Variable-frequency pump wax injection system

A variable frequency pump and wax injection technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of waste of wax oil and failure to consider the requirements of injection speed, etc., to reduce the loss of wax oil, avoid waste, Reduce the effect of subsequent processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

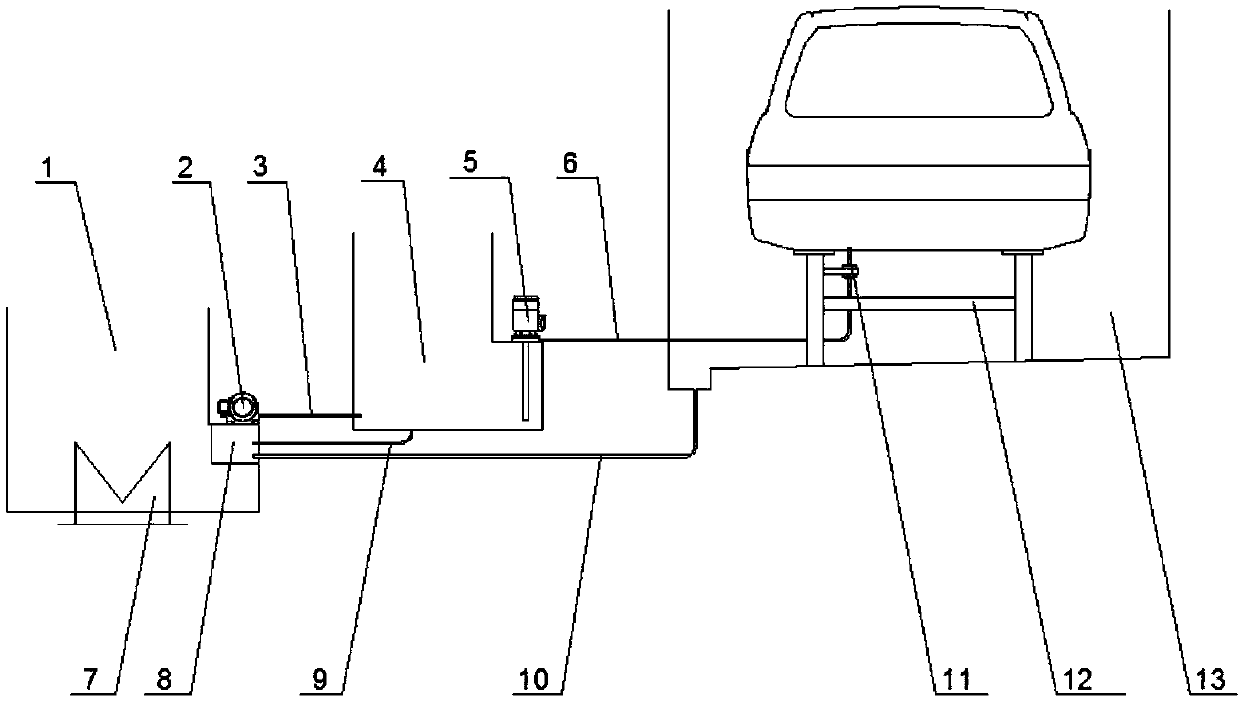

[0015] Attached below figure 1 The present invention is described further:

[0016] A variable frequency pump wax injection system, comprising a wax storage tank 1, a working tank 4, a frequency conversion pump 5 and a fixture tank 13, the wax storage tank 1 transports liquid wax to the working tank 4 through a working pipeline 3 through a pump 2, and the The working tank 4 is provided with a variable frequency pump 5, and by adjusting the frequency of the variable frequency pump 5, the injection amount of liquid wax is adjusted to ensure that the cavity of the vehicle body is filled with liquid wax, and the part of the liquid wax that is not bonded to the inner wall of the cavity, It also flows into the fixture tank 13, and the excess liquid wax returns to the filter 8 in the wax storage tank 1 through the return pipe B10, and the liquid wax automatically returns to the wax storage tank 1 after filtering; the frequency conversion pump 5 and One end of the wax injection pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com