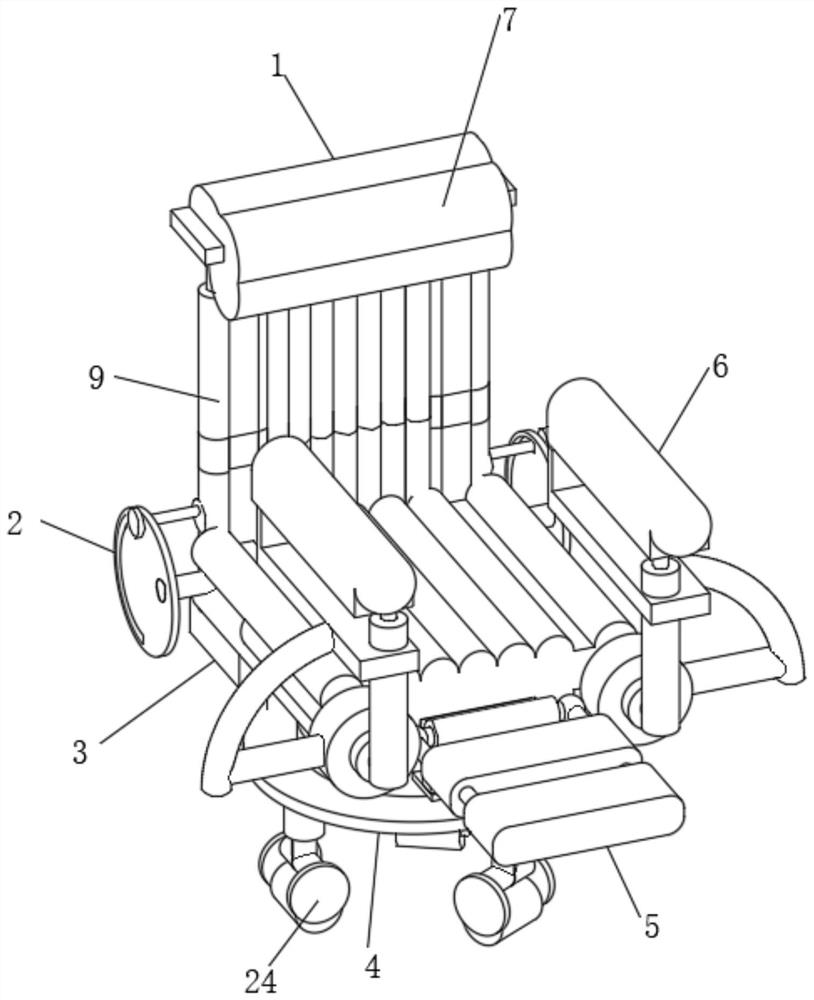

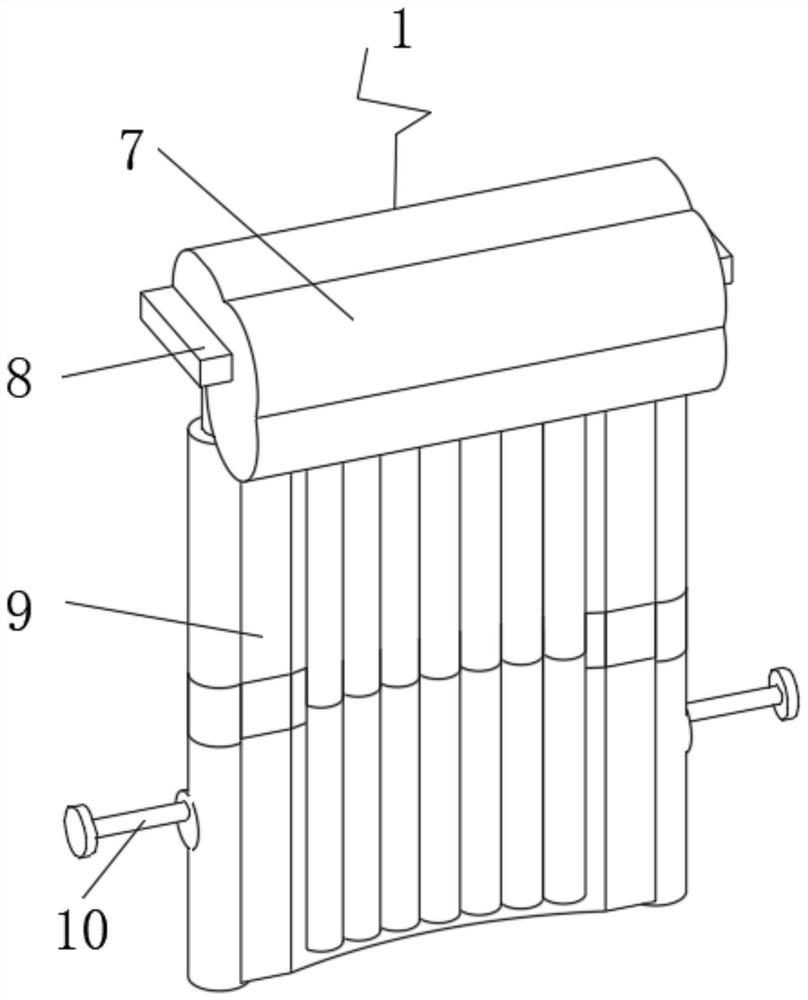

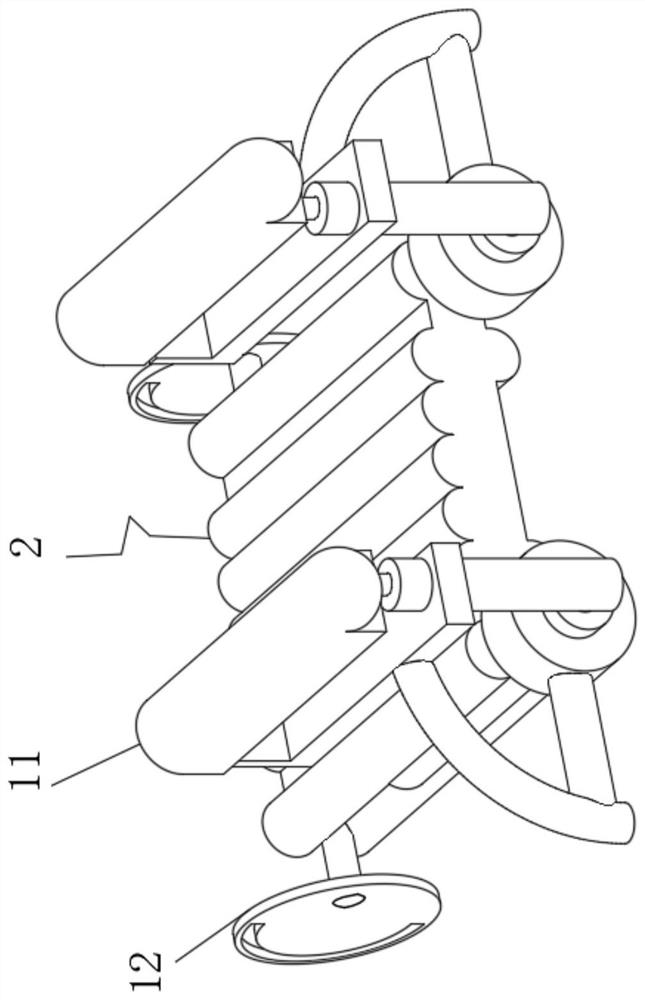

Office chair

The invention discloses an office chair. The office chair comprises a back structure, wherein the lower end of the back structure is rotatably connected with an adjusting structure; the rear end of the back structure and the rear end of the adjusting structure are both communicated with a cold and hot structure; a second armrest component (11) further comprises a communicating pipe (30) and an auxiliary heater (31); the auxiliary heater (31) is mounted at the bottom of the inner end of an armrest frame (13), and the upper end of the auxiliary heater (31) is communicated with the communicating pipe (30); a first armrest component is fixedly connected to one side of the upper end of the adjusting structure; a pedal structure is rotationally connected to the front end of the adjusting structure; and a displacement structure is rotationally connected to the bottom end of the back structure and the bottom end of the adjusting structure. According to the office chair, through the arrangement of the cold and hot structures, the purpose of cold and hot treatment of the inner end is achieved.

Owner:岑土秀

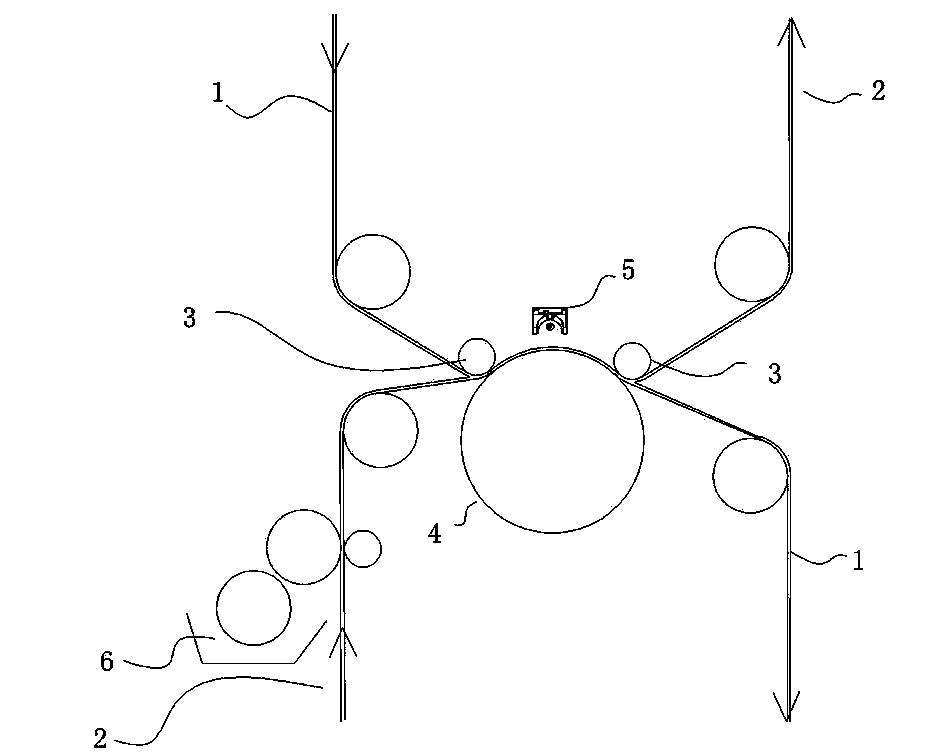

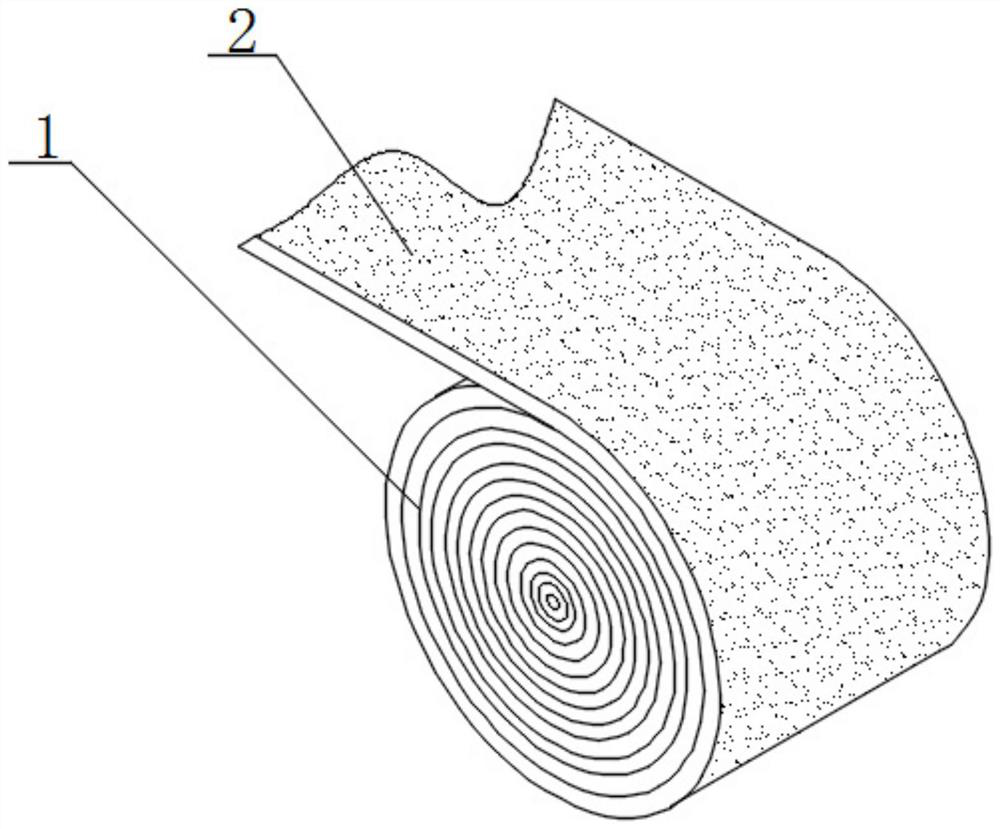

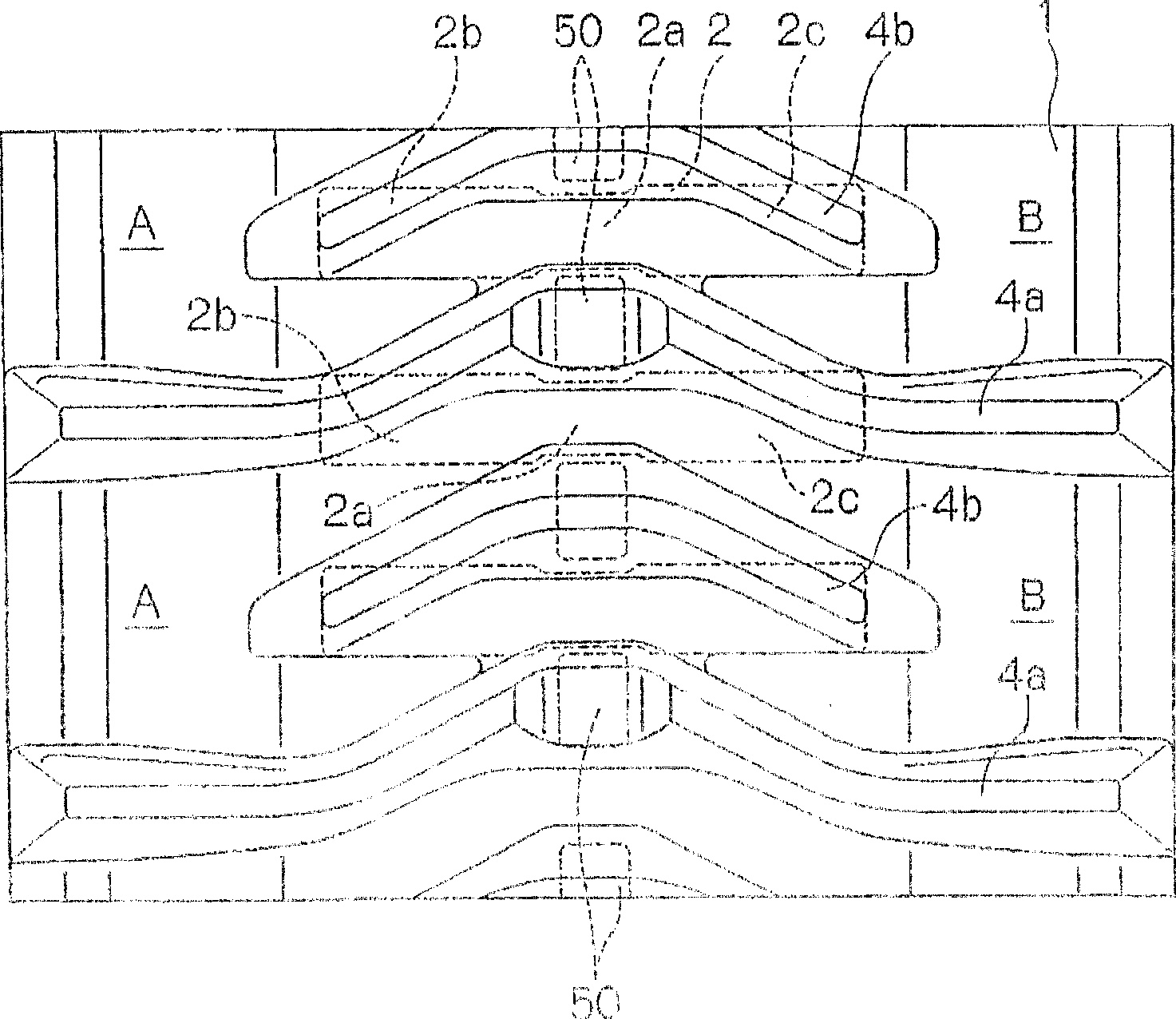

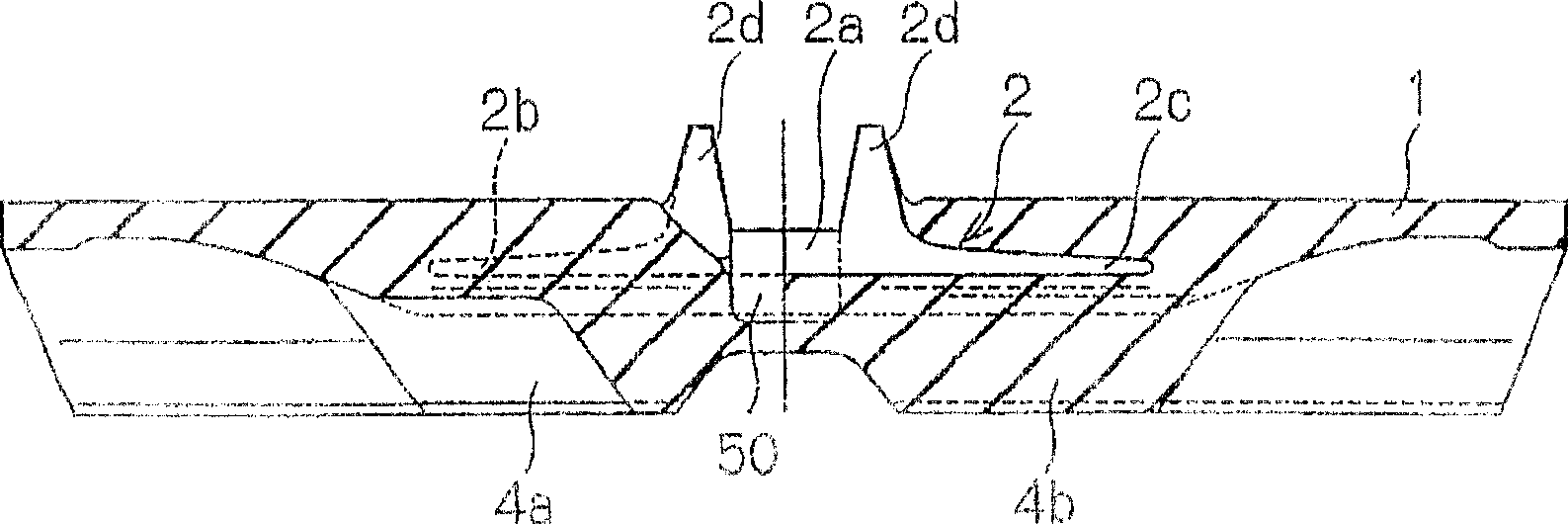

A rubber crawler

InactiveCN100465046CWon't curePrevent up and down movementEndless track vehiclesElastomerEngineering

A rubber crawler running mainly on a damp ground and capable of eliminating the production of mud balls passed through the engagement holes thereof with the teeth of sprockets and reducing vibration, comprising an endless rubber elastic body, cores buried therein at specified pitches in the longitudinal direction, steel cords surrounding the cores from the outside, the engagement parts thereof with the sprockets formed between the cores, and lugs formed on the outer peripheral surface of the endless rubber elastic body. The engagement parts thereof with the sprockets are characterized by bottomed recesses formed therein. The lugs are desirably formed on the outsides of the bottomed recesses.

Owner:BRIDGESTONE CORP

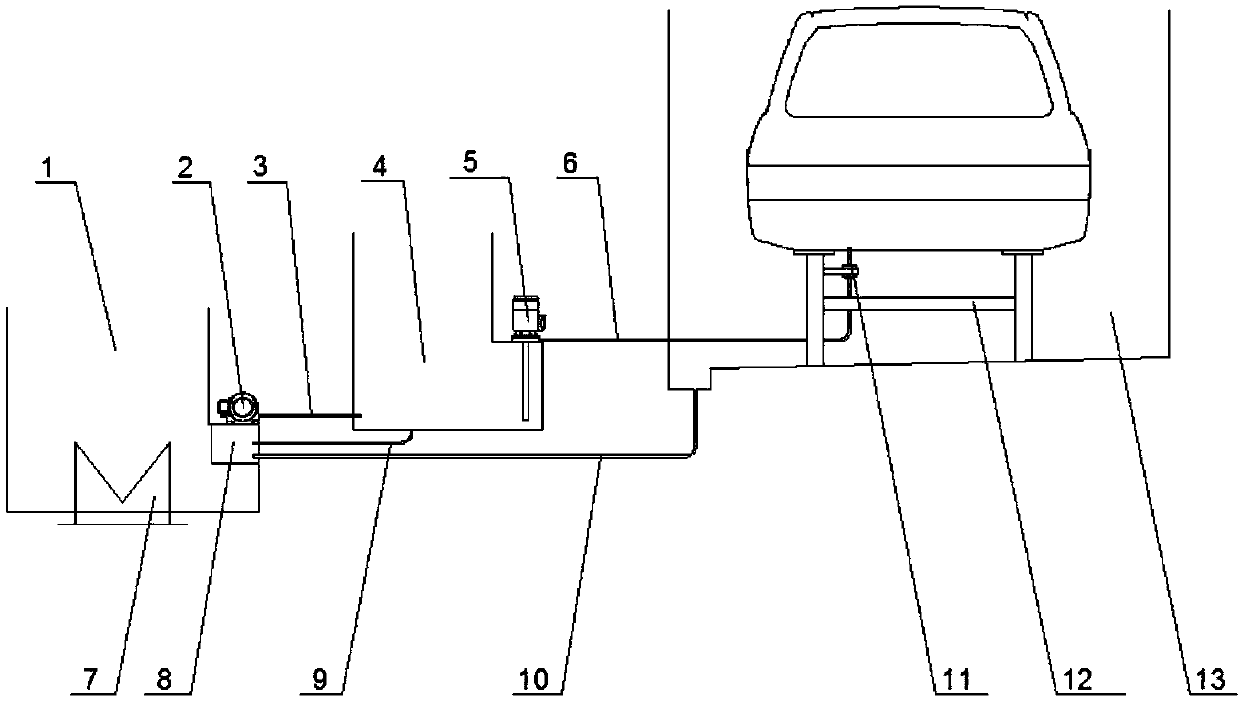

Variable-frequency pump wax injection system

The invention discloses a variable-frequency pump wax injection system comprising a wax storage groove, a work groove, a variable-frequency pump and a clamp groove. The wax storage groove conveys liquid wax into the work groove through a work pipeline by means of a pump. The variable-frequency pump is arranged in the work groove and connected with one end of a wax injection pipeline. The other endof the wax injection pipeline is connected with a wax injection spray nozzle. The wax injection spray nozzle is fixed to a wax injection clamp. The wax injection clamp is arranged in the clamp groove. The variable-frequency pump wax injection system has the beneficial effects that the variable-frequency pump providing different flows of liquid wax for each cavity area is arranged in the work groove, and flow control can be achieved through control over the rotation speed of the variable-frequency pump. The variable-frequency pump adopting different rotation speeds for different injection points enables cavities of different volumes to achieve the full wax state at the same time, so that the wax loss can be reduced, the number of follow-up processing steps can be reduced, and operation andadjustment are convenient.

Owner:大连京丰机械制造有限公司

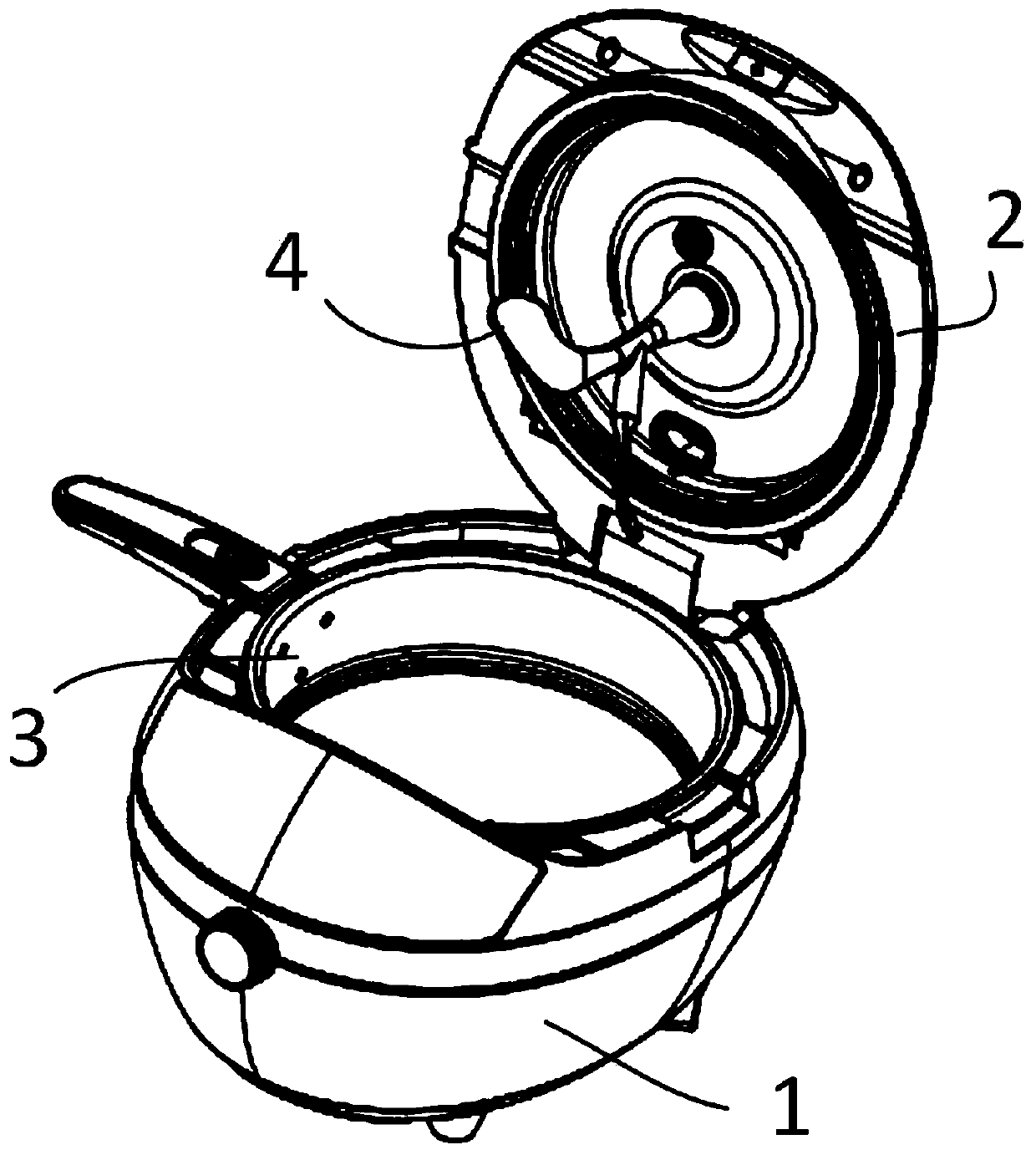

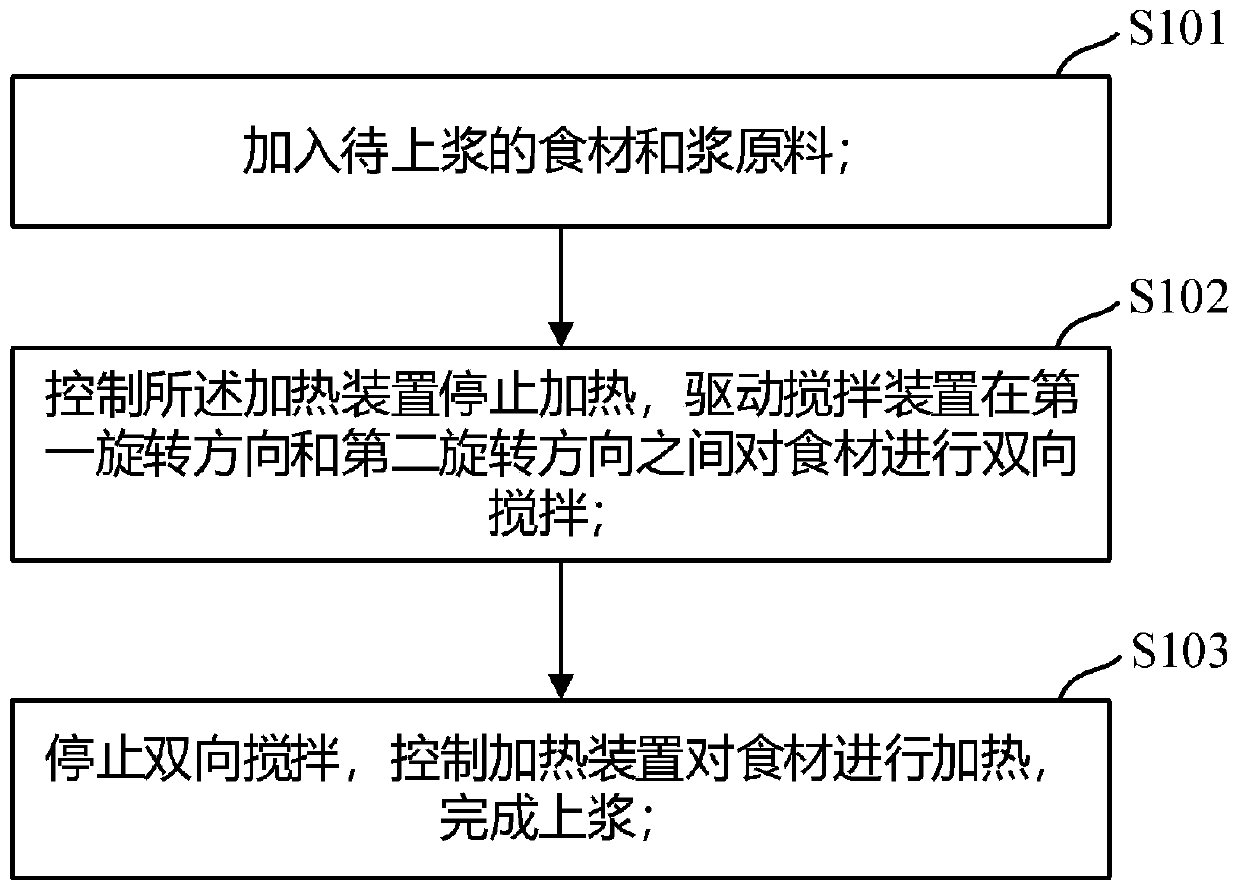

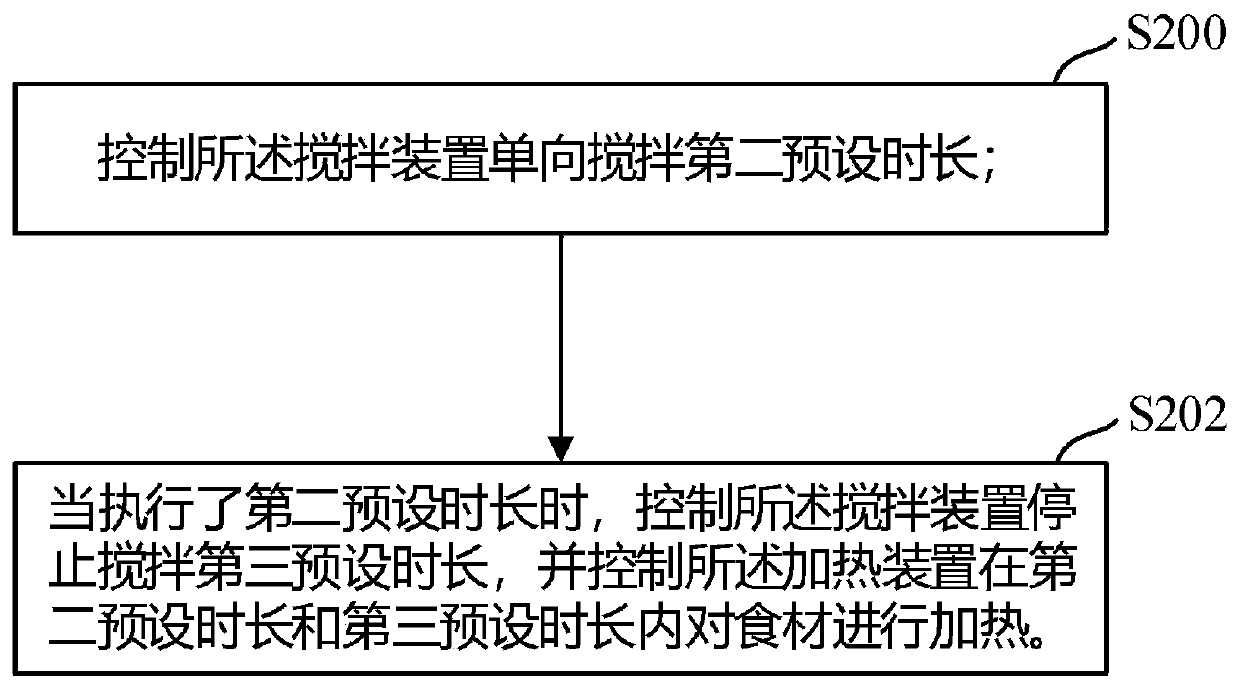

Food material starching method of cooker, cooker and computer storage medium

ActiveCN110353508AWon't cureGuaranteed liquidityVessels with intergral heatingTime-controlled ignitorsEngineeringFood material

The invention discloses a food material starching method of a cooker, the cooker and a computer storage medium. The cooker comprises a pot body, a stirring device and a driving device, wherein an inner container and a heating device are arranged in the pot body; and the driving device drives the stirring device to rotate. The starching method comprises the following steps: S101, adding a to-be-starched food material and a starch raw material; S102, controlling the heating device to stop heating, and driving the stirring device to carry out bidirectional stirring on the food material between afirst rotation direction and a second rotation direction; and S103, stopping the bidirectional stirring, and controlling the heating device to heat the food material, thereby finishing the starching,wherein the first rotation direction and the second rotation direction are opposite. According to the cooking method, automatic starching can be realized, so that automation is realized.

Owner:JOYOUNG CO LTD

A high-performance sand mist-containing sealing layer material and its preparation method

ActiveCN111777945BImprove compatibilityImprove stabilityAntifouling/underwater paintsPaints with biocidesRoad engineeringSuspending Agents

A high-performance sand mist-containing sealing layer material and its preparation method belong to the road engineering technical field, and the material composition includes zwitterionic emulsified asphalt, suspension thickener, viscosity-increasing and toughening agent, film-forming agent, suspending agent, and preservative and anti-skid fine sand; the preparation method includes preparing a base material, preparing a concentrated solution of a sand-mist seal layer, preparing a high-performance sand-mist seal layer material and construction. The finger-drying time of the sand mist-containing sealing layer material obtained in the present invention is 10-30 minutes, the drawing strength at 60°C is 0.35-1.1 MPa, and the wet wheel abrasion value is 22.8-56 g / m 2 , Corundum 7 days of uniform suspension, service life of more than 3 years. The high-temperature drawing strength of the present invention is at least 20% higher than the existing traditional sand mist-containing sealing layer materials, which can solve the problems of poor high-temperature adhesion and poor wear resistance of existing materials, and has the advantages of short drying time, good maintenance effect, and easy to use. Long life and other advantages.

Owner:辽宁省交通科学研究院有限责任公司

A high-power tile-type phased array antenna

ActiveCN110797624BAchieve high power transmissionReal-time heat dissipationParticular array feeding systemsDe-icing/drying-out arrangementsControl signalElectrical connection

The invention discloses a high-power tile-type phased array antenna, which comprises a first printed circuit board layer, a second printed circuit board layer and a third printed circuit board layer arranged in sequence; the first printed circuit board layer The circuit board layer is used to transmit radio frequency signals and implement a power division network of 64 units; the second printed circuit board layer is electrically connected to the first printed circuit board layer, and is used to control the phase shift and attenuation of the signal; the The third printed circuit board layer is electrically connected to the second printed circuit board layer for power supply and signal input control; the first printed circuit board layer is provided with a number of chips for signal output; A heat dissipation cold plate is also provided between the second printed circuit board layer and the third printed circuit board layer, and the heat absorption end of the heat dissipation cold plate contacts the chip. The invention can solve the problem of chip heating in the antenna in real time, thereby truly realizing high-power transmission of signals.

Owner:成都华芯天微科技有限公司

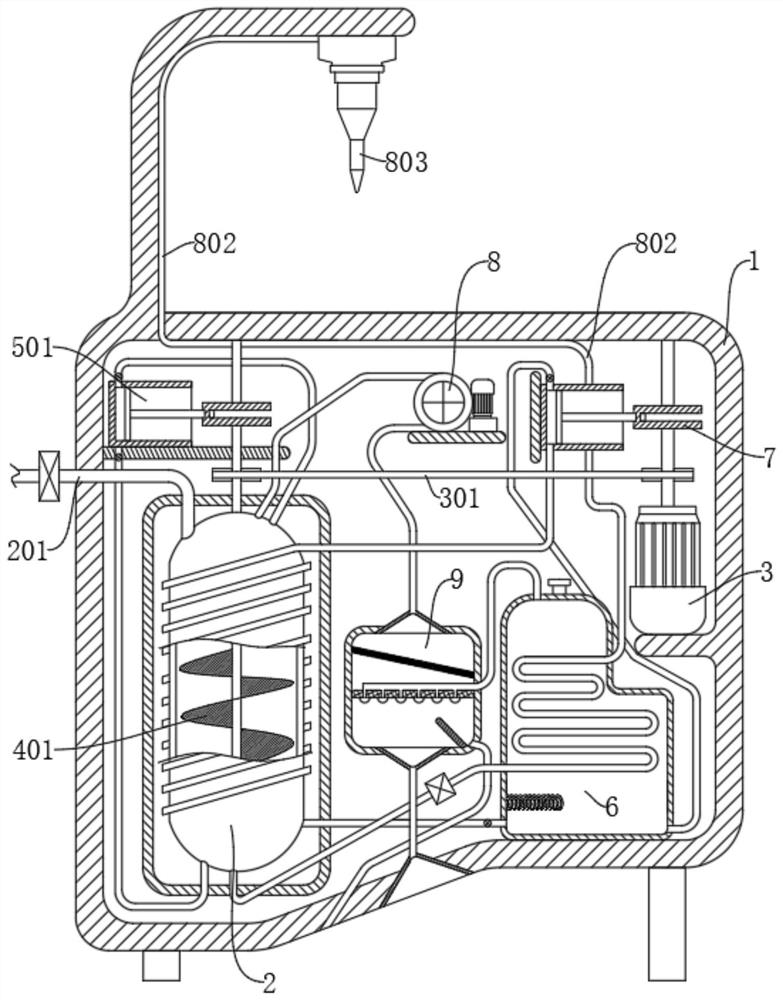

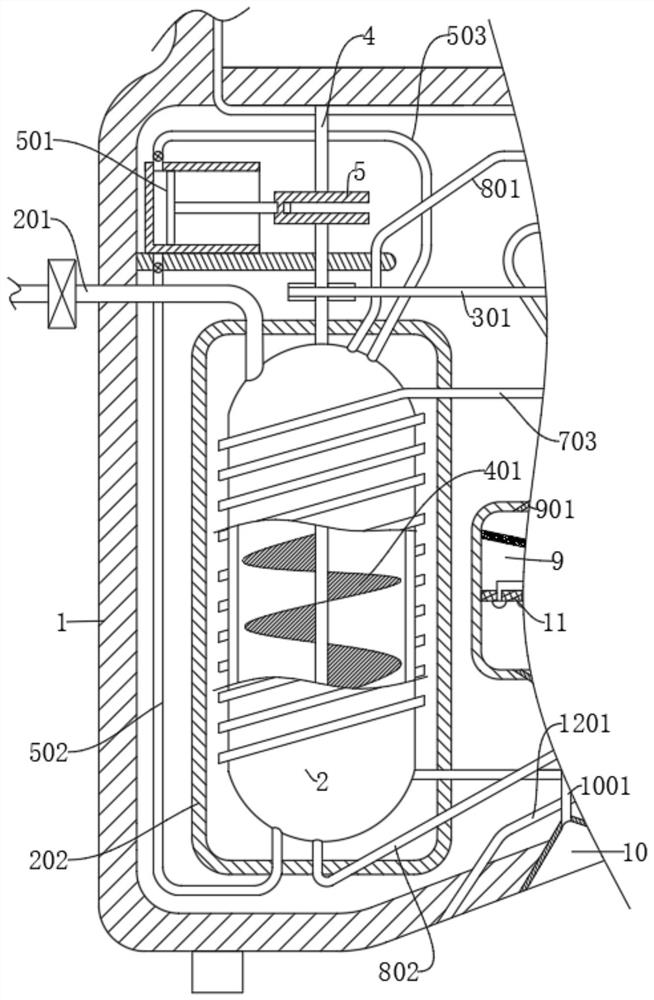

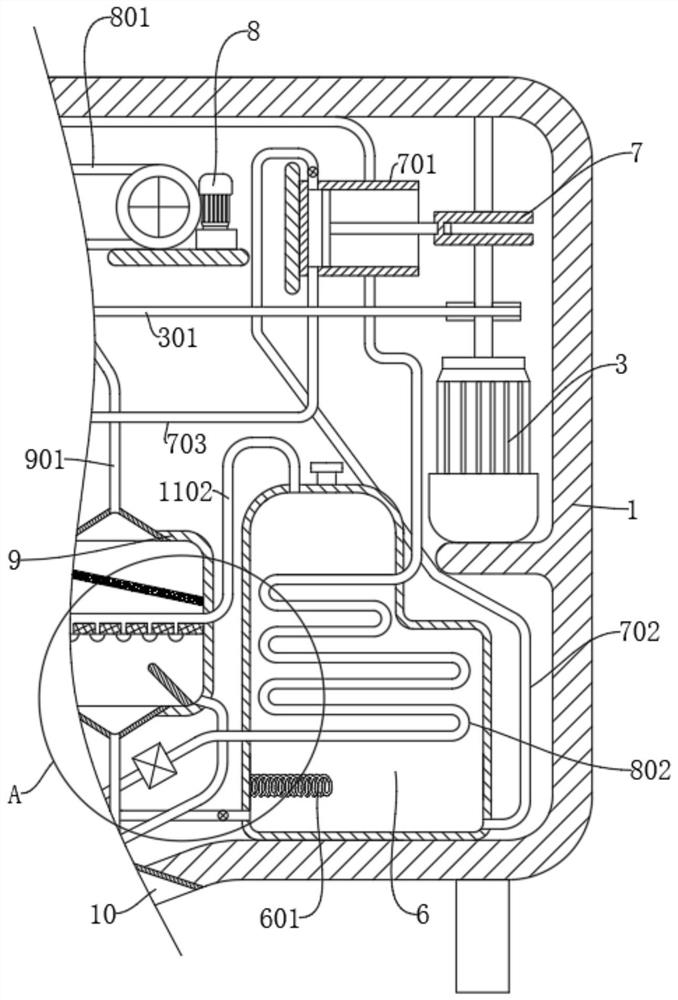

Mixing and processing device for silicone sealant production and processing method thereof

InactiveCN113578102AWon't cureImprove filling efficiencyCombination devicesRotary stirring mixersImpellerElectric machine

The invention discloses a mixing and processing device for silicone sealant production and a processing method thereof, belonging to the technical field of sealant production. The mixing and processing device for silicone sealant production comprises: a box body; a mixing tank, a motor, a water tank and a second piston assembly, which are all located in the box body; a feeding pipe, which is connected to the top of the mixing tank; a mixing impeller, which is positioned in the mixing tank and rotates under driving by the motor; a filling head, which is positioned at the top of the box body and communicates with the bottom of the mixing tank through a sixth hollow pipe; a heating wire, which is positioned in the water tank; and a second crankshaft, which is fixed to the output end of the motor and rotationally connected with the second piston assembly. Compared with an existing mixing and processing device in the market, the mixing and processing device for silicone sealant production in the invention has the advantages that in a processing process, water vapor generated by hot water in the water tank is used for carrying out dust falling treatment on a pressurizing mechanism, secondary utilization of the hot water is achieved, filling efficiency is improved, and meanwhile, filling quality is improved.

Owner:江苏华硅新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com