A rubber crawler

A technology of rubber crawler and rubber elastic body is applied in the field of rubber crawler, which can solve the problems of operator vibration, bringing into the joint hole, and the runner 10 moving up and down, so as to improve the propulsion force, avoid the up and down movement, and prevent vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

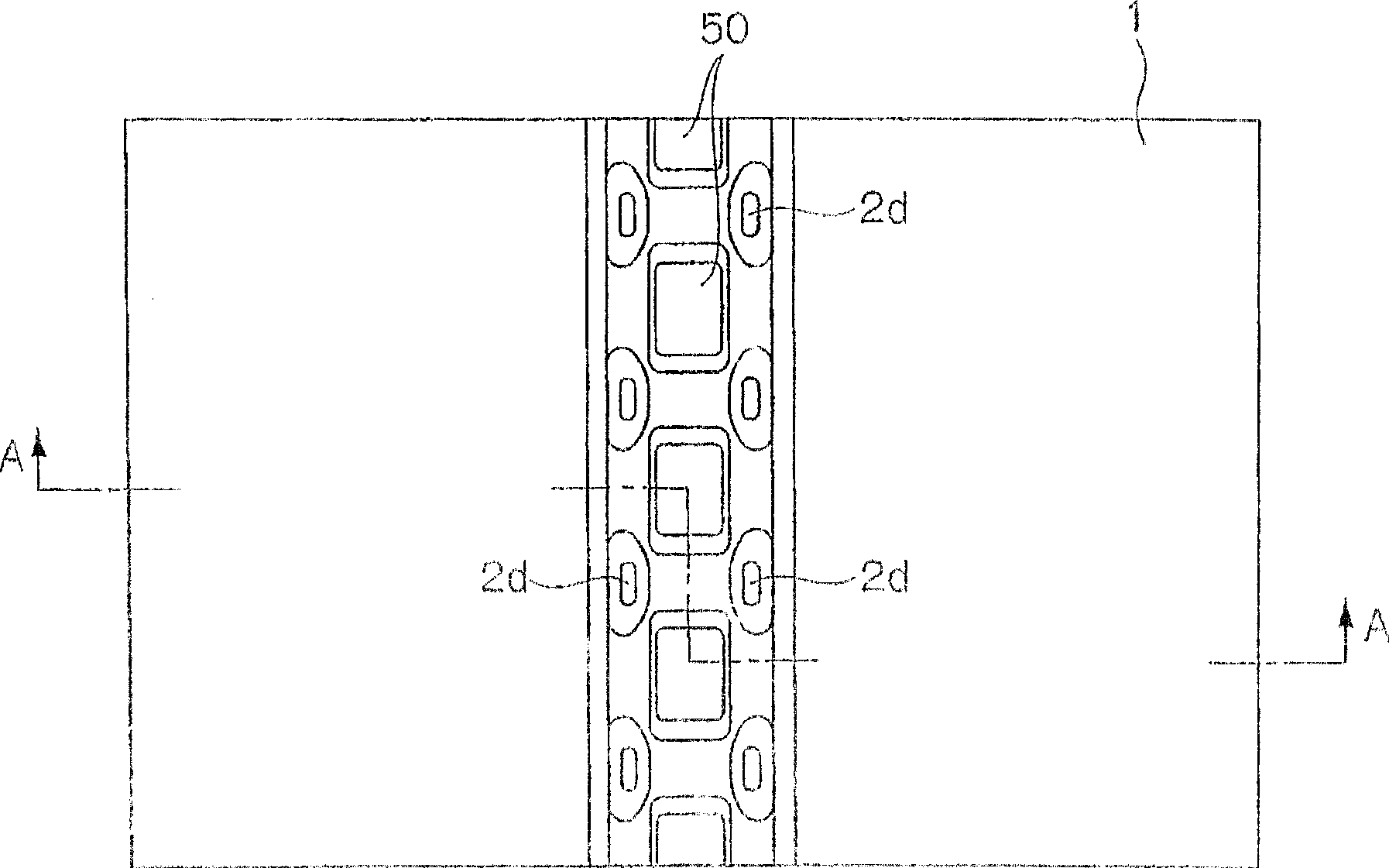

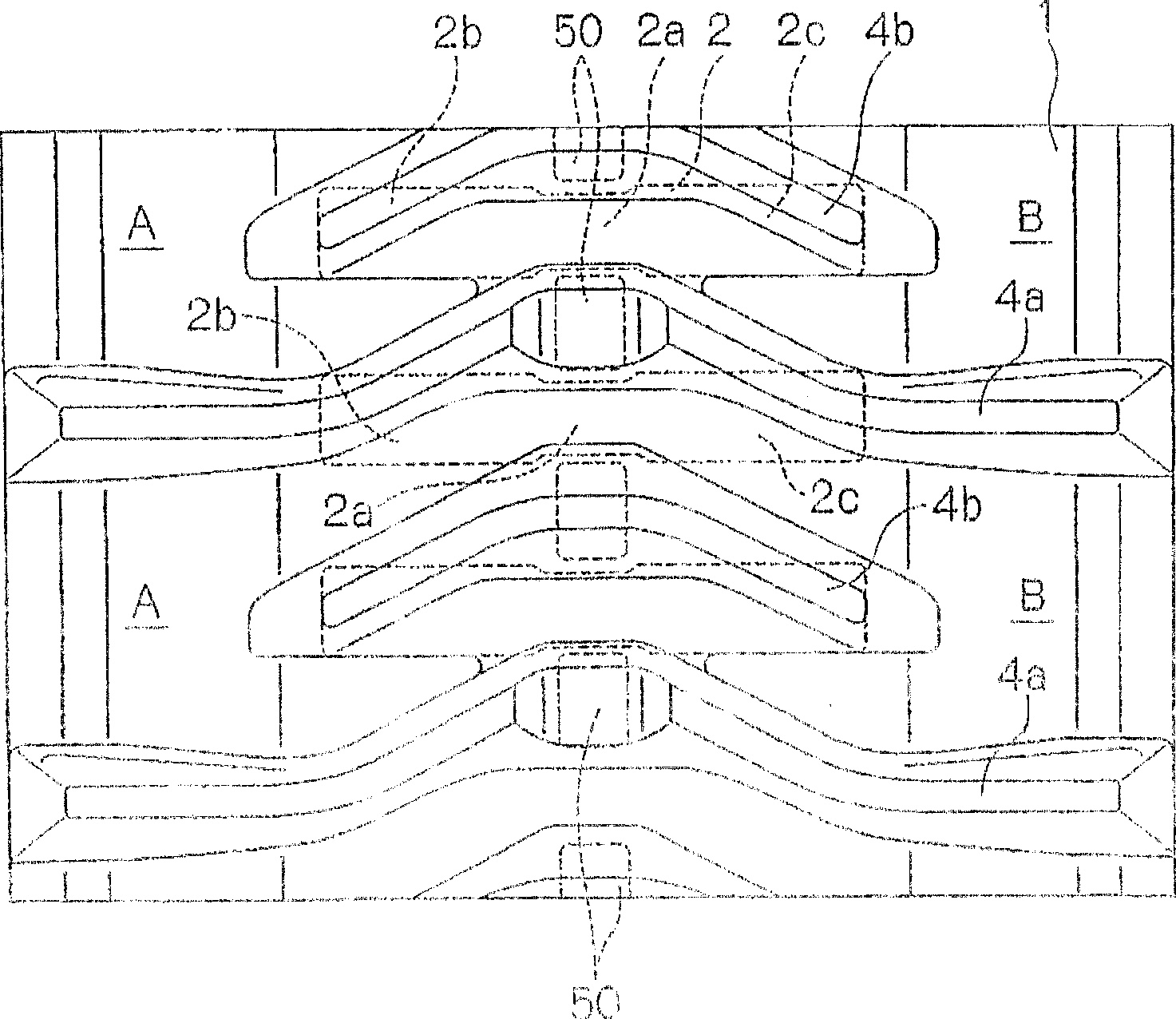

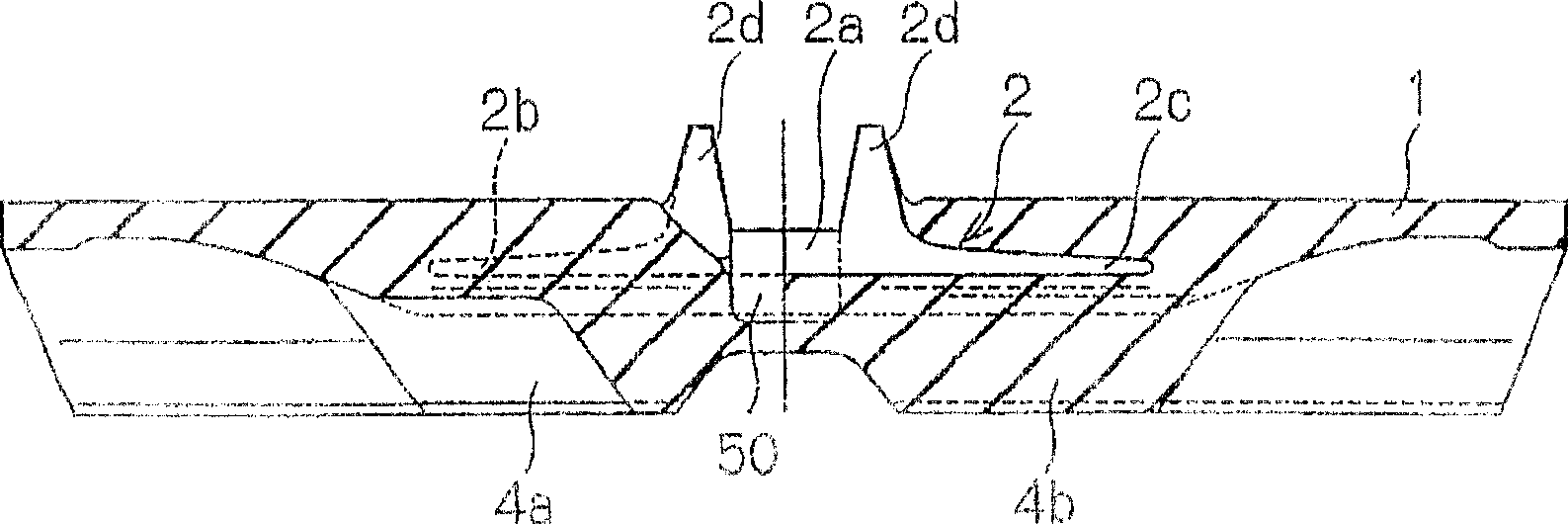

[0022] The rubber track of the present invention will be described in more detail based on the examples below. figure 1 It is the inner peripheral side plan view of the 1st example of the rubber crawler of this invention. figure 2 yes figure 1 A top view of the outer peripheral side of the rubber track. image 3 is along figure 1 A cross-sectional view taken along line A-A. in addition, Figure 4 is an enlarged cross-sectional view along the longitudinal direction of the concave portion. Figure 5 It is an enlarged cross-sectional view along the width direction of the above-mentioned concave portion.

[0023] In the figure, 1 is a rubber elastic body constituting the base of the rubber track, which is connected in a ring shape in the vertical direction in the figure. 2 is a core member embedded in the rubber elastic body, which is embedded at a fixed interval along the length direction of the rubber elastic body 1. The left and right wing parts 2b, 2c of the core mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com