Liquid silica gel cold-runner mould

A liquid silicone and cold runner technology, applied in the field of silicone mold manufacturing, can solve the problems of silicone products such as lack of glue, trapped air, poor cavity exhaust, etc., achieve good cooling effect, reduce local temperature differences, and improve cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

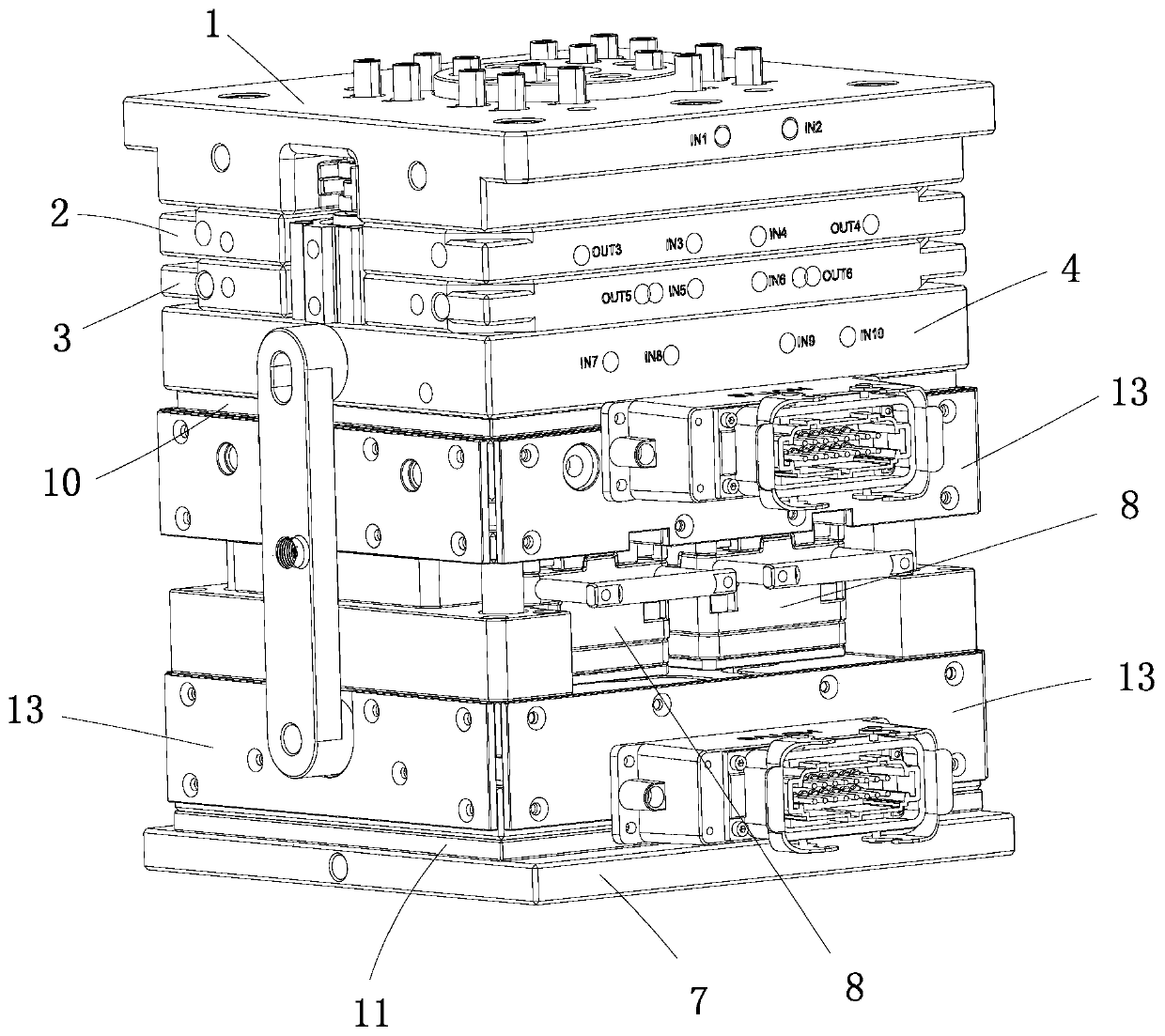

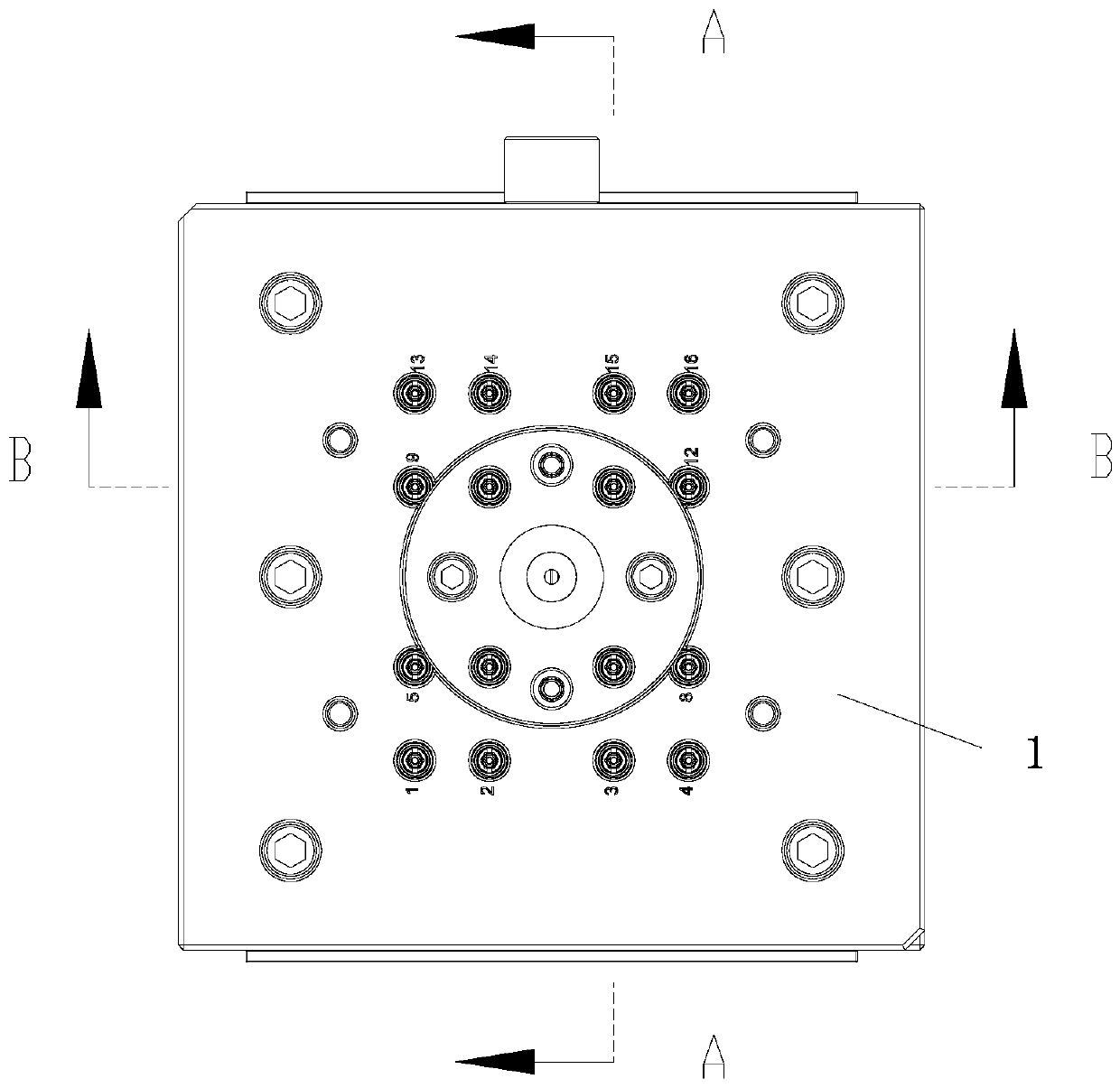

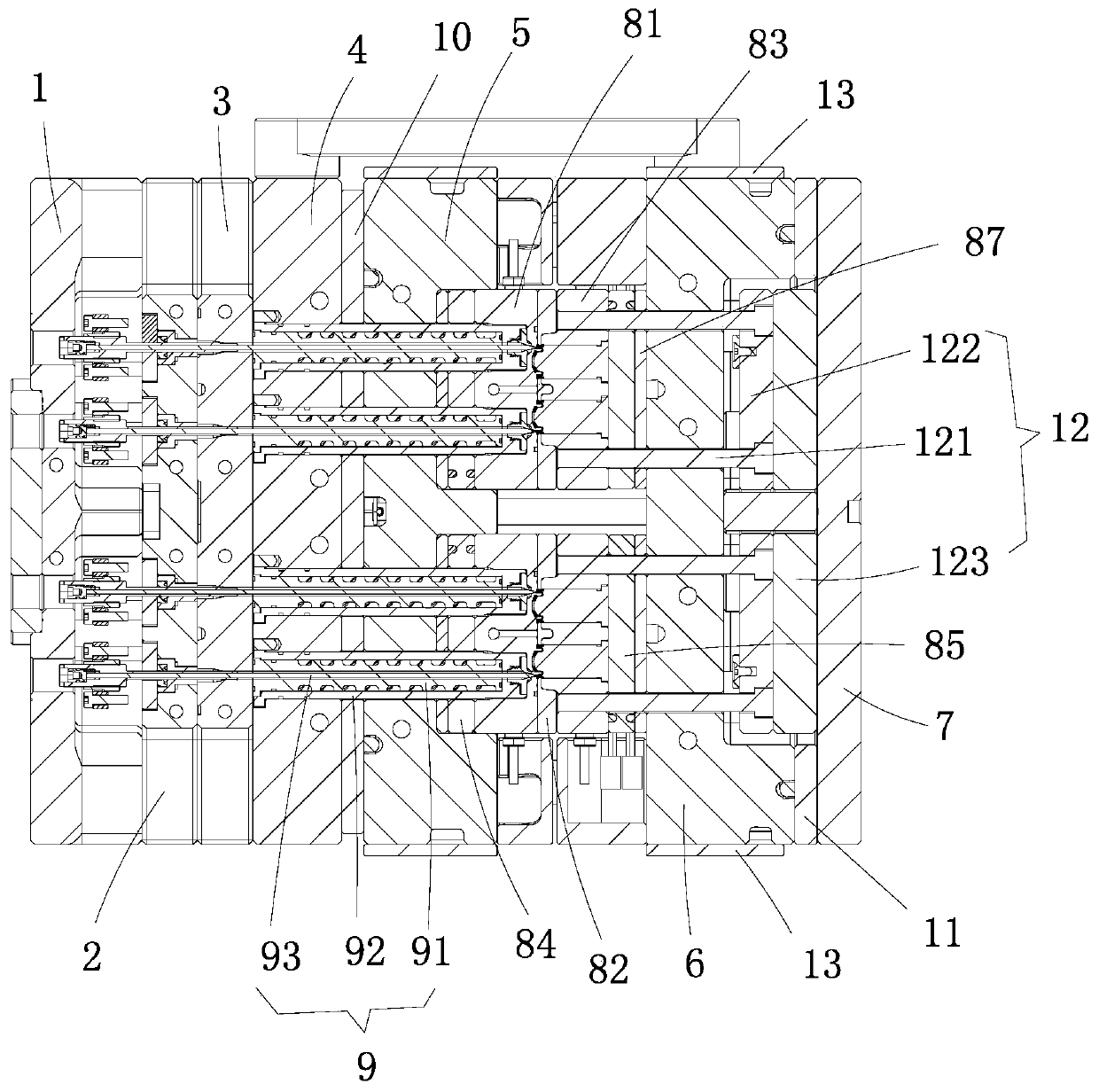

[0032] see Figure 1 to Figure 6 , this embodiment provides a liquid silicone cold runner mold, which has a mold core 8, and the mold core 8 includes a concave template 81, a stripping template 82 and a convex template 83 arranged in layers, and the material flow end of the corresponding cavity on the concave template 81 There is a vent hole 811, and the end of the vent hole 811 is used to communicate with the vacuum pump outside the mould. There is a sealing ring between the concave plate 81 and the stripping plate 82. The cavity and the vent hole 811 are located in the sealing area surrounded by the sealing ring. Inside.

[0033] If the air in the cavity cannot be completely exhausted before injecting the liquid silicone into the cavity, the air in the cavity will be trapped at the end of the material flow due to the high temperature and compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com