Mixing and processing device for silicone sealant production and processing method thereof

A silicone sealant and processing device technology, which is applied in the direction of mixing methods, combination devices, separation methods, etc., can solve problems such as low filling efficiency and silicone sealant curing, and achieve improved filling efficiency, improved reliability, The effect of improving filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

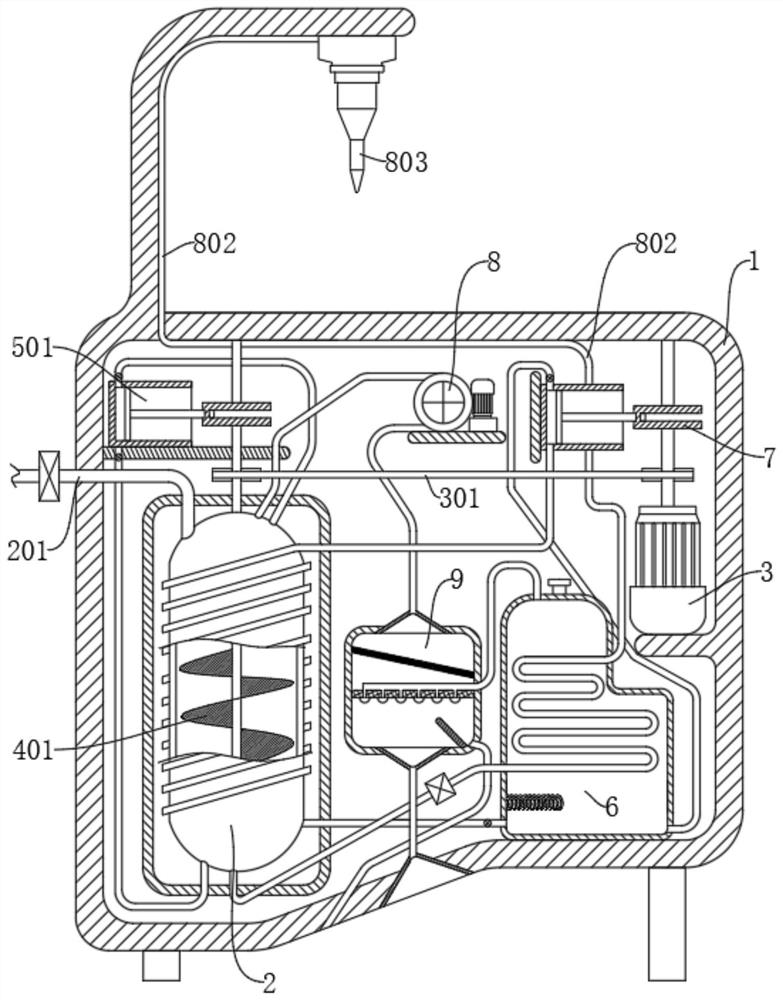

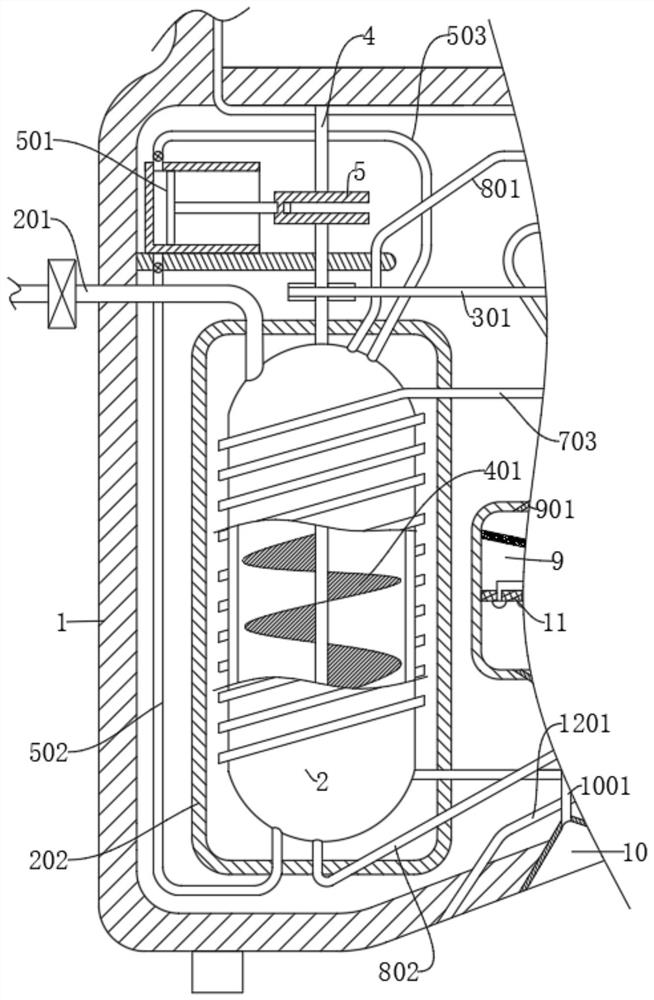

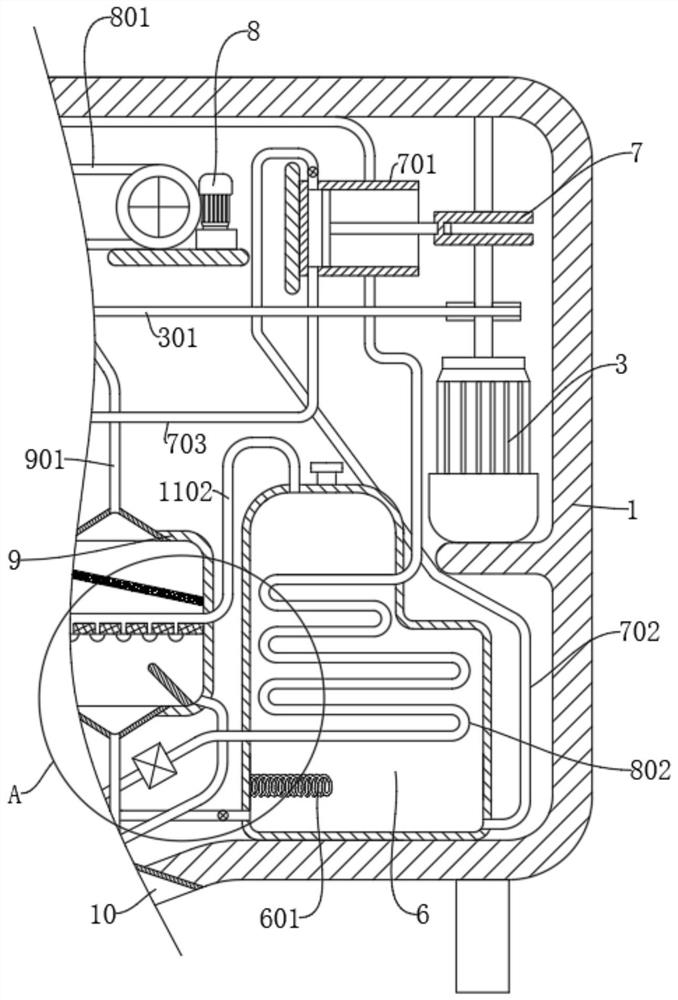

[0028] refer to Figure 1-5 , a silicone sealant production mixing processing device, including a box 1, also includes: a mixing tank 2, a motor 3, a water tank 6 and a second piston assembly 701, all located in the box 1; feed pipe 201 , connected to the top of the mixing tank 2; the mixing impeller 401 is located in the mixing tank 2 and driven by the motor 3; the filling head 803 is located at the top of the box body 1 and connected to the bottom of the mixing tank 2 through the sixth hollow tube 802 The heating wire 601 is located in the water tank 6; the second crankshaft 7 is fixed on the output end of the motor 3 and is connected in rotation with the second piston assembly 701; wherein, the two sides of the second piston assembly 701 and the water tank 6 are respectively The third hollow tube 702 and the fourth hollow tube 703 are connected, and the third hollow tube 702 and the fourth hollow tube 703 are provided with check valves, and the fourth hollow tube 703 is wou...

Embodiment 2

[0033] refer to Figure 1-5 , on the basis of Example 1, further,

[0034] A rotating shaft 4 is rotatably connected in the box body 1 , and a belt 301 is connected between the rotating shaft 4 and the output end of the motor 3 , and the mixing impeller 401 is fixed on the rotating shaft 4 .

[0035] The first crankshaft 5 is fixedly connected to the rotating shaft 4, and the first piston assembly 501 is arranged in the box body 1. The first piston assembly 501 is connected to the first crankshaft 5 in rotation. A first hollow tube 502 is connected, a second hollow tube 503 is connected between the first piston assembly 501 and the top of the mixing tank 2 , and a one-way valve is provided in the first hollow tube 502 and the second hollow tube 503 .

[0036] Start the motor 3, the motor 3 drives the rotating shaft 4 to rotate through the belt 301, and the rotating shaft 4 drives the mixing impeller 401 to rotate.

[0037] At the same time, the rotating shaft 4 drives the fi...

Embodiment 3

[0039] refer to Figure 1-5 , on the basis of Example 2, further,

[0040] The sixth hollow tube 802 runs through the water tank 6 .

[0041] When the mixture is filled by the pressurizing mechanism, when the mixture enters the sixth hollow tube 802, it passes through the water tank 6 through the sixth hollow tube 802, and the mixture in the sixth hollow tube 802 is heated by hot water. Heating to prevent the temperature of the mixture from dropping during the filling process,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com