Laser pattern positioning impression transfer method

A transfer method and pattern technology, applied in printing, post-processing of printing, ink transfer from original manuscript, etc., can solve the problems of low pattern surface quality, long process route, low precision, etc. Energy consumption, the effect of improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

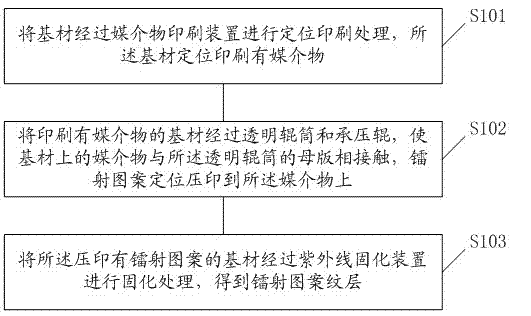

[0045] see figure 1 , the present invention provides a first embodiment of a laser pattern positioning imprint transfer method, including:

[0046] S101, the base material is subjected to positional printing processing through a medium printing device, and the base material is positionally printed with a medium.

[0047] The substrate can be, but not limited to, plastic film, leather, paper or aluminum foil. Preferably, the substrate is a plastic film. More preferably, the substrate is a PET film, which is also known as a high temperature resistant polyester film. As one of the embodiments of the present invention, the thickness of the PET film is preferably 15um, but not limited thereto.

[0048] The vehicle may be, but not limited to, a radiation curable polymer such as varnish, ink, varnish, adhesive. Preferably, the medium is UV (Ultra-Violet Ray, ultraviolet) varnish, UV ink.

[0049] The printing speed of the substrate positioning printing medium is preferably 30-100 ...

no. 2 example

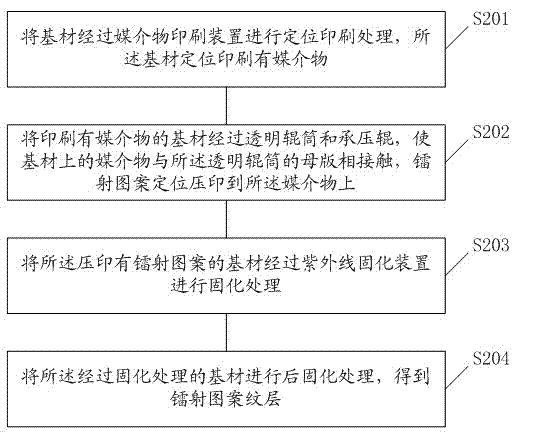

[0077] see figure 2 , the present invention provides a second embodiment of a laser pattern positioning imprint transfer method, including:

[0078] S201, the base material is subjected to positional printing processing through a medium printing device, and the base material is positionally printed with a medium.

[0079] S202, passing the substrate printed with the medium through the transparent roller and the pressure roller, so that the medium on the substrate is in contact with the master plate of the transparent roller, and positioning and embossing the laser pattern on the medium.

[0080] S203, curing the substrate embossed with the laser pattern through an ultraviolet curing device.

[0081] It should be noted that the operation methods and principles of steps S201 and S101, S202 and S102, and S203 and S103 are consistent, and will not be repeated here.

[0082] S204, performing post-curing treatment on the cured substrate to obtain a laser patterned layer.

[0083...

no. 3 example

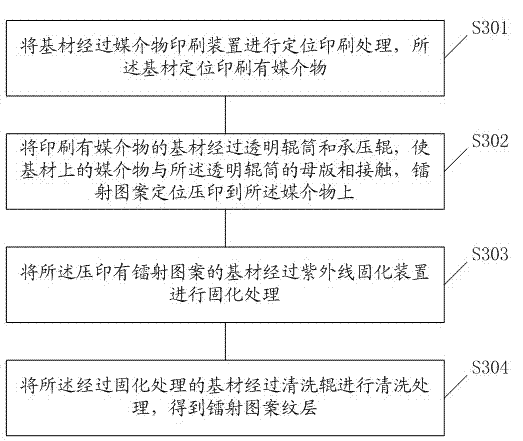

[0085] see image 3 , the present invention provides a third embodiment of a laser pattern positioning imprint transfer method, including:

[0086] S301, the base material is subjected to positioning printing processing through a media printing device, and the base material is position-printed with a media.

[0087] S302, passing the substrate printed with the medium through the transparent roller and the pressure roller, so that the medium on the substrate is in contact with the master plate of the transparent roller, and positioning and embossing the laser pattern on the medium.

[0088] S303, curing the substrate embossed with the laser pattern through an ultraviolet curing device.

[0089] It should be noted that the operation methods and principles of steps S301 and S101, S302 and S102, and S303 and S103 are the same, and will not be repeated here.

[0090]S304, cleaning the cured substrate through a cleaning roller to obtain a laser patterned layer.

[0091] and figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com