Patents

Literature

43 results about "Silicone injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone Injection. Silicone injections are exactly what they sound like — injections of silicone into the body, and in this context generally (but not exclusively) to the male genitalia. The potential changes are, for lack of a better word, "monstrous.".

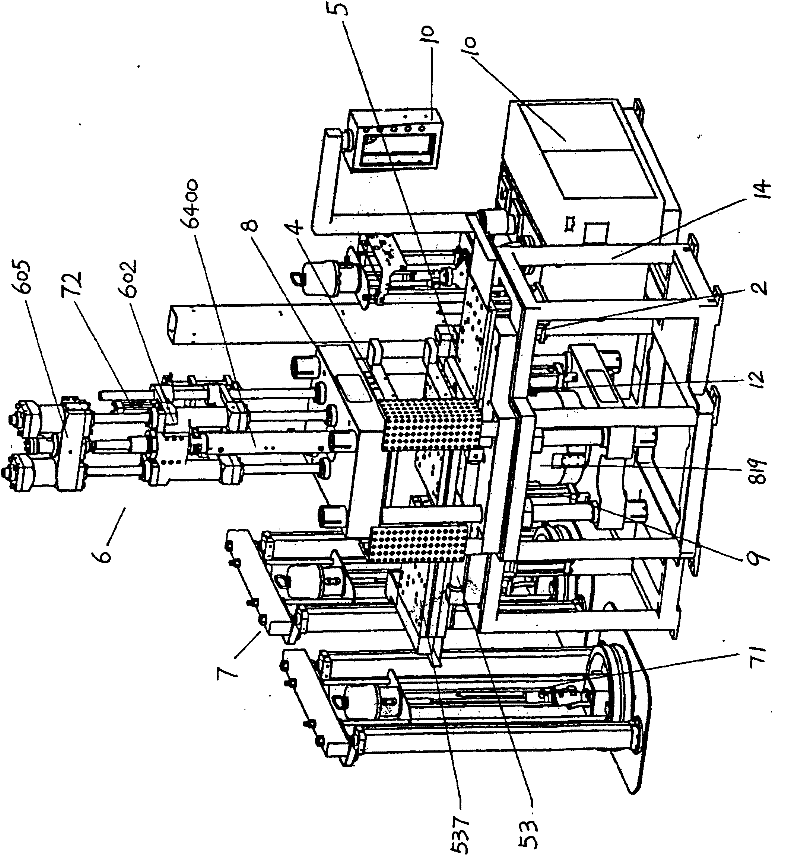

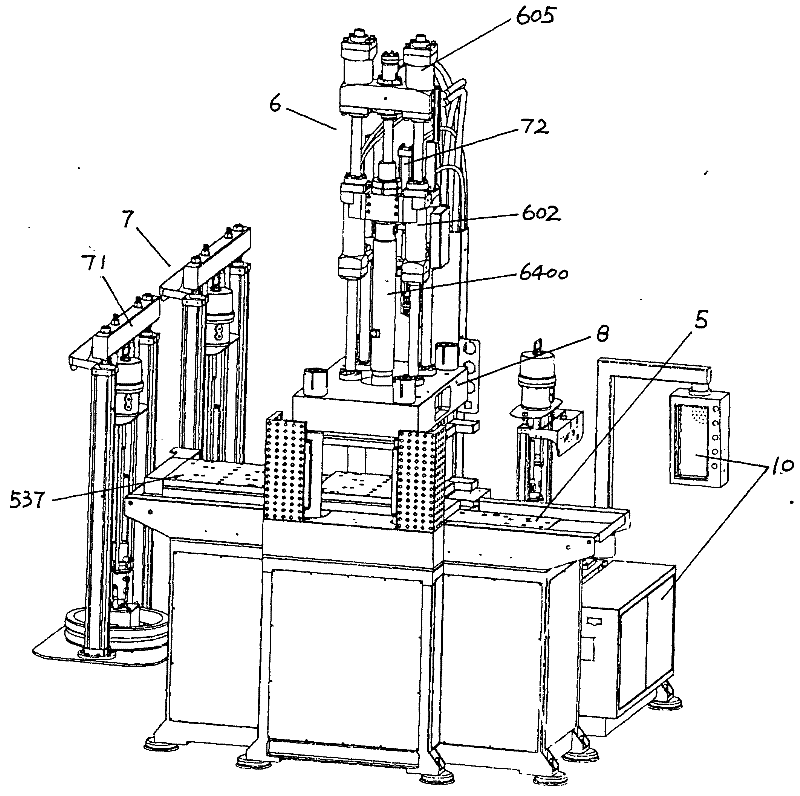

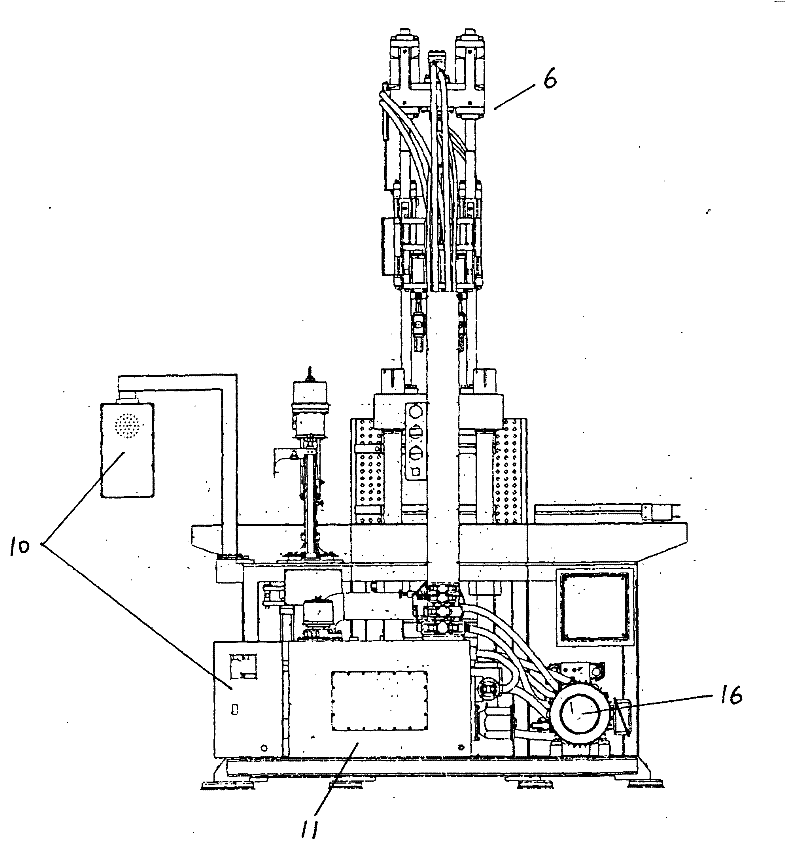

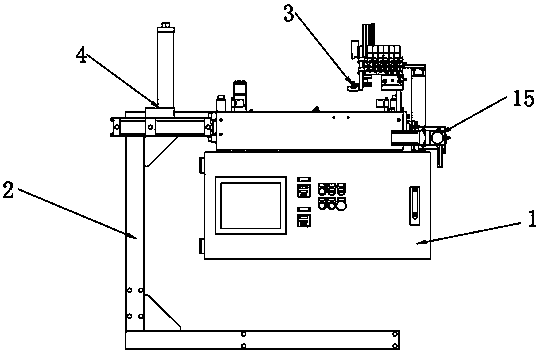

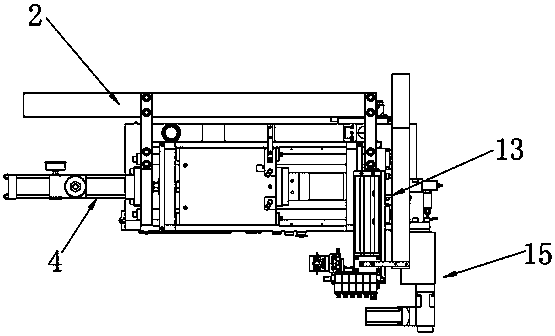

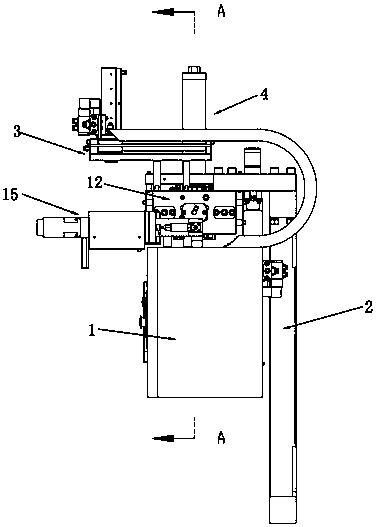

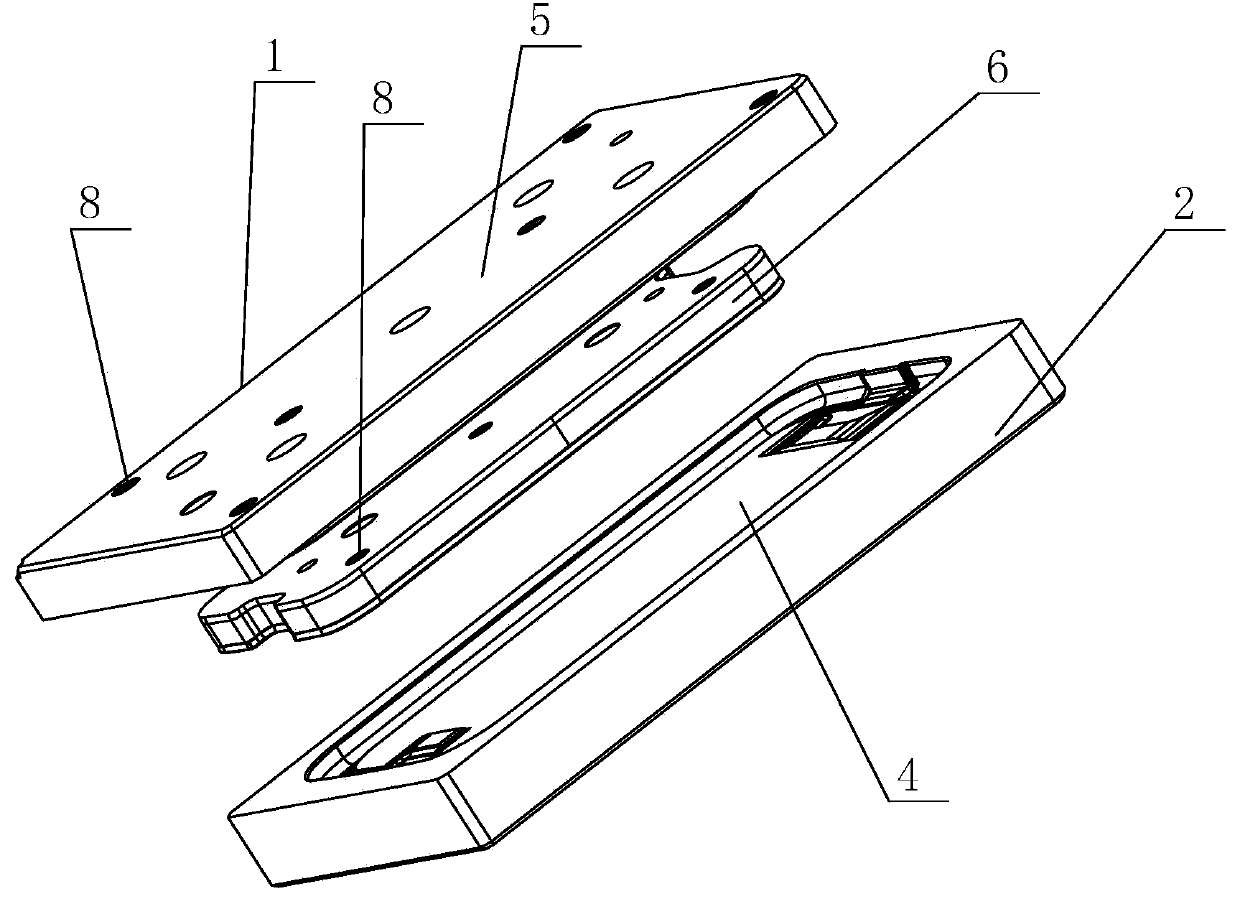

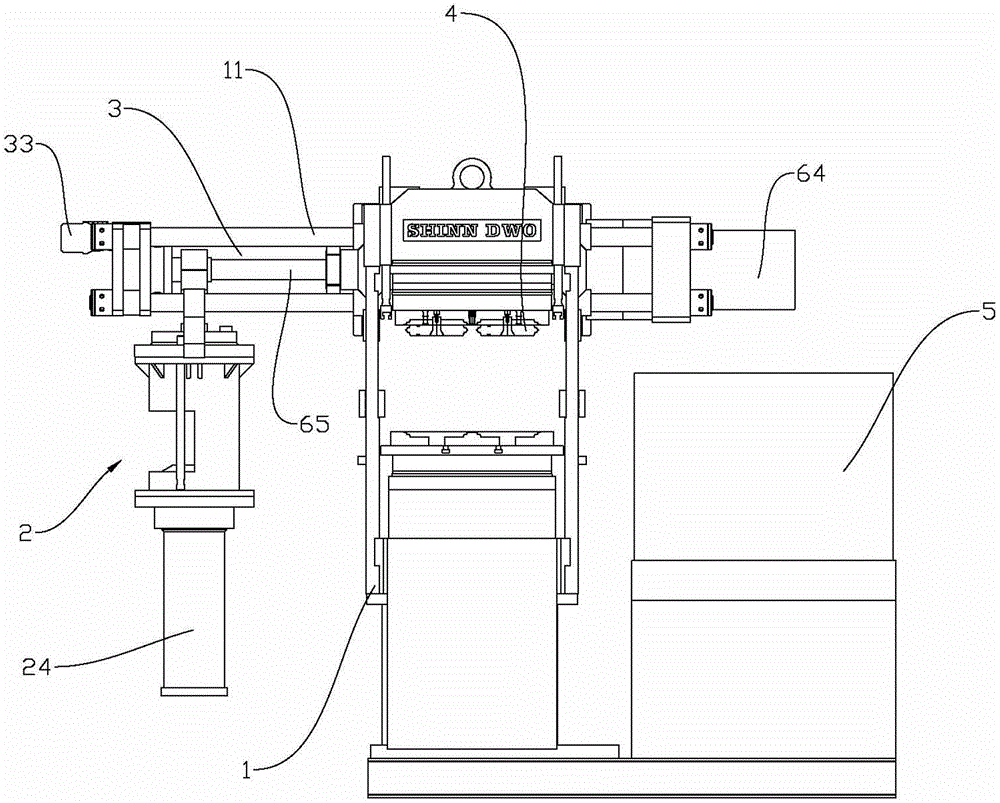

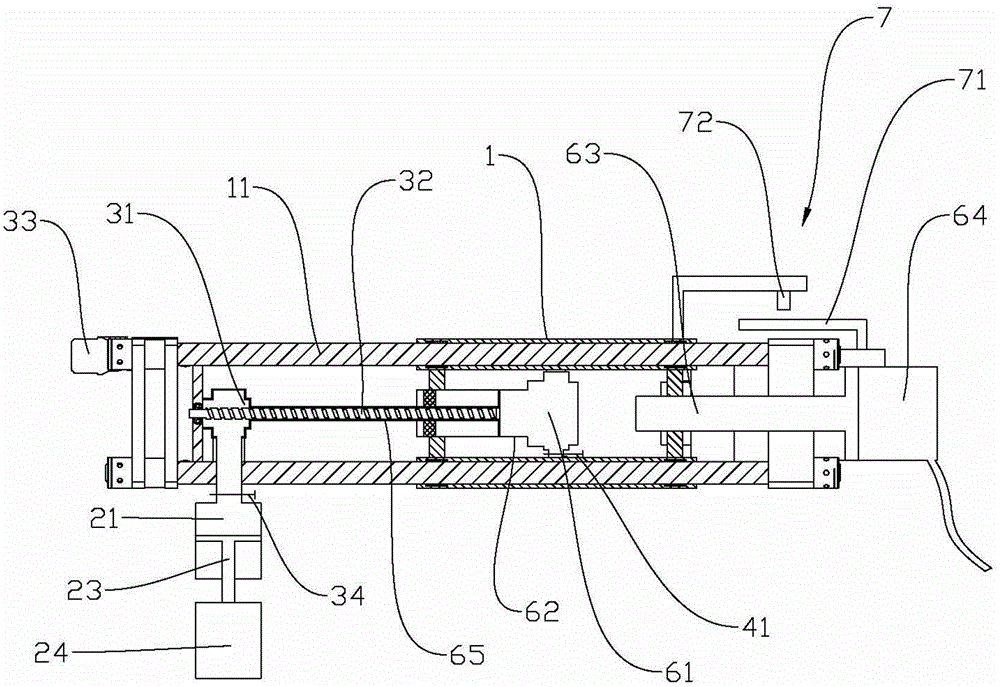

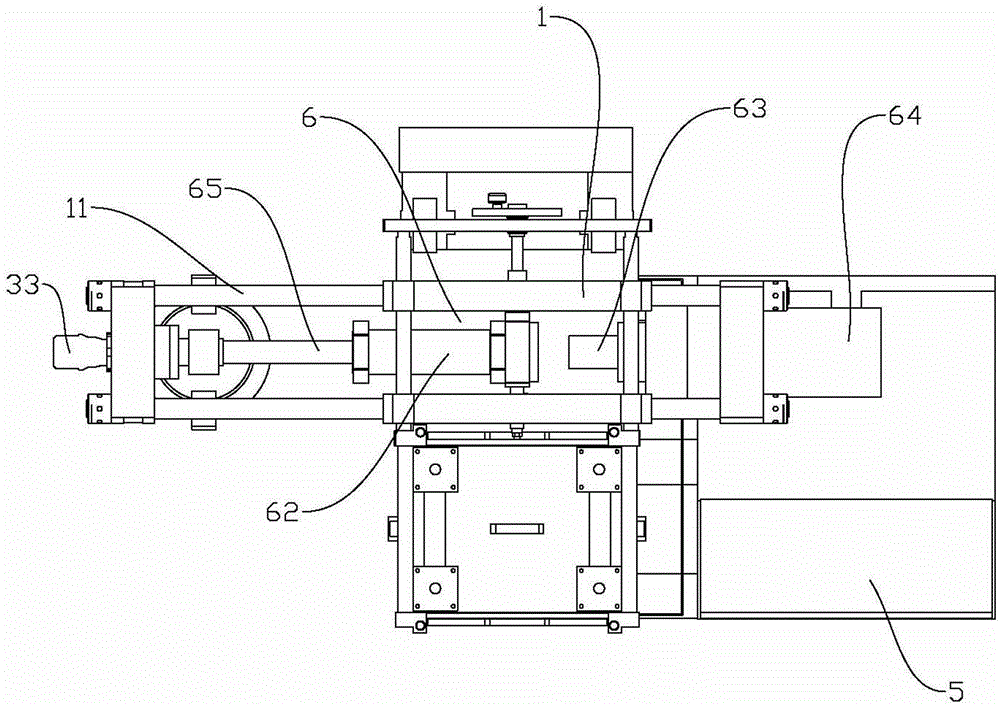

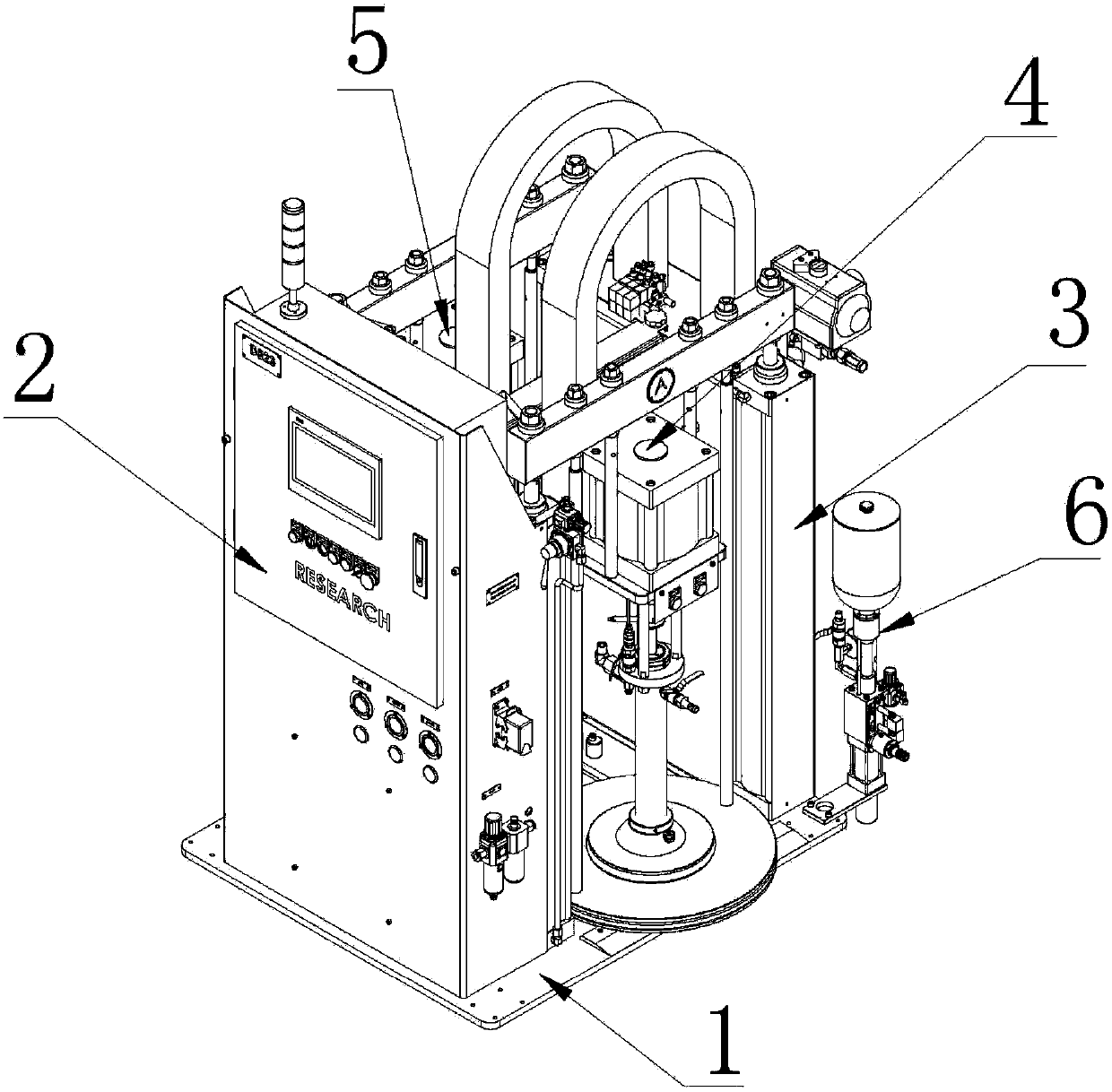

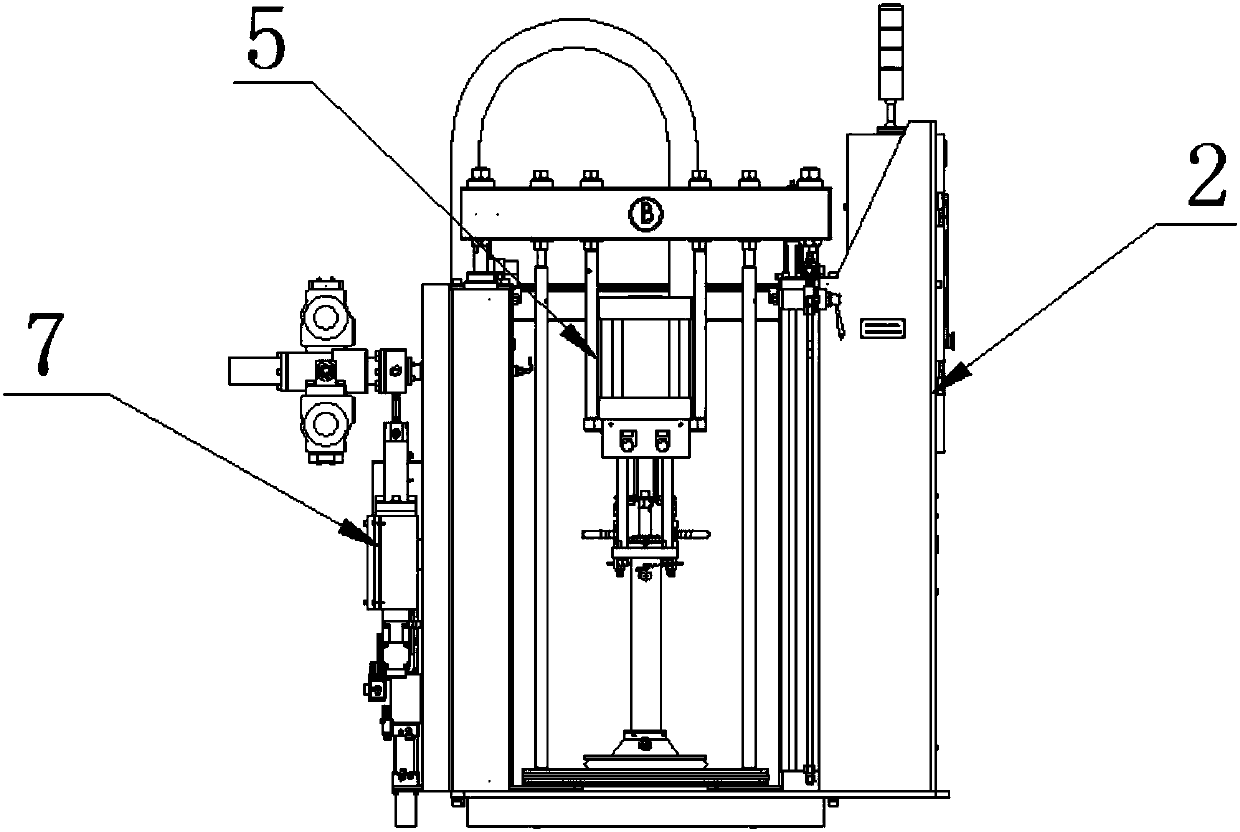

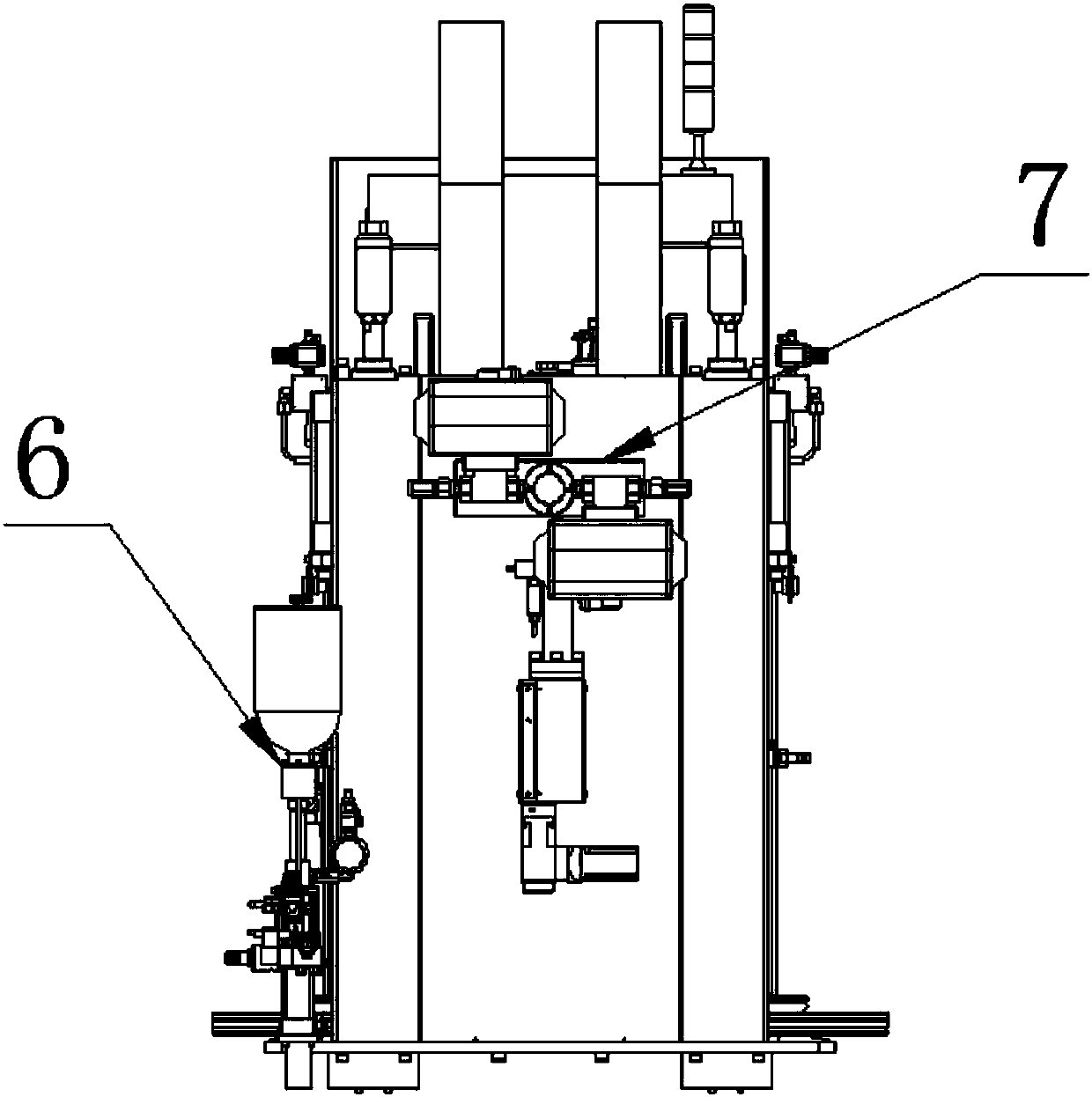

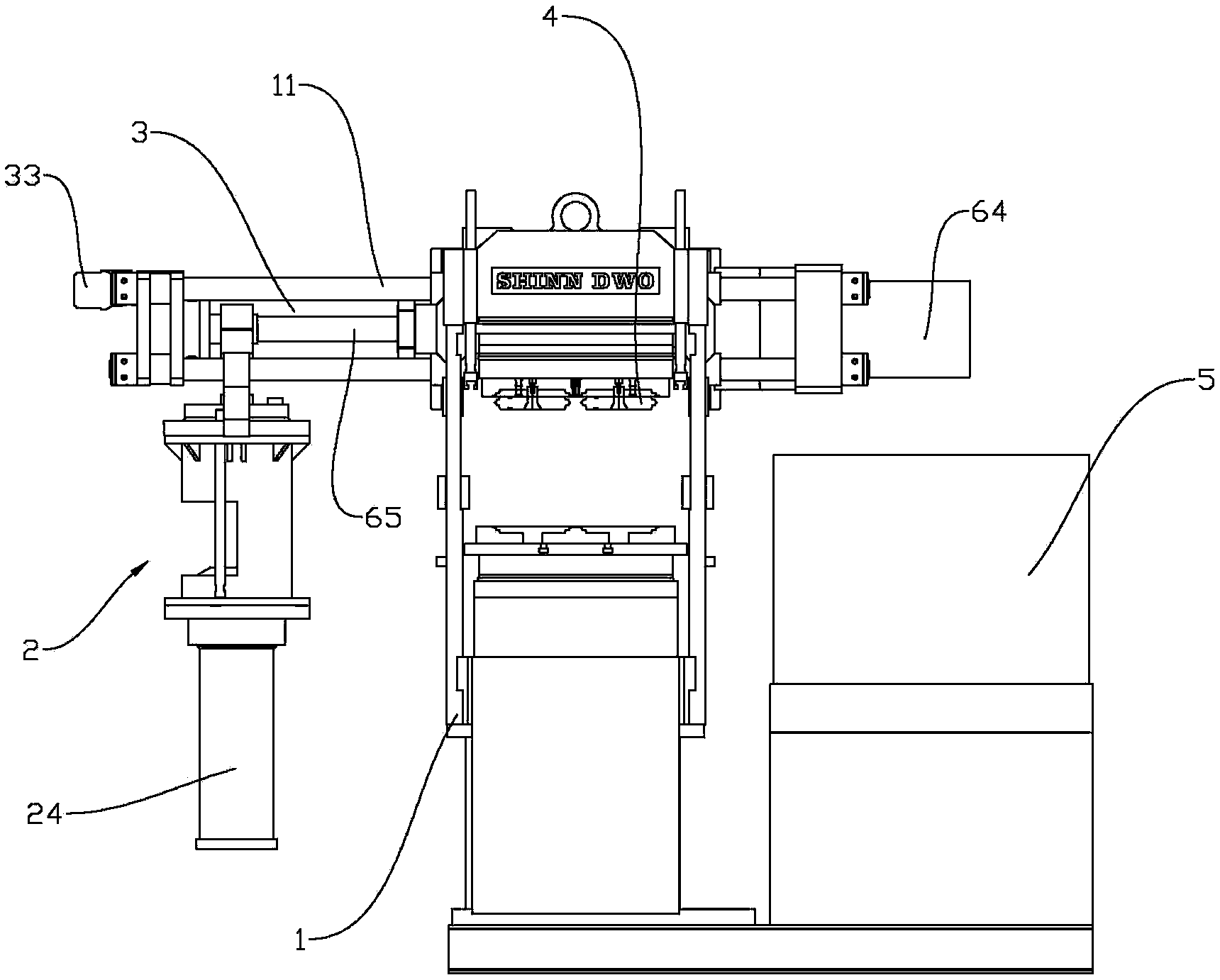

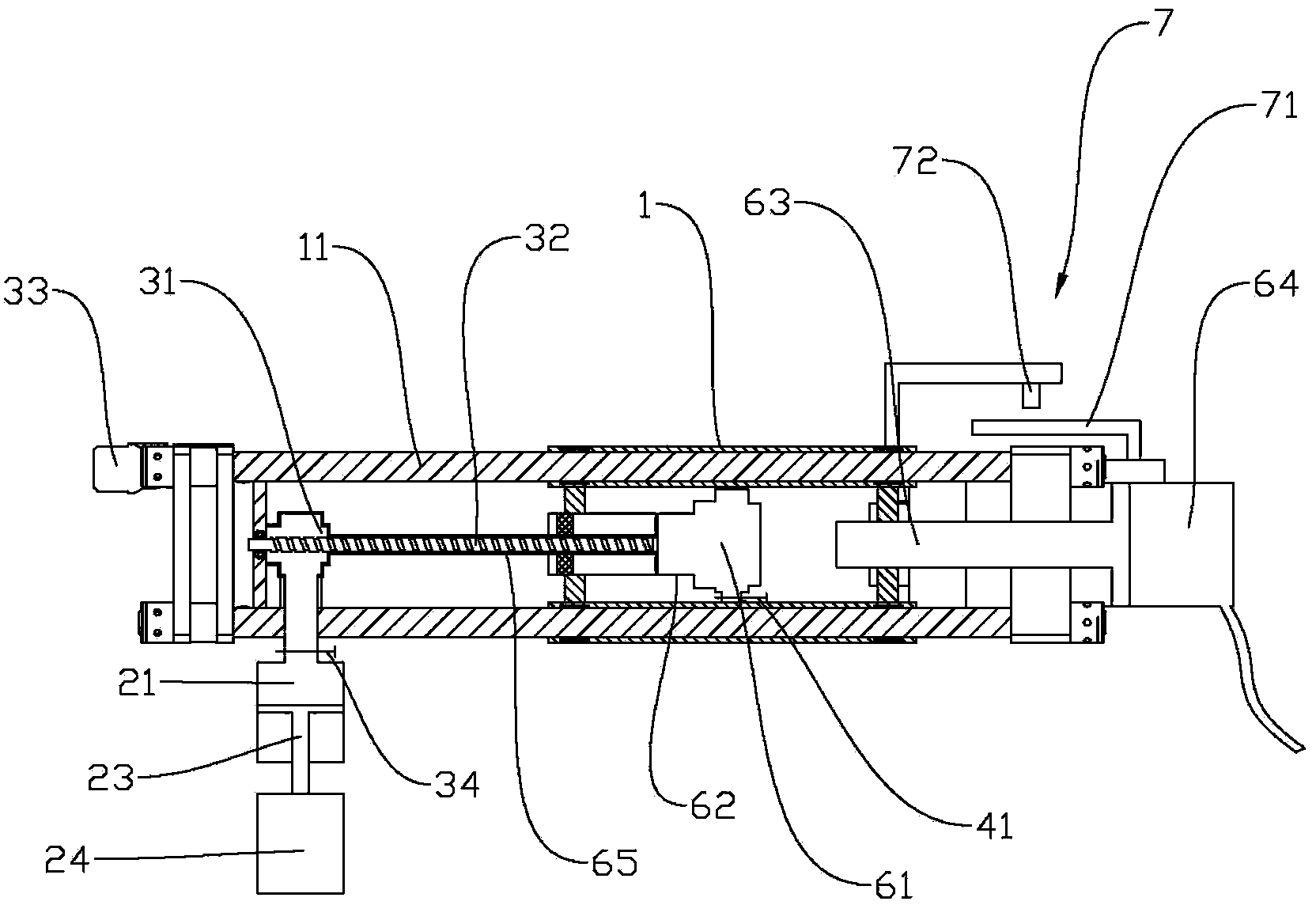

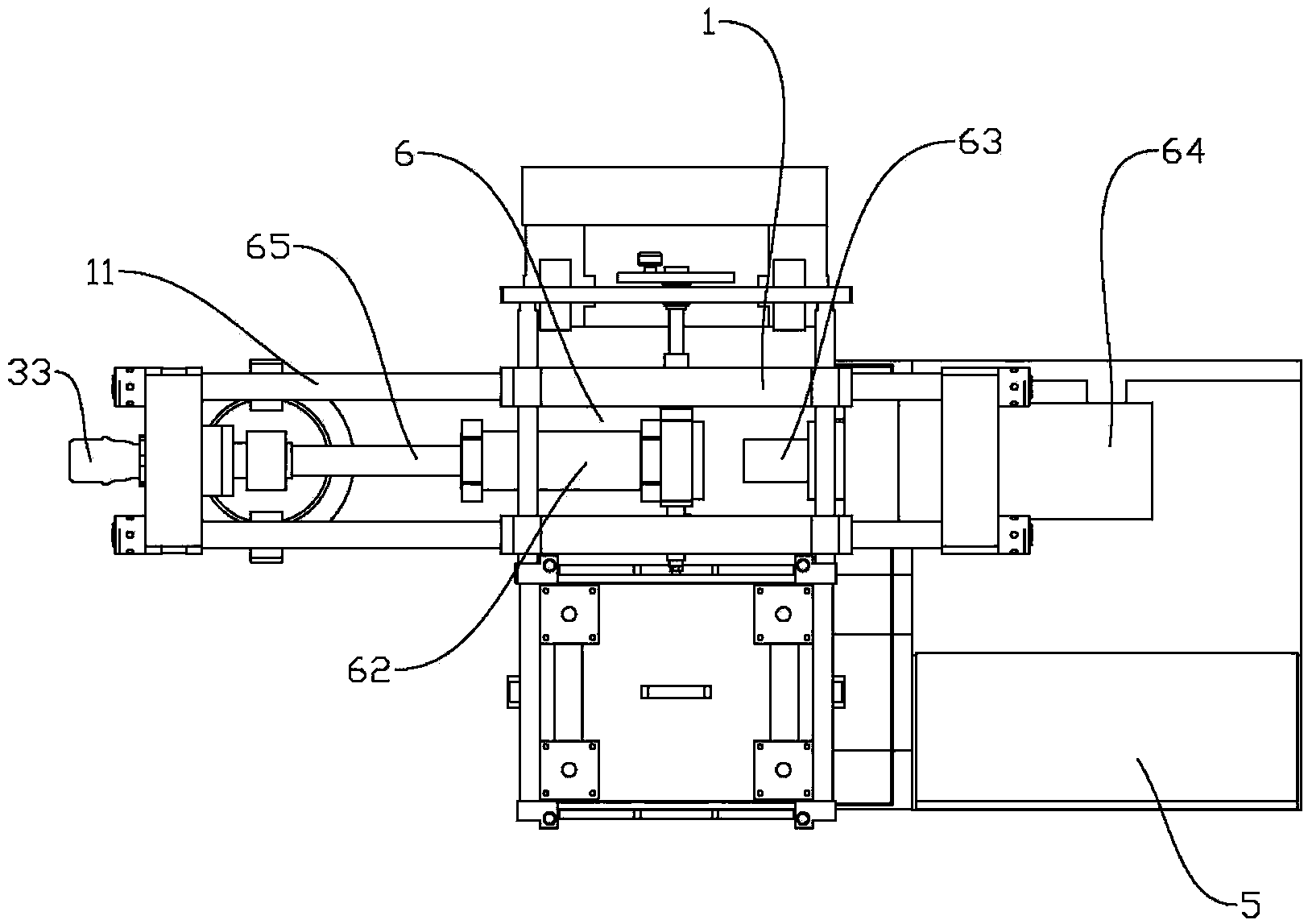

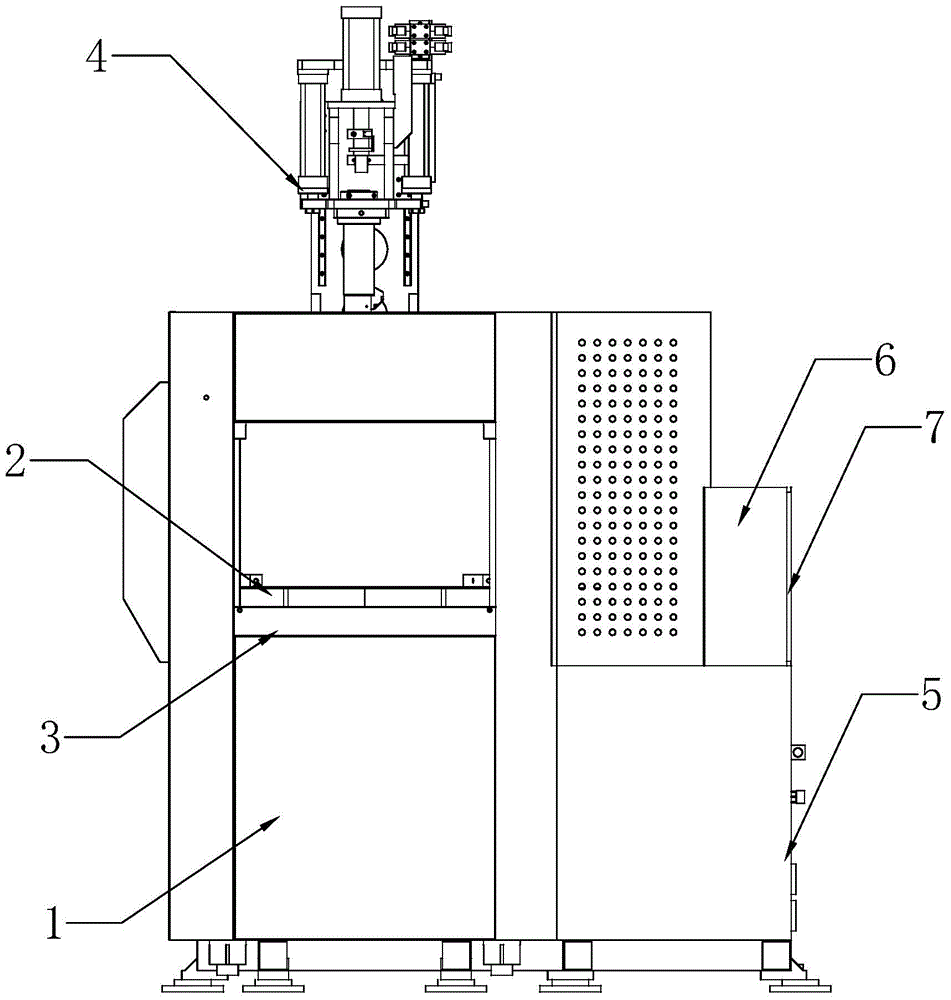

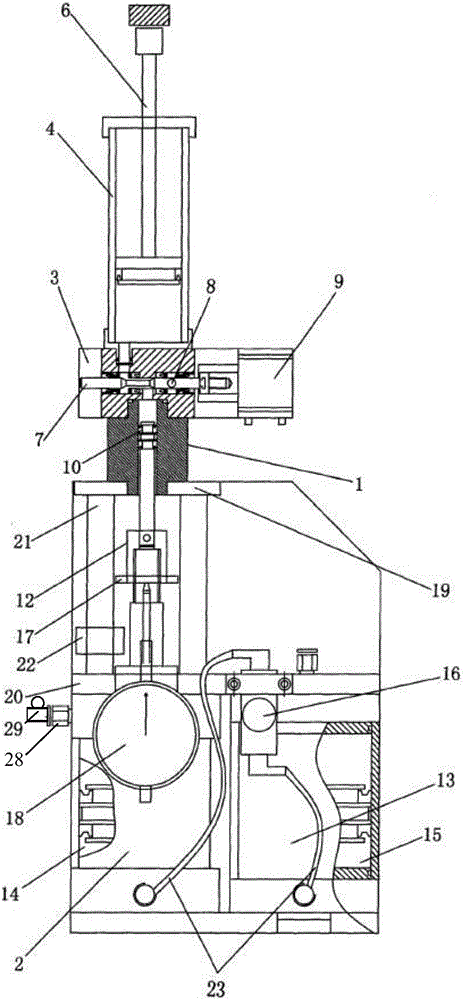

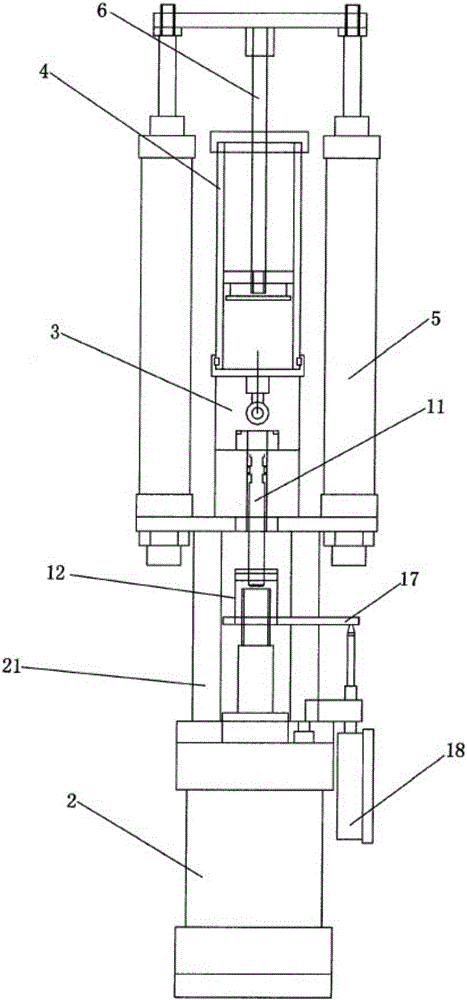

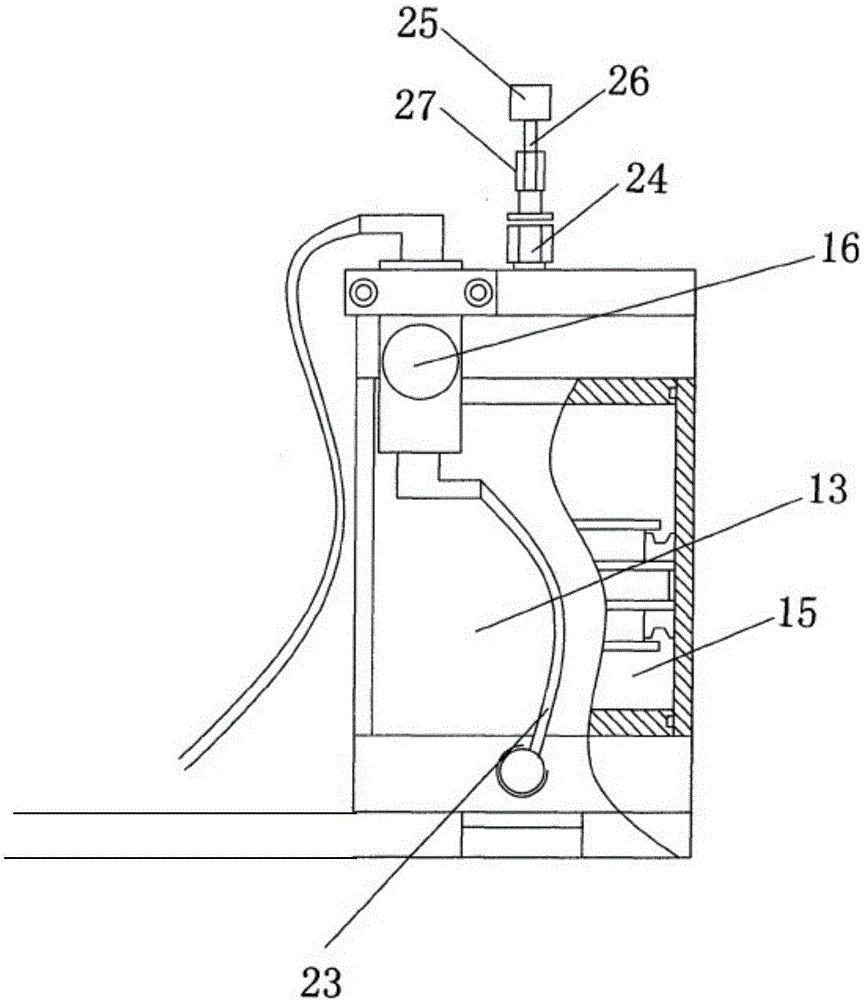

Two-component liquid silicone injection-molding complete equipment

The invention discloses two-component liquid silicone injection-molding complete equipment which aims to solve the technical problem that the equipment needs to precisely inject two-component liquid silicone materials. The two-component liquid silicone injection-molding complete equipment comprises a main machine and a charging system, wherein the main machine comprises a template assembly, an injection mechanism, a sliding plate mechanism, an upper mold, lower left and right molds, a cold runner mechanism, an ejection mechanism, an electrical cabinet arranged at the right rear part of a rack, an electrical cabinet, an operating electrical cabinet, an oil box, a positioning system, a fast cylinder, a main oil way board and an injecting oil way board. The rear part of the electrical cabinet is connected and fixed with the right side surface of the rear part of the oil box. Compared with the prior art, the two-component liquid silicone injection-molding complete equipment is in a vertical machine structure, comprises the ejection mechanism, the cold runner mechanism, the sliding plate mechanism, the injection mechanism, a charging mechanism, a metering mechanism, a positioning mechanism and the template assembly, and carries out simultaneous injection-molding for A and B agent liquid silicone, and can greatly improve the production efficiency.

Owner:董富有

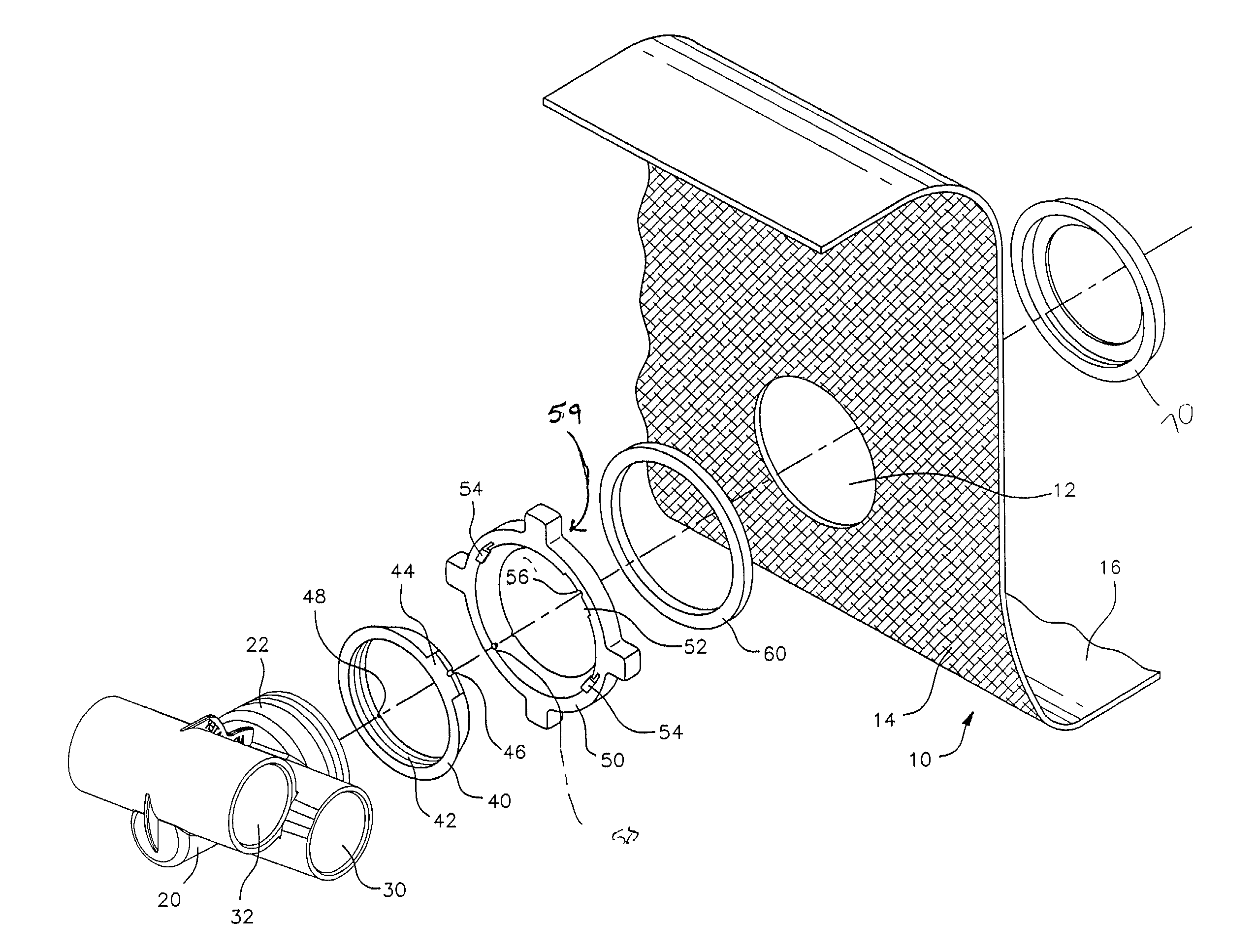

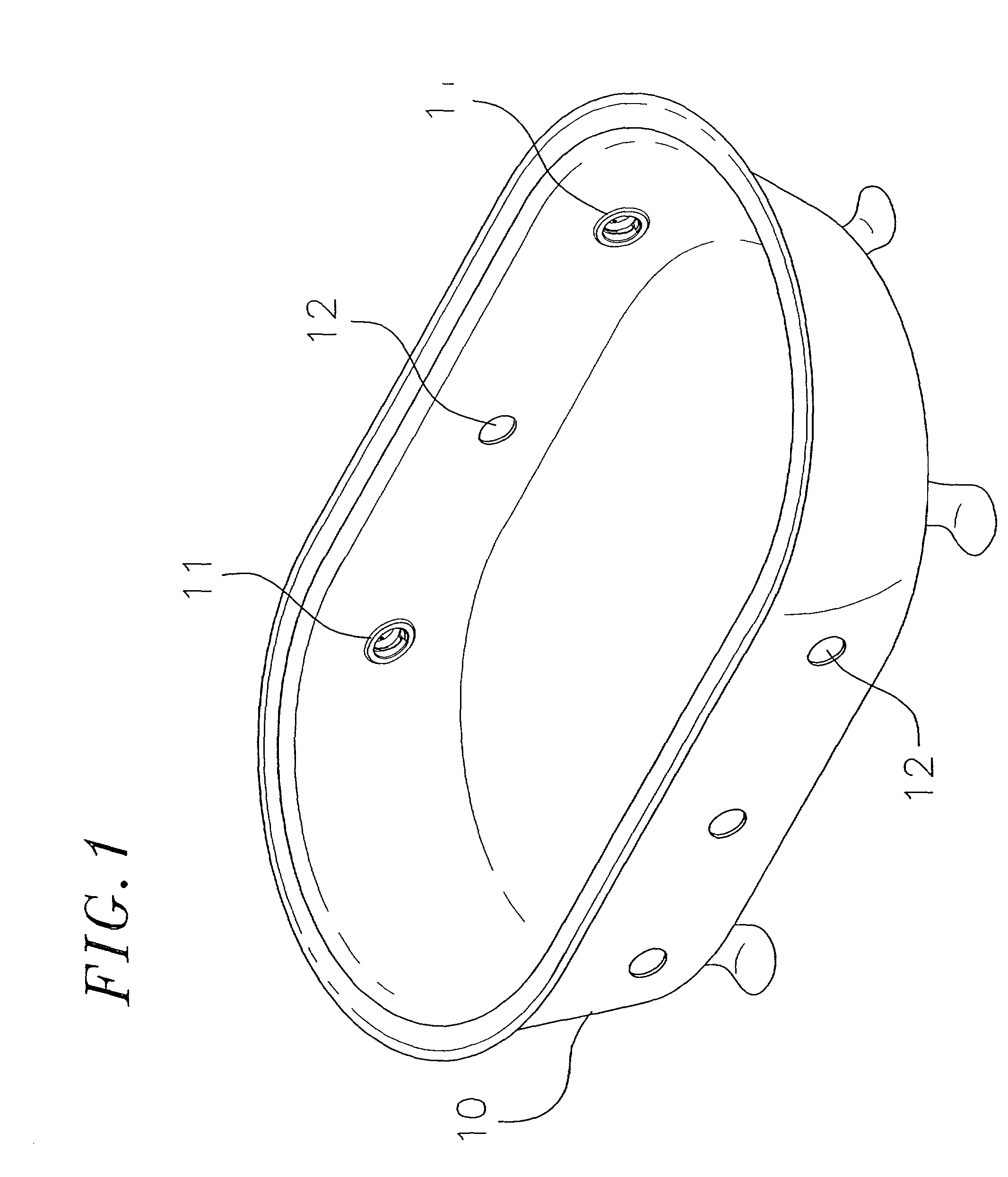

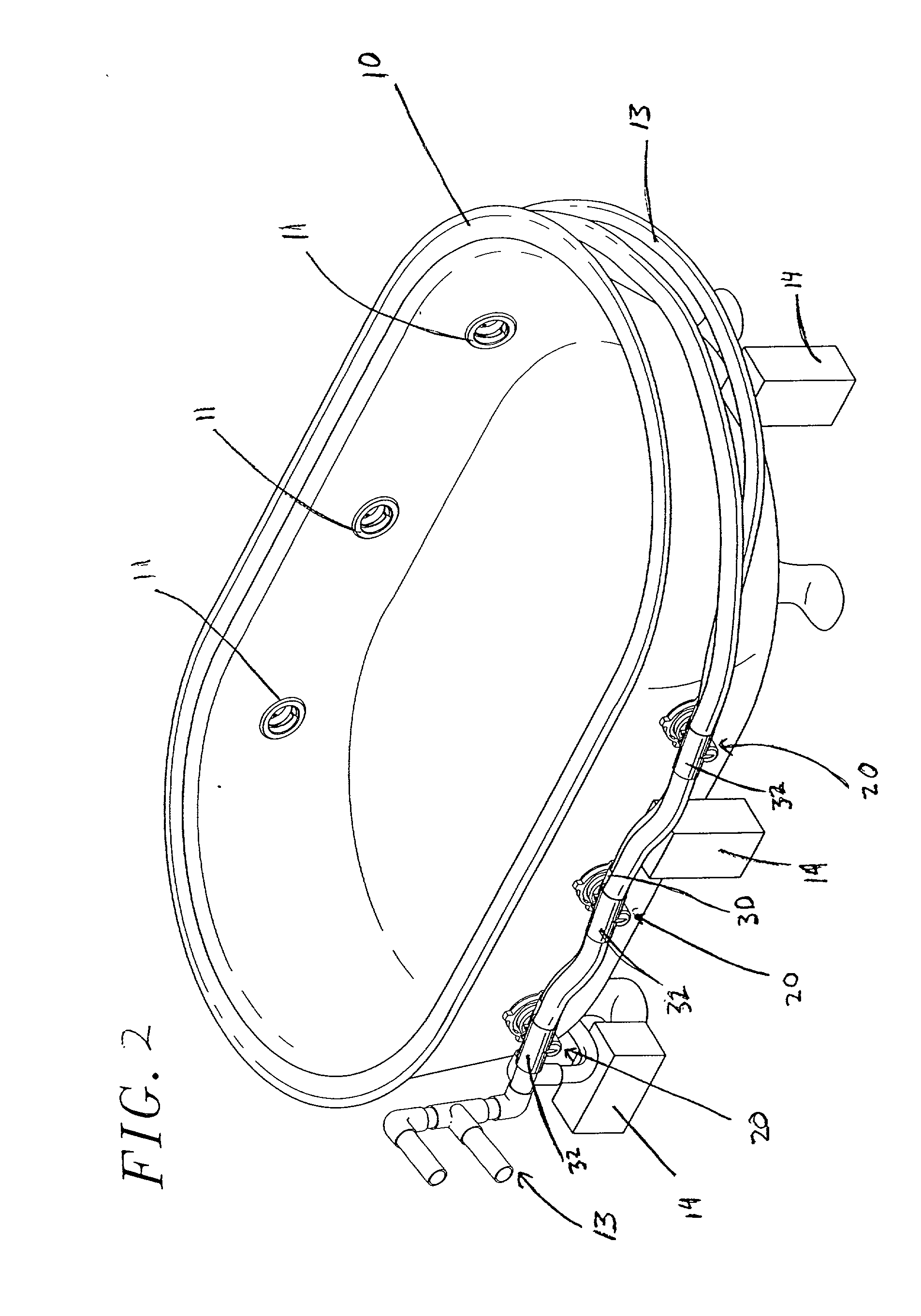

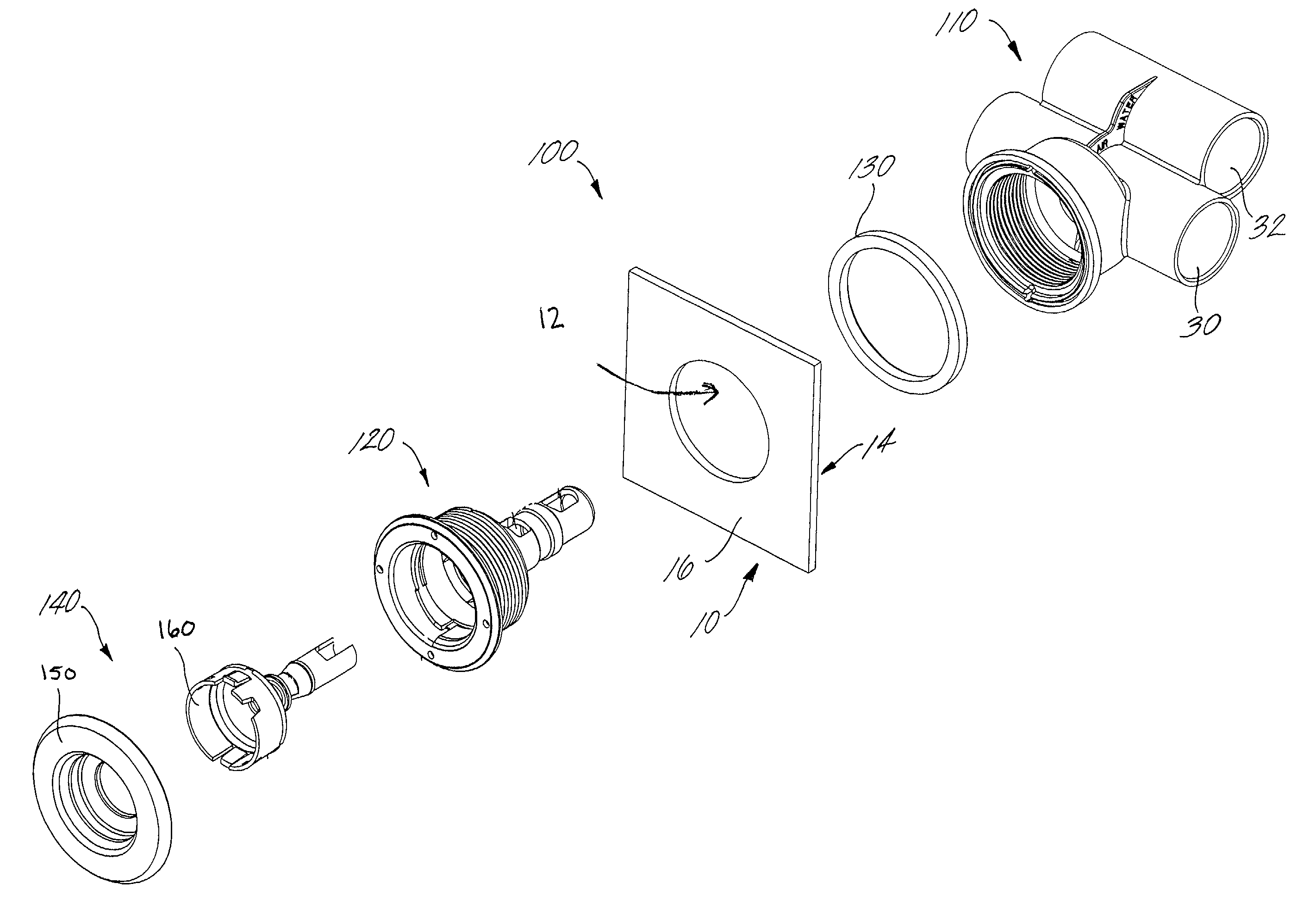

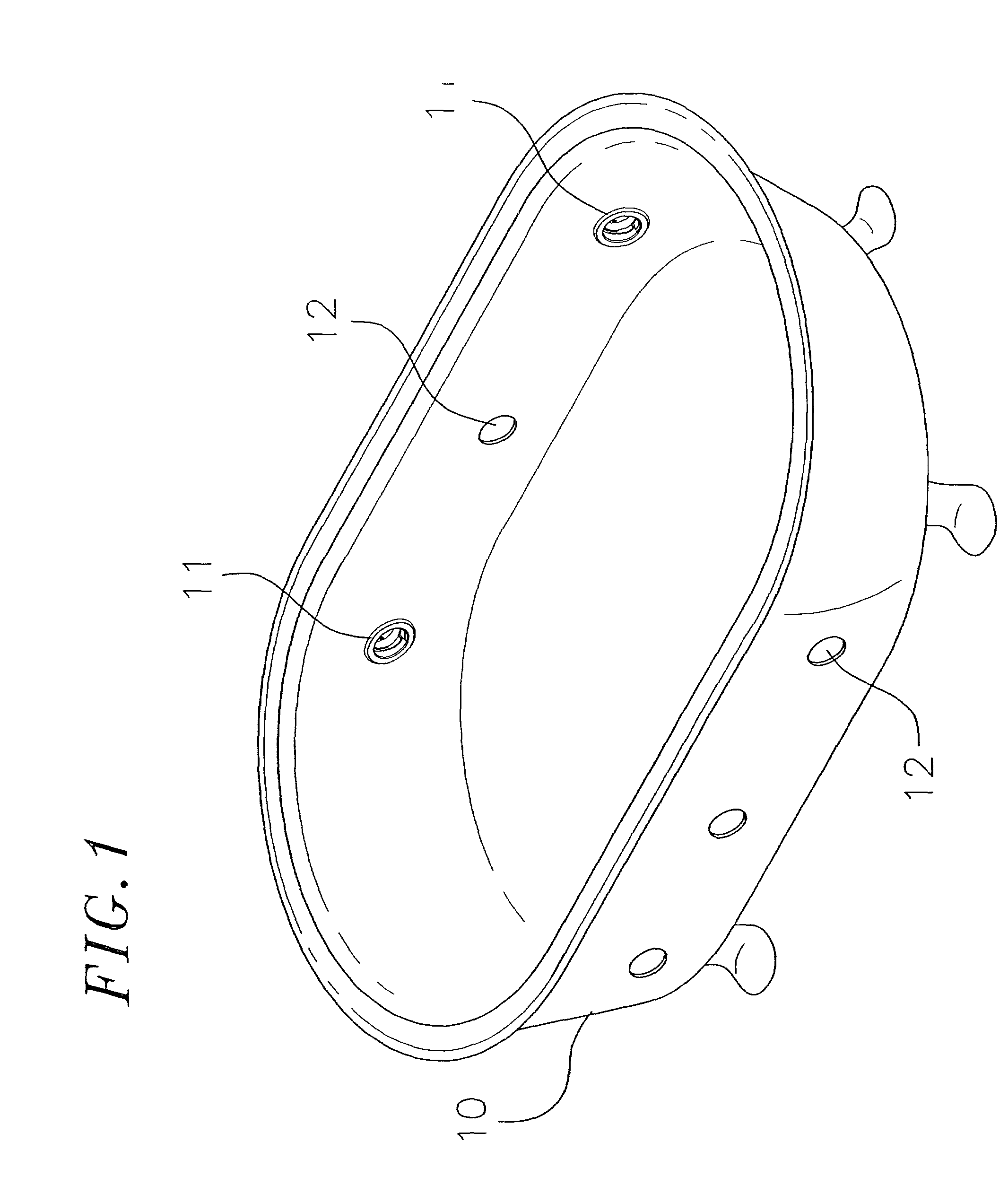

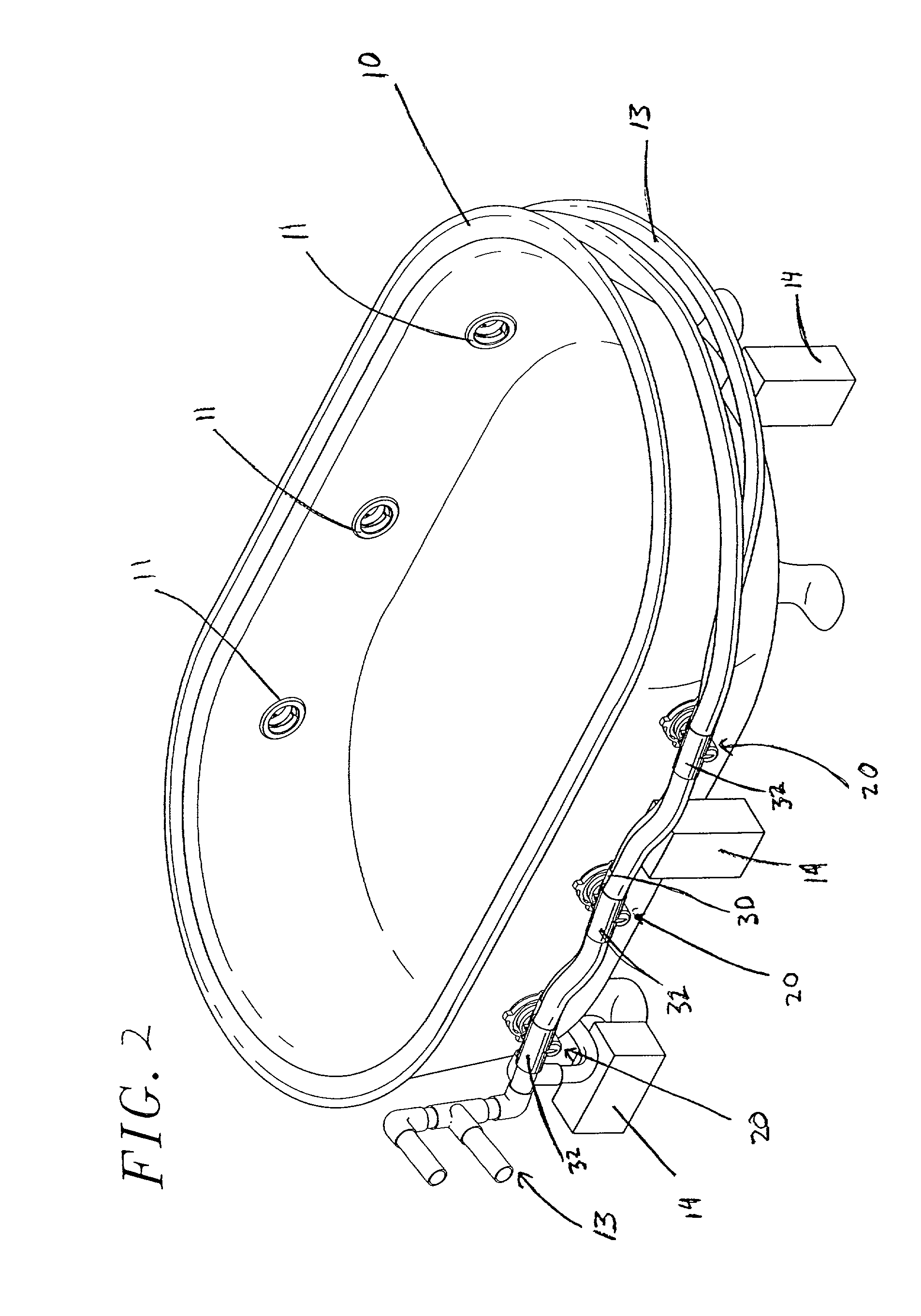

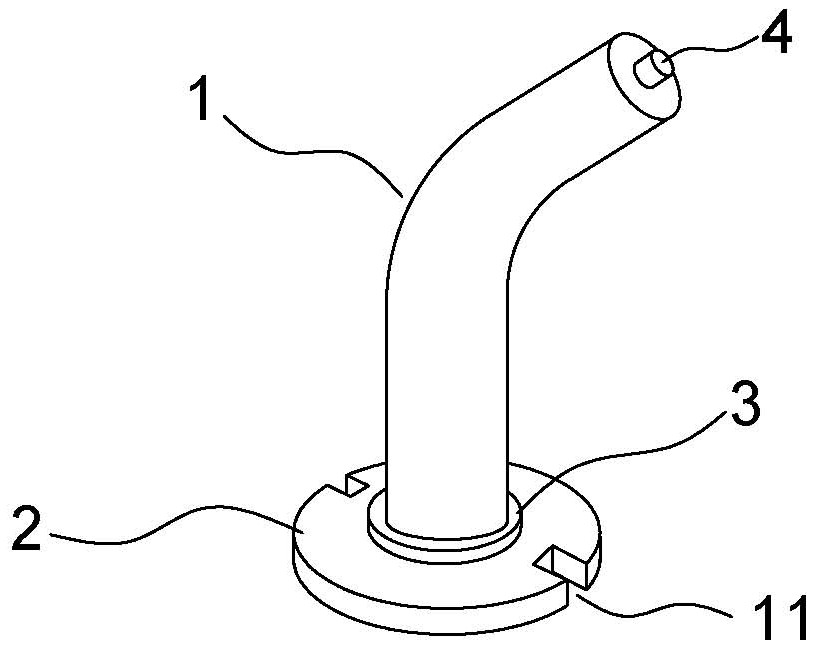

Spa jet mounting assembly and method of installation

A spa jet mounting assembly and method of installing and utilizing the same. An outer housing with an interior threaded chamber is connected to water and air pipes outside a bath. An inner housing, with an external threaded section is inserted through a passageway in the bath, and threadedly fastened within the threaded chamber of the outer housing. The bath surface and one or more gaskets are secured between flanges of the inner and outer housings. The inner housing includes one or more ports to drain water from the assembly. The opening in the bath can be sealed with an o-ring or by forming a seal via silicone injection. With the injection technique, silicone is injected into the inlet port of the outer housing, air is released through the outlet port of the outer housing, and a seal is formed around the passageway.

Owner:G G DISTRIBUTION & DEV CO

Spa jet mounting assembly and method of installation

Owner:G G DISTRIBUTION & DEV CO

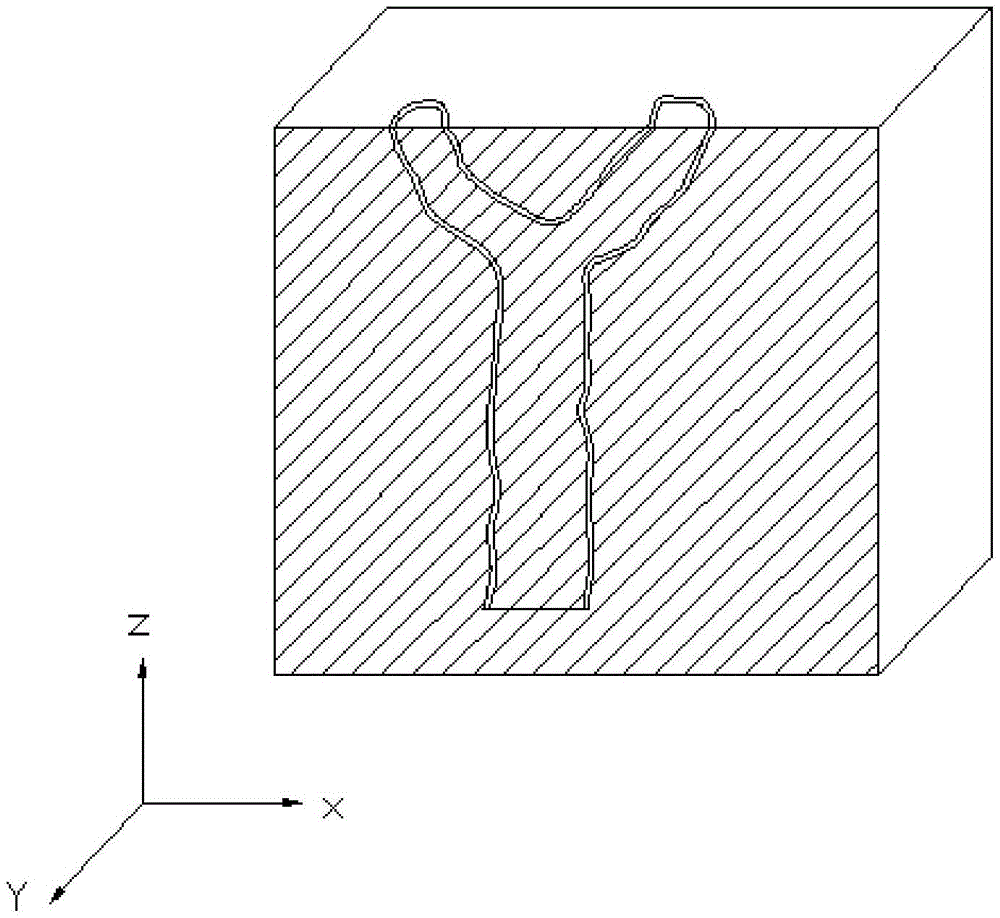

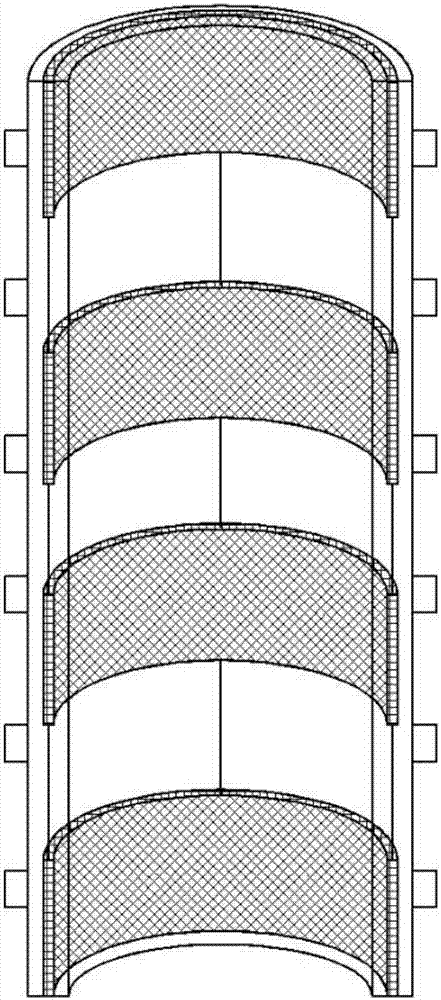

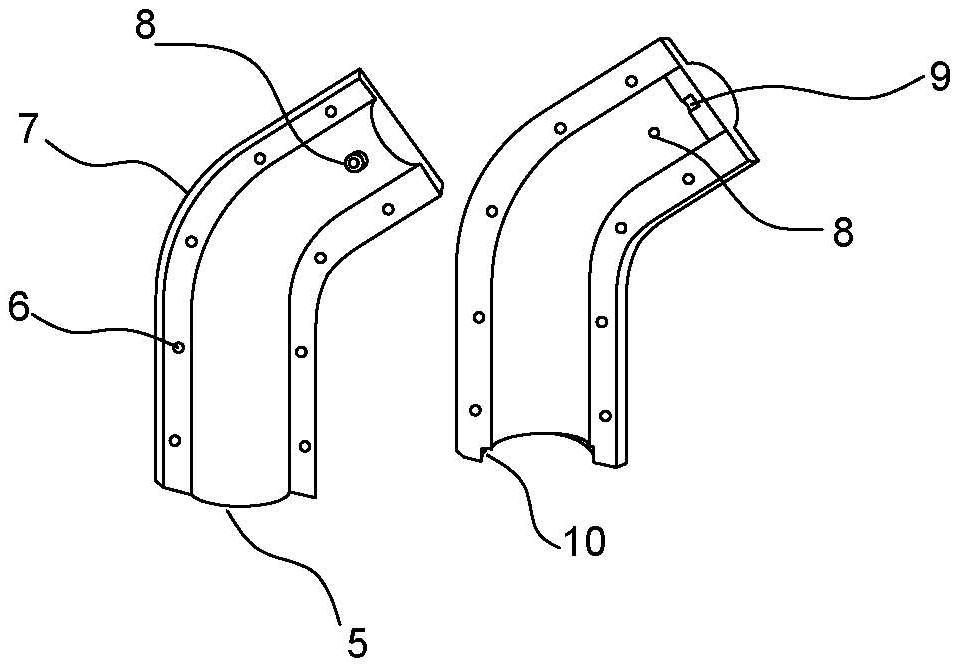

3D printing and injection molding based silicone individualized airway stent preparation technology

InactiveCN105616043AReduce the risk of restenosisCompatible with airway structureStentsProsthesisComputer Aided DesignAirway structure

The invention discloses a technology integrating 3D printing and silicone injection molding of an individualized airway stent mold.The technology achieves preparation of individualized medical airway stents.According to the technology, a real airway model of a patient is extracted and reestablished based on a CT image of the patient, then the individualized airway stent mold is obtained based on the model through computer aided design and the 3D printing, and finally the individualized airway stent conforming to the airway structure of the patient is prepared through silicone casting so as to reduce the risk of airway restenosis.

Owner:CHANGZHOU UNIV

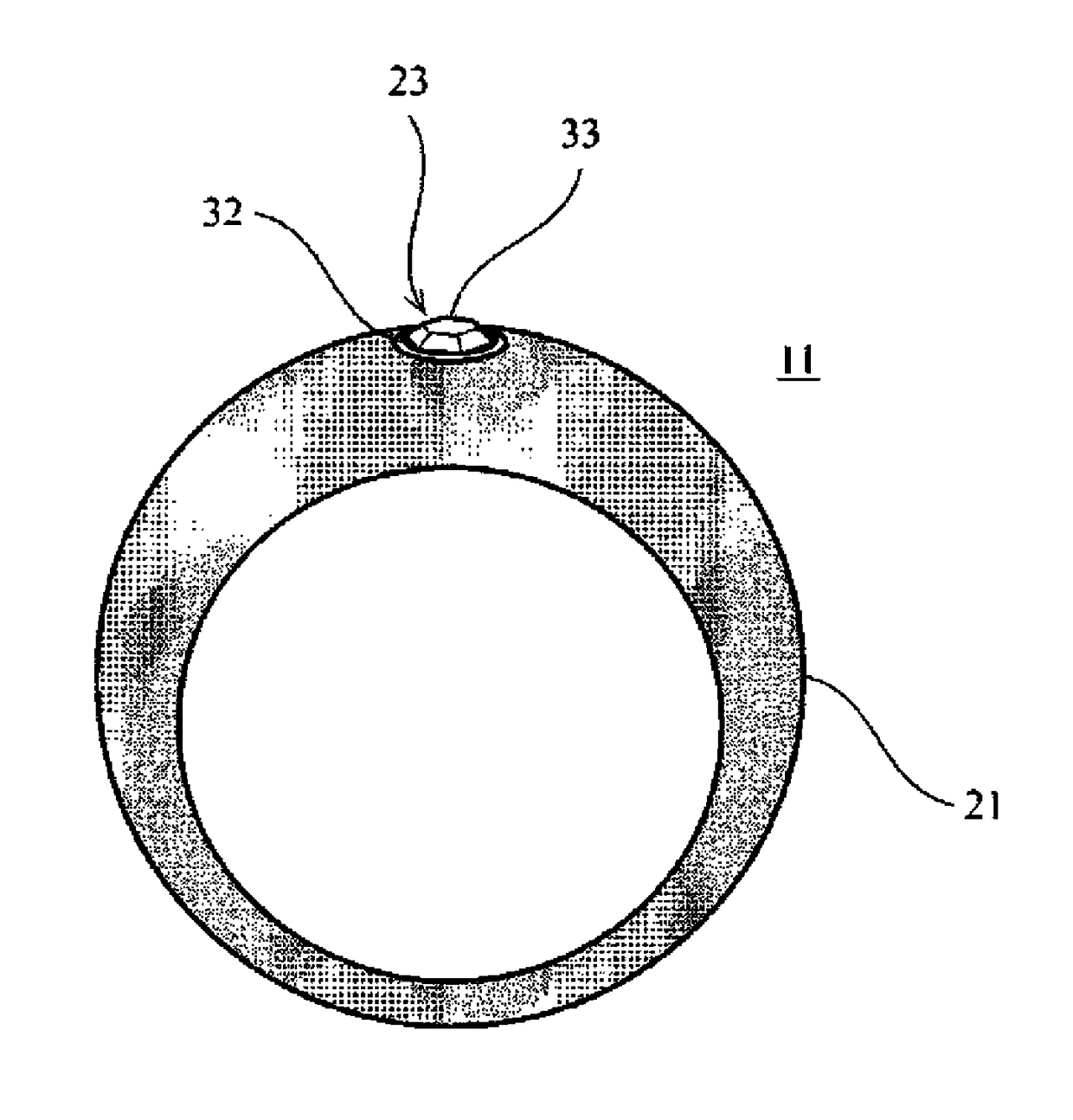

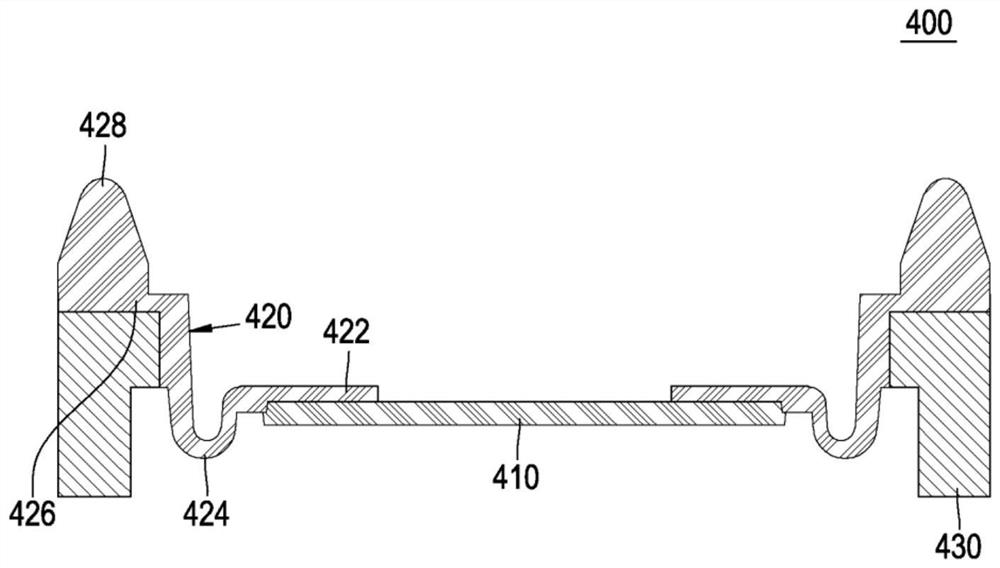

Body ornament manufacturing method, body ornament-molding die and body ornament

ActiveUS20170196320A1Improve aestheticsHigh yieldDomestic articlesFinger-ringsInjection portBiomedical engineering

Silicone is placed between an upper die and an injection-pressing rubber-lid upper die, and the silicone injection passage is pressurized by the injection-pressing rubber-lid upper die. With this, the silicone is caused to flow into an injection port through the silicone injection passage. Then, sequentially through the injection port and the disc silicone-flow passage, the silicone is caused to flow toward an inner periphery of a silicone injection space. Further, the silicone flows between both circumferential sides of the silicone-flow deflection region. In this way, the silicone flows in a peculiar manner in conformity with a shape of the silicone-flow deflection region.

Owner:BISO

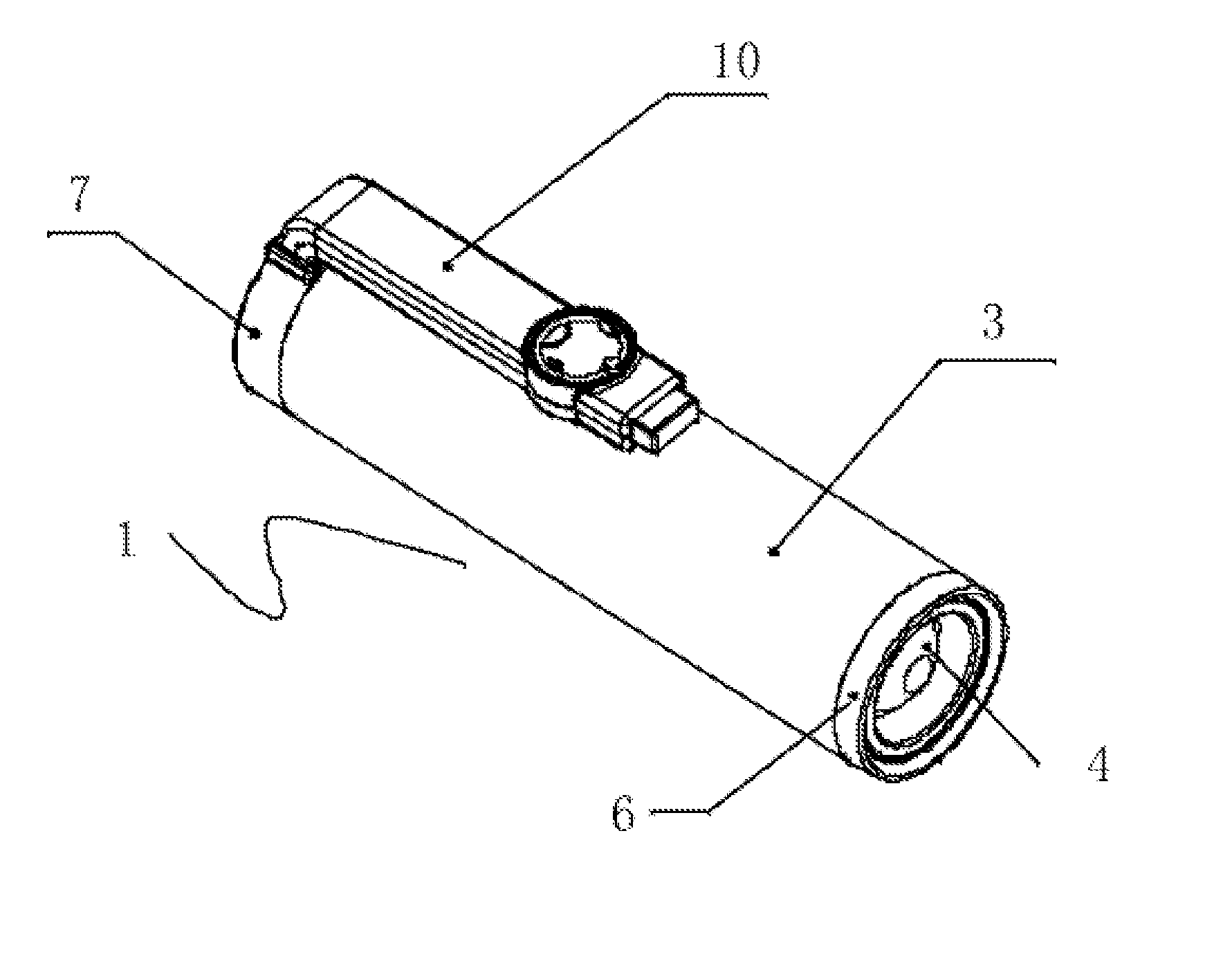

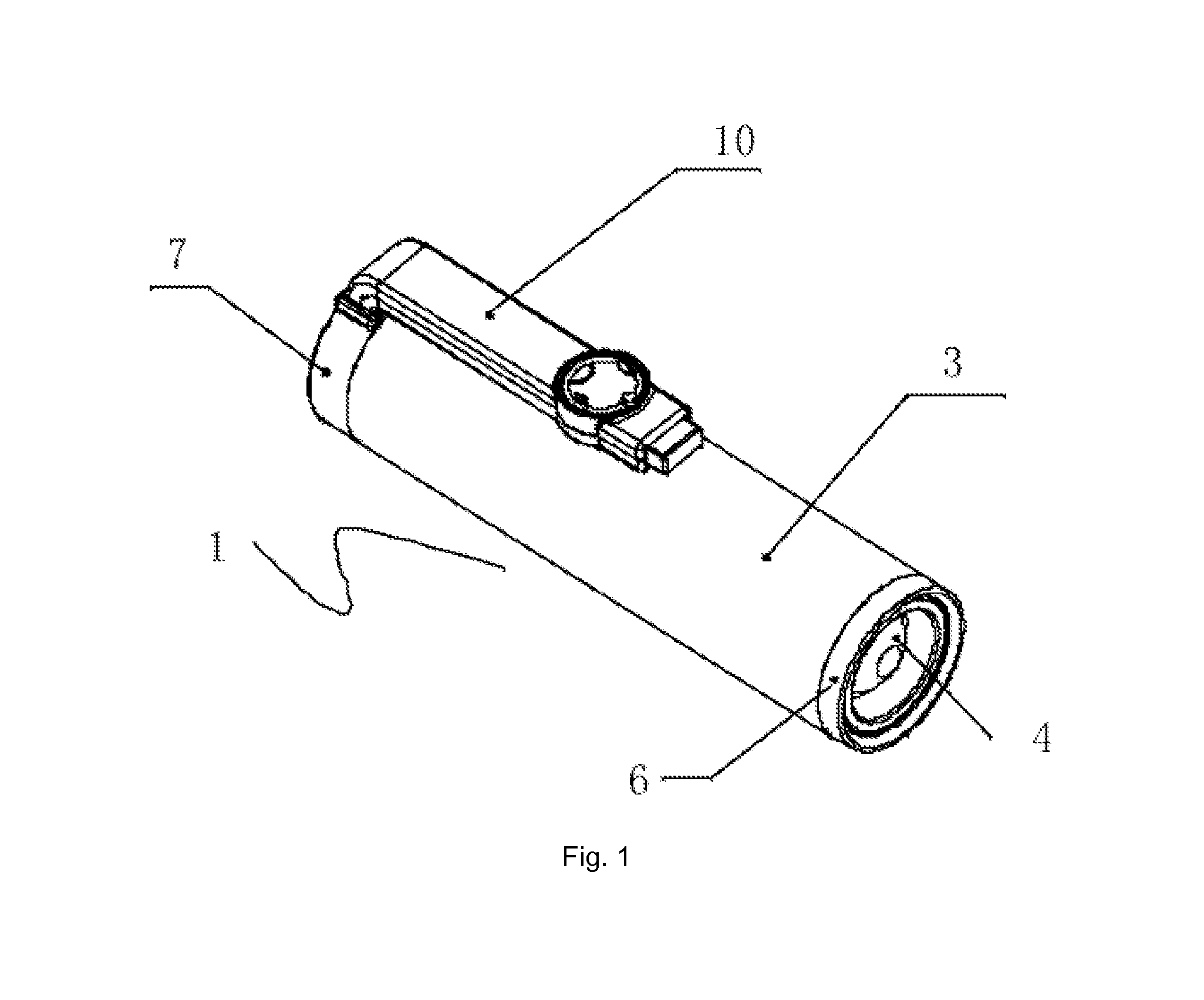

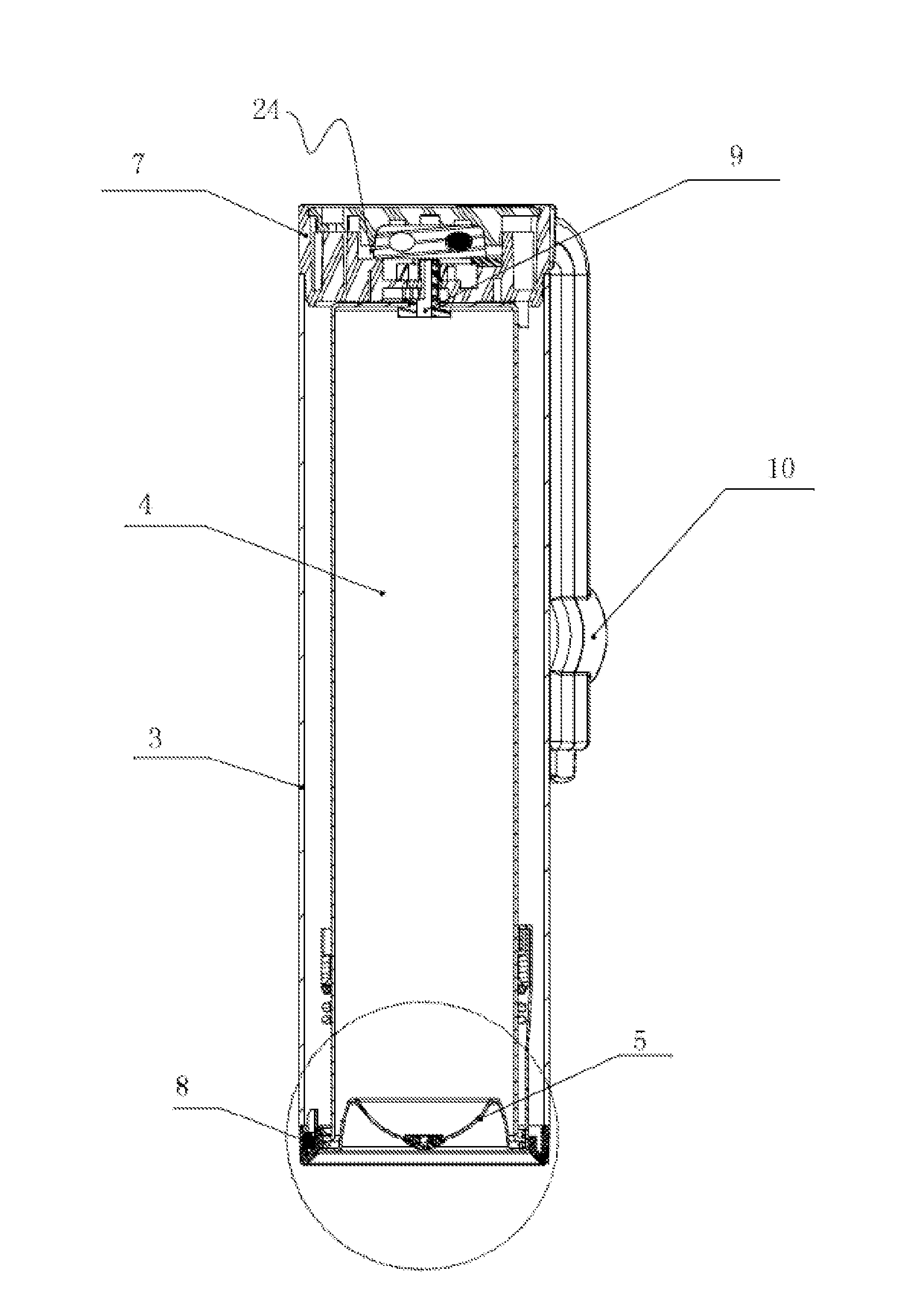

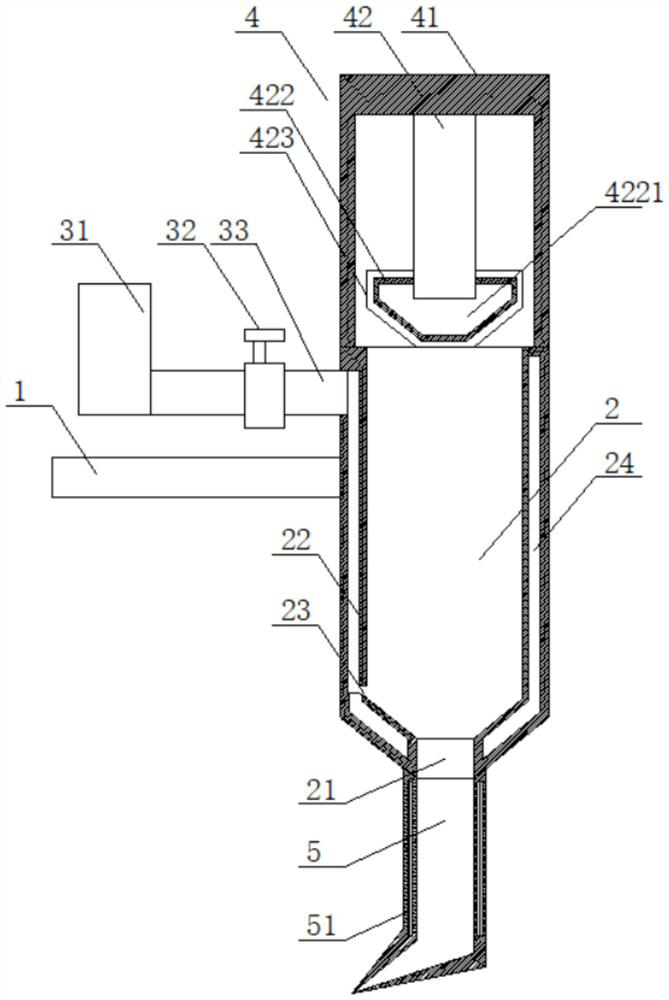

Portable Fire Extinguisher

A portable fire extinguisher includes a housing (3) and a cartridge (4) arranged within the housing (3). The cartridge (4) is fixedly connected at a bottom thereof to the housing (3) via a fastening device (40). This on the one hand facilitates shifting, and on the other hand allows the cartridge (4) to be fixed appropriately in the housing (3), thus not easily rotated or loosened, also, the need of a production site for waiting for silicone solidification by standing for seven to eight hours is avoided when silicone injection for fixing is used, thus improving production efficiency.

Owner:NANO FIRE LLC

Method for processing gondola water faucet water outlet panel

InactiveCN101143477APrevent mildewStable qualityAbrasion apparatusDomestic articlesInjection pressureTime efficient

The invention belongs to the molding technology field and is an improvement of the prior art, relating to a processing method for a sprinkler watering plate. After the injection pressure of a liquid silicone injection molding machine, a molded product is selected from a molding die-blank. The molded product is removed from a large rough edge of a frame artificially. The molded product without rough edges is removed from burrs, flying edges and rusty spots through levigation. The molded product after levigation is tested through water testing and then the qualified product is packaged. The invention has the advantages mentioned below. First, the invention adopts the liquid silicone mine, which belongs to a natural environmental material and does not mildew, so that it avoids a mildewing of a traditional rubber and a bad effect to human health. Second, adopting the injection molding leads to a product with stable quality, and saves time, energy and material resource. Third, the invention has a wide applicable range and a strong practicability. The use of liquid silicone for the molded watering panel is a future trend of the sprinkler product. The processing method can be widely used.

Owner:李建新

Liquid silicone two-shot molding, surface treatment method for middle parts

ActiveCN101134194BEvenly dispersedIncrease surface tensionPretreated surfacesCoatingsSilica gelUltimate tensile strength

The invention discloses a surface treatment method for liquid silica gel secondary molding and double-shot molding middle parts. The method includes: 1. Diluting the primer with a dilution additive, and using a foam-shaped polymer to dilute the diluted primer The material is applied to the surface of the part. The ratio of the diluted primer to the additive is generally 1:1 to 1:5, so as not to affect the bonding effect of the primer, so as to improve the dispersion effect of the primer on the surface of the part. The primer is evenly distributed on the surface of the part, and the appearance is clear after secondary molding or double-shot coating with liquid silicone. 2. Use plasma treatment, and other treatment methods to improve the surface tension of parts, improve the surface tension of parts, so that the primer and liquid silicone LSR / parts, self-adhesive liquid silicone Self-bonding LSR and parts, liquid silicone and parts are very good Firmly bonded, solving the problem of low bonding strength in the liquid silicone injection process.

Owner:JIERUI PRECISE SILICONE INJECTION MOLDING

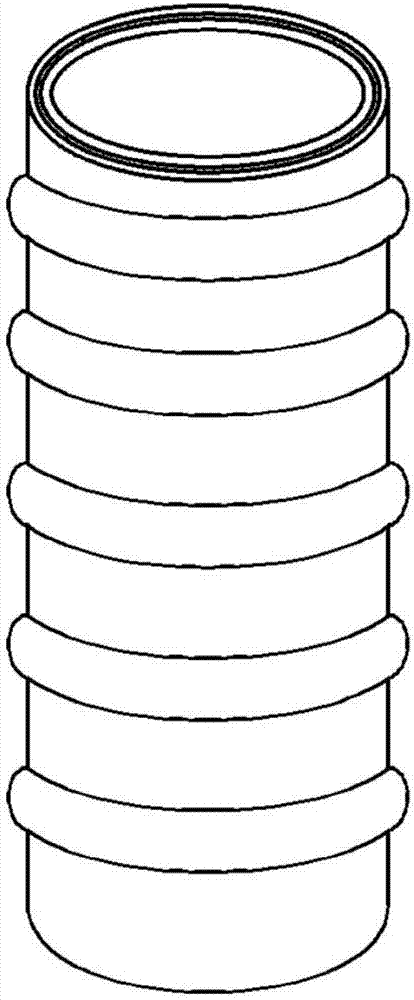

Preparation technology of reinforced silicone airway stent

InactiveCN107115165AImplantation does not affectImprove radial support strengthStentsProsthesisInsertion stentAlloy

The invention discloses a preparation technology of a reinforced silicone airway stent. The preparation technology of the reinforced silicone airway stent comprises the following steps: in an environment at the temperature of 37 DEG C, placing a woven nickel-titanium memory alloy annular skeleton into a mould before injection moulding of a silicone stent, wherein the thickness of the wall surface of the silicone stent is 1-1.5mm, and the distance between a metal wire as well as an outer wall surface and an inner wall surface is 0.3-0.5mm; and fixing the head and the tail of the mould by utilizing an extended metal wire, and carrying out silicone injection moulding, wherein an anti-slip circular projection is arranged outside the silicone stent, the projection is located at a depression of an airway cartilaginous ring, and the projection thickness is 1-2mm. The reinforced silicone airway stent disclosed by the invention is in a contraction state before being implanted into a human body and can be expanded to predetermined dimensions in the environment at the temperature of 37 DEG C after being implanted into an airway of a patient. Therefore, the advantages of the silicone support are reserved, and radial supporting strength is also enhanced.

Owner:CHANGZHOU UNIV

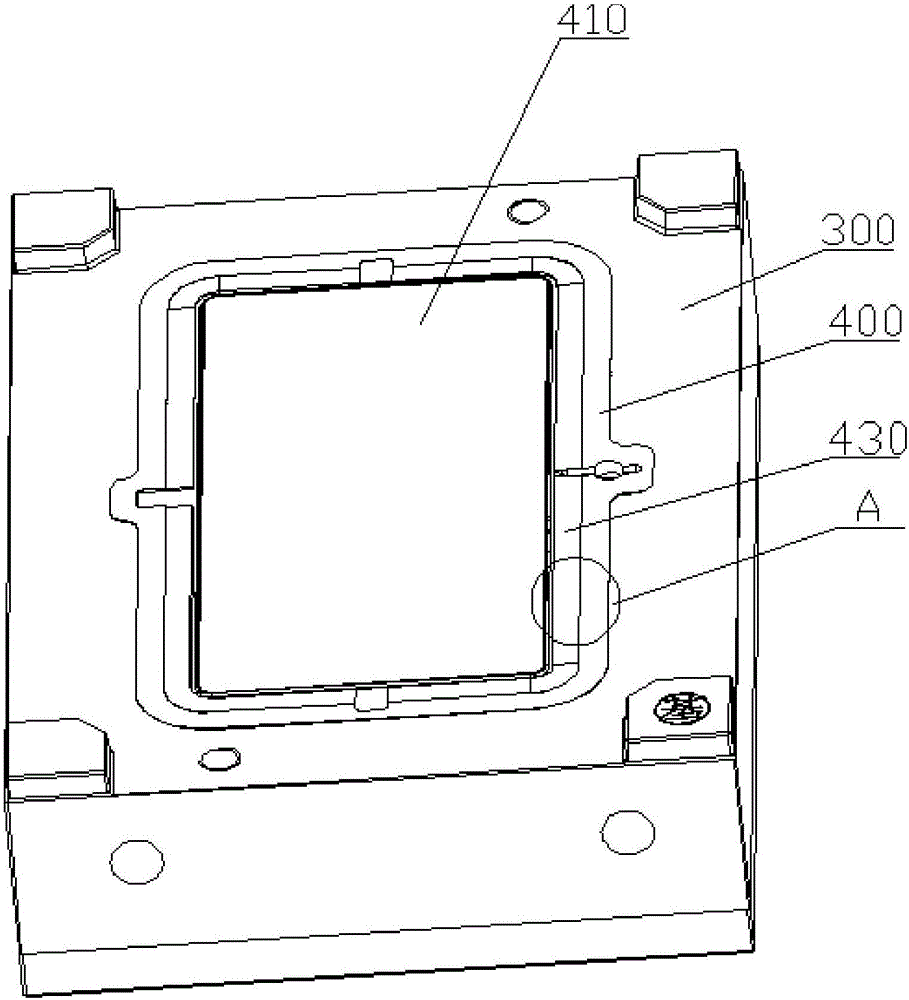

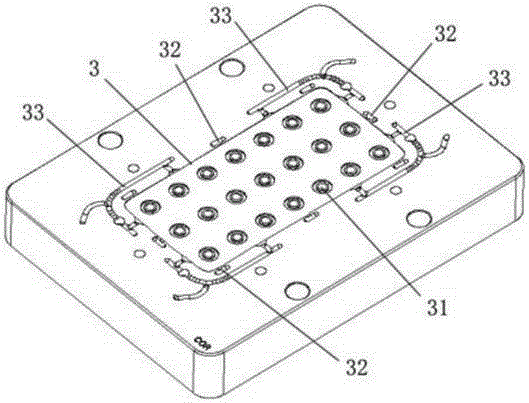

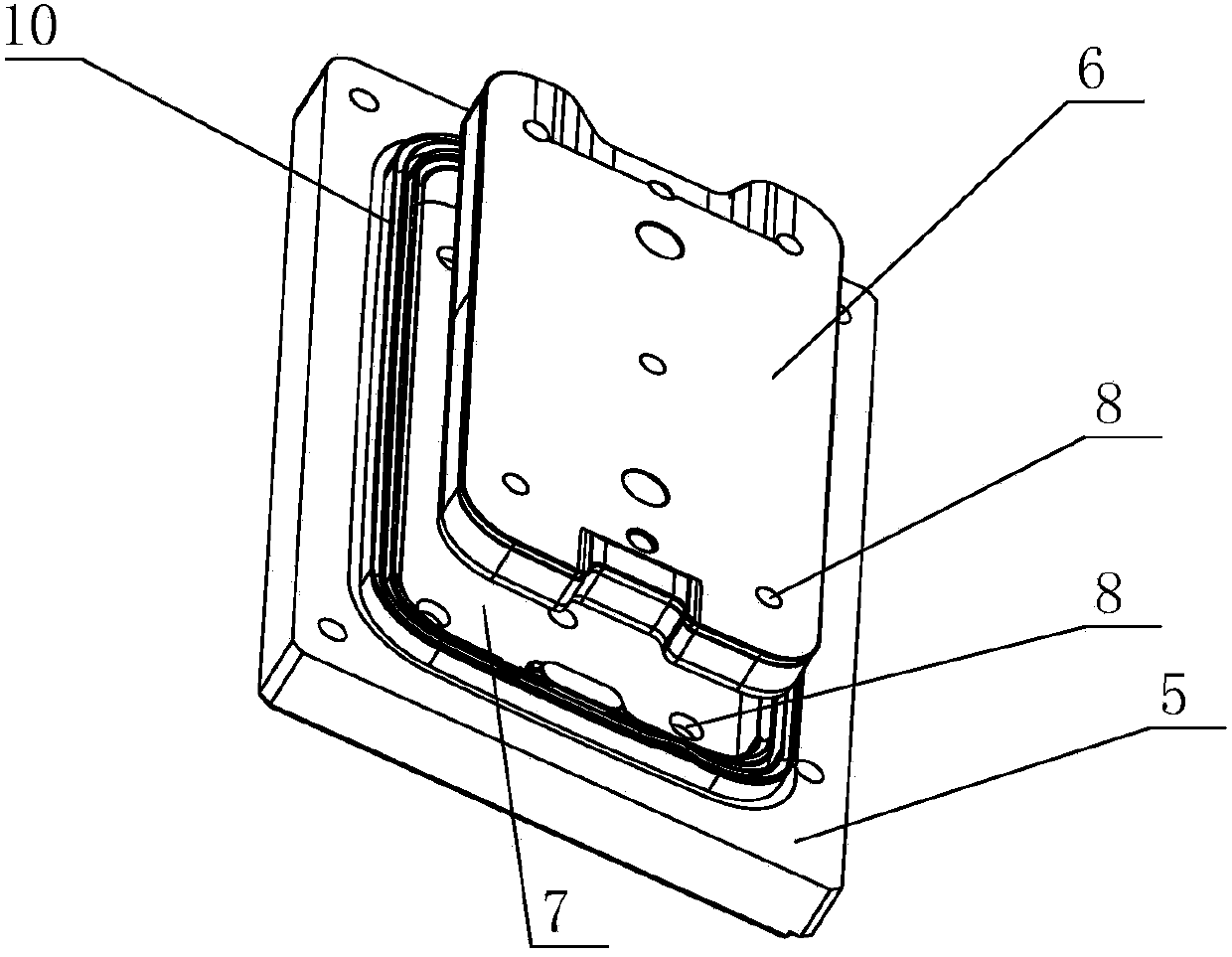

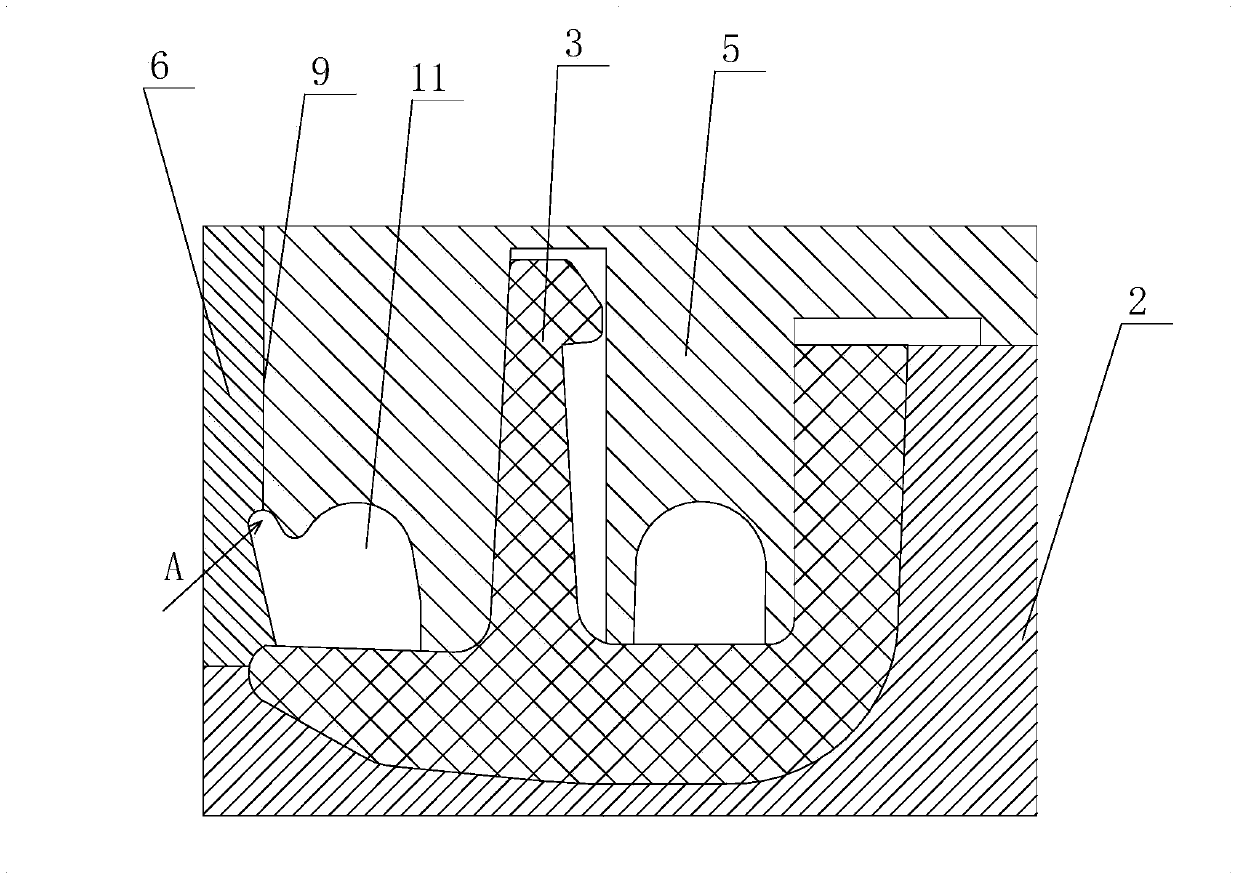

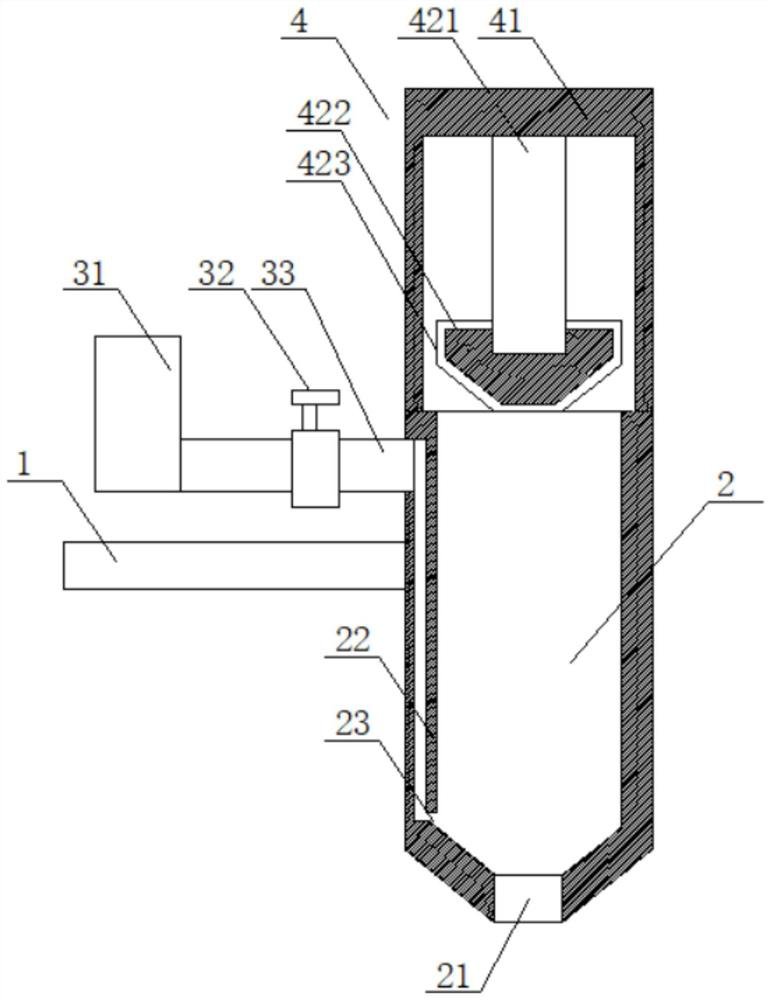

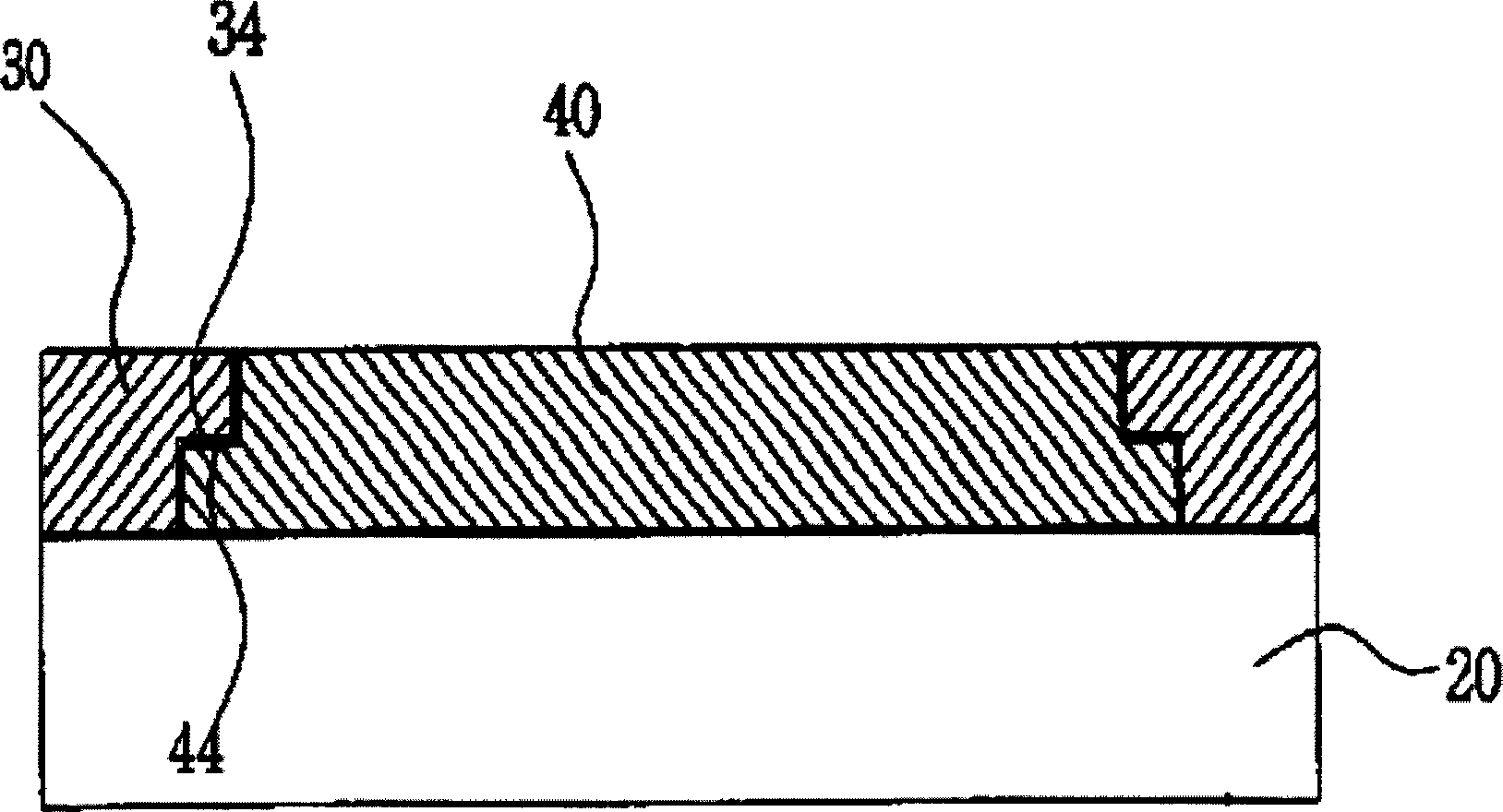

A liquid silicone injection mold

The invention discloses a liquid silicone rubber injection mold used for injection forming of a rubber edge structure at the side edge of a basal body. The liquid silicone rubber injection mold includes a front mold plate, a front mold core, a back mold plate, a back mold core and a pouring sleeve, and is characterized in that: the back mold core is provided with a basal body fixing groove, a rubber inlet groove communicated with the pouring sleeve, and a rubber overflow area; the basal body fixing groove is used for fixing the basal body, and a silicone rubber edge forming cavity is formed between the side edge of the basal body and the sidewall of the basal body fixing groove after the basal body is fixed and the mold is clamped; the rubber inlet groove is arranged along the sidewall of the basal body fixing groove; after mold clamping, a rubber inlet channel for communicating the rubber inlet groove and the silicone rubber edge forming cavity is formed between the top of the sidewall of the basal body fixing body and the front mold core; the rubber overflow area is arranged along one side, far away from the rubber edge forming cavity, of the rubber inlet groove, and is communicated with the rubber inlet groove through a rubber overflow channel; and the bottom of the rubber inlet channel is lower than the bottom of the rubber overflow channel. The liquid silicone rubber injection mold has the advantage of being good in injection effect and easy to control.

Owner:DONGGUAN HUAQING OPTICAL TECH

Miniaturized liquid silicone rubber forming machine suitable for three-plate molds

The invention relates to a miniaturized liquid silicone rubber forming machine suitable for three-plate molds. The miniaturized liquid silicone rubber forming machine comprises an electric box, a rack, a pneumatic triaxial manipulator, a pneumohydraulic pressure-cylinder, a fixed plate, a front push plate, an ejector cylinder, a middle push plate, a connecting pole, a front template, a middle template, a rear template, a guide sleeve, a guide pillar and a liquid silicone rubber injection unit. The pneumohydraulic pressure-cylinder drives the front template and the middle template to move for mold closing with the rear template; the liquid silicone rubber injection unit injects liquid silicone rubber into a mold cavity for molding of a product in the mold cavity; the pneumohydraulic pressure-cylinder drives the front template and the middle template to move backwards for mold closing with the rear template, and simultaneously the ejector cylinder drives the middle template to move forwards to pull out the molded product; and the pneumatic triaxial manipulator clamps the molded product. manual operation is not required during the whole process; the degree of automation is high; structure layout design is optimized; mold closing stroke of the front and rear templates is shortened; the miniaturized liquid silicone rubber forming machine is light in weight and small in size; the miniaturized design is convenient for transport; the miniaturized liquid silicone rubber forming machine occupies small space; production is accelerated; application range is widened; and requirements are met.

Owner:肖海斌

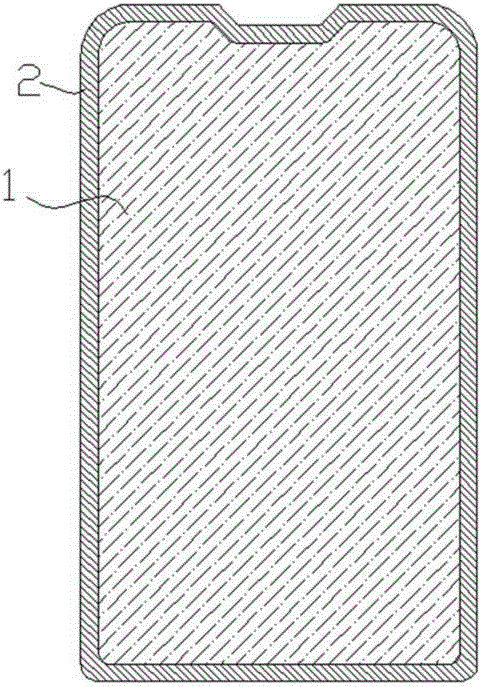

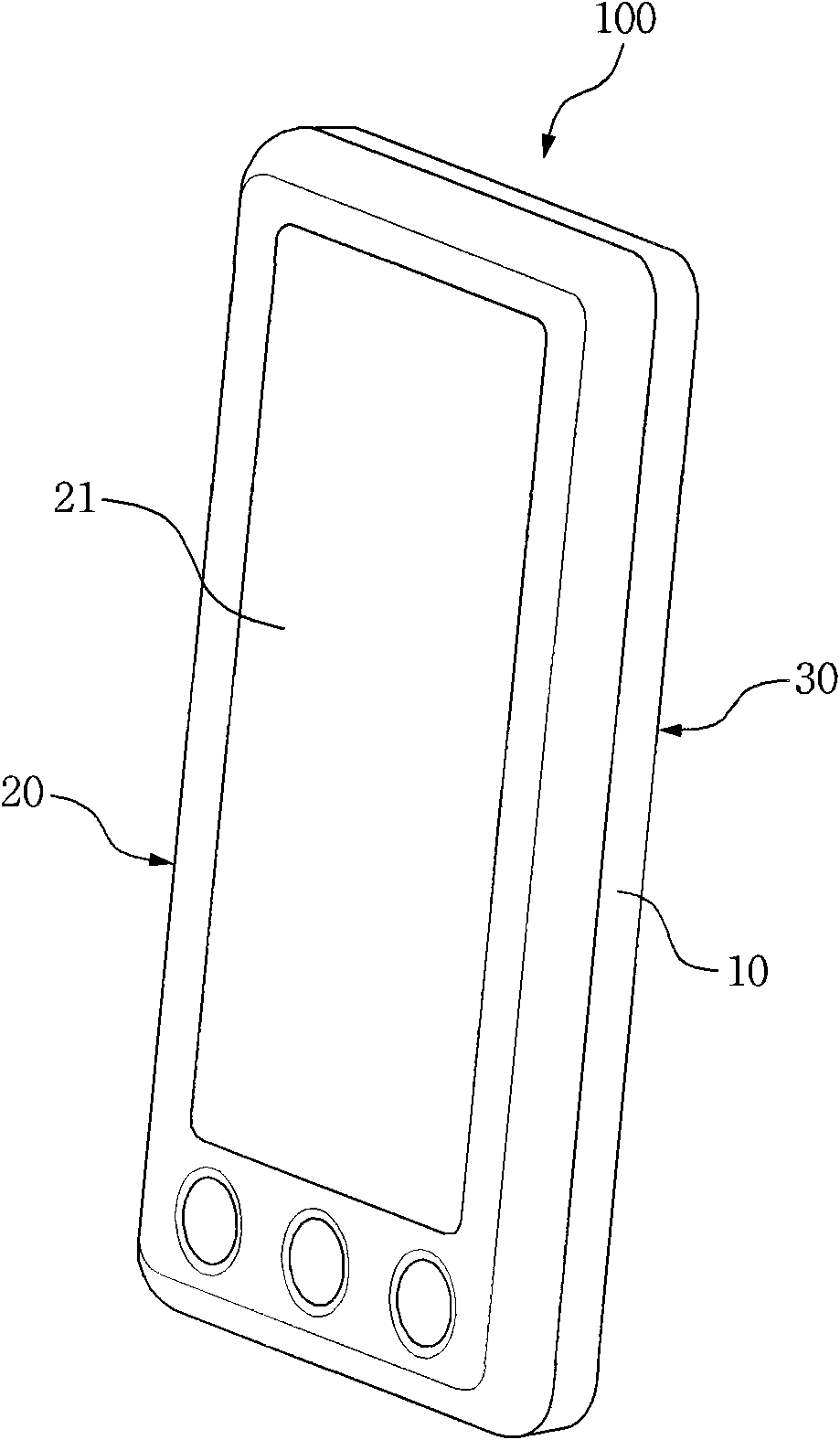

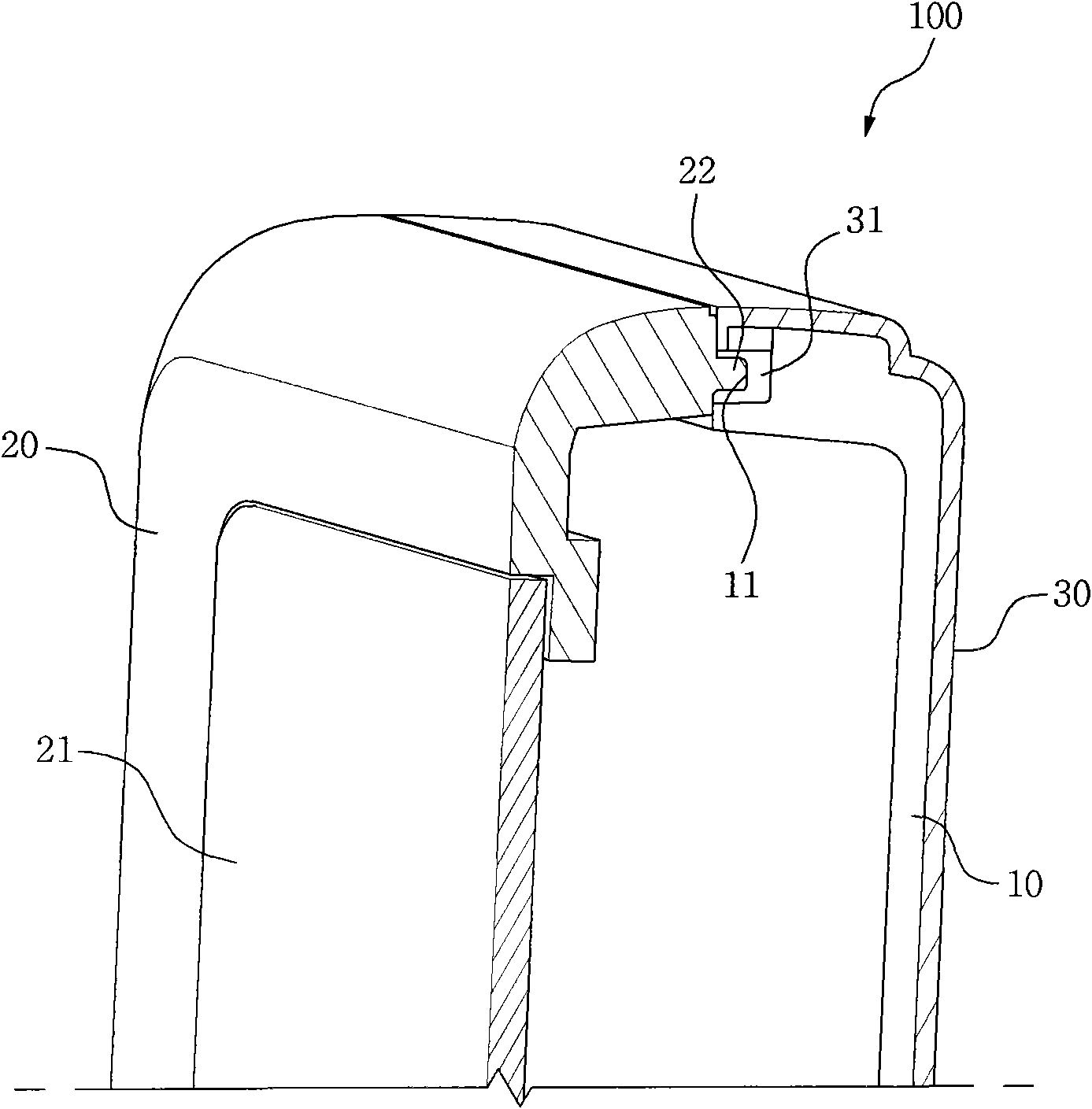

Portable electronic device integrated with silicone

The present invention relates to a portable electronic device integrated with a silicone in which a molding silicone is integrated with an outer side surface of a body housing of the portable electronic device through a double injection or an insert injection molding methods, so that it can feel the soft grip when an user is touched on the outer surface of the portable electronic device. Also, a water proof injection silicone packing part is integrally formed at a combining portion between a cover housing and a body housing, so that it can closely adhere to them, whereby it can be perfectly cut off the moisture from outside. The portable electronic device comprises the body housing, and a cover housing covering the body housing and combined therewith, wherein the whole outer side surface of the body housing is integrated with injection silicone through silicone injection molding methods.

Owner:WOOJEON & HANDAN CO LTD

Liquid silicone rubber injection mould

The invention discloses a liquid silicone rubber injection mould. The liquid silicone rubber injection mould comprises an upper mould and a lower mould, wherein a lower mould cavity for holding a plastic piece to be machined is formed in the lower mould. The liquid silicone rubber injection mould is characterized in that the upper mould consists of a first upper mould and a second upper mould; an upper mould cavity is formed in the bottom of the first upper mould; the second upper mould is fixedly arranged inside the upper mould cavity; the adhesion part of the lateral wall of the second upper mould and the inner lateral wall of the upper mould cavity is used as a mould joint; a sealant face is formed at the periphery of the upper mould cavity and on the upper edge of the first upper mould; the sealant face and the plastic piece are tightly adhered to form a sealing area for injecting silicone rubber in a mould closing process. According to the liquid silicone rubber injection mould, the adhesion part of the lateral wall of the second upper mould and the inner lateral wall of the upper mould cavity is used as the mould joint, so that one part of the silicone rubber piece is individually machined. Therefore, not only can the machining difficulty be reduced, but also air discharge can be realized through the middle joint and the mould repairing and modification in a later period are convenient. According to the liquid silicone rubber injection mould, the injection effect of silicone rubber is good, and the quality of products in scale production is stable and reliable.

Owner:RUIJIA YIXING TECH

Silicone ejection oil pressure molding machine

The invention discloses a silicone ejection oil pressure molding machine which comprises a machine frame, a storage device, a feeding device, a molding mould, a control device and a power supply. A first cavity is arranged in the storage device, the feeding device is provided with a channel, and the first cavity is communicated with the channel. The silicone ejection oil pressure molding machine is characterized by comprising an accurate injection device which is provided with a second cavity, one end of the second cavity is communicated with the channel, the other end of the second cavity is communicated with an injection hole of the molding mould, and the accurate injection device is provided with a monitoring device for monitoring silicone injection amount. By adopting the structure, the silicone ejection oil pressure molding machine can perform accurate injection voluntarily by adopting the accurate injection device, achieves automation of a whole production process of seal rings, reduces labor intensity of operators, and can improve production efficiency.

Owner:ZHONGSHAN XIONGBING RUBBER

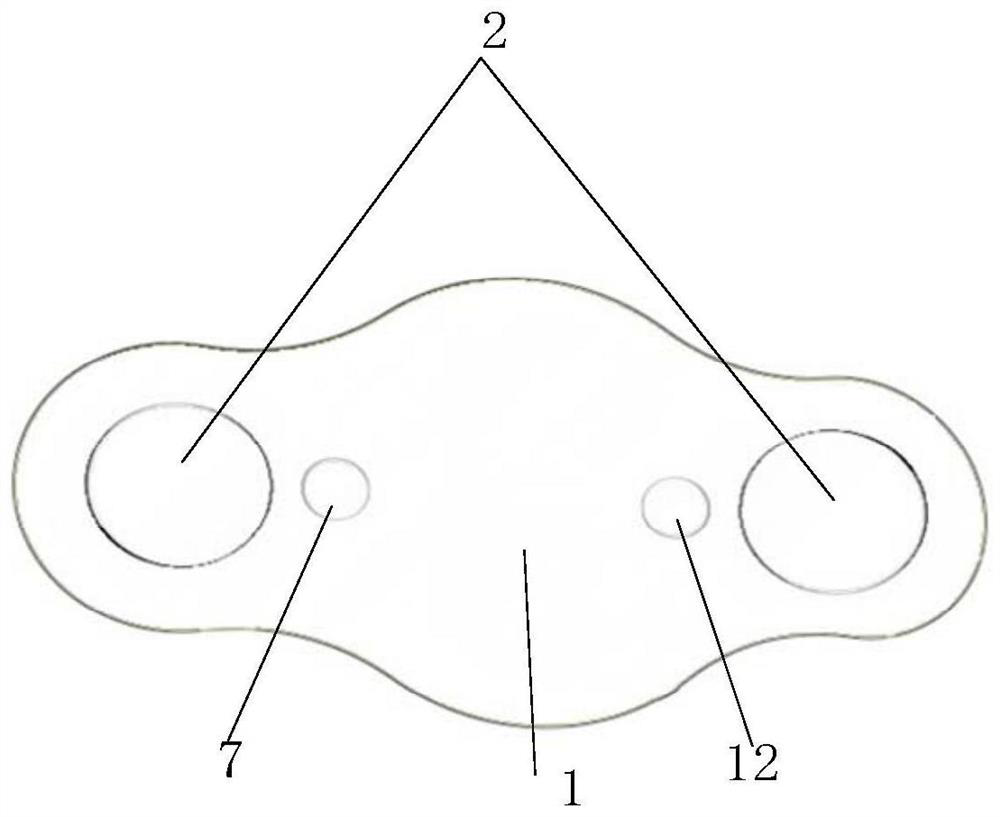

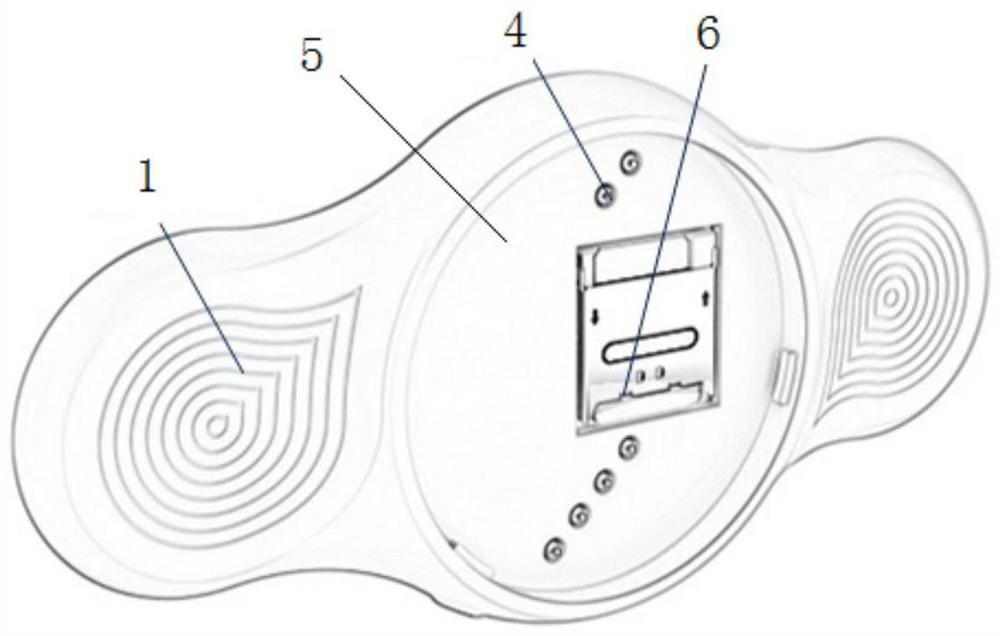

A patch type physiological multi-parameter monitoring device

ActiveCN108451513BEasy to useImprove waterproof sealing performanceMeasurement devicesDiagnostics using spectroscopyHuman bodyContinuous use

A patch-type device for use in physiological multi-parameter collection and monitoring, comprising: a flat housing (1) having a flexible material, which is suitable for being attached to the skin of a human body, wherein a front side of the housing (1) may adhere onto the skin of the human body by means of an adhesive; the front side and / or a back side is provided with a pulse wave sensor (11), which is integrated with the housing (1) by means of liquid silicone injection molding or solid silicone compression molding; a circuit module, which is used for processing collected physiological parameters data, is sealingly installed within the housing (1), and the circuit module is connected to the pulse wave sensor (11). The device is easy to use, the electrode may be recycled to save costs, and wearing the device for a long time will not cause discomfort to the skin, while the device has good sealing and waterproof performance, continuous usage time is long, and data collection is more comprehensive.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

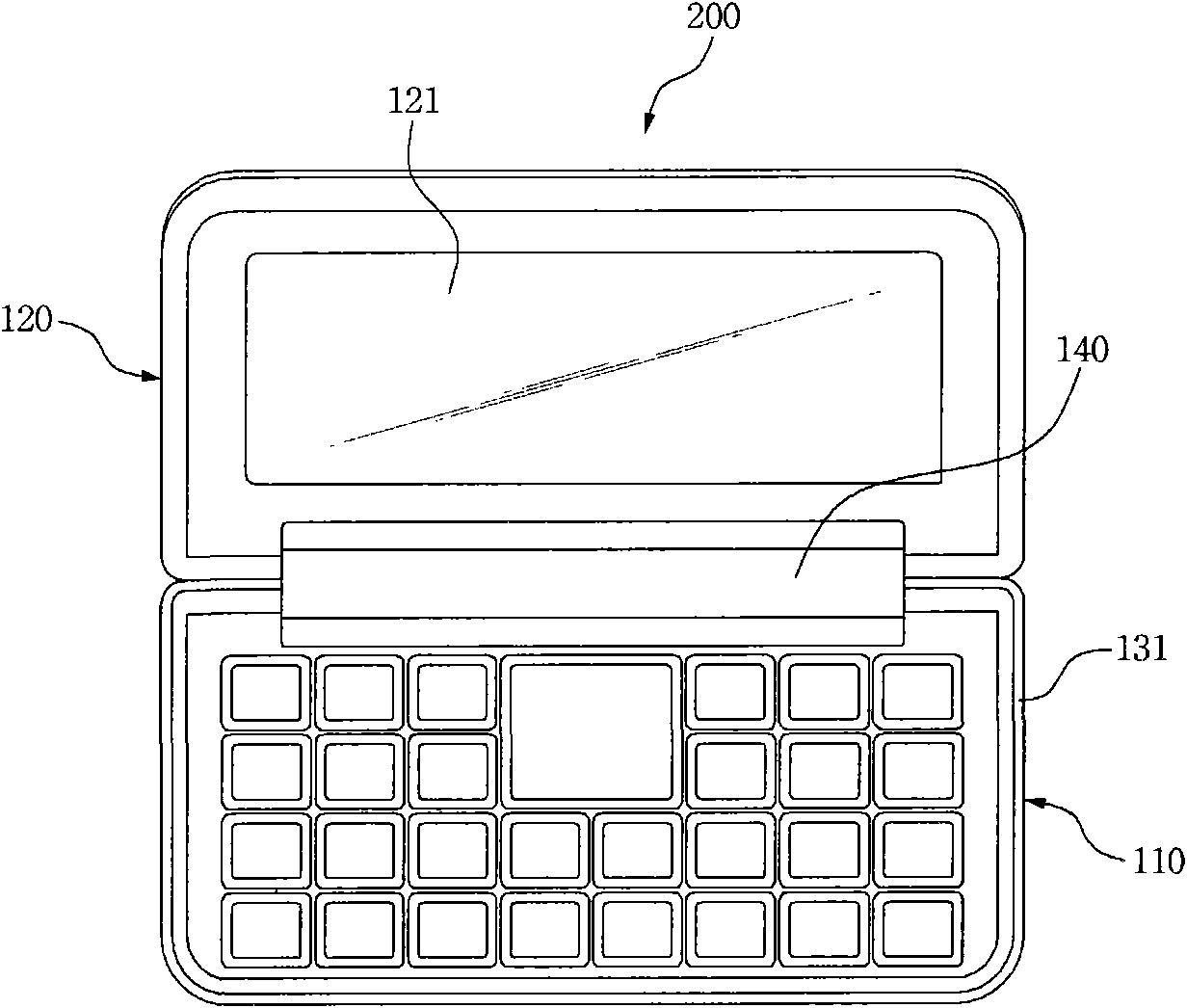

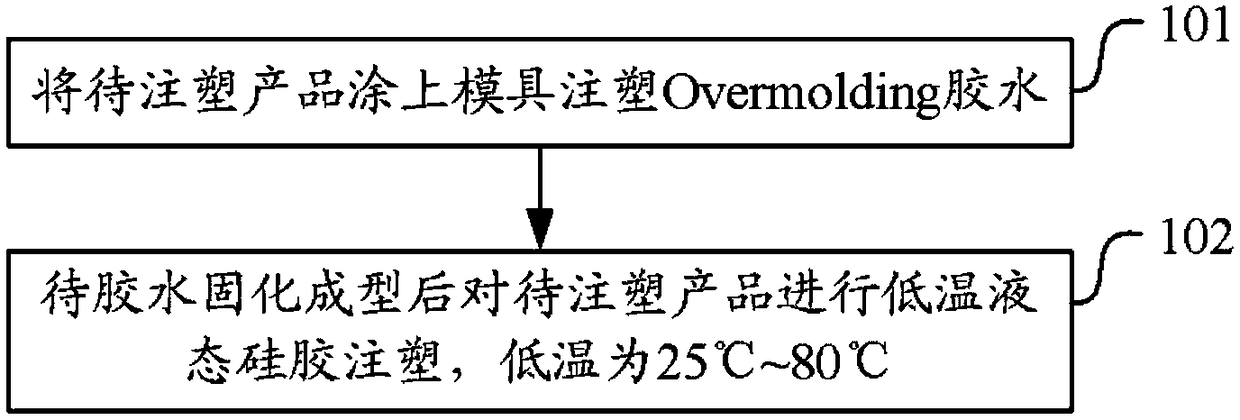

A liquid silicone injection molding method and electronic equipment with a display

ActiveCN105437449BGuaranteed not to burn outGuaranteed adhesionTelephone set constructionsPolymer scienceGlass cover

Provided in the present invention are a liquid silicone rubber injection molding method and an electronic device with a display screen. The method comprises: coating the product to be injected with Overmolding glue, injecting a liquid silicone rubber at a low temperature on the product after the glue solidified, the low temperature is from 25℃ to 80℃. The electronic device with a display screen comprises a device housing and a display module, the display module comprises a glass cover plate and a display screen and is molded by injecting the liquid silicone rubber at a low temperature, wherein the display screen is bonded with the glass cover plate, the width of the glass cover plate is less than that of the display screen, and the edge of the display screen is fixed to the device housing. In the present invention, the width of the glass cover plate is less than that of the display screen, and the edge of the display screen is fixed by the device housing, therefore blocked areas are no longer required to be printed on the two sides of the glass cover plate. Injecting the liquid silicone rubber at a low temperature on the electronic device ensures that the electronic device will not be burned out and the binding force between the silicone rubber and the electronic device at a low temperature environment.

Owner:BANMA ZHIXING NETWORK HONGKONG CO LTD

Manufacturing method of novel displacement-preventing water guide silicone tube placed in brain

InactiveCN109203349ANot easy to ageSimple processDomestic articlesLaser beam welding apparatusRubber materialCross-link

The invention discloses a manufacturing method of a novel displacement-preventing water guide silicone tube placed in the brain. The manufacturing method of the novel displacement-preventing water guide silicone tube placed in the brain includes the following steps that firstly, a die is manufactured according to the drawing design; secondly, liquid silicone injection forming is conducted; thirdly, thermoset liquid silicone rubber (LSR) is divided into an A component and a B component, a cross-linking agent (containing hydrogen silicon oil) and a catalyst (containing platinum) are separated and are put into the two components correspondingly, and the A component and the B component are then mixed during use; fourthly, before each time of injection molding, rubber materials of the A component and the B component are put on a rubber mixing machine to be evenly mixed and then are put into an injection molding cavity immediately, under the pressure effect of a press machine, the rubber materials pass through a runner and flow into a six-hole die, then heating and pressurizing vulcanization is conducted, and the silicone rubber thin-wall micro rubber tube is manufactured; fifthly, a formed support is subjected to edge demounting and trimming; and sixthly, a laser punching machine is used for punching the formed support. The manufacturing method of the novel displacement-preventing water guide silicone tube placed in the brain is simple in technology and low in cost, and the manufactured silicone rubber tube is proper in hardness and not likely to be aged and can be applied to the field of hydrocephaly drainage surgeries at a large scale.

Owner:陈国强 +1

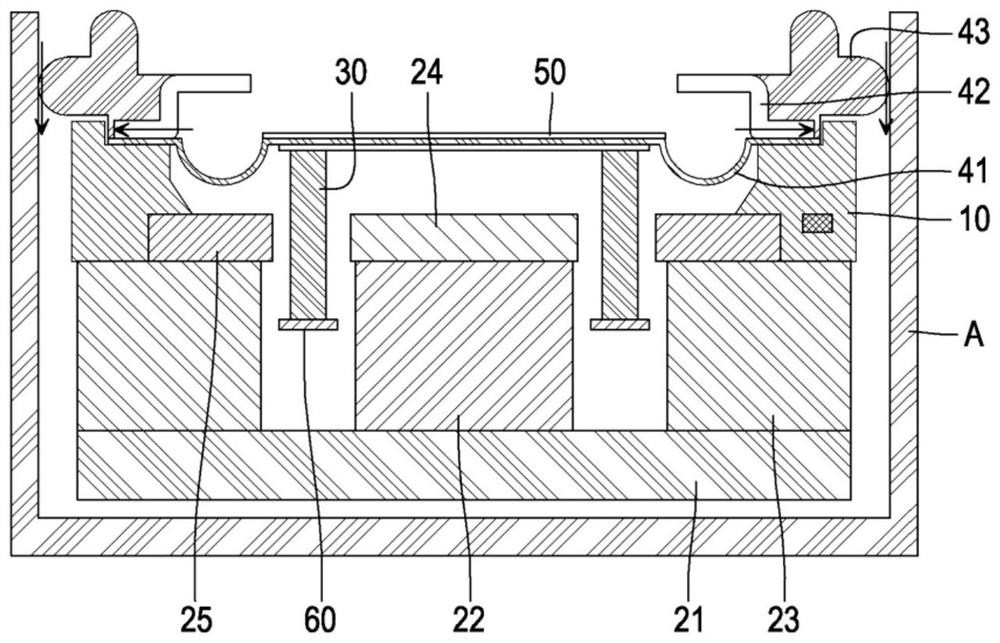

A precise liquid silicone injection machine and its production line for silicone products

The invention relates to a precise liquid silica gel injection machine and a silica gel product production line thereof. The precise liquid silica gel injection machine comprises a machine frame, a control electricity box, a lifting device, an A silica gel pumping device, a B silica gel pumping device, a color paste pumping device and a plurality of hollow rubber pipes; the control electricity box is installed in front of the machine frame; two silica gel storage buckets loaded with A silica gel and B silica gel are placed on the machine frame; the lifting device drives the A silica gel pumping device and the B silica gel pumping device to stretch into the silica gel storage buckets to pump the silica gel; and the color paste pumping device pumps color paste independently. The precise liquid silica gel injection machine further comprises a three-liquid quantitative injection device; the A silica gel pumping device, the B silica gel pumping device and the color paste pumping device convey the A silica gel, the B silica gel and the color paste to the three-liquid quantitative injection device through the rubber pipes, and the three-liquid quantitative injection device precisely controls the mixing ratio of the A silica gel, the B silica gel and the color paste, so that high-purity liquid silica gel is obtained and directly and quantitatively injected into a mold cavity of a flat plate machine through the rubber pipes.

Owner:中山川崎机械科技有限公司

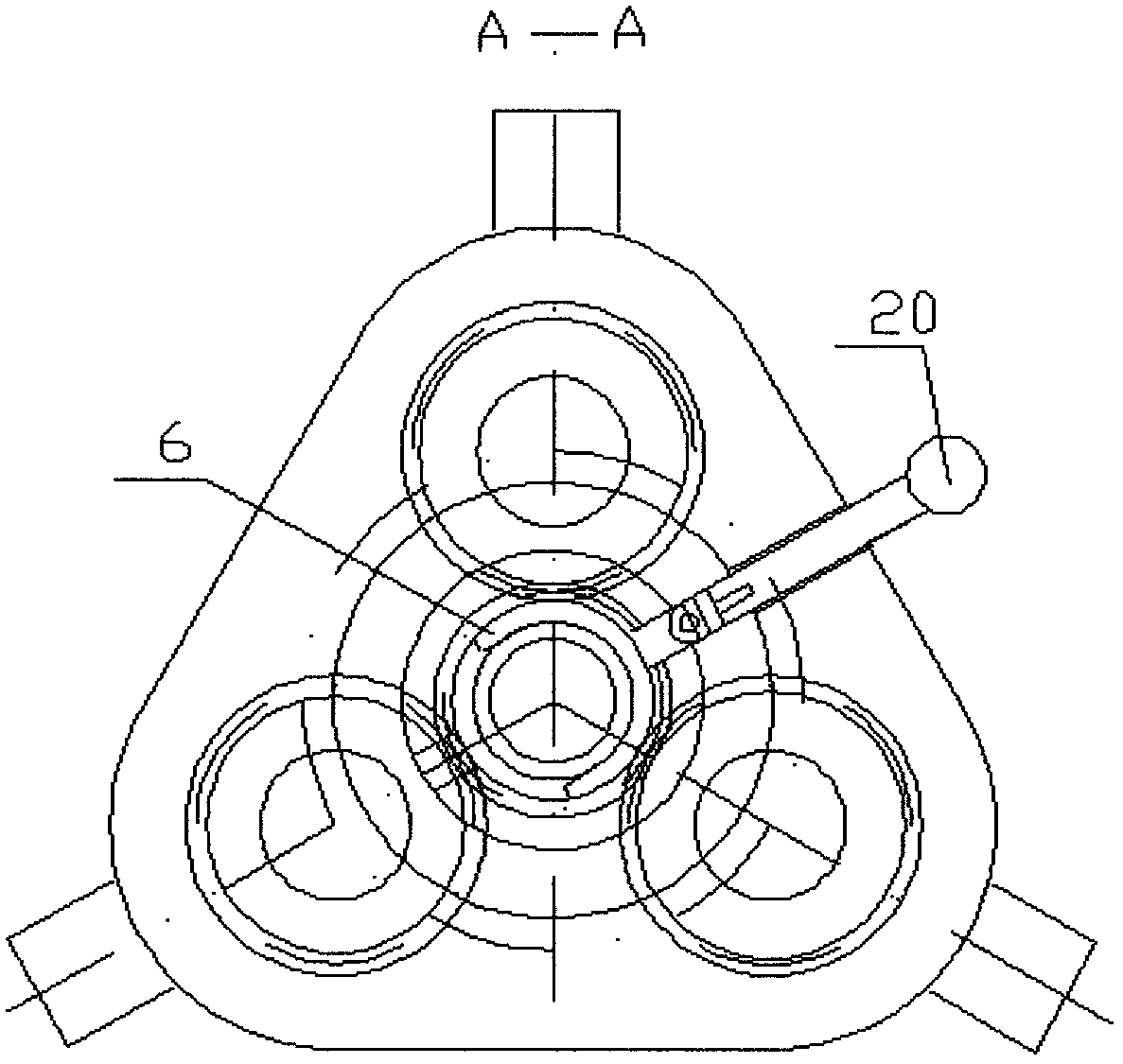

Three-color liquid silicone injection molding device

The invention aims at providing a three-color-liquid-silica-gel injection molding device. According to the three-color-liquid-silica-gel injection molding device, the multi-cavity individually driving method is adopted, and according to a gear changing box, single driving or two-shaft driving or three-shaft simultaneous driving of screws in three injection molding cavities is achieved, and three-cavity simultaneous injection molding or single-cavity injection molding or double-cavity injection molding is achieved. According to the three-color-liquid-silica-gel injection molding device, transmission gears of three screw pump screws are driven by a middle sliding gear, three pump shafts are independent, and each pump shaft is transmitted by a transmission shaft and a transmission gear. The three-color-liquid-silica-gel injection molding device is composed of a middle transmission spline shaft, a first-cavity transmission shaft, a first-cavity transmission gear limiting sleeve, a first-cavity transmission gear, a sliding gear shifting fork, a middle sliding gear, a second-cavity transmission gear, a third-cavity transmission gear, a middle sliding gear limiting sleeve, a first-cavity screw shaft, a connecting transition disc, a screw front-end bearing, a pump, a first-cavity screw, a control rod and the like. By means of the three-color-liquid-silica-gel injection molding device, the simultaneous injection molding problem of multi-color liquid gel can be solved, the structure is reliable, and using is convenient.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

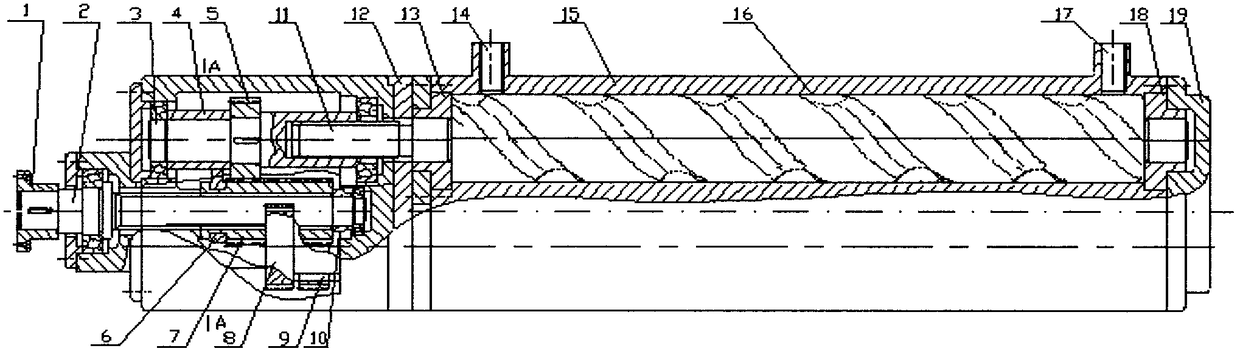

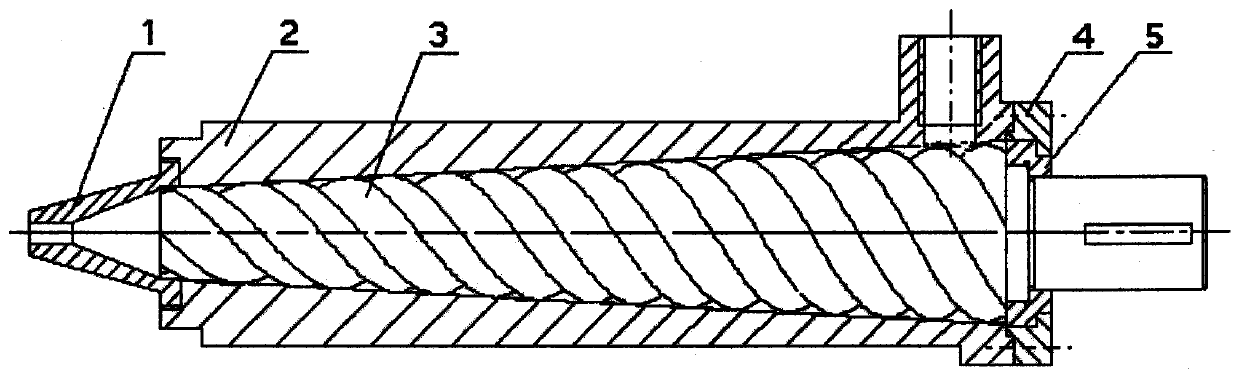

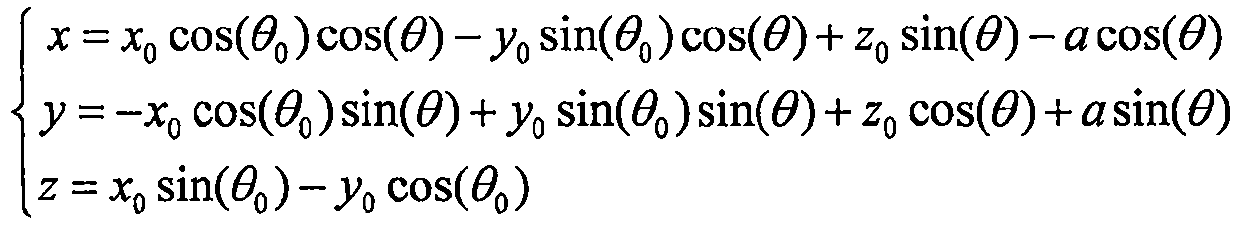

Special-shaped curve silicone injection molding machine screw

The invention provides a special-shaped curve silica gel injection molding machine screw. A special-shaped curve is adopted for rotating along a cone to form a non-cylindrical uniform-pitch spiral curved surface, and the special-shaped curve parameter, the pitch and the screw cone taper of the special-shaped curve screw are set according to the requirements for the injection molding amount and the injection molding pressure. The practical device of the special-shaped curve silica gel injection molding machine is composed of an injection cavity, a pump body, the special-shaped curve screw, a pump cover and a large-end sealing thrust bearing. A motor drives the special-shaped curve screw to rotate in the pump body, heated silica gel materials enter the pump body through a feeding port and are pushed by a spiral curved surface groove of the special-shaped curve screw to move towards the injection cavity, due to the fact that the outer diameter part of the special-shaped curve screw is contained and supported in a conical pipe of the pump body, the linear speeds of the silica gel materials at different axial positions are different when the silica gel materials move towards the injection cavity, the silica gel materials are gradually pressurized, and the silica gel materials entering the injection cavity reach the injection pressure requirement and are extruded out to enter a silica gel product die.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

A method for making an individualized intestinal fistula stent and its applicable mold

ActiveCN110640950BIncrease elasticityReasonable designAdditive manufacturing apparatusColostomyAnatomical structuresFistula

The present invention relates to a manufacturing method of an individualized intestinal fistula stent and a suitable mold thereof. The manufacturing method comprises: 1) shadow meglumine angiography to obtain the size of the distal and proximal intestine; 2) using graphic design software to design the mold; 3) using 3D Printing or metal powder printing to make the mold; 4) Using silicone injection molding to make the bracket. The mold applicable to the method includes a shell and an inner core; both the shell and the inner core are inverted L-shaped; the inner core is placed in the outer shell so that an injection molding cavity is formed between the two. The invention has reasonable design and simple operation, and can make the prepared bracket highly consistent with the patient's intestinal fistula anatomical structure, and can use silica gel to make the bracket, so that the bracket has better elasticity and fully meets the needs of intestinal fistula treatment.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

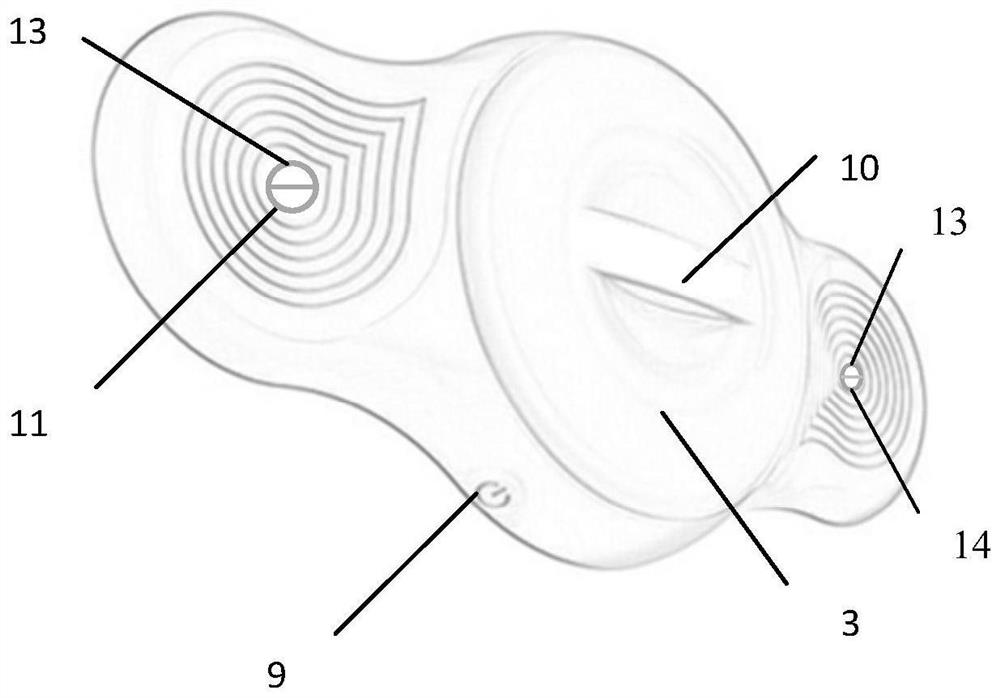

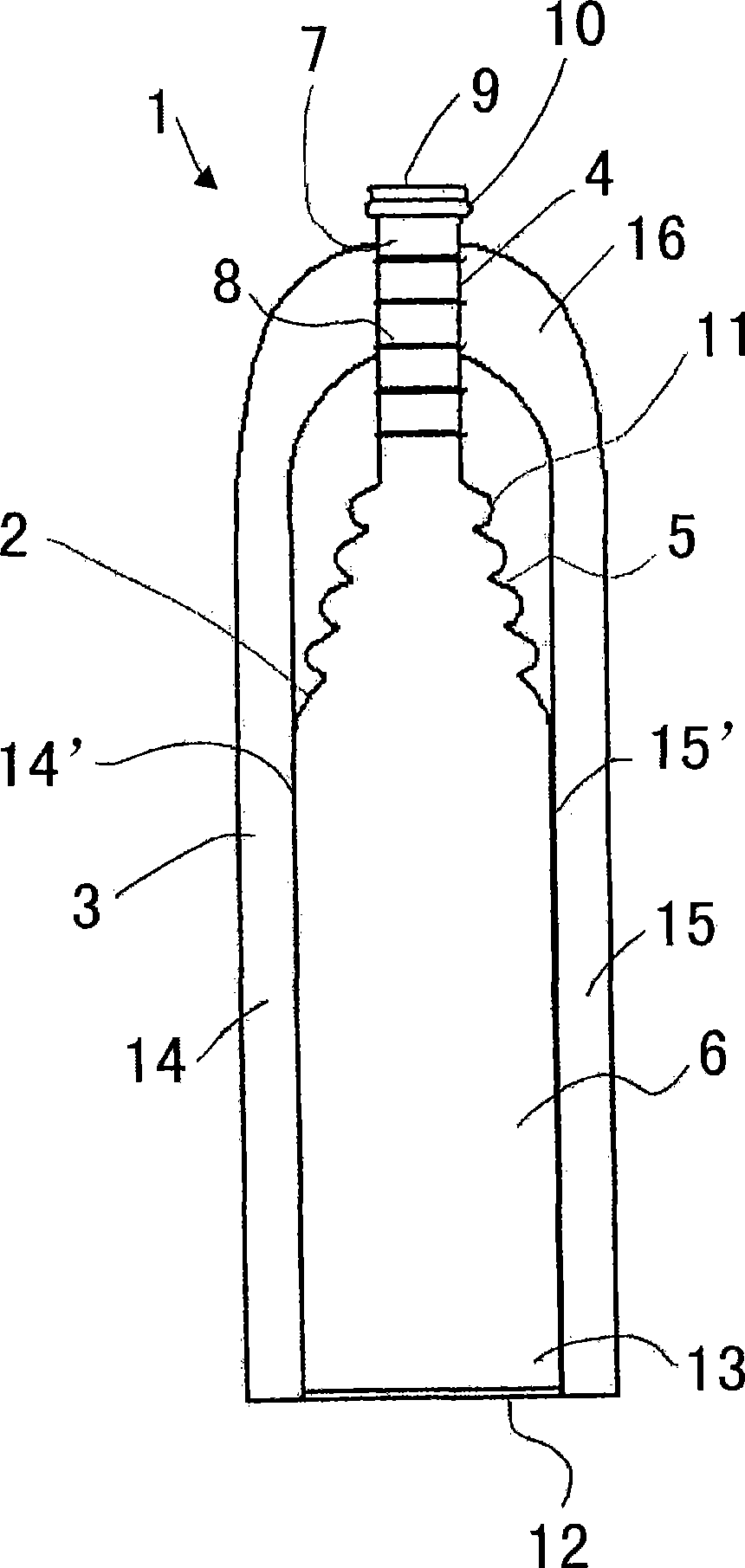

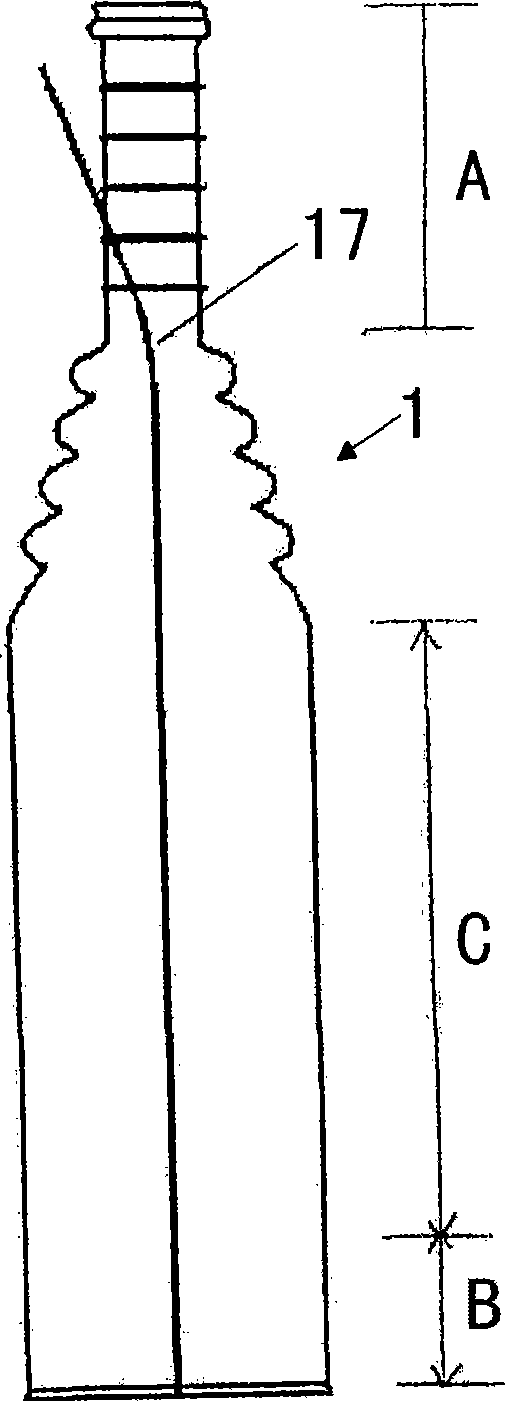

Urisheath with moulded unrolling strip

ActiveCN101394816AReduce unevennessReduce wrinklesMale contraceptivesBodily discharge devicesEngineeringInjection moulding

The urisheath provided here includes an element of thin material (a strip) that allows at least two lengths of it to run in a parallel fashion down either side of the sheath. The is obtained by injection moulding the strip in liquid silicone in the silicone injection moulding process for the urisheath, either by one, two or more component injection moulding. The injection moulding takes place in an injection moulding form for a urisheath with a cavity for the body portion and a cavity for the strip portion wherein the cavity for the body portion is connected to the cavity for the strip portion creating an attachment zone between the strip and the sheath.

Owner:COLOPLAST AS

Silicone ejection oil pressure molding machine

Owner:ZHONGSHAN XIONGBING RUBBER

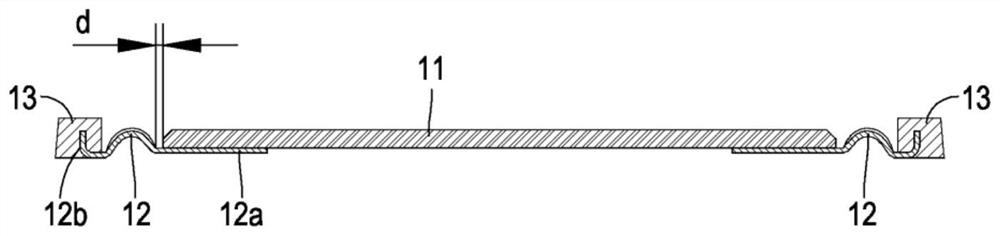

Diaphragm for waterproof microspeaker and microspeaker having same

PendingCN114598972AReduce the numberImprove waterproof functionPolymeric diaphragmsLoudspeaker diaphragm materialsEngineeringLoudspeaker

A high water pressure microspeaker is provided. The diaphragm of the waterproof micro speaker includes: a side wall portion having a predetermined height and forming an outer portion; a central portion positioned on an inner side of the dome portion; and a silicone injection molded portion including a dome portion protruding upward or downward along an inner circumference of the side wall portion and a waterproof portion protruding upward or outward from the side wall portion, in which the side wall portion and the central portion are formed of plastic, and the central portion and the side wall portions are integrally manufactured with the silicone injection molded portion by bijection injection molding.

Owner:EM TECHNOLOGY CO LTD

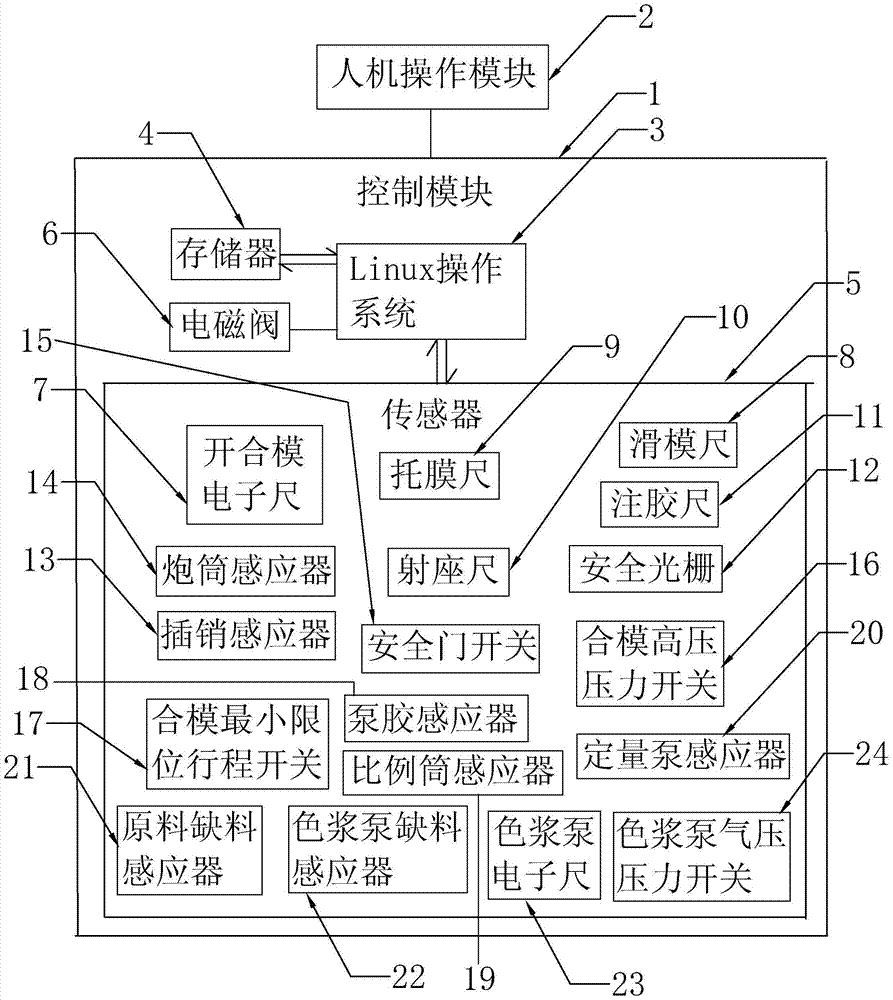

Liquid silicone injection molding system and method for producing liquid silicone molded products

The invention discloses a liquid silica gel injection molding control system. The system comprises a control module and a man-machine operation module. The control module is electrically connected to the man-machine operation module. The invention also discloses a method for producing a liquid silica gel molded product. The method comprises the following steps of building a production flow process by control program pre-written by the man-machine operation module, storing the production flow process in a memory of the control module, inputting control parameters into the man-machine operation module, according to production demand, calling the production flow process stored in the memory, by the control module, transmitting an instruction for starting a liquid silica gel injection molding device, and carrying out corresponding processes by the liquid silica gel injection molding device according to the written production flow process and set motion control parameters to produce the corresponding liquid silica gel molded product. The system has the characteristics of good functions and good compatibility.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

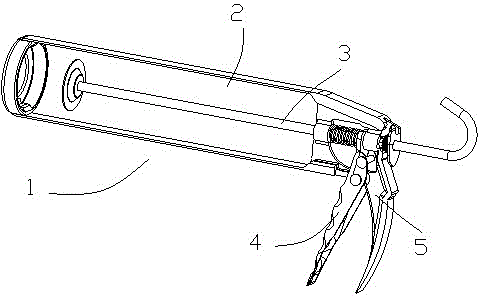

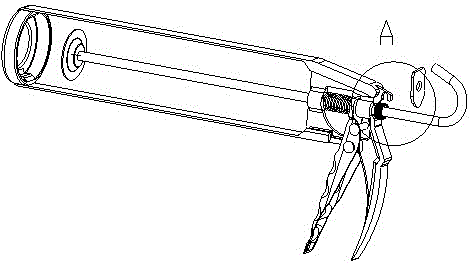

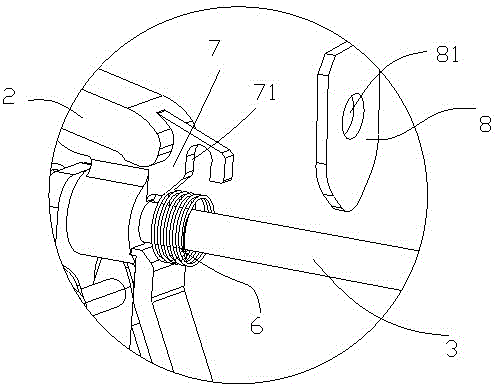

Shrinkproof type silica gel injection device

The invention discloses a shrinkproof type silica gel injection device which comprises a long cylindrical accommodating cylinder body, wherein a locking long rod is arranged inside the accommodating cylinder body, a fixed handle and a movable hand are arranged at the tail part of the accommodating cylinder body, a triangular locking card is arranged at the tail part of the accommodating cylinder body, a clamp hook is arranged on the locking card, a clamping bulged piece is arranged at the tail part of the locking long rod, a fixing through hole is formed in the clamping bulged piece, and the clamping bulged piece is matched with the clamp hook. According to the shrinkproof type silica gel injection device provided by the invention, the locking card at the tail part of the accommodating cylinder body and the clamping bulged piece at the tail part of the locking long rod are used, a user can directly clamp the clamping bulged piece on the clamp hook of the locking card, the locking long rod is effectively prevented from sliding outward, and the usability and the reliability of the silica gel injection device are improved. The shrinkproof type silica gel injection device has a simple structure, is convenient to operate, and is strong in practicability.

Owner:李赵和

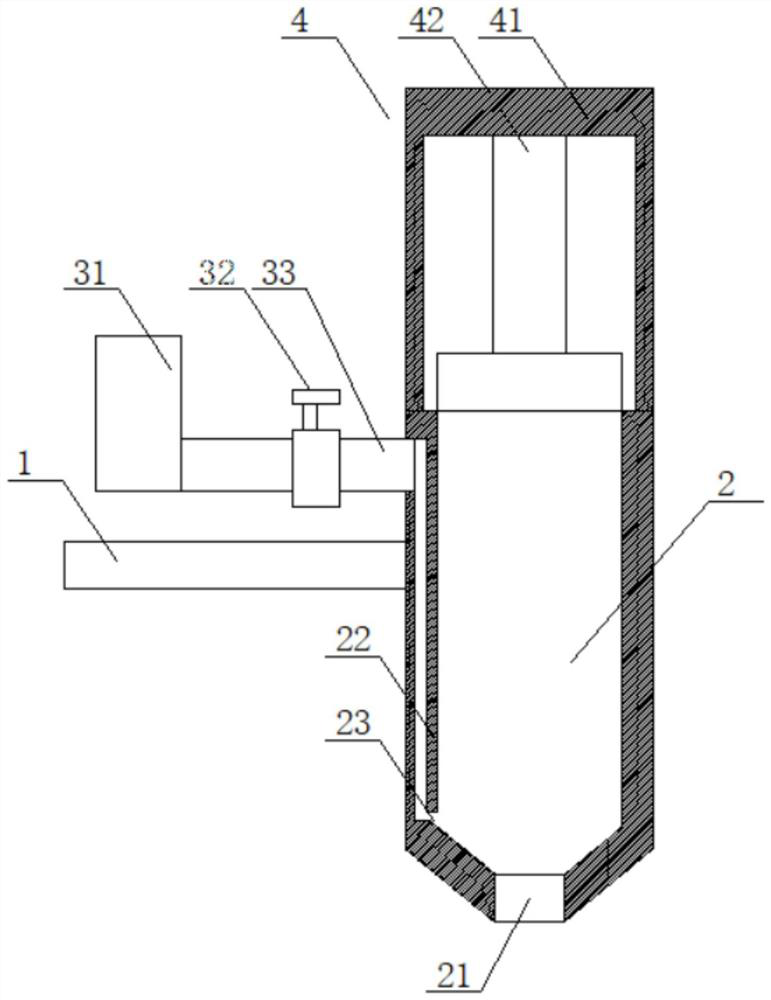

A liquid silicone injection molding system

The invention relates to a liquid silicone injection molding system, comprising: a fixed frame, a material storage room, a feeding mechanism, and a pressure oil cylinder; the material storage room is connected to the fixed frame, and the bottom of the material storage room is provided with a material outlet; The pressing oil cylinder is arranged at the upper end of the storage room, and the pressing oil cylinder includes a cylinder body and a pressing piston; the pressing piston fits with the storage room; the feeding mechanism is arranged on the side wall of the storage room, The feeding mechanism includes a material preparation bin, a feeding pump, and a feeding pipe; the preparation bin is arranged outside the storage room, and the feeding pipe is connected between the preparation bin and the storage room, and the feeding pump is arranged on the feeding pipe ; The feeding pipe leads to the inner wall of the storage chamber, and a side baffle is arranged at the connection between the feeding pipe and the storage chamber; the pressing piston is up and down along the side baffle and the inner wall of the storage chamber Move: the inner wall of the storage chamber and the side baffle form a barrel shape, and the inner wall of the storage chamber covered by the removed side baffle is sunken toward the outside of the storage chamber.

Owner:浙江永浩工贸有限公司

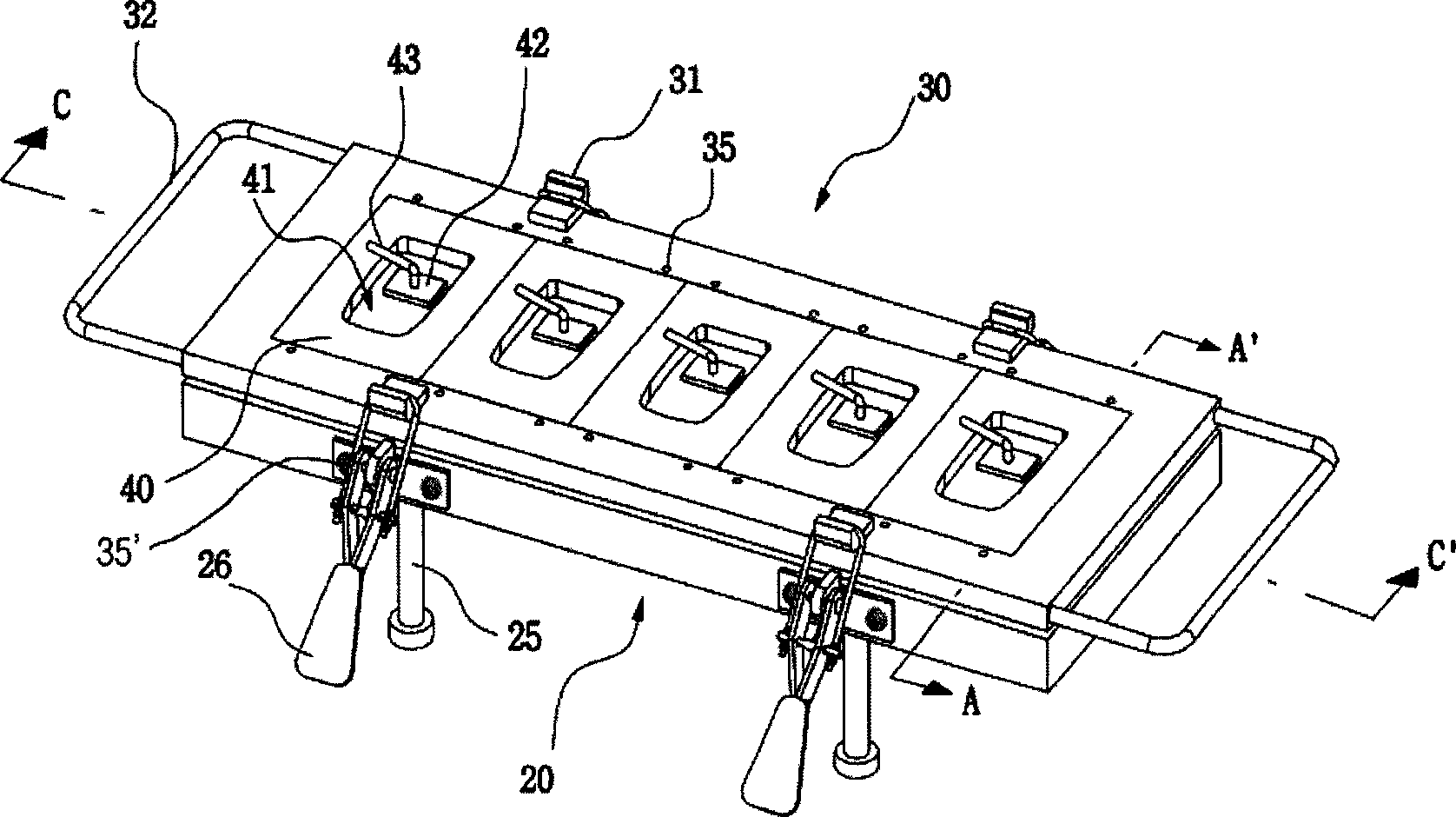

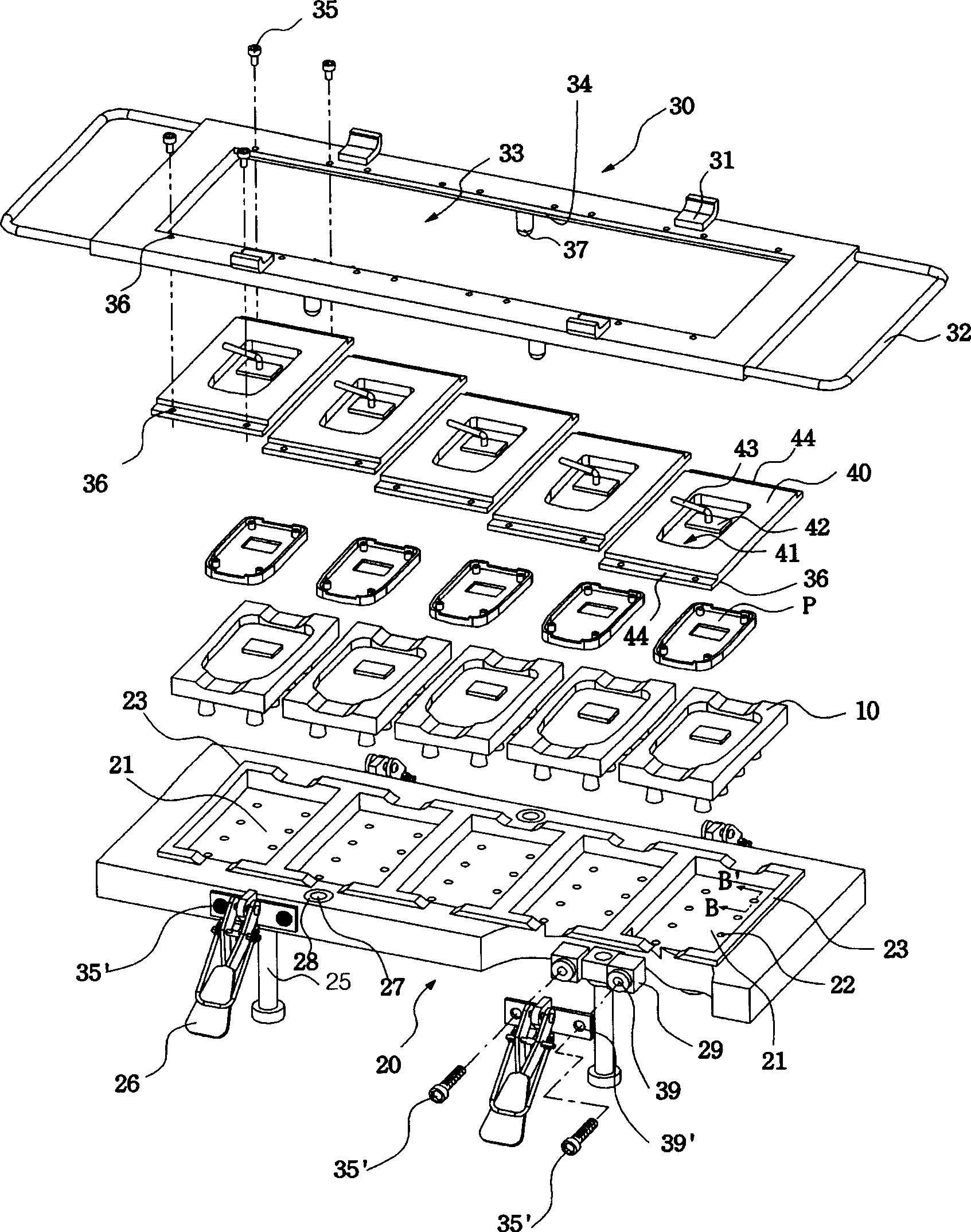

Electromagnetic wave shielding coating selective spraying apparatus

InactiveCN1772396AAvoid failureLiquid surface applicatorsSpraying apparatusElectromagnetic electron waveSynthetic resin

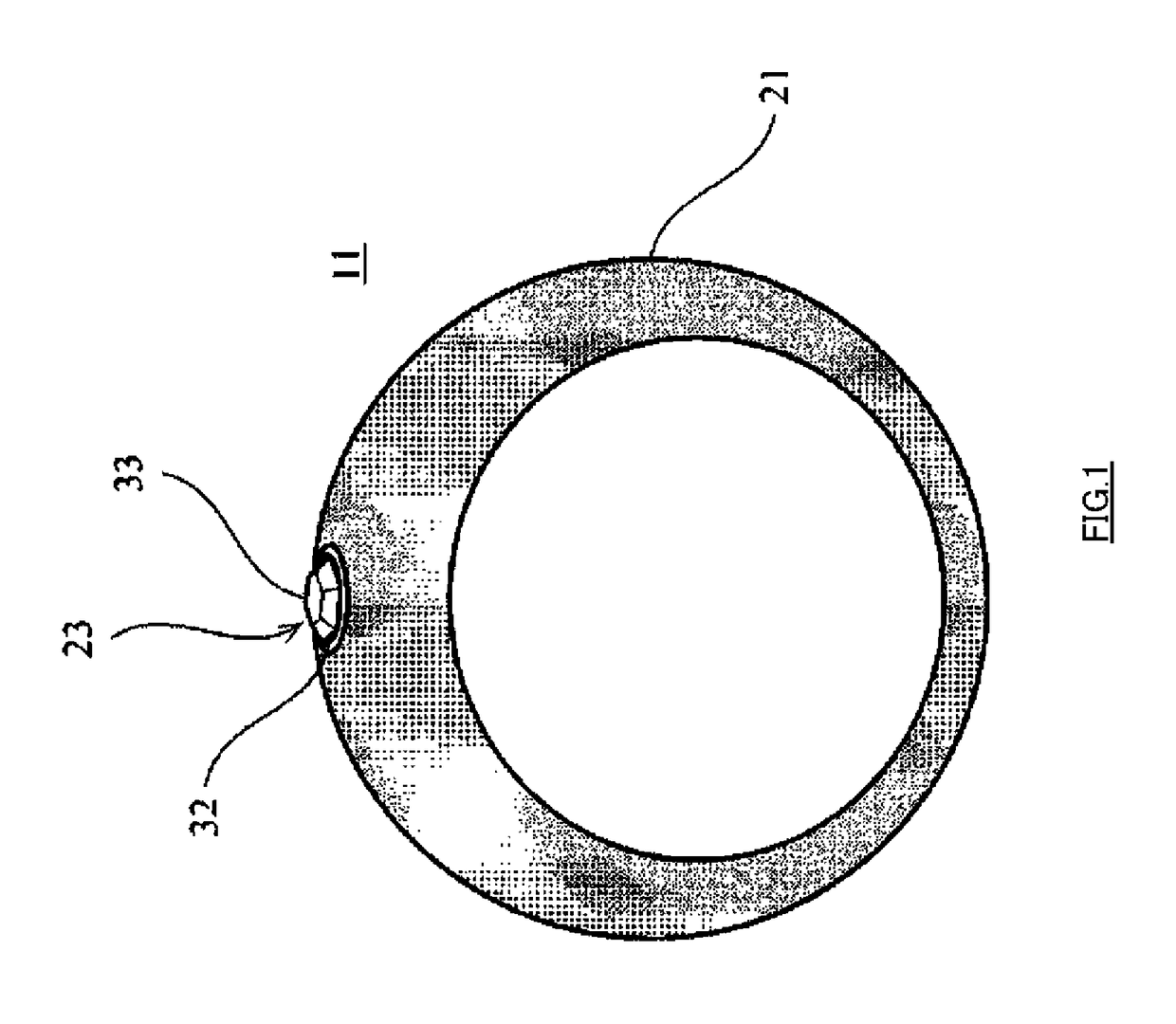

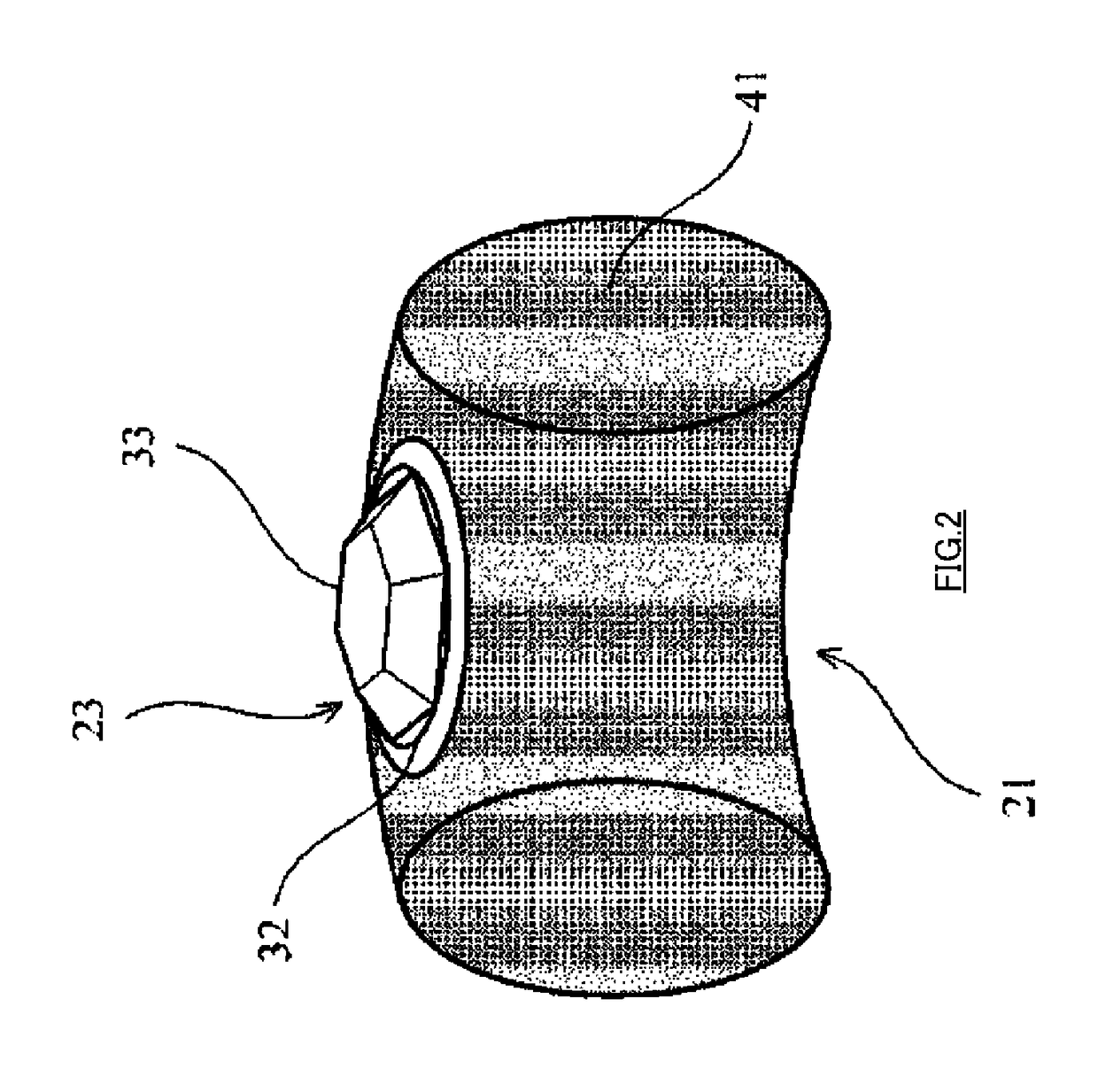

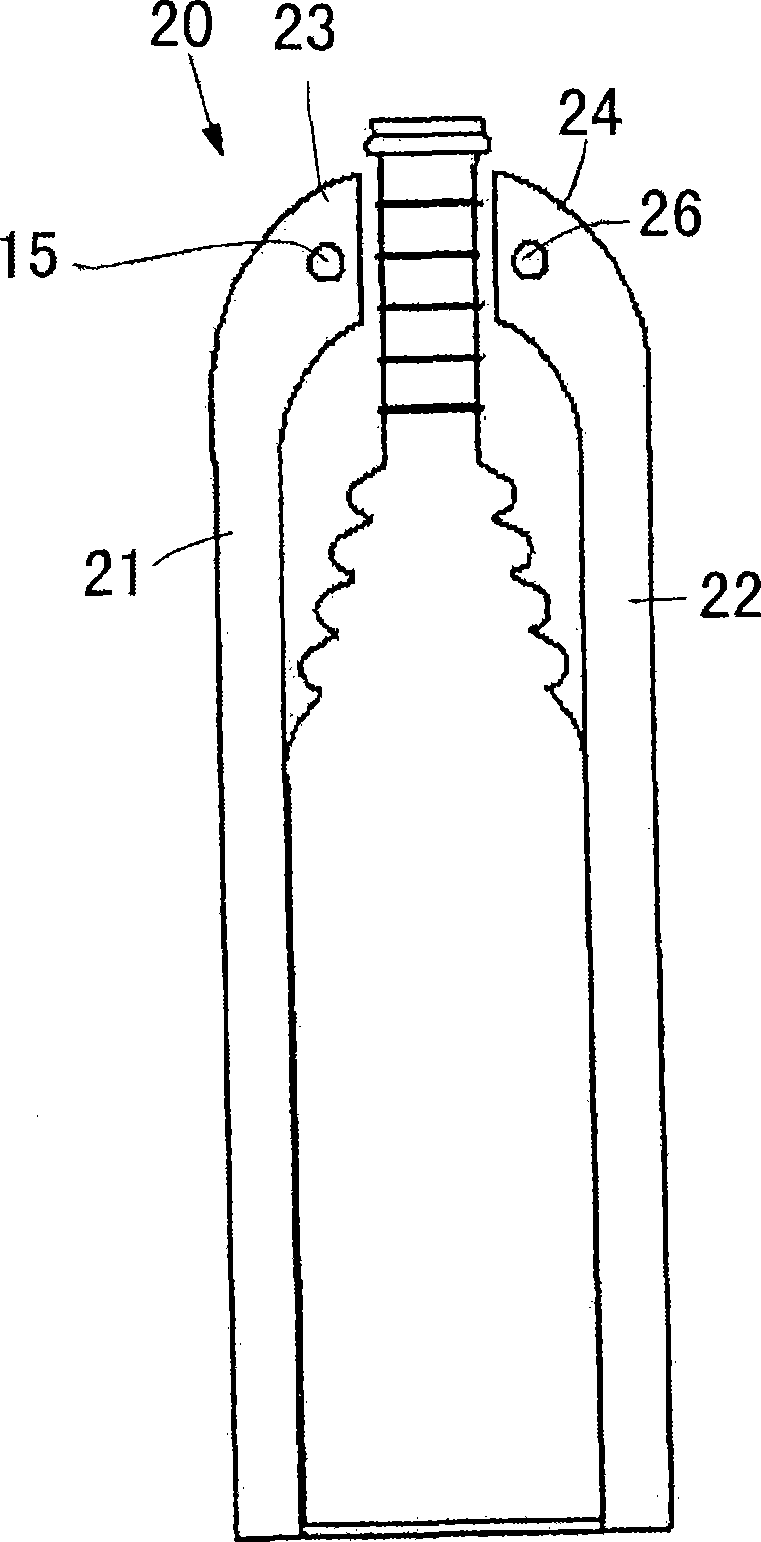

The invention relates to an electromagnetic wave shielding paint selective spraying device having a jig including a plurality of individually detachable core plates, a machine tool (20) made of a plurality of silicone resin molds (10) for housing a mobile phone body shell (P), synthetic resin material ) and fixtures. Wherein, the machine tool (20) has a plurality of silicone resin injection grooves (21), the silicone resin injection groove has a plurality of exhaust holes (22) with a narrow upper and a wider lower structure, and the bottom of the machine tool has 4 support rods (25 ), a pair of pads (29) with a plurality of nut holes (39) are respectively inserted on both sides; a pair of clamping plates (31) are formed on both sides above the clamp, and a pair of clamping plates (31) are formed in the center along the quadrilateral periphery on the back side. The opening (33) of the lower step (34) of each screw hole (36), a plurality of core plates (40) with an open portion (41), a closed portion (42) and a closed portion support platform (43) are arranged up and down with a The upper steps (44) of a plurality of screw holes (36) are connected to the screw holes 36 by screws.

Owner:夏在基

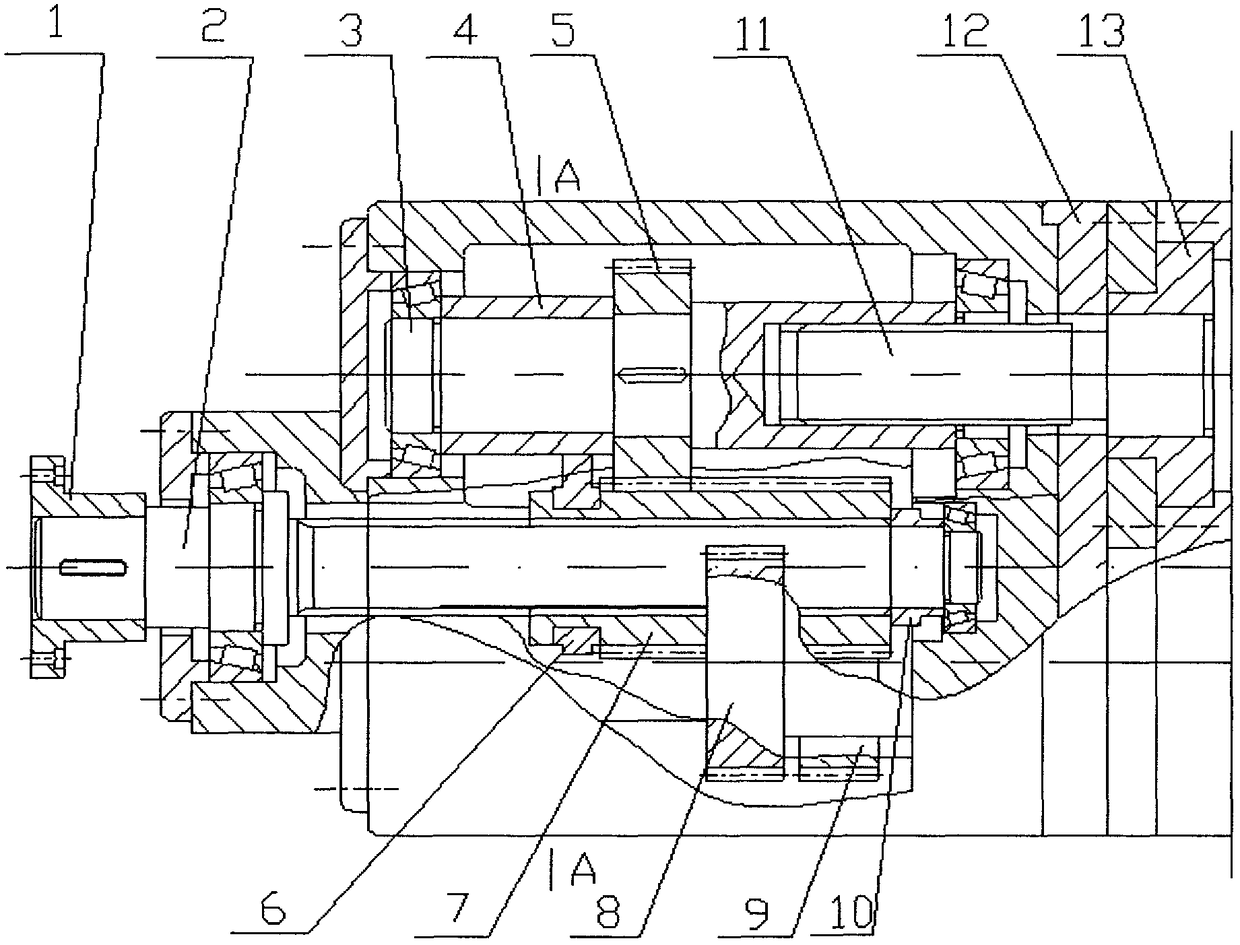

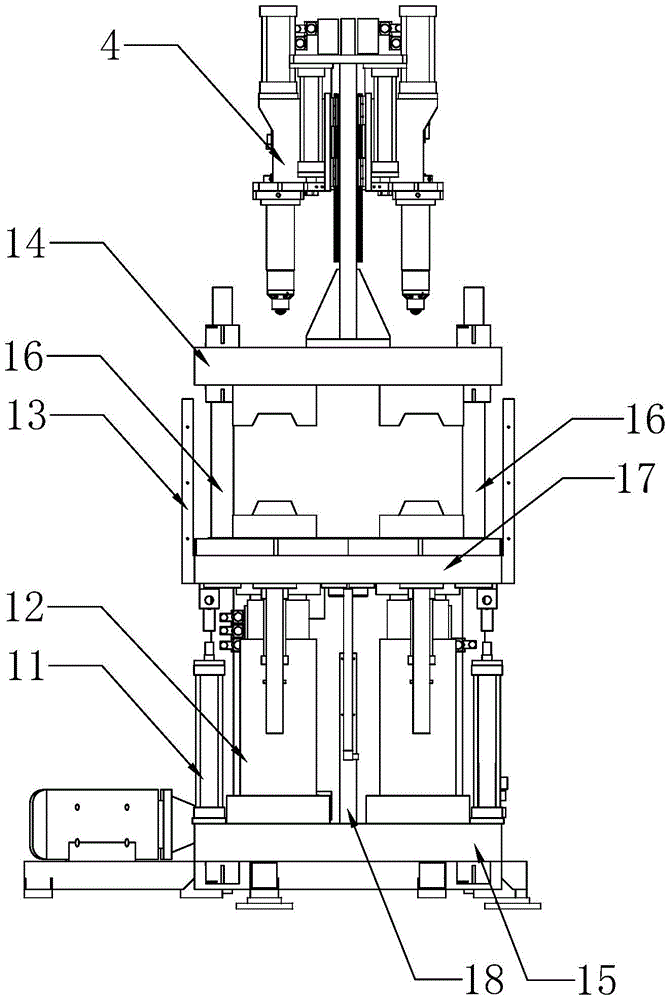

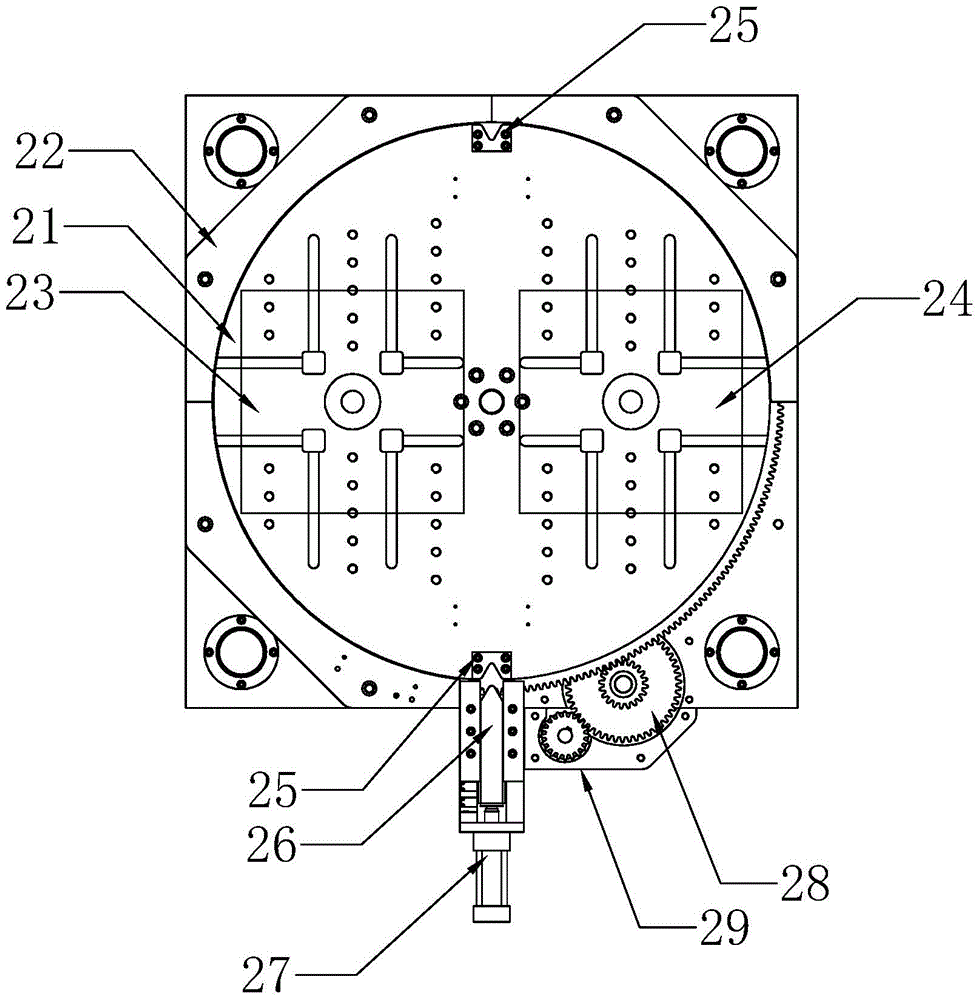

Main unit of two-color liquid silicone injection molding machine

The embodiment of the invention discloses a mainframe of a double-color liquid silica gel injection molding machine. The mainframe comprises a clamping unit, a rotary table mechanism, a mould supporting mechanism, an injection mechanism, a hydraulic system and an electronic control system, wherein the clamping unit is arranged at the bottom of the rotary table mechanism; the mould supporting mechanism is arranged between the clamping unit and the rotary table mechanism; the injection mechanism is arranged on the top of the rotary table mechanism; the electronic control system is arranged in an electric box at the side of the clamping unit; the clamping unit, the rotary table mechanism, the mould supporting mechanism and the injection mechanism are respectively internally provided with two groups of working modules which are independent from each other, and the two groups of working modules in the clamping unit, the rotary table mechanism, the mould supporting mechanism and the injection mechanism are respectively connected with the hydraulic system in a controlling way. The mainframe of the double-color liquid silica gel injection molding machine is matched with two feeders which are independently researched and developed, so that liquid silica gel products with two different colors can be produced; furthermore, the mainframe has the characteristics of being intelligent and high in efficiency.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

A color paste pump for liquid silicone injection

ActiveCN102889204BControl speedControl the flow rate of the one-way throttle valve to control the speedPositive displacement pump componentsLiquid fuel engine componentsPulp and paper industrySilica gel

The invention discloses a color paste pump used for injecting liquid silica gel, which comprises a pump body, a color paste storage device, an air cylinder and a change-over valve, wherein the color paste storage device comprises a color paste cup spliced on the change-over valve; the pump body further comprises a piston rod provided with a seal ring; and the piston rod is connected with the output end of the air cylinder through a piston connector. The color paste pump used for injecting liquid silica gel is characterized in that the air cylinder is also connected with an oil cylinder; the air cavity of the air cylinder is connected with the oil cavity of the oil cylinder through oil pipes; and a hydraulic one-way throttle valve is arranged between the oil pipes. As the hydraulic one-way throttle valve is arranged between the oil pipes, and the piston connector is also connected with a measurement plate, the speed for hydraulic oil to flow into the air cavity of the air cylinder from the oil cavity of the oil cylinder can be controlled by controlling the flow of the one-way throttle valve, so that the upward-motion speed of the piston rod of the color paste pump can be controlled, and the color paste output speed can be controlled. A meter is used for measuring the displacement value of the piston rod motion, and the color paste output speed and the color paste output amount can be known by observing the variation of a meter value.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com