Patents

Literature

31results about How to "Meet the needs of different processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application of acid copper leveling agent

ActiveCN103924268AMeet the needs of different processesGood water solubilityOrganic chemistrySolubilityLeveling effect

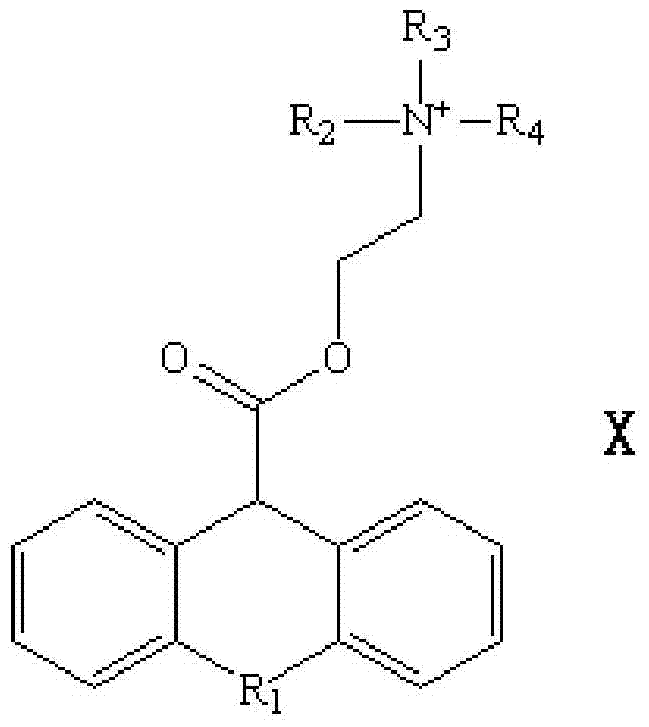

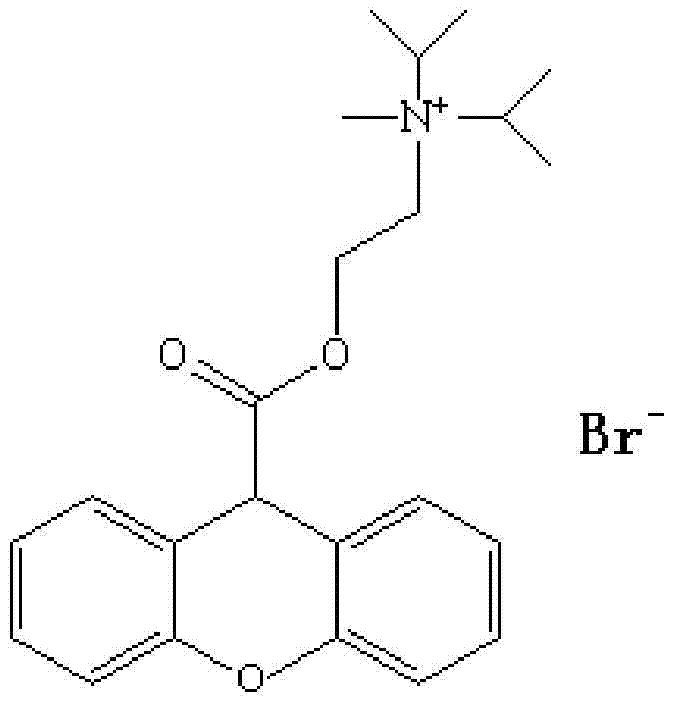

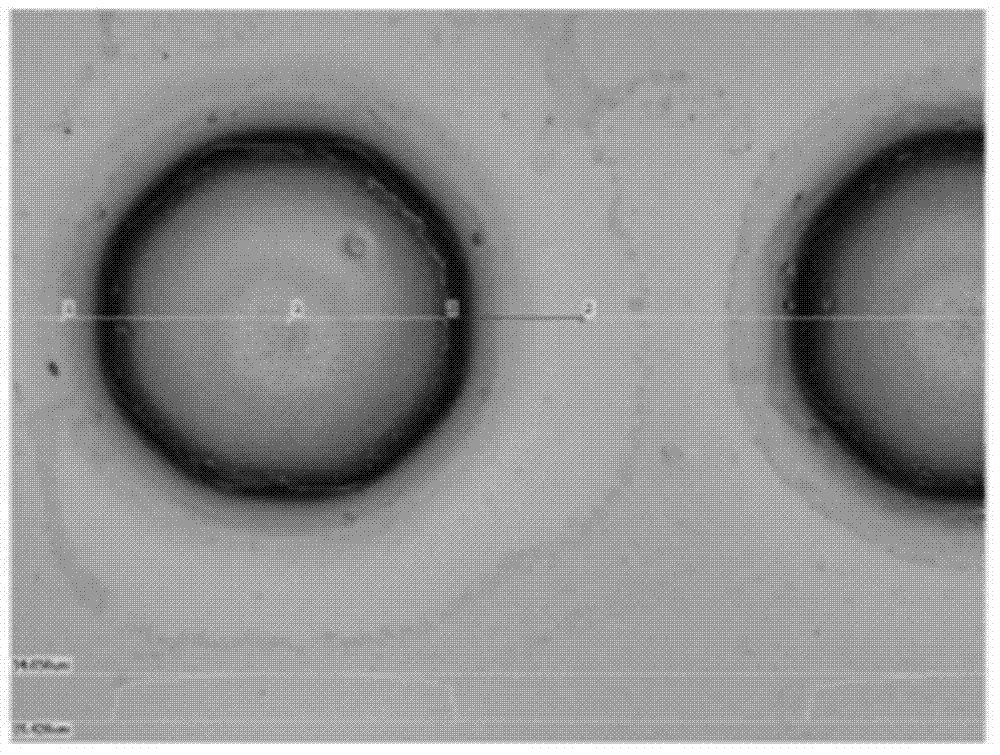

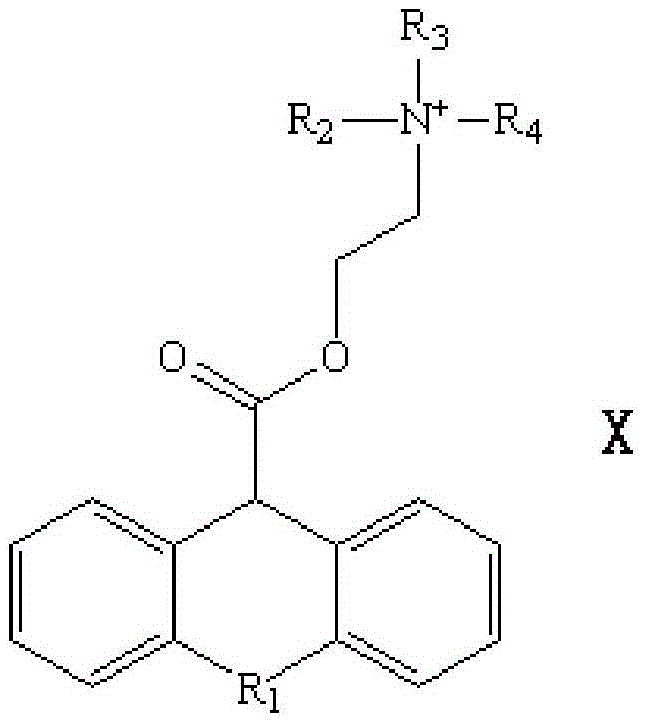

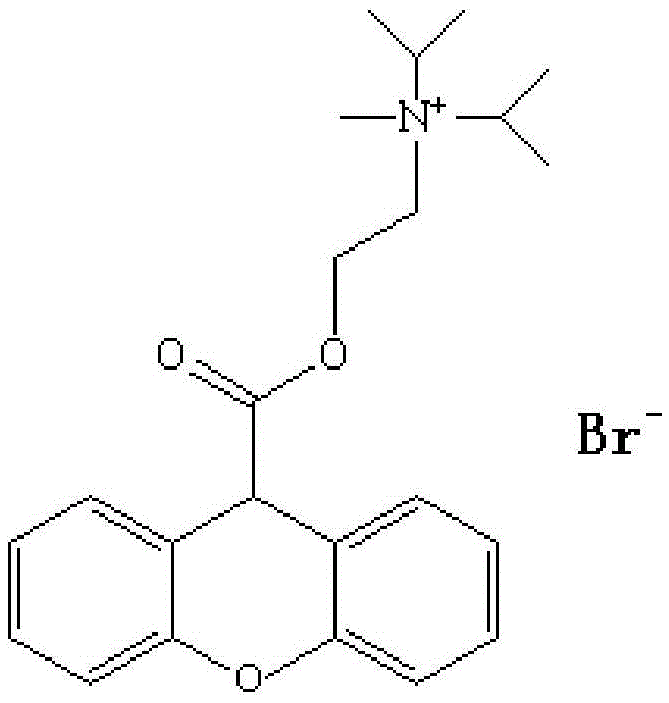

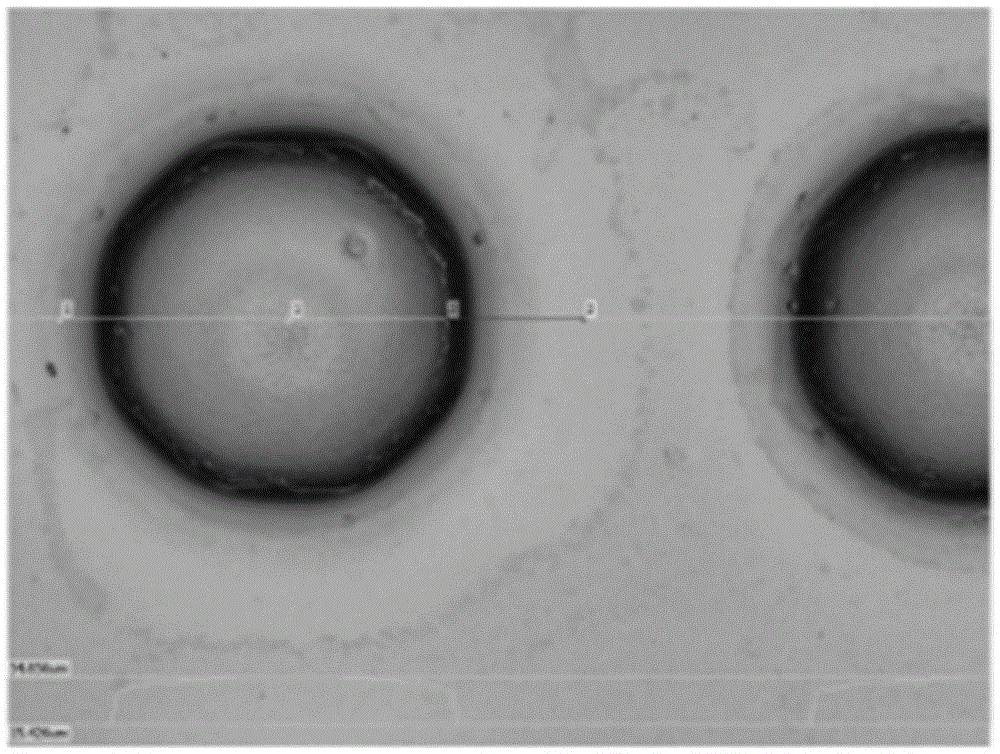

The invention discloses an application of an acid copper leveling agent. The molecular structural formula of the acid copper leveling agent is shown in the specification. In the formula, an anion X is Cl<-> or Br<->; R1 is O or S or N, and R2, R3 and R4 can be one of H, alkyl groups, alkenyl groups, aralkyl groups, heteroarylalkyl groups, substituted alkyl groups, substituted alkenyl groups, substituted aralkyl groups or substituted heteroarylalkyl groups. The acid copper leveling agent is used in adjustable surface morphology wafer electroplating. Novel acid copper leveling agent molecules having the advantages of good water solubility, colorlessness, non-toxicity and environmental protection are designed and developed, and are different from previous dye leveling agents, and the novel acid copper leveling molecules are compounded with a traditional leveling agent or other molecules having a leveling effect to form the acid copper leveling agent as a composite leveling agent in acid copper electroplating, so the effective control of the copper electroplating surface morphology is realized by blending the molecule concentration proportions of the composite leveling agent in a same chemical system in order to meet demands of different technologies.

Owner:SUZHOU SHINHAO MATERIALS

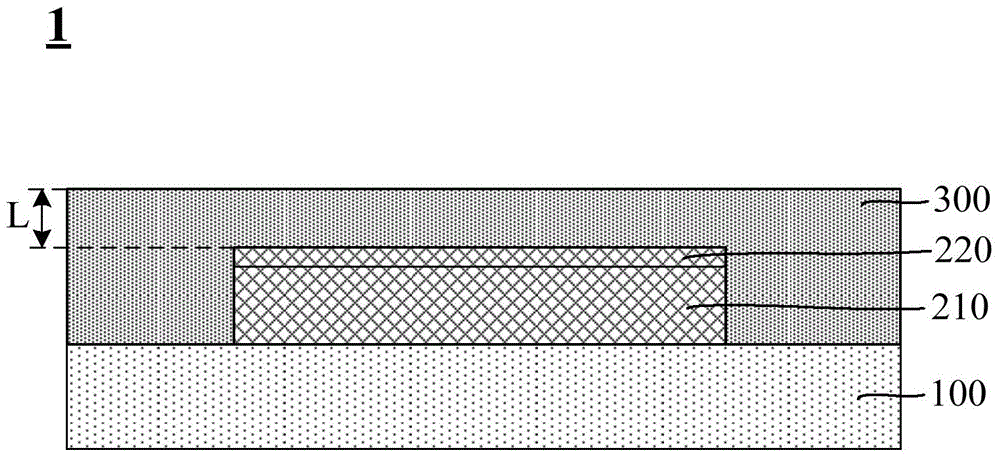

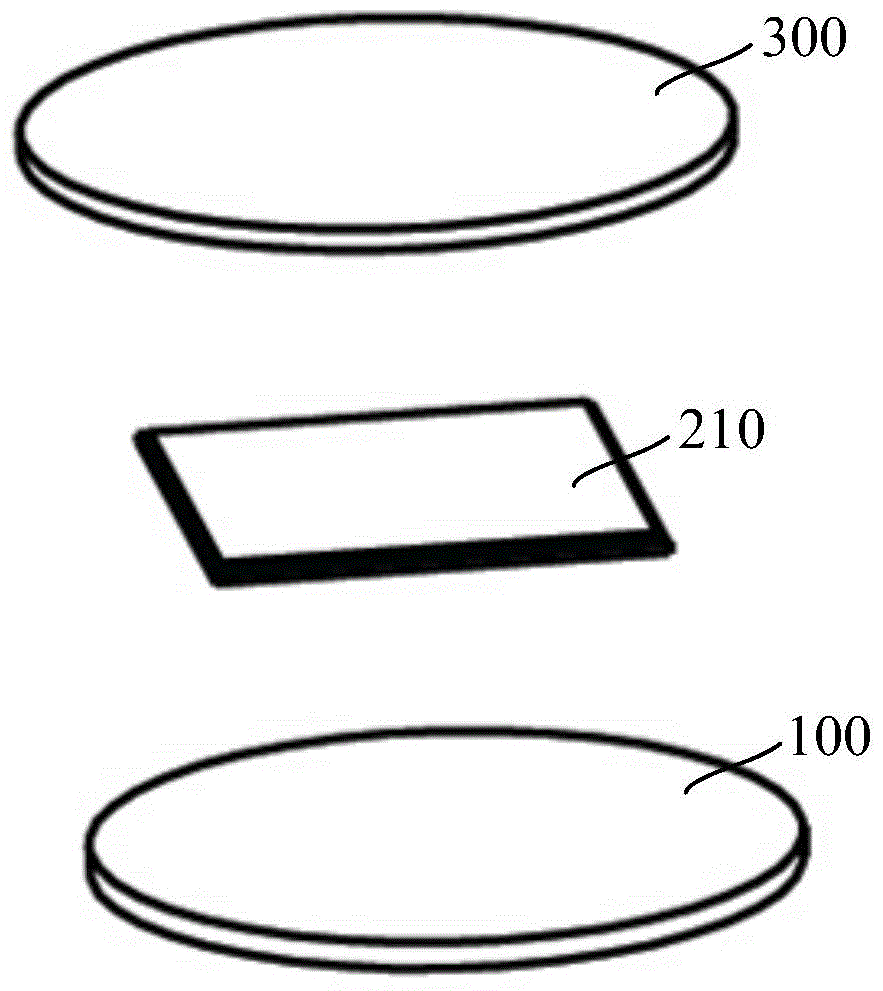

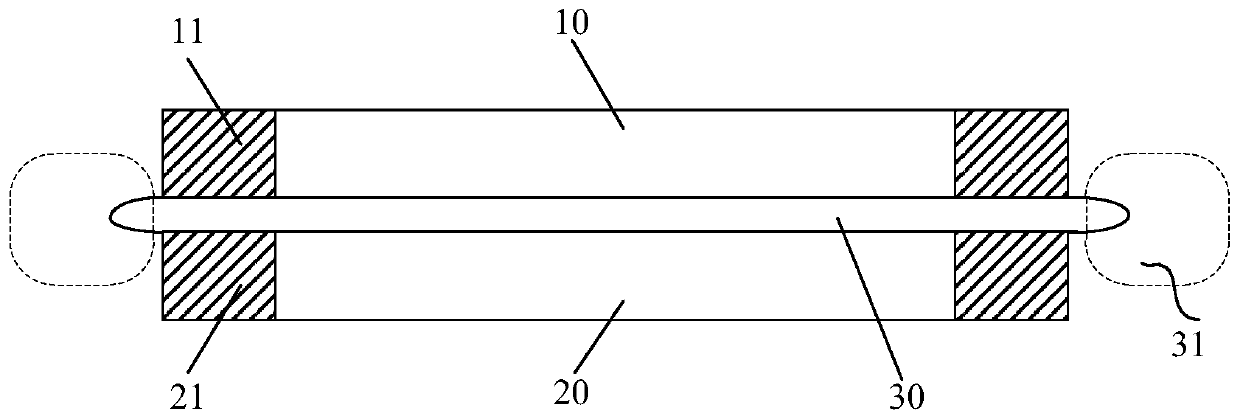

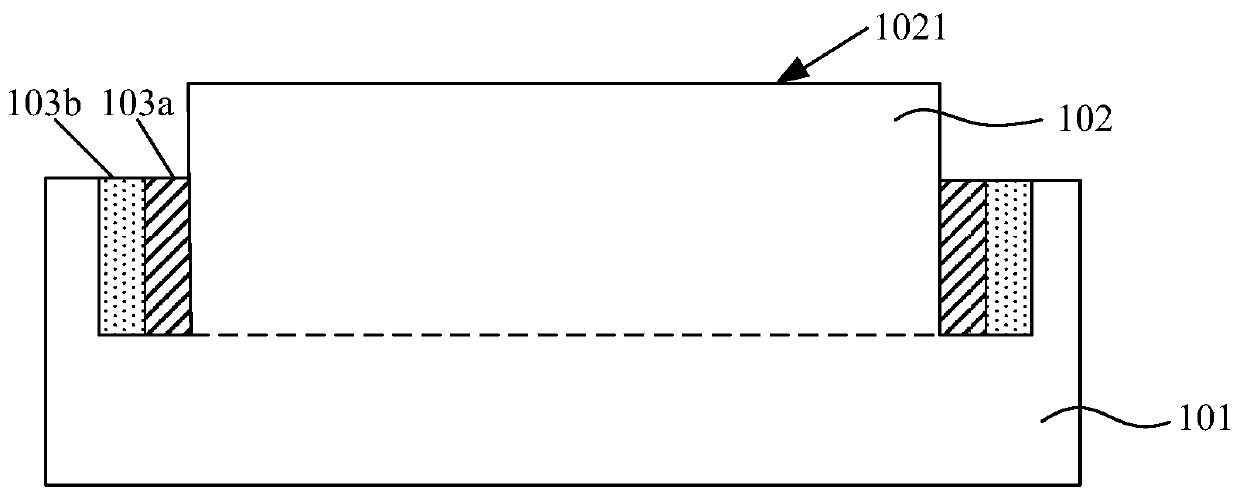

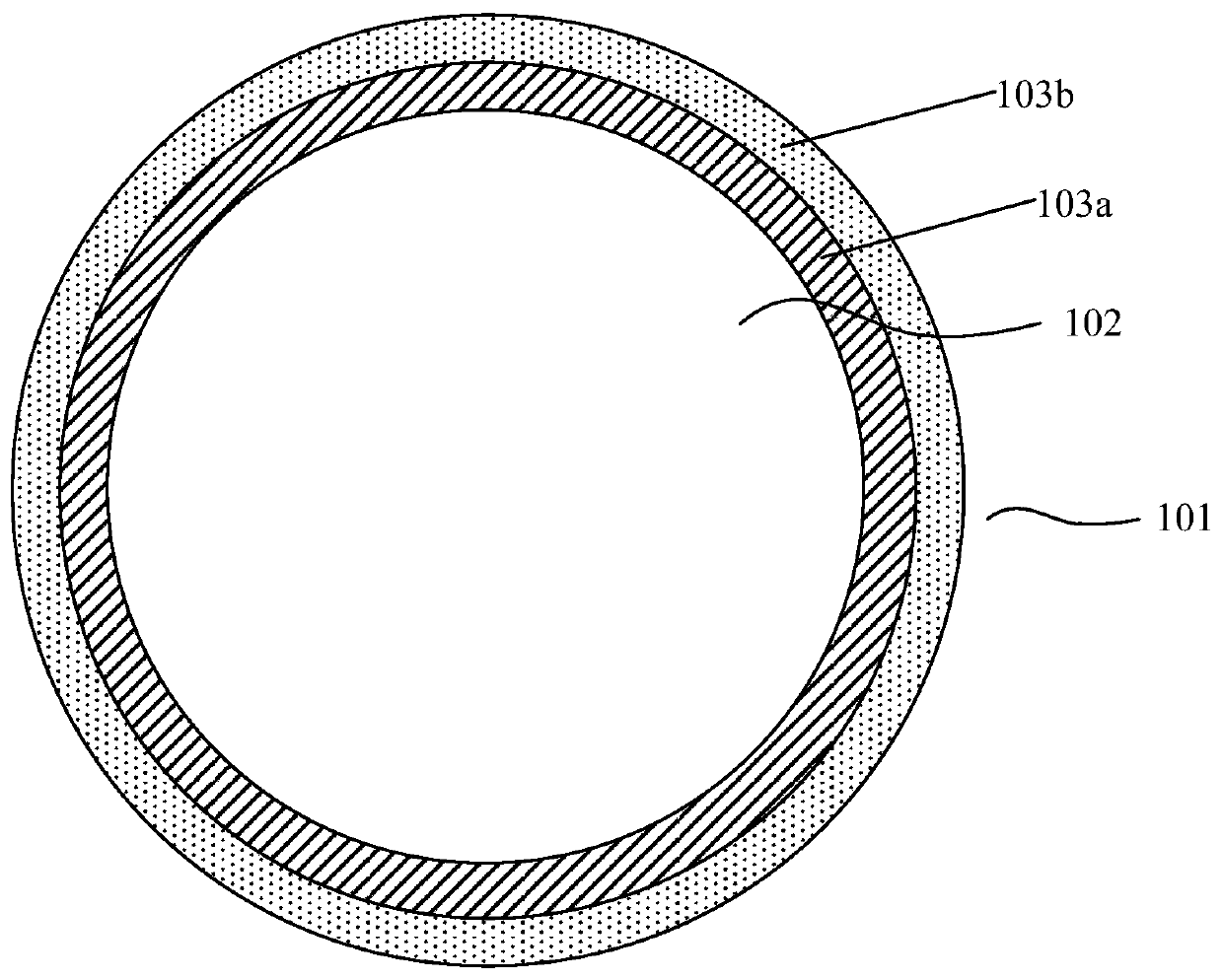

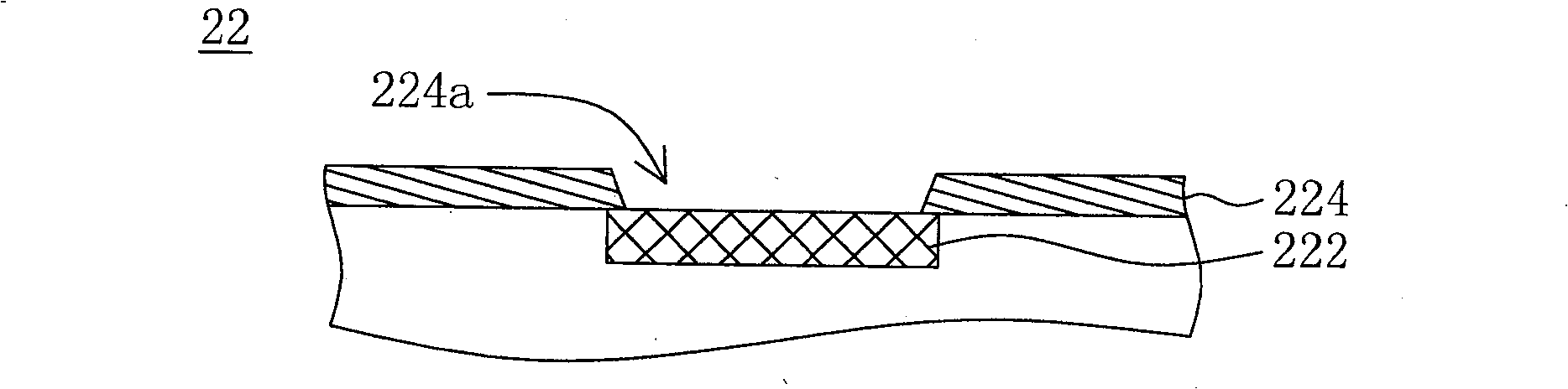

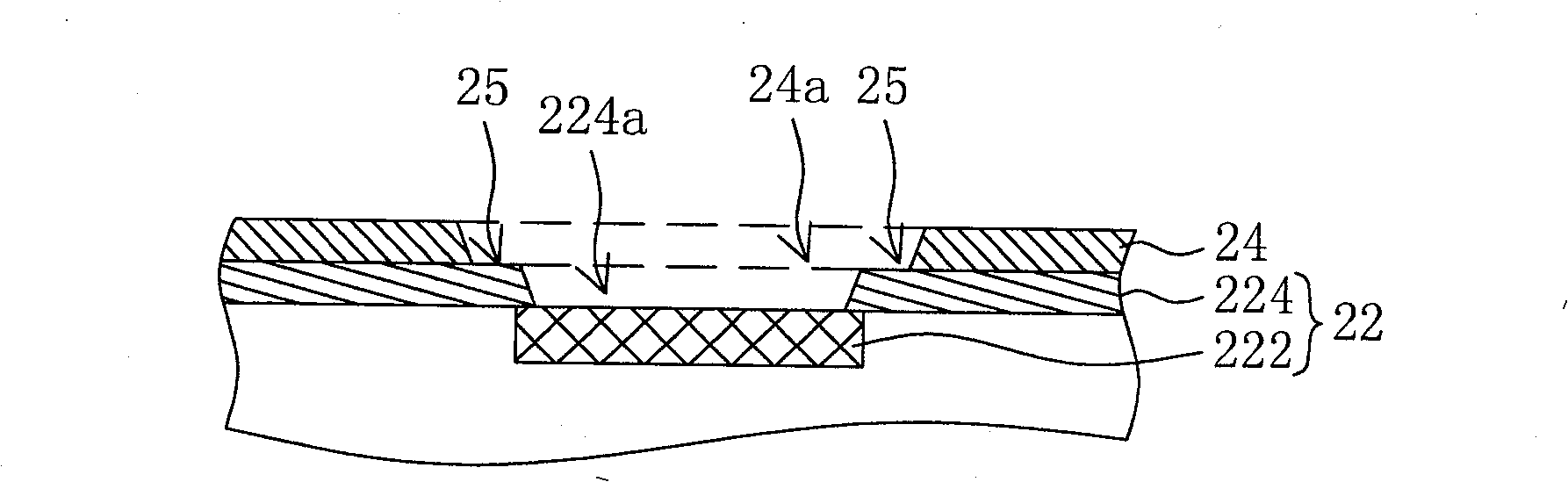

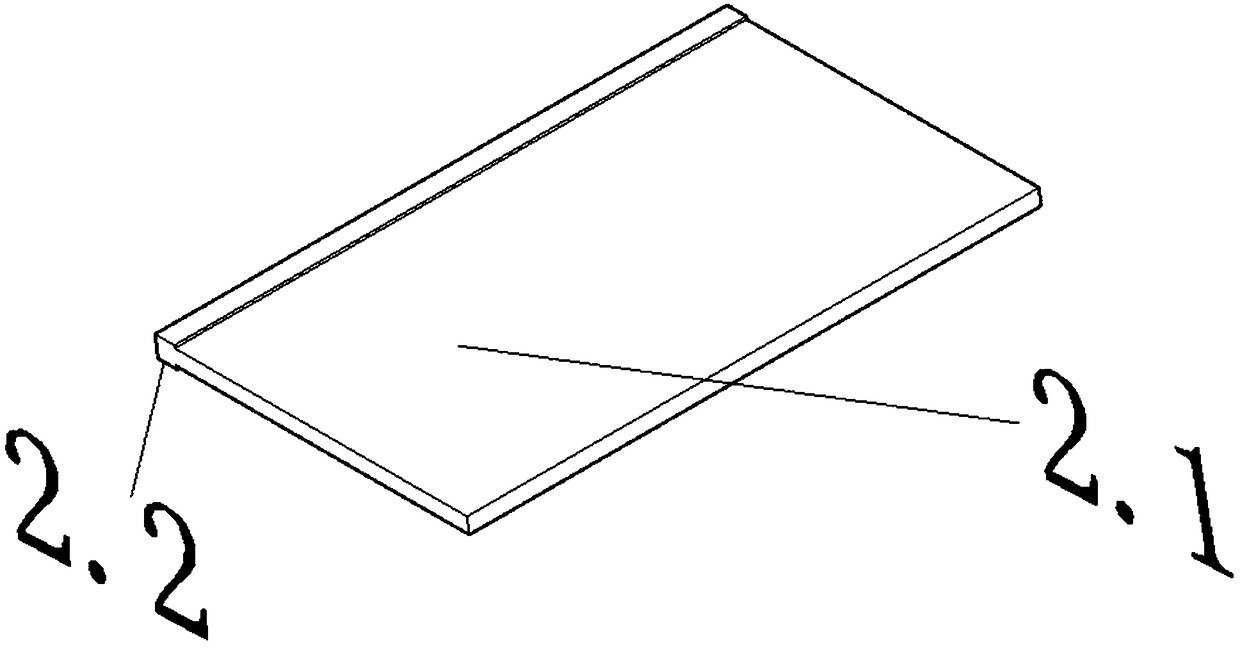

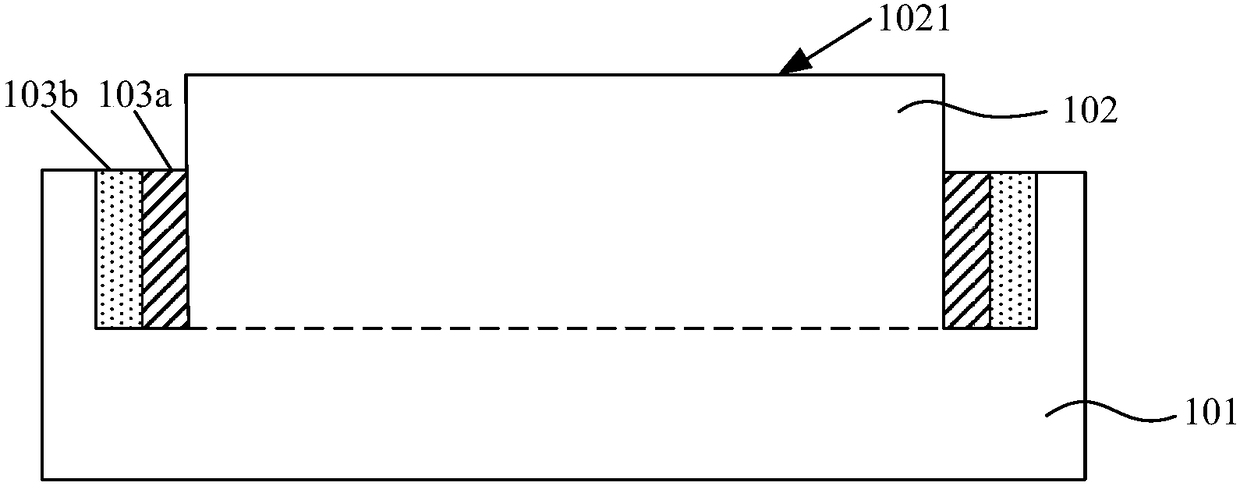

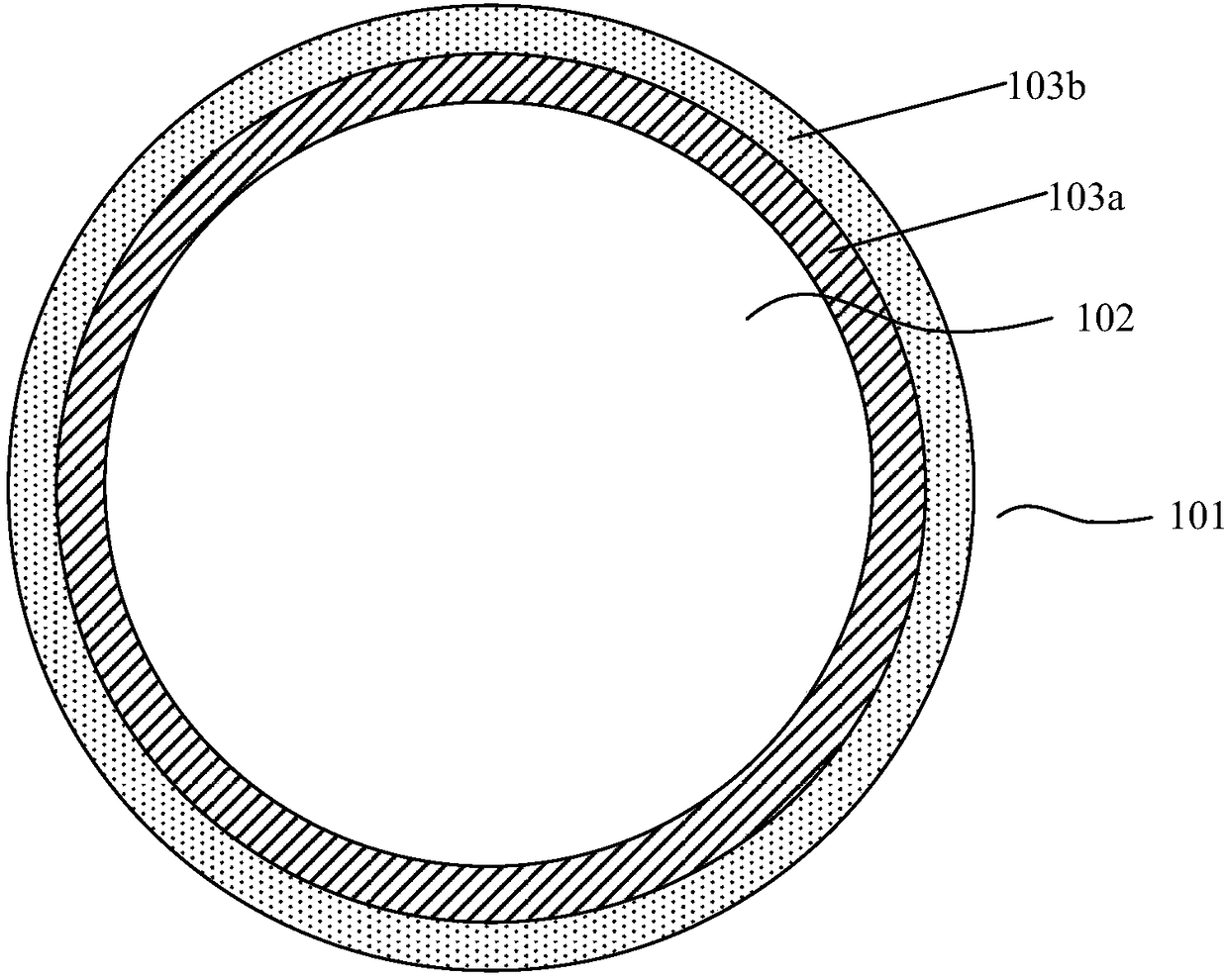

Fingerprint identification device and fingerprint identification assembly with mould pressing protection layer

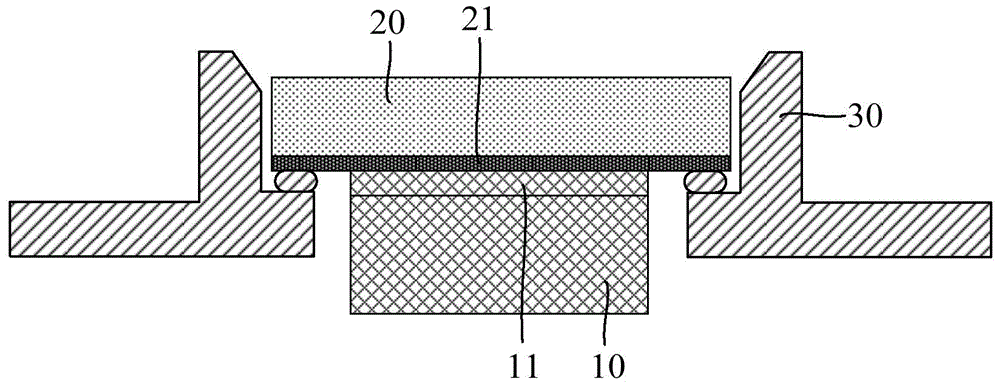

InactiveCN104102924AThe overall thickness is thinHigh sensitivityCharacter and pattern recognitionUltrasound attenuationEngineering

The invention relates to the technical field of integrated circuit manufacture and packaging, and discloses a fingerprint identification device and a fingerprint identification assembly with a mould pressing protection layer. In the invention, a mould pressing mode can be adopted to form a thinner protection layer, the protection layer is formed on the surface of a fingerprint identification chip to become one part of the fingerprint identification device without forming a lens for protection subsequently, so that, technical steps are reduced. Since the protection layer formed in the above way can be thin, the attenuation of a fingerprint signal after the fingerprint signal passes through the protection layer is reduced, the sensitivity of the fingerprint identification chip is enhanced, and fingerprint identification efficiency is improved.

Owner:SILEAD

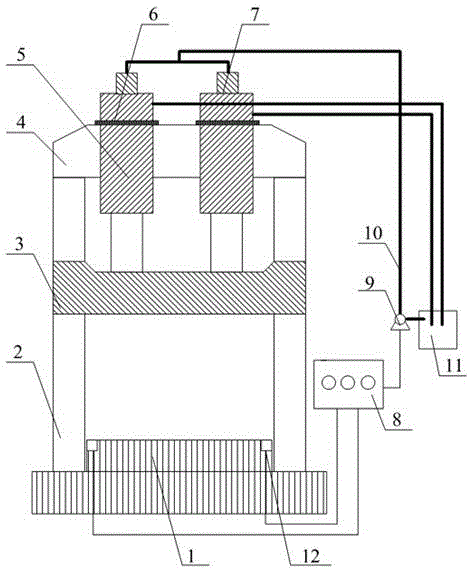

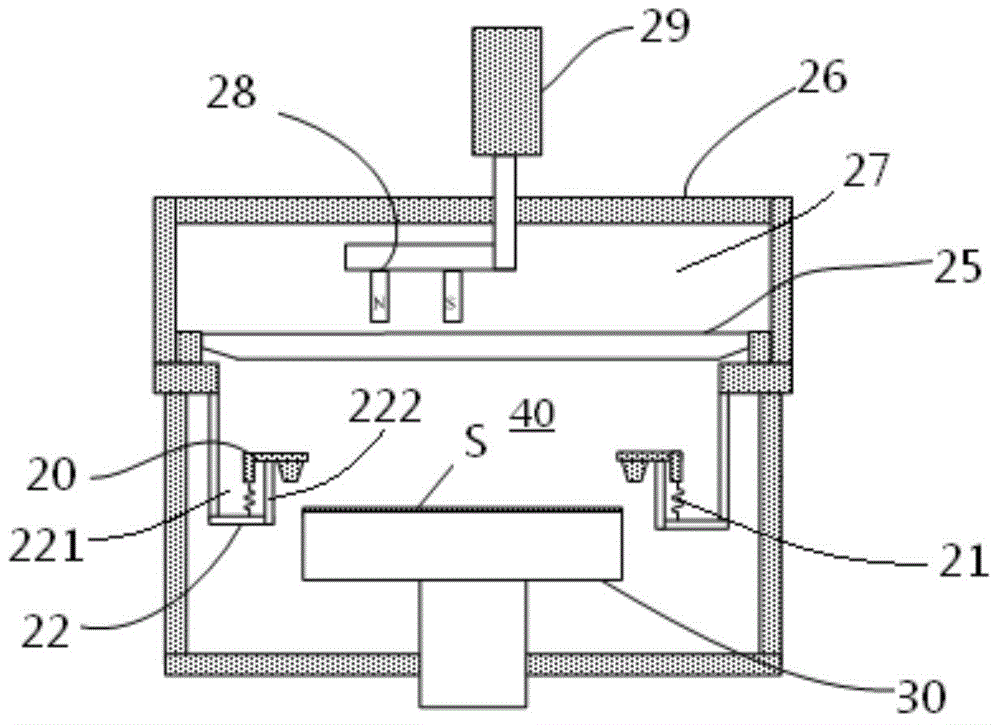

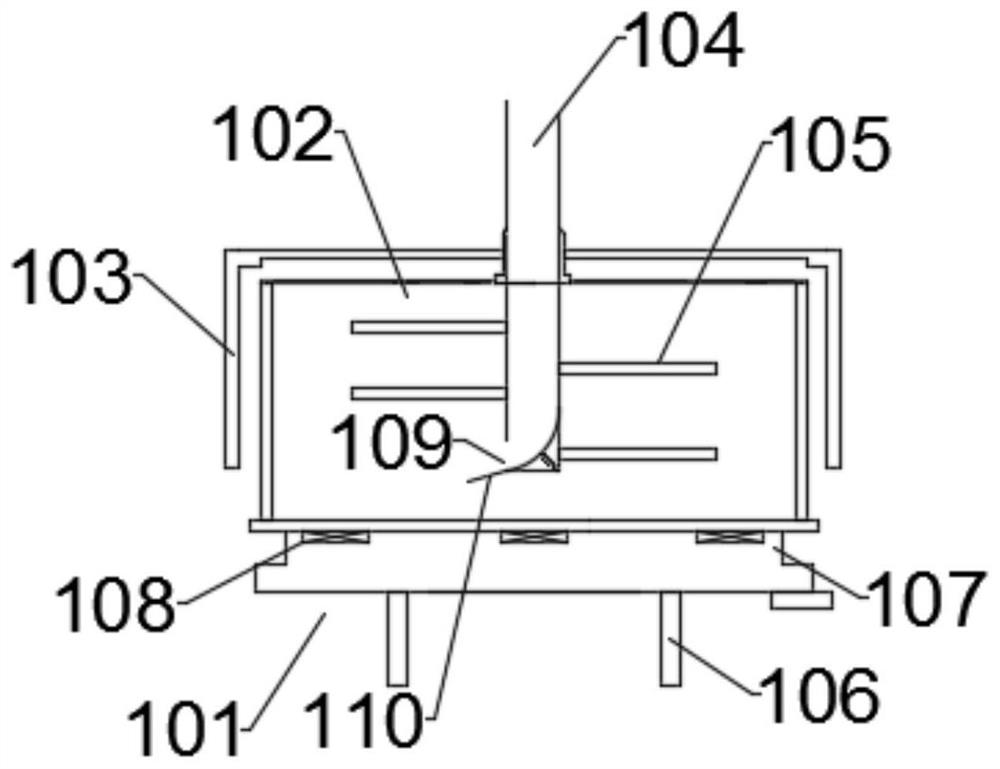

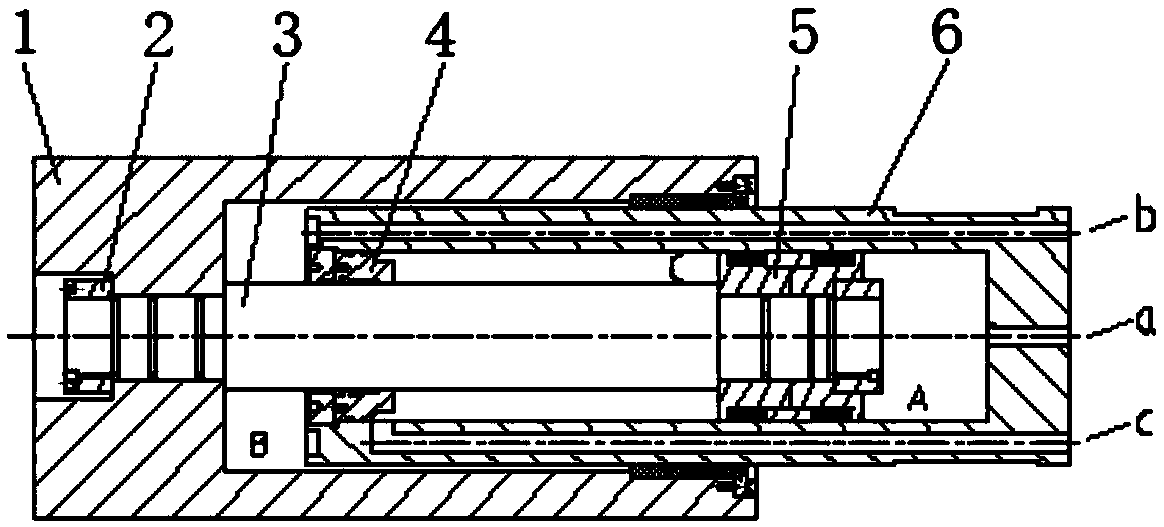

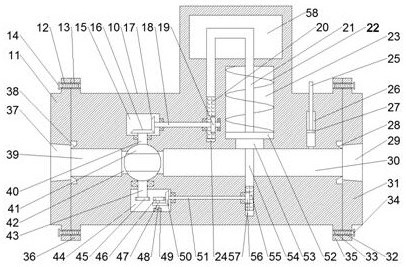

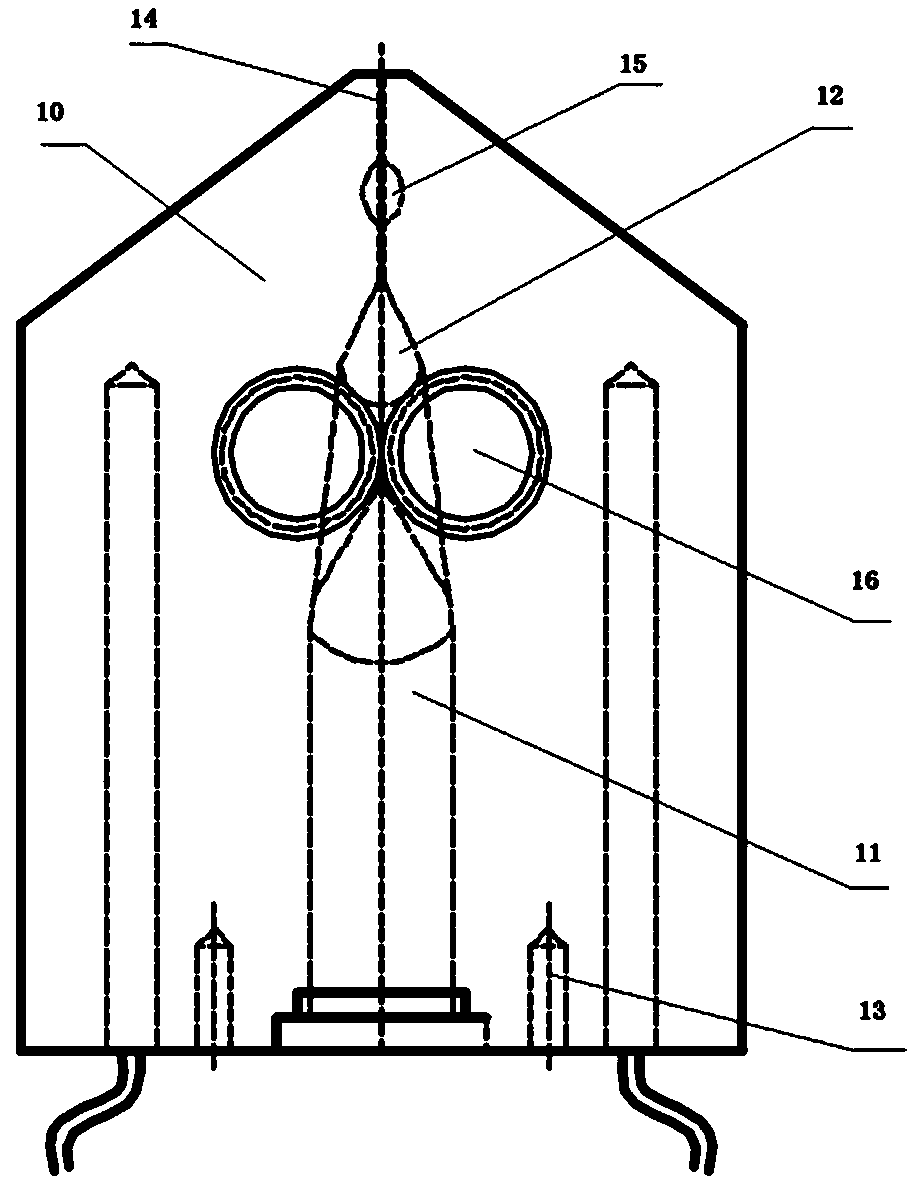

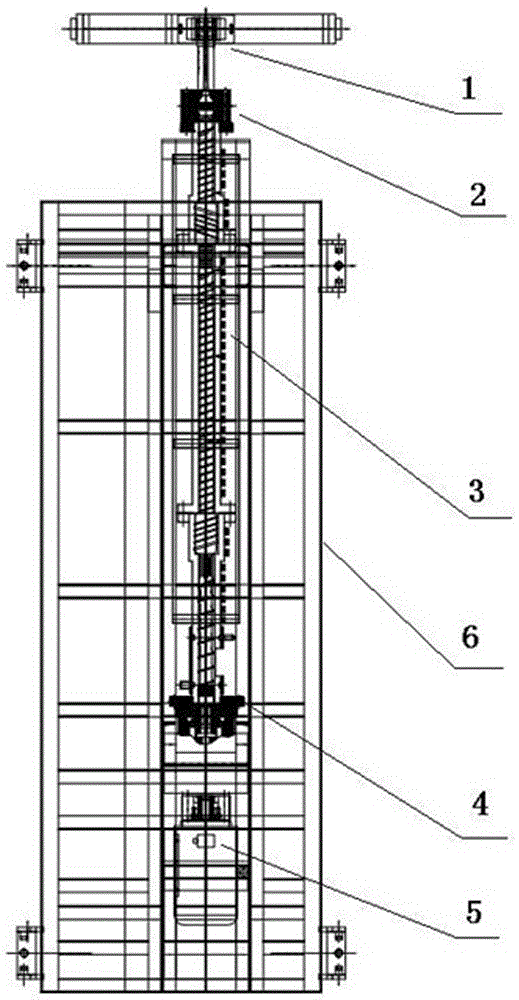

Four-column hydraulic press

The invention discloses a four-column hydraulic press and belongs to the field of metal forming machinery. The four-column hydraulic press comprises a machine base, stand columns, an upper beam, a movable beam and hydraulic cylinders, wherein the stand columns are fixedly installed on the machine base, the upper beam is fixedly installed on the top portions of the stand columns, the movable beam is installed on the stand columns in a sleeved mode, the hydraulic cylinders are fixedly installed on the upper beam, an output rod of each hydraulic cylinder is connected with the movable beam to drive the movable beam to move vertically along the stand columns, the hydraulic cylinders are connected with a plunger pump which is connected with a hydraulic control unit, and multiple pressure sensors are arranged on the machine base and are connected with the hydraulic control unit. According to the four-column hydraulic press, pressure information of the hydraulic press can be fed back to the hydraulic control unit, the hydraulic control unit regulates the pressure of the hydraulic cylinders quickly according to forming technological parameters, so that the pressure during the whole hydraulic process is controlled more accurately, and requirements of different technologies are met; the number of the pressure sensors is four, the four pressure sensors are arranged on four corners of the machine base, and pressure signals obtained through measurement are more accurate.

Owner:南通华德锻压机床有限公司

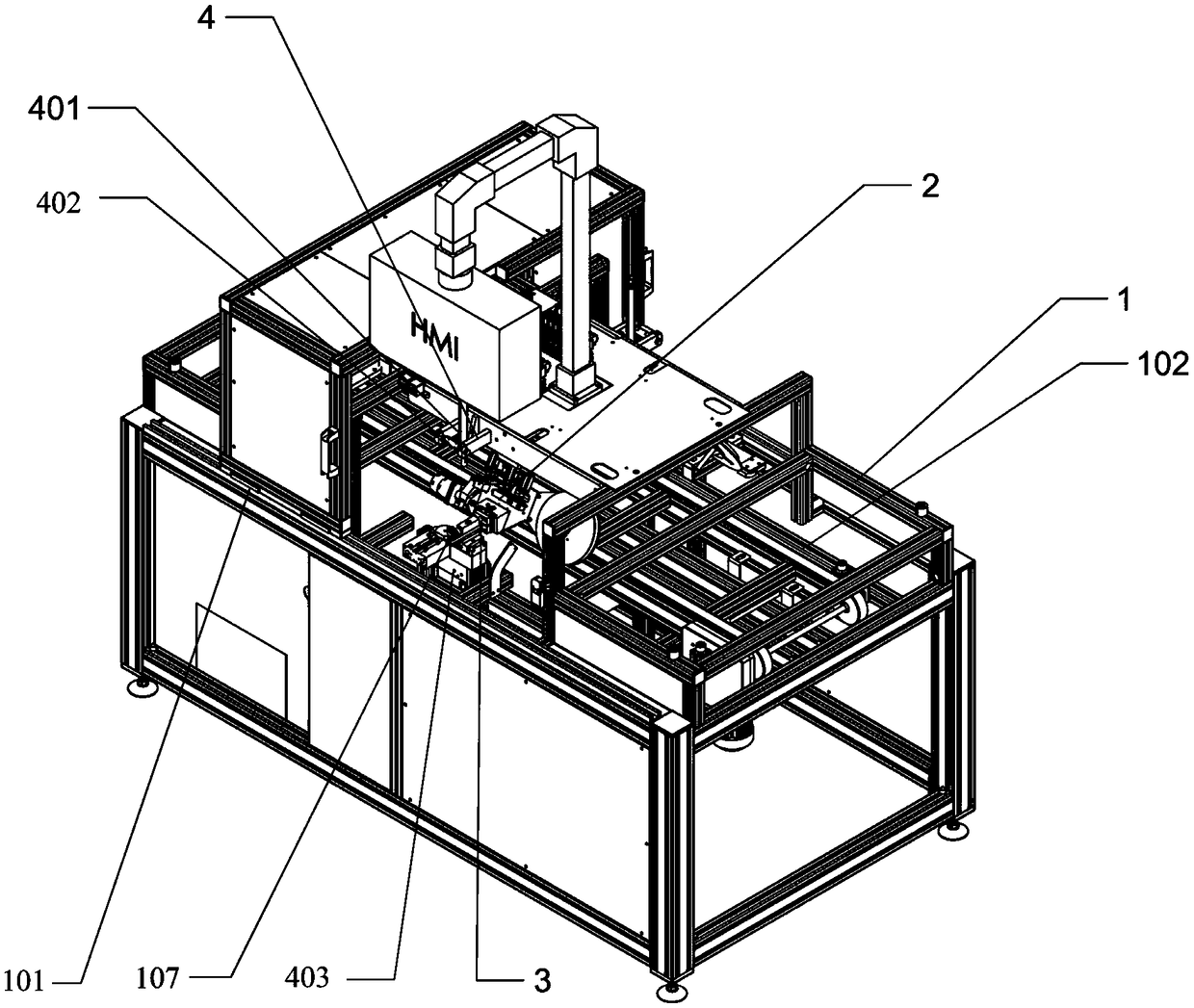

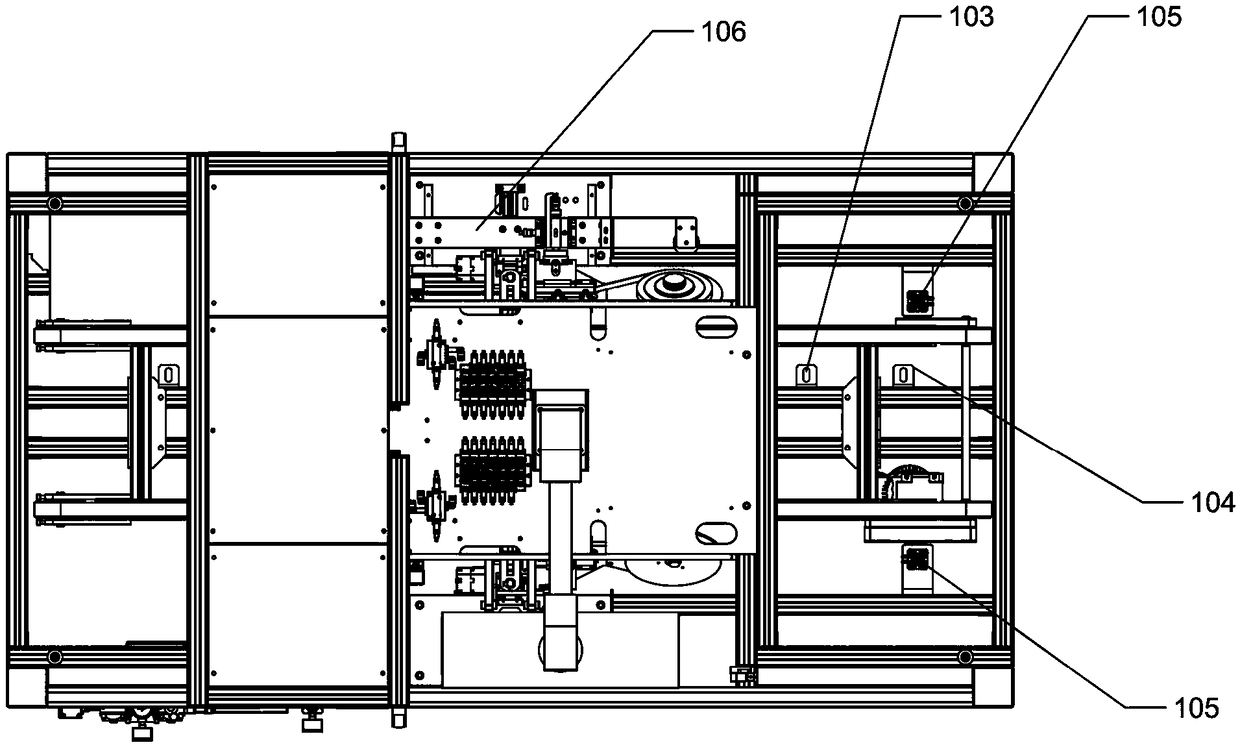

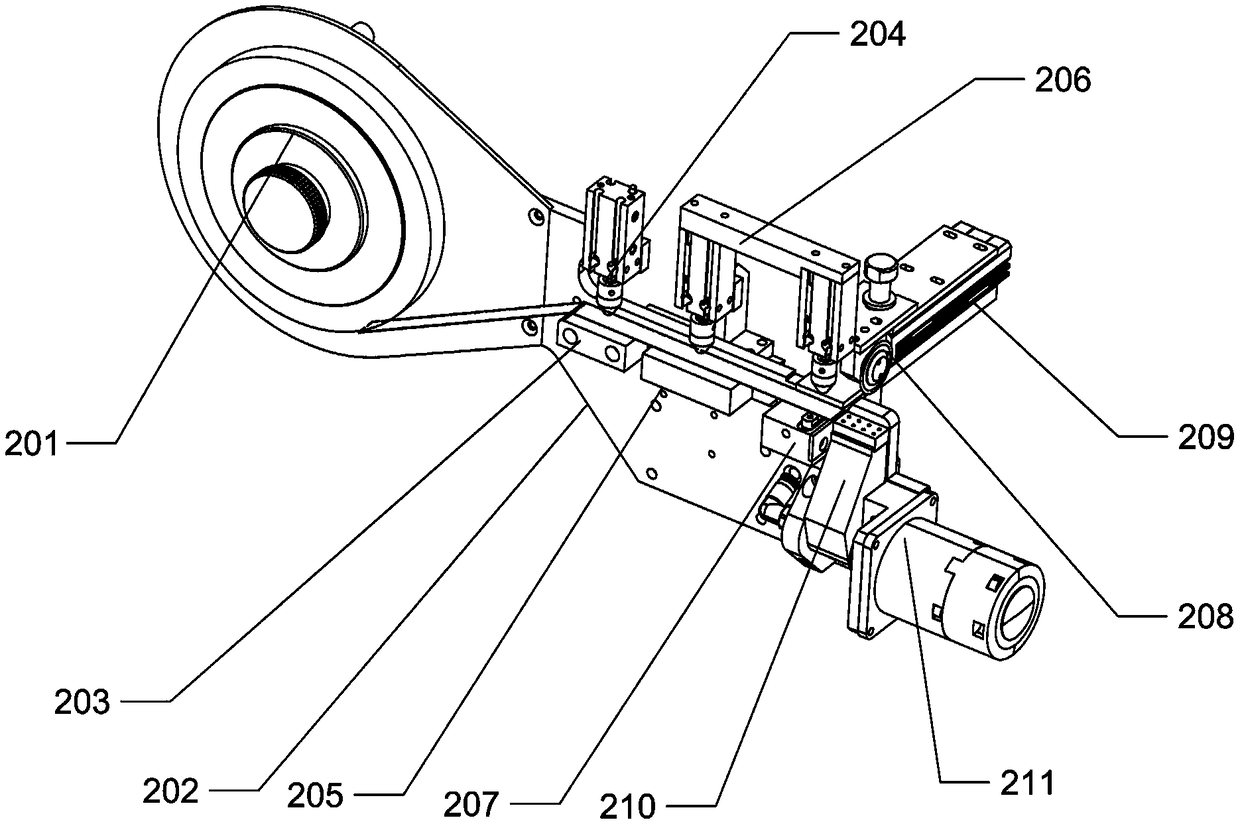

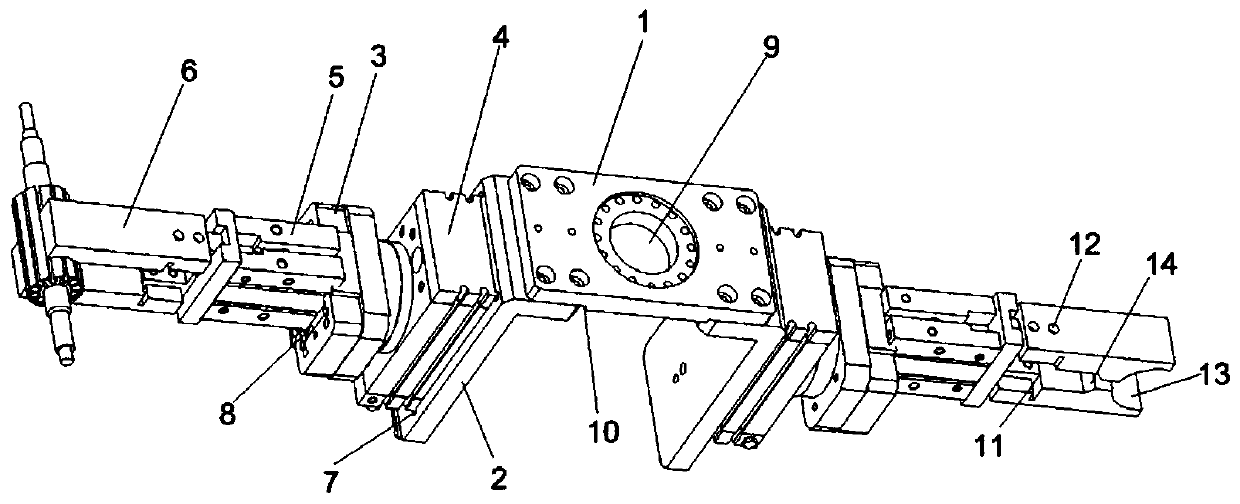

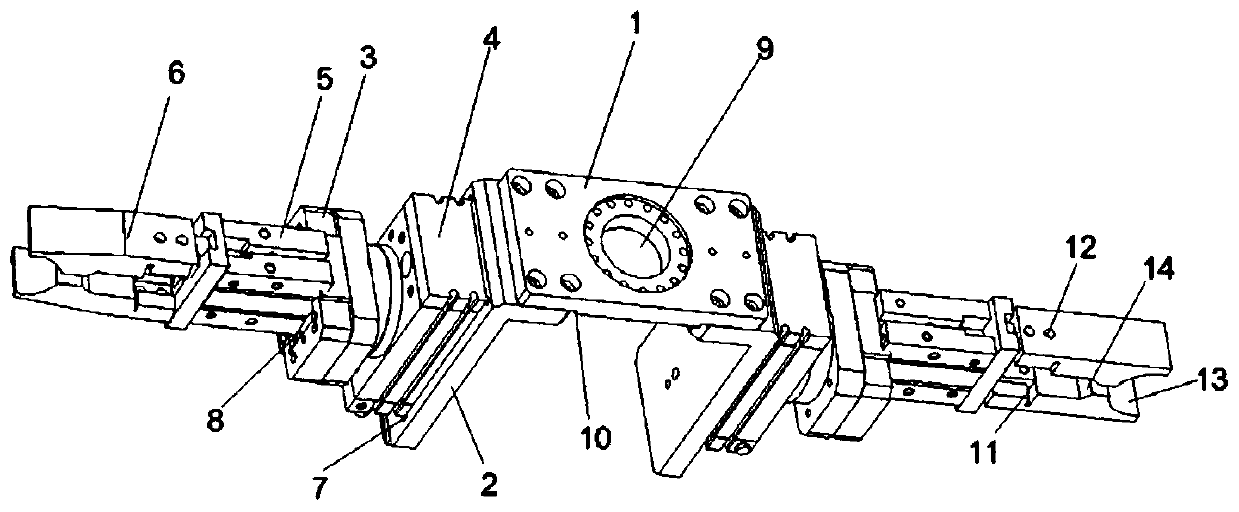

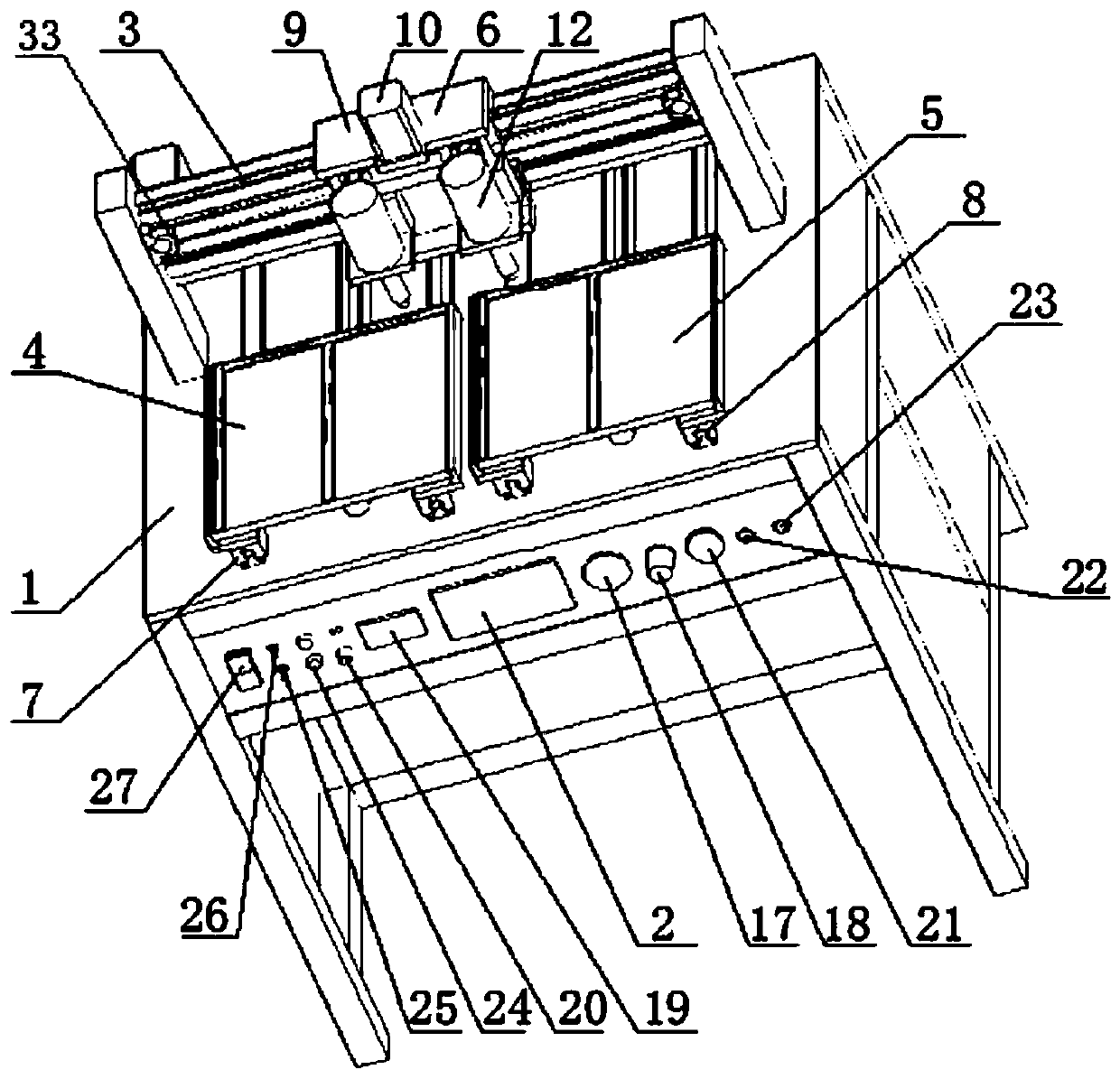

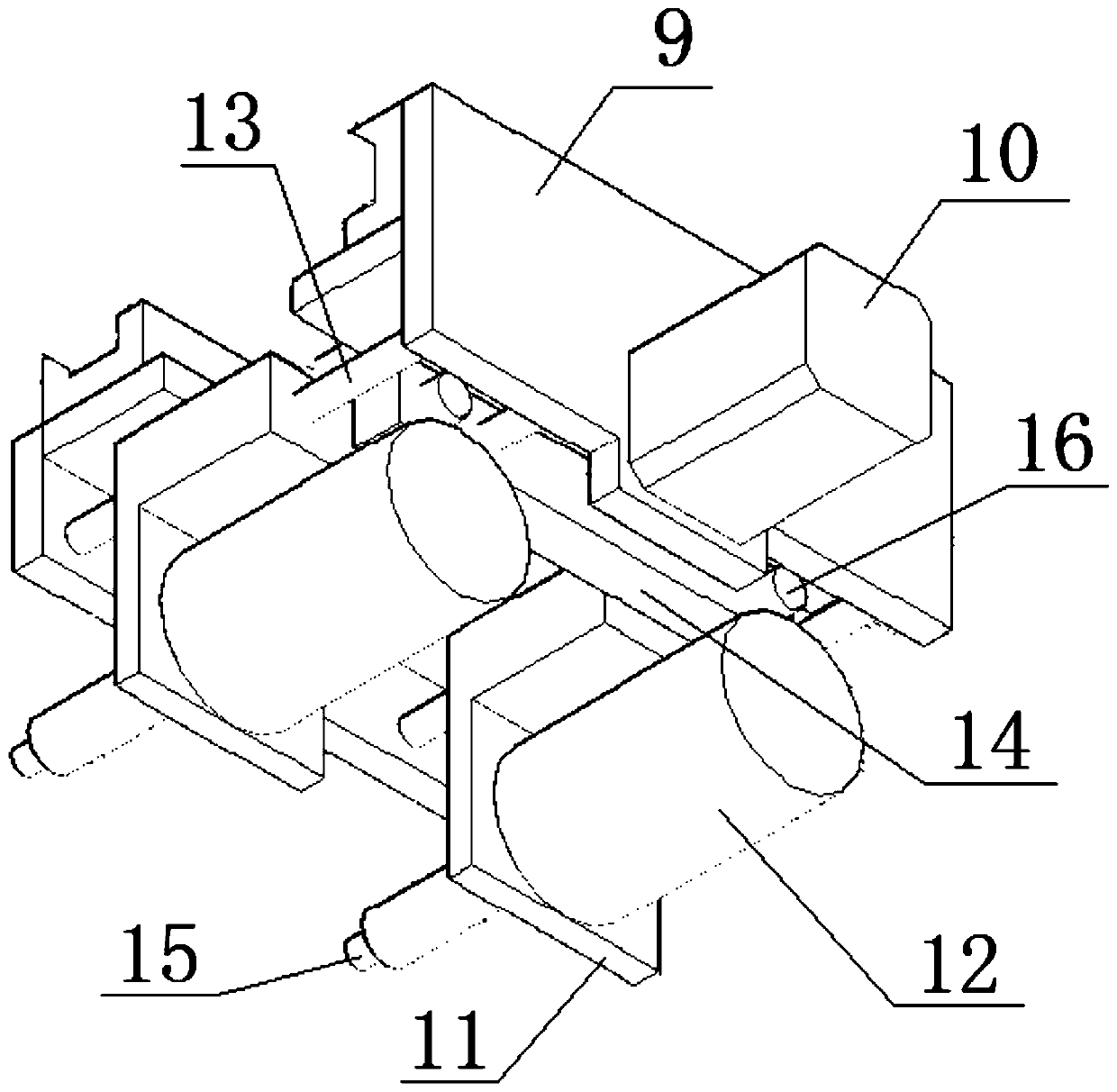

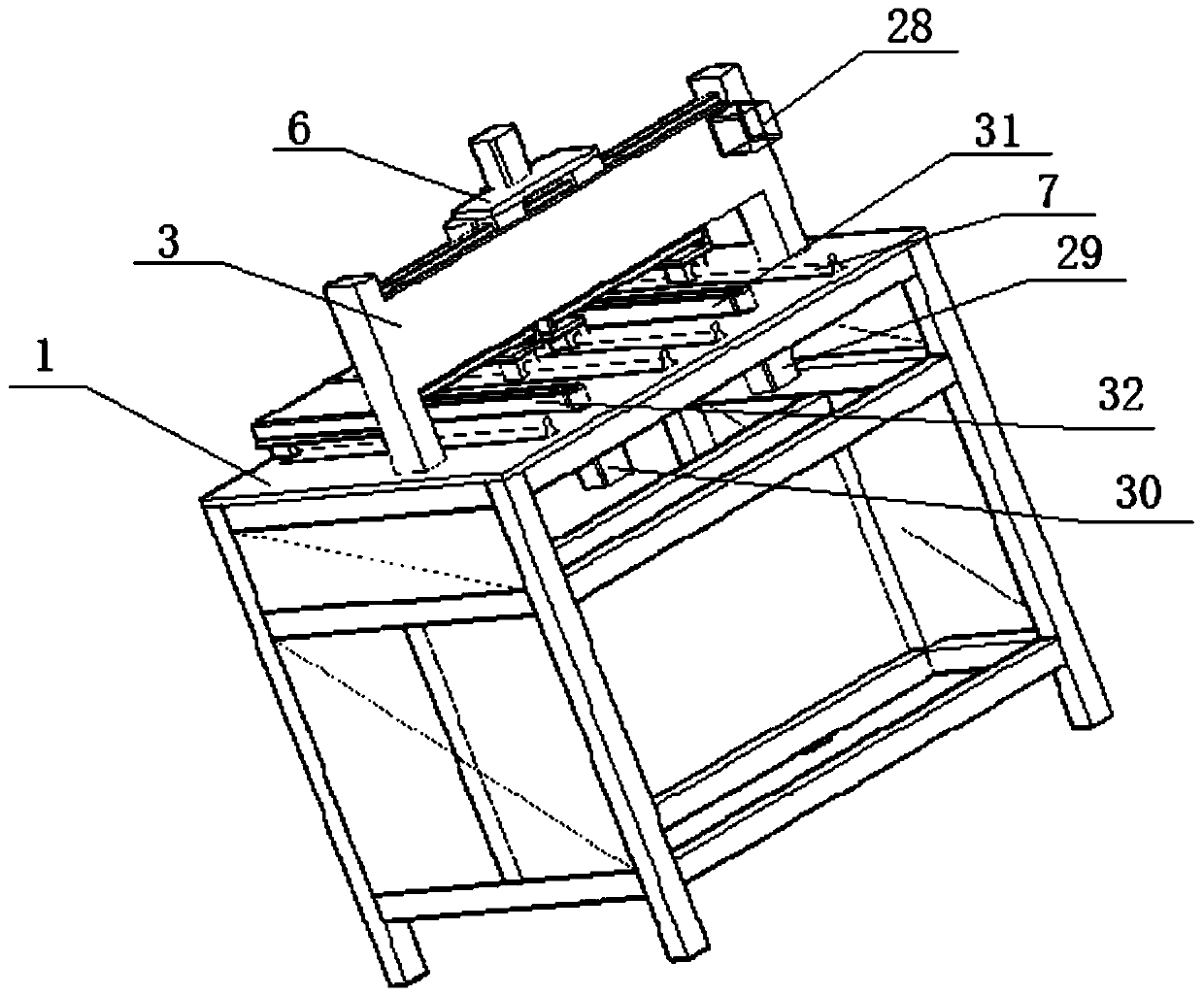

Device for adhering adhesive tape in CIGS glass substrate wiring hole

The invention relates to a device for adhering adhesive tape in a CIGS glass substrate wiring hole. The device comprises a conveying positioning module, an adhesive tape cutting and adhering module, apositioning and guiding module and an adhesive tape press-fit module; due to the cooperative work of the modules, the process requirement of full-automatic production from feeding, cutting and adhering to discharging is met; meanwhile, while the automatic cutting action on the adhesive tape is completed, automatic adhering of the adhesive tape is achieved through a downward pressing mechanism; acylinder output speed and pressure are convenient to adjust, and a downward pressing protecting mechanism is used for protecting glass; and compared with manual work, the takt is fast and stable in the whole process. The device adopting the structure can achieve automatic adhering operation of the adhesive tape in the CIGS glass substrate wiring hole, and can be applied to adhesive tape in variouswidths, the cutting length can be adjusted within a certain range, and the requirements of different processes can be met.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

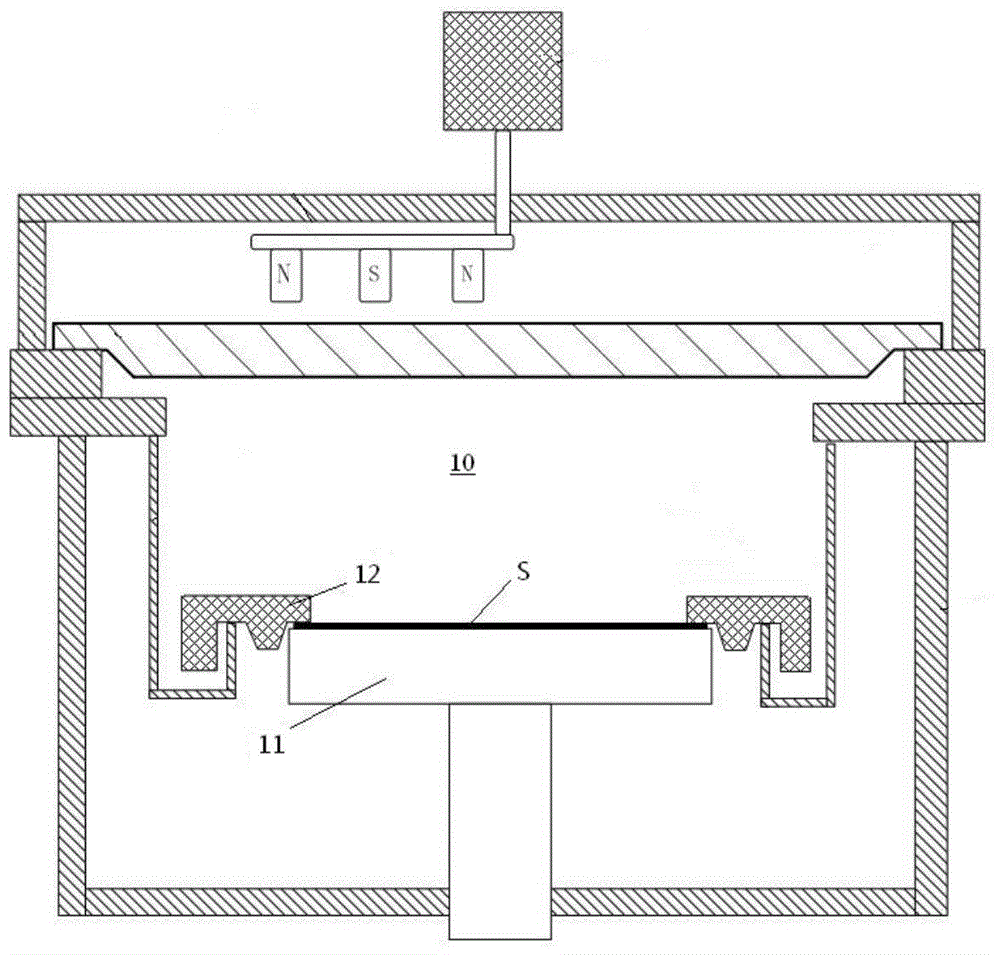

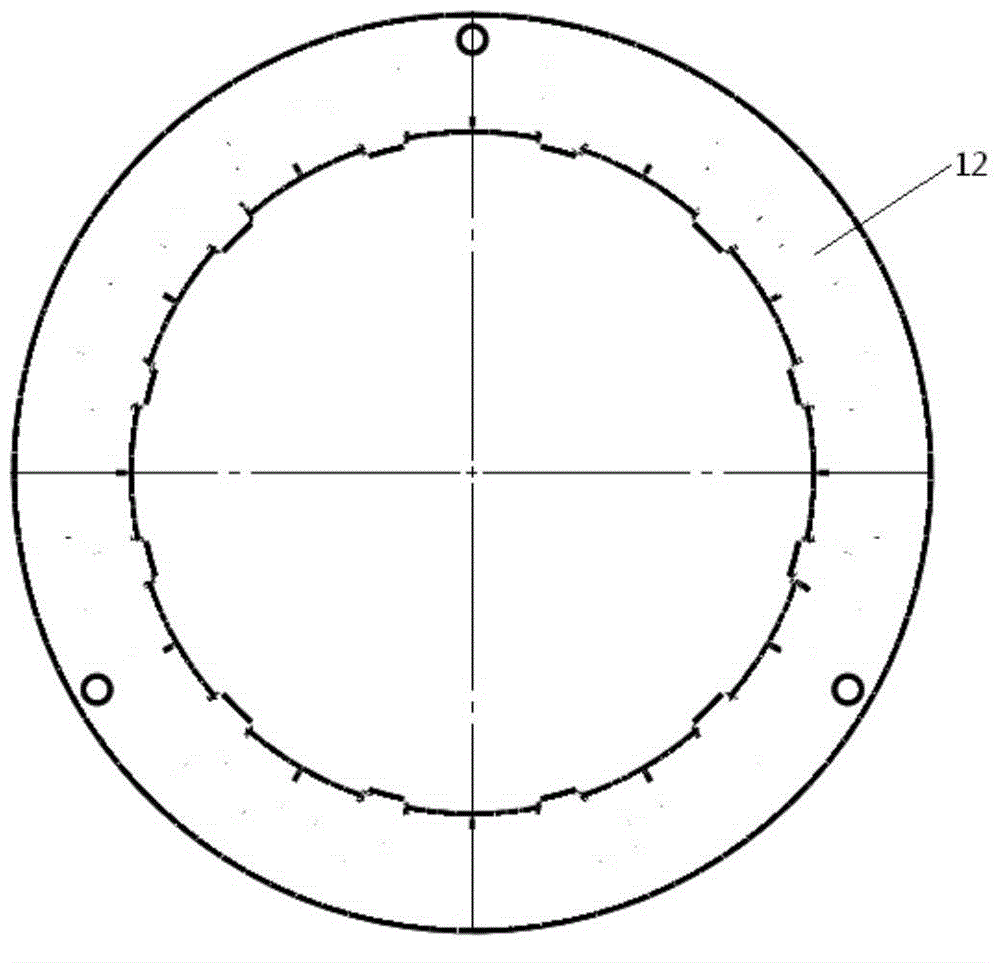

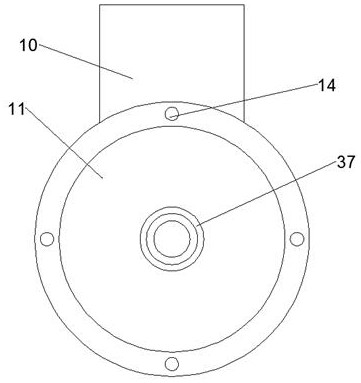

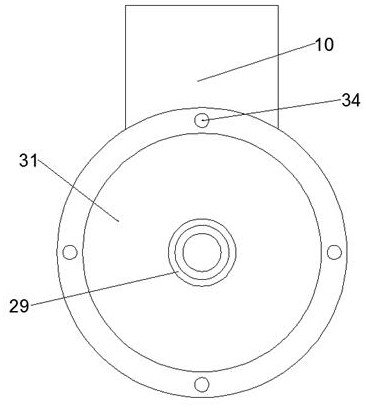

Pressure ring assembly and semiconductor processing equipment

InactiveCN106158698AMeet the needs of different processesMeet back pressure requirementsSemiconductor/solid-state device manufacturingElastic componentMetallic materials

The invention provides a pressure ring assembly and semiconductor processing equipment. The pressure ring assembly is used for cooperating with a base carrying a substrate in use, and comprises a pressure ring, a supporting member used for supporting the pressure ring, and an elastic component, wherein the pressure ring is used for laminating an edge region of the upper surface of the substrate, so as to fix the substrate; and the elastic component is fixed between the pressure ring and the supporting member, and a downward elastic force applied to the pressure ring is realized through stretching the elastic component when the substrate is fixed by the pressure ring. The pressure ring assembly provided by the invention does not need to satisfy a backpressure requirement through limiting the pressure ring to adopt heavy materials, nor to satisfy a backpressure requirement through increasing balance weight additionally, thus the pressure ring material can be extent to light metal or non-metallic materials so as to satisfy the requirements of different processes, thereby improving the applicability of the semiconductor processing equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Application of a kind of acid copper leveler

ActiveCN103924268BGood water solubilityEnvironmentally friendlyOrganic chemistrySolubilityLeveling effect

The invention discloses an application of an acid copper leveling agent. The molecular structural formula of the acid copper leveling agent is shown in the specification. In the formula, an anion X is Cl<-> or Br<->; R1 is O or S or N, and R2, R3 and R4 can be one of H, alkyl groups, alkenyl groups, aralkyl groups, heteroarylalkyl groups, substituted alkyl groups, substituted alkenyl groups, substituted aralkyl groups or substituted heteroarylalkyl groups. The acid copper leveling agent is used in adjustable surface morphology wafer electroplating. Novel acid copper leveling agent molecules having the advantages of good water solubility, colorlessness, non-toxicity and environmental protection are designed and developed, and are different from previous dye leveling agents, and the novel acid copper leveling molecules are compounded with a traditional leveling agent or other molecules having a leveling effect to form the acid copper leveling agent as a composite leveling agent in acid copper electroplating, so the effective control of the copper electroplating surface morphology is realized by blending the molecule concentration proportions of the composite leveling agent in a same chemical system in order to meet demands of different technologies.

Owner:SUZHOU SHINHAO MATERIALS

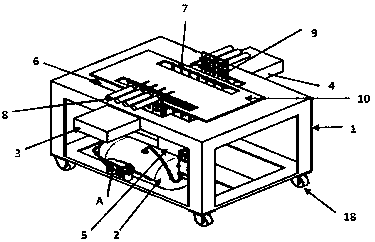

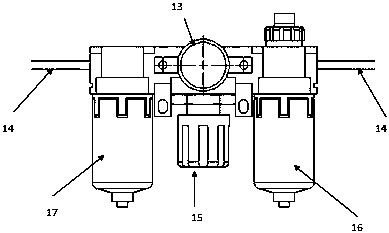

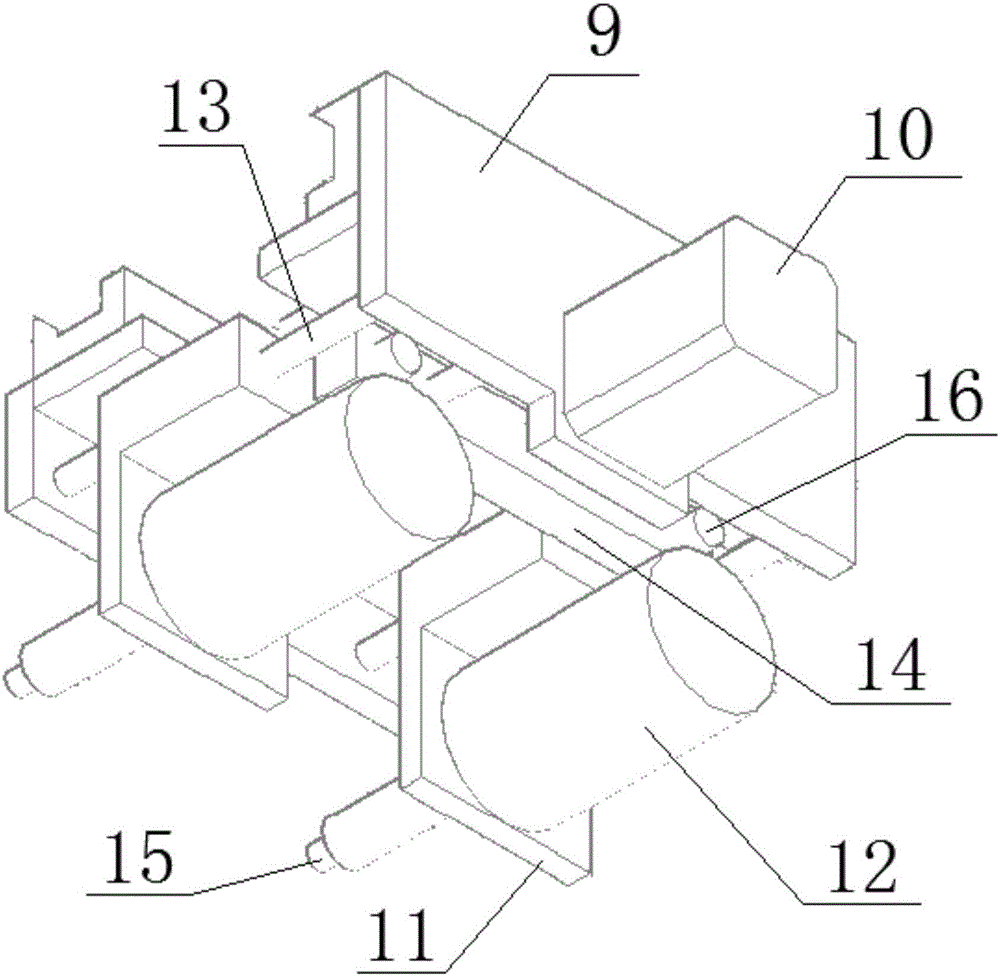

Automatic punching device for cylinder body water sleeve

InactiveCN108789623AImprove efficiencyThe punching process is stableFoundry mouldsFoundry coresCylinder blockBody water

The invention discloses an automatic punching device for a cylinder body water sleeve. The automatic punching device comprises a steel structure bracket, an air storage tank, a first air cylinder, a second air cylinder, a third air cylinder, universal wheels, an operating electric cabinet and a PLC program controller; the steel structure bracket comprises an upper platform and a lower platform, the air storage tank is arranged on the lower platform, a groove is formed in the middle of the upper platform, a positioning jig is arranged in the groove, and a first side face air drill and a secondside face air drill are arranged on the two sides of the positioning jig correspondingly; the first air cylinder and the second air cylinder are arranged at the edges of the two sides of the upper platform correspondingly, a bottom air drill is arranged at the bottom of the upper platform, the third air cylinder is also arranged at the bottom of the upper platform, and the third air cylinder drives the bottom air drill to vertically penetrate through the upper platform and the positioning jig; the air storage tank communicates with the first air cylinder, the second air cylinder and the thirdair cylinder through an air pipe; the air pipe is provided with an oil cup, a pressure gauge, a pressure adjusting valve and an air filter; and the PLC program controller is arranged on the upper sideof the operating electric cabinet, and the universal wheels are mounted at the bottom of the steel structure bracket.

Owner:苏州勤美达精密机械有限公司

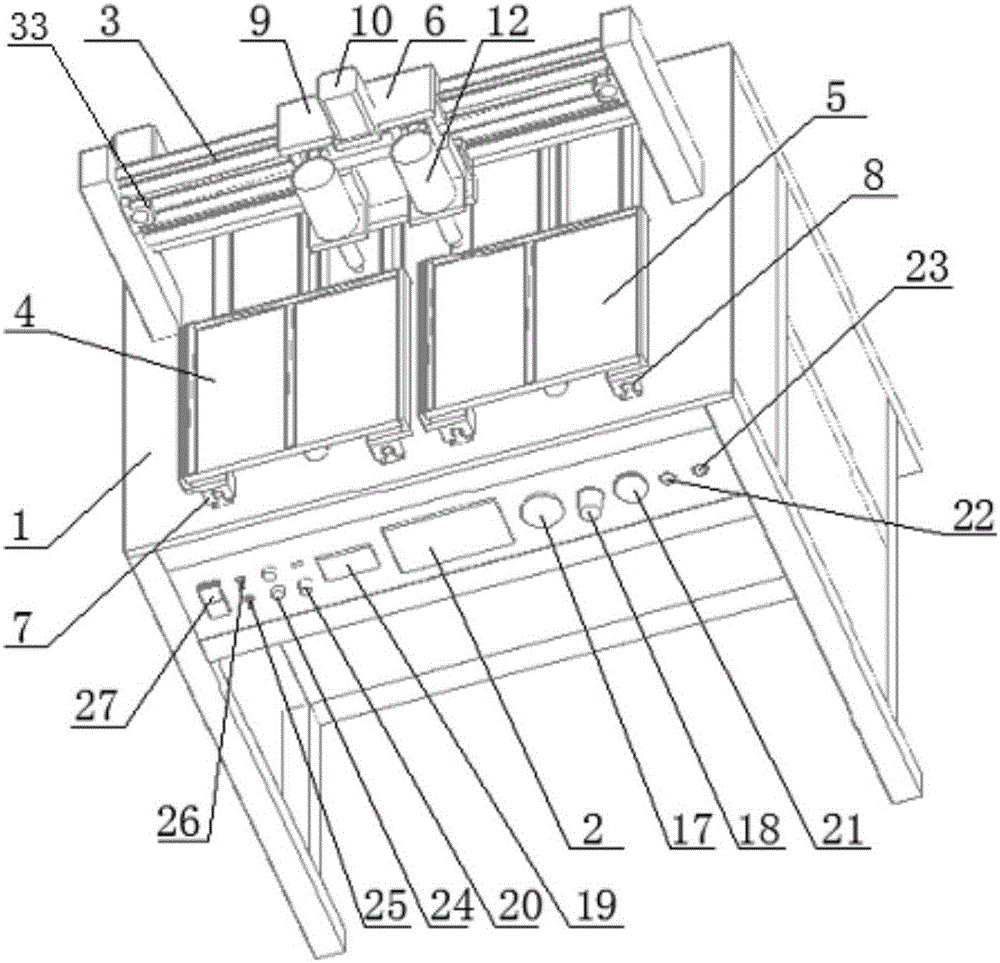

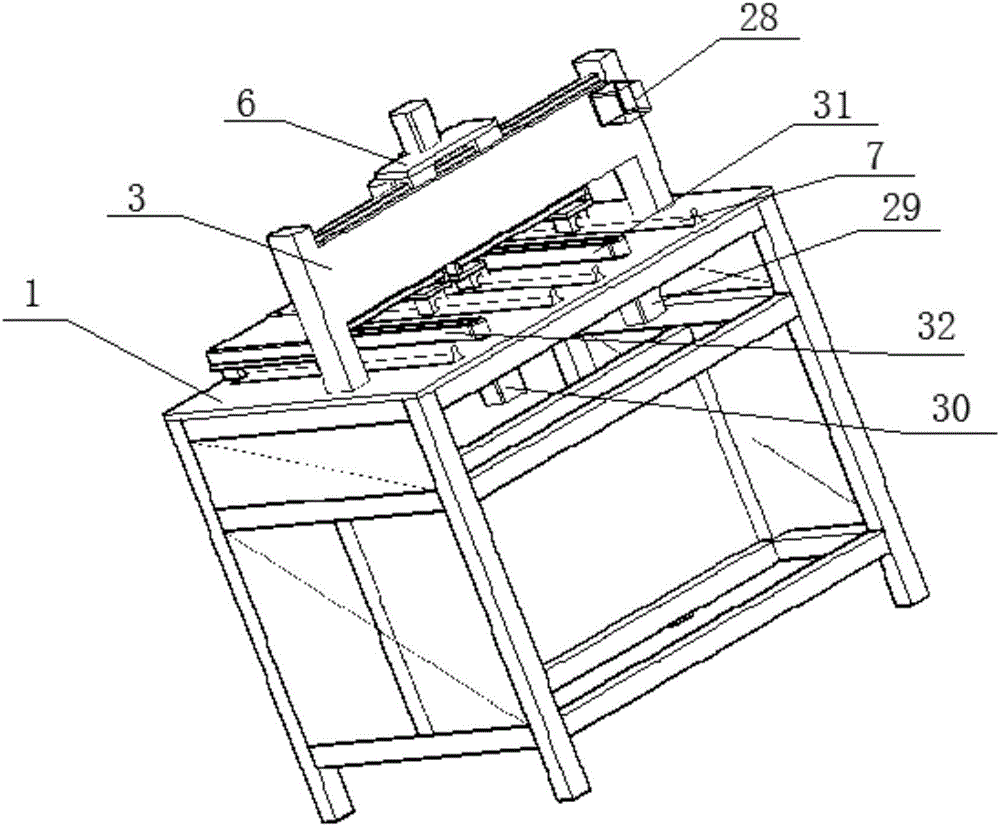

Full-automatic double-workbench plate wiping machine

ActiveCN106180021AQuality improvementFinish quicklyFlexible article cleaningCleaning using toolsWorking pressureMotion controller

The invention relates to a full-automatic double-workbench plate wiping machine. The full-automatic double-workbench plate wiping machine comprises a machine table, a motion controller, a truss, a first workbench, a second workbench and a plate wiping device. The motion controller is arranged in the machine table; the truss is transversely and fixedly arranged at the upper end of the machine table, and the plate wiping device is arranged on the truss and can move along the truss; the first workbench and the second workbench are longitudinally arranged at the upper end of the machine table side by side and can longitudinally move to the position below the truss; the first workbench, the second workbench and the plate wiping device are all controlled by the programmable motion controller; and the plate wiping device provides downward adjustable working pressure through a needle type air cylinder. Compared with the prior art, the double workbenches of the full-automatic double-workbench plate wiping machine can conduct plate wiping, and COB plate wiping work can be rapidly and stably completed with high quality.

Owner:深圳市拓普微科技开发有限公司

Mechanical arm clamp for motor rotor production

PendingCN111251330AMeet the needs of different operating environmentsEasy to operateProgramme-controlled manipulatorGripping headsRobot handElectric machinery

The invention relates to a part of motor production equipment, in particular to a mechanical arm clamp for motor rotor production. The mechanical arm clamp for motor rotor production comprises a rotating connecting plate and rotor clamping structures symmetrically mounted on the two ends of the rotating connecting plate, the rotor clamping structures comprise clamping claws, pneumatic fingers usedfor driving the clamping claws to be clamped or loosened and rotating air cylinders used for driving the pneumatic fingers to rotate, the pneumatic fingers are mounted on the rotating air cylinders through fixed plates, and the rotating air cylinders are mounted on the rotating connecting plate through mounting plates. The clamp is assembled with a mechanical arm through the rotating connecting plate, the clamp can carry out front, back, left, right, up and down moving and rotating in cooperation with the mechanical arm, the mechanical arm can conveniently assist a worker for operation, manual cost is reduced, labor intensity of the worker is reduced, product quality is ensured, meanwhile, the rotating air cylinders are adopted to drive the clamping claws to rotate, the clamping claws canindependently rotate, and different procedure needs during motor rotor machining and assembling can be met.

Owner:浙江精力工具有限公司

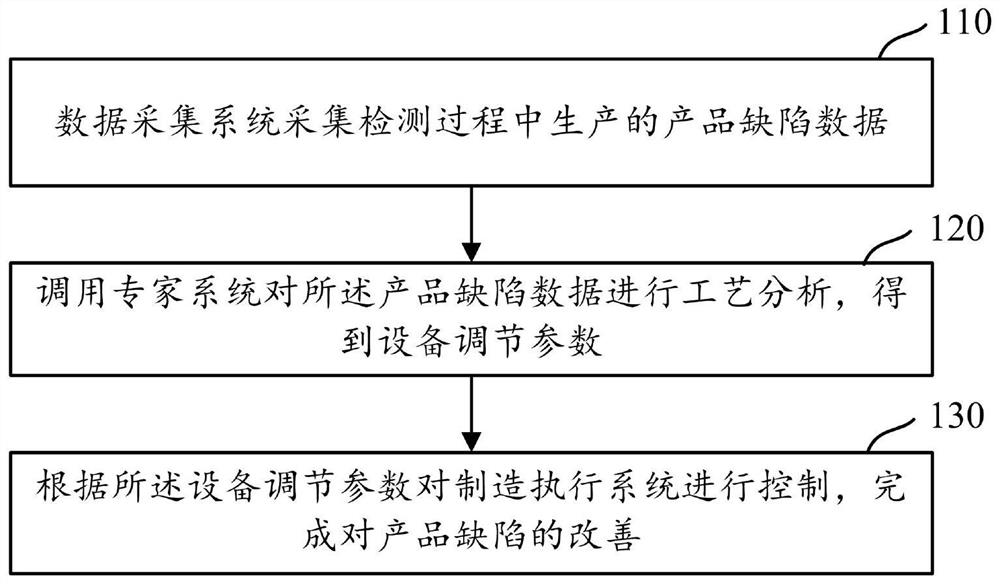

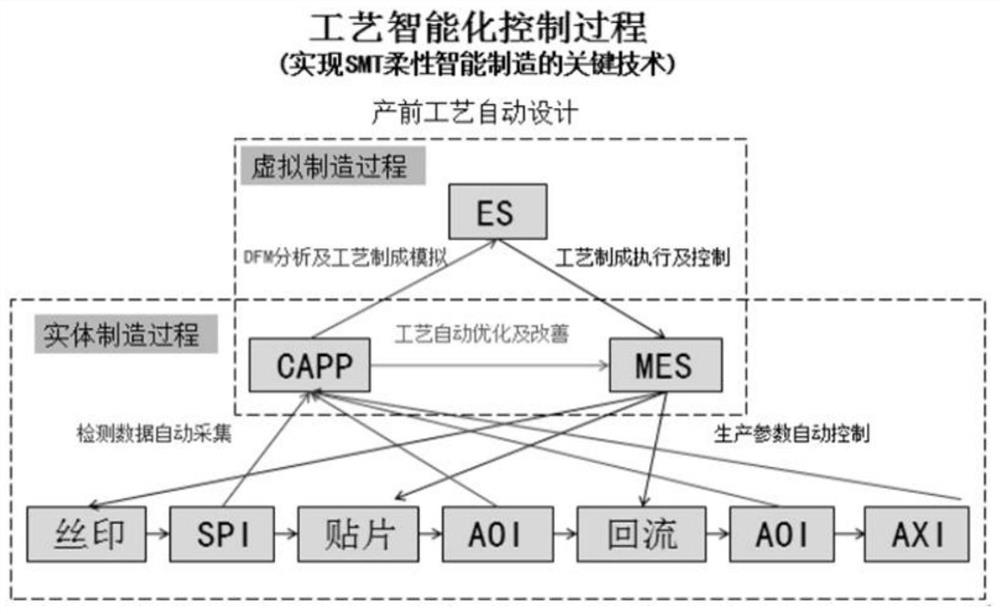

SMT intelligent process optimization control method

PendingCN112327790AImprove quick response abilityAdaptablePrinted circuit assemblingKnowledge representationProcess optimizationData acquisition

The embodiment of the invention discloses an SMT intelligent process optimization control method. The method is characterized in that the method comprises the steps that: a data collection system collects product defect data generated in a detection process; an expert system is called to carry out process analysis on the product defect data to obtain equipment adjustment parameters; and a manufacturing execution system is controlled according to the equipment adjustment parameters to finish improvement of product defects. According to the method of the invention, the quick response capabilityof the SMT process in a new product import process can be improved, so that an SMT mounting production line has stronger product adaptability, and meets the requirements of different products for different process procedures.

Owner:TELECOM TECH INSTR RES INST

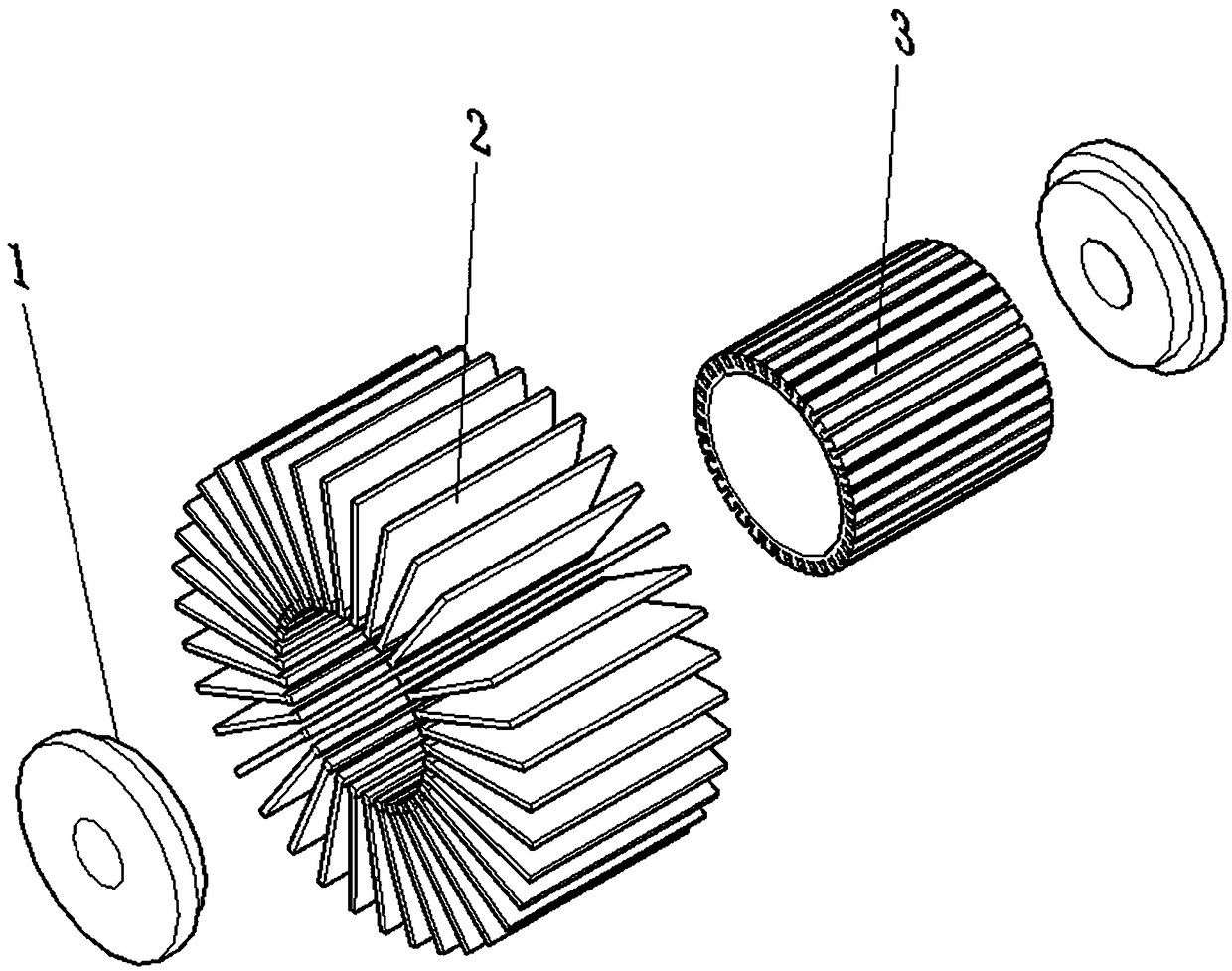

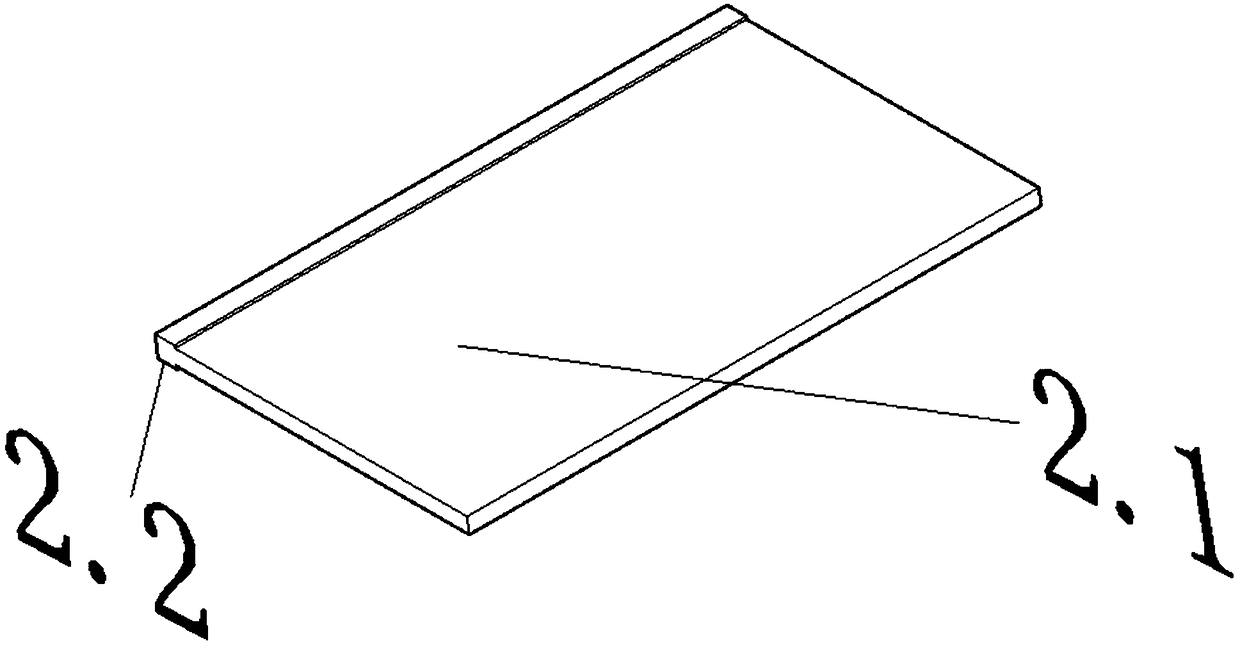

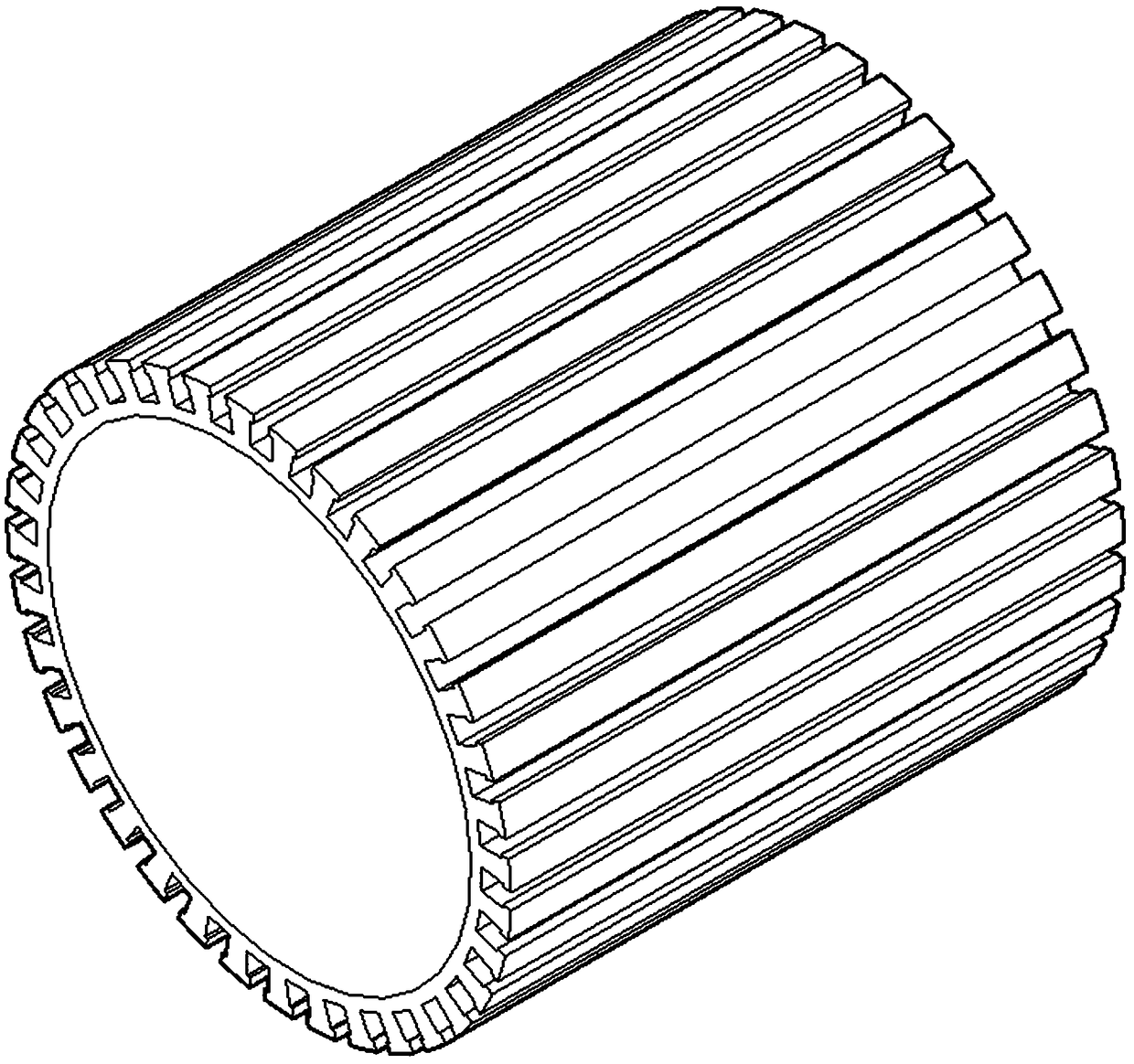

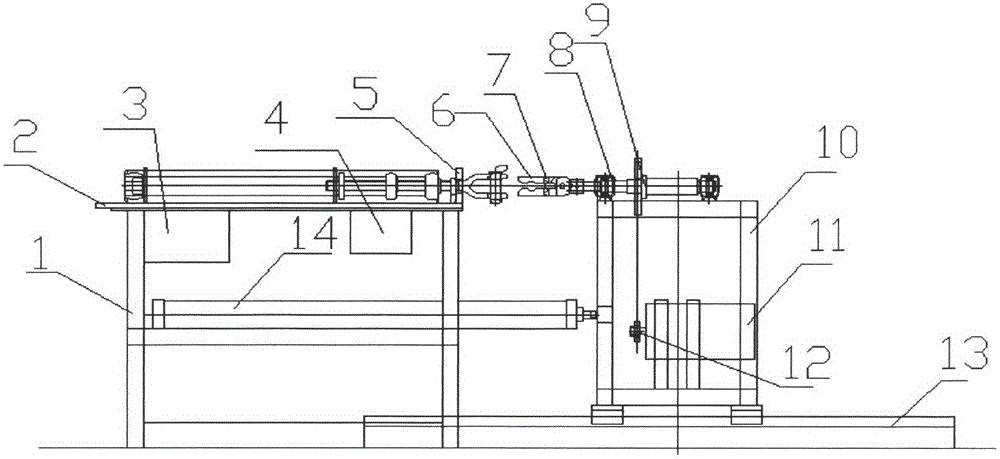

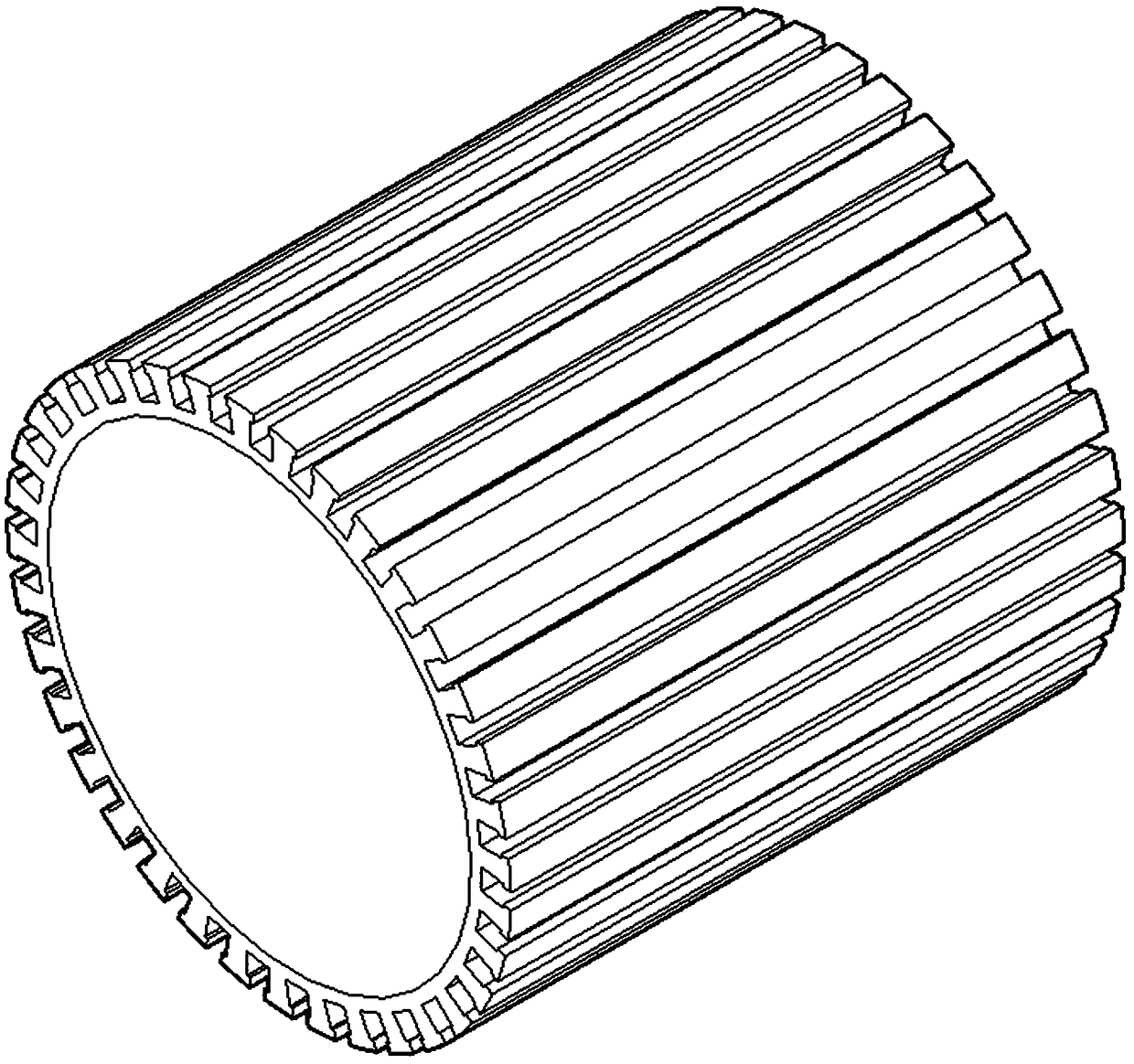

Novel grinding tool

PendingCN109108847AMeet the needs of different processesGood processing effectSupport wheelsEngineering

The invention discloses a novel grinding tool. The novel grinding tool comprises a grinding core (3), the periphery of the grinding core (3) is detachably provided with a grinding brush (2), and the periphery of the grinding core (3) is provided with at least one connection groove (3.1) in the radial direction or the circumferential direction. According to the novel grinding tool, a detachable arrangement manner is adopted to perform coordination of the grinding core and the grinding brush, replacement can be performed when any one of the grinding core and the grinding brush is damaged, so that the use cost is effectively lowered.

Owner:四会市冠源机械科技有限公司

Etching electrodes and edge etching devices

ActiveCN108470670BAdjust the occlusion areaMeet the needs of different processesElectric discharge tubesEngineeringMechanical engineering

The invention relates to an etching electrode and an edge etching device; the etching electrode comprises the following parts: an electrode body including a pedestal and a projection electrode arranged on the pedestal, wherein the projection electrode top is the electrode surface, and an annular groove is formed between the pedestal and the projection electrode; at least one shield ring embedded inside and outside the electrode body in an encircling manner, and the at least one shield ring is located in the annular groove; a drive unit connected with the shield ring and used for controlling each shield ring to move up and down in the direction vertical to the electrode surface, wherein in rising, the shield ring moves to the electrode surface direction, and in descending, the shield ring moves to the pedestal direction.

Owner:淮安西德工业设计有限公司

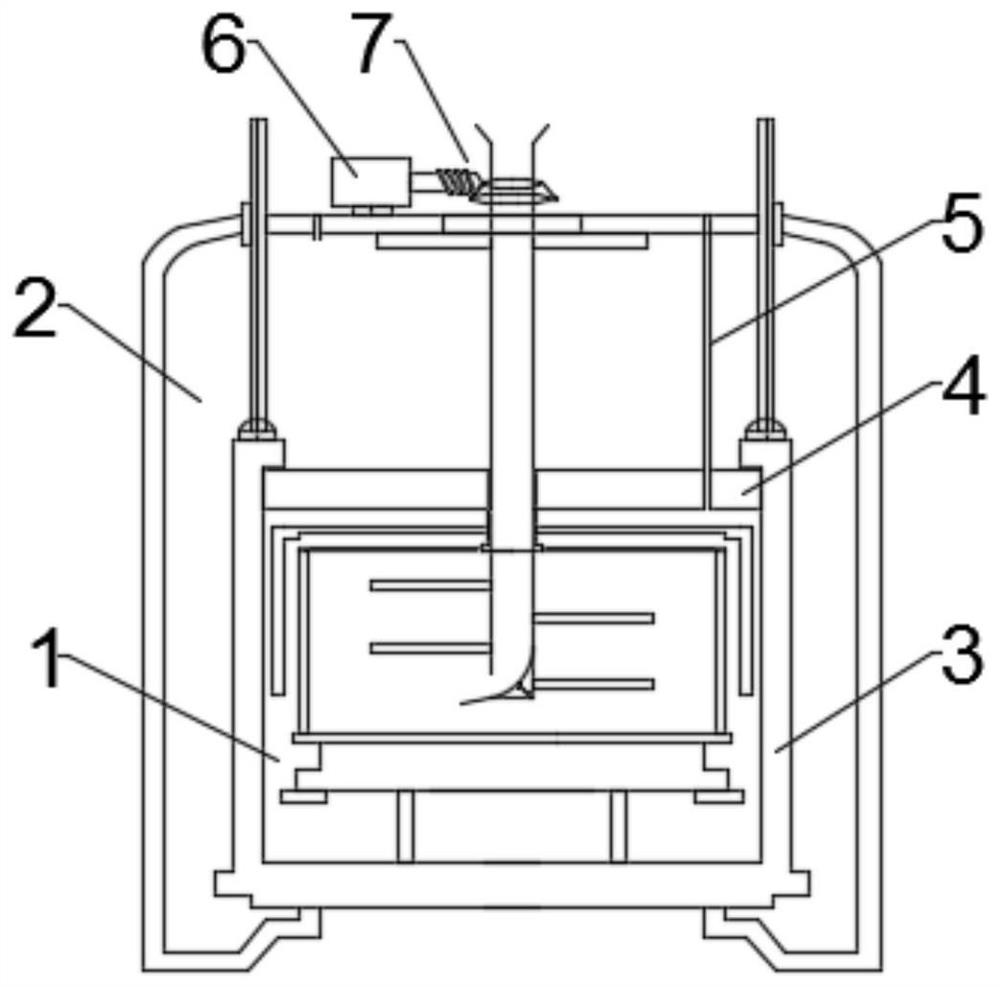

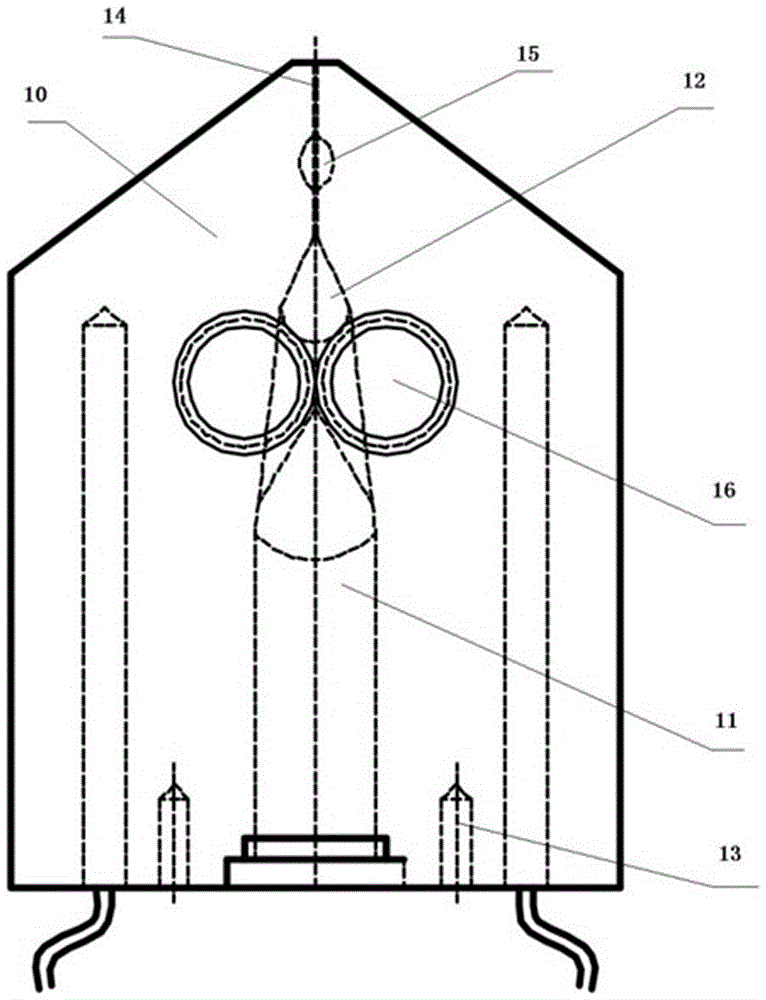

Anisotropic conductive solder paste and its preparation method and integrated preparation device

ActiveCN112122822BImprove thermal conductivityPrevent extrusionWelding/cutting media/materialsMetal working apparatusPolymer resinAdhesive

The invention relates to an anisotropic conductive solder paste, which comprises tin-bismuth-silver solder balls, adhesives, polymer resins, interstitial particles and auxiliary additives; the preparation method comprises the following steps: placing a reactor in a protective gas environment and Add components to the reactor in sequence, then fully mix, then carry out differential settlement, and finally add curing agent and auxiliary agent for vacuum degassing; the preparation device includes an inner operating chamber and an outer environment chamber, the inner operating chamber It includes a differentiation base and a fusion chamber, the fusion chamber is installed with a rotary shear feeding pipe, the differentiation base includes a hydraulic telescopic support, a chassis is fixedly installed on the top of the hydraulic telescopic support, and several distribution boxes are installed on the chassis. Uniform and mutually independent vibrating pieces; the invention disperses low-melting tin-bismuth-silver solder balls in the adhesive to form anisotropic conductive solder, the preparation process is simple, and seamless processing is realized through the integrated preparation device, improving product quality.

Owner:深圳远芯光路科技有限公司

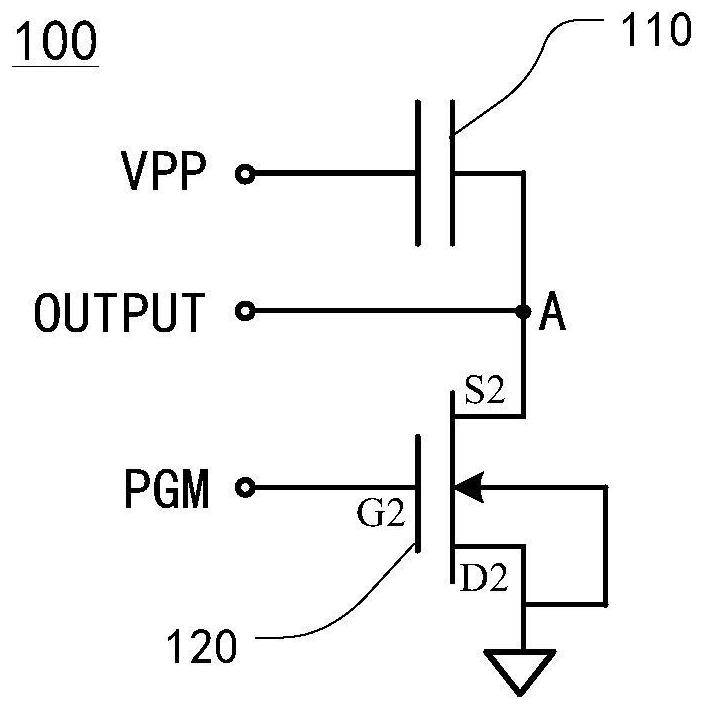

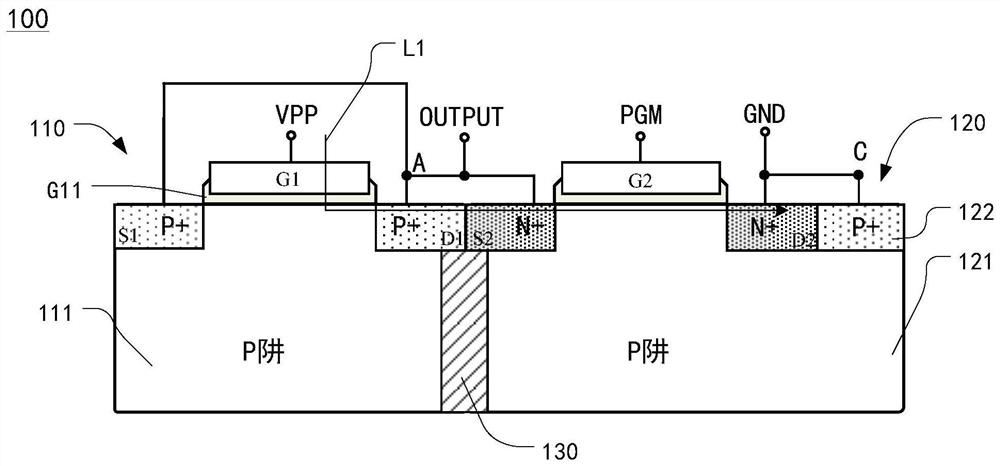

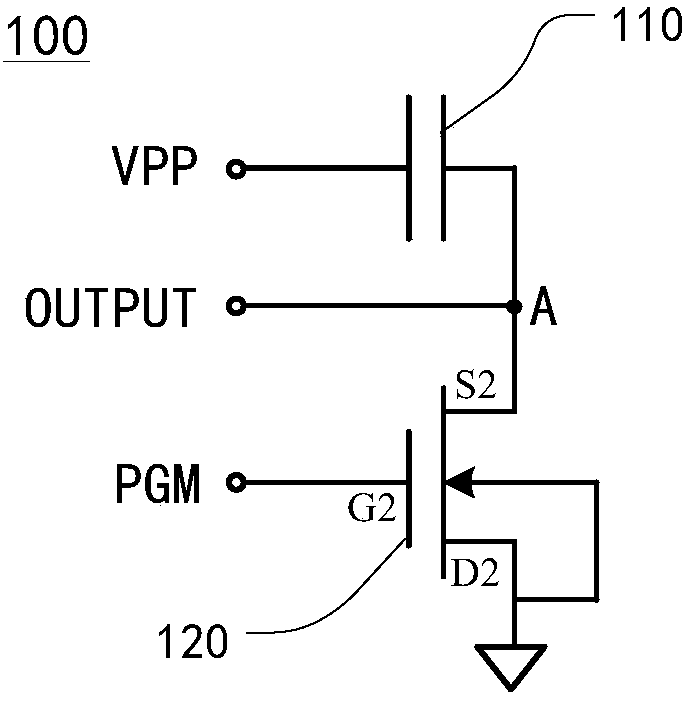

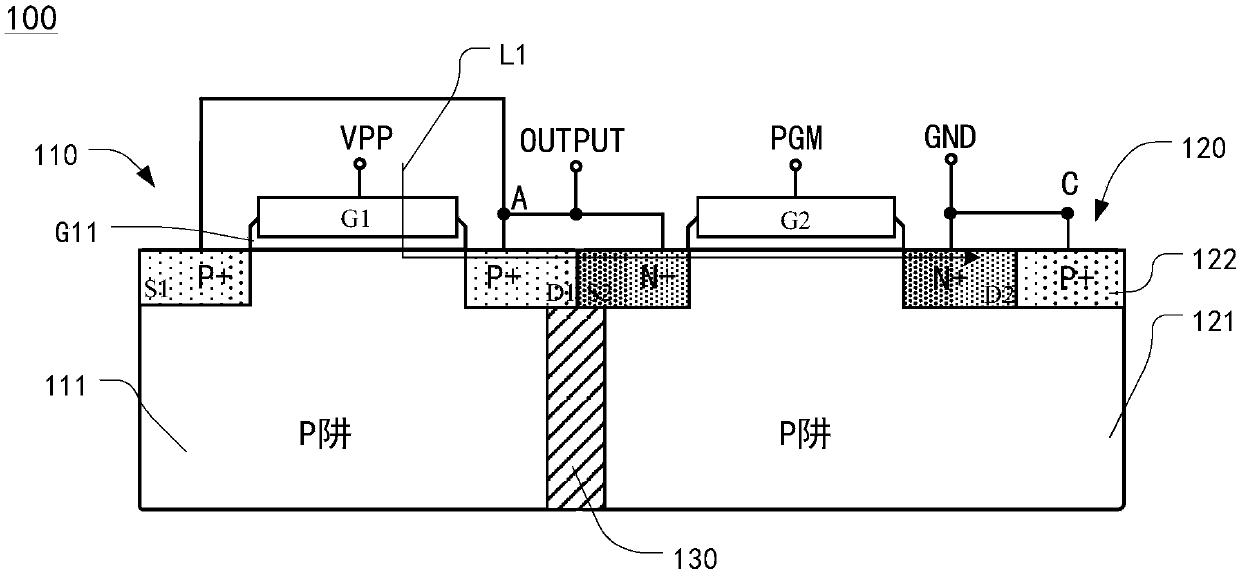

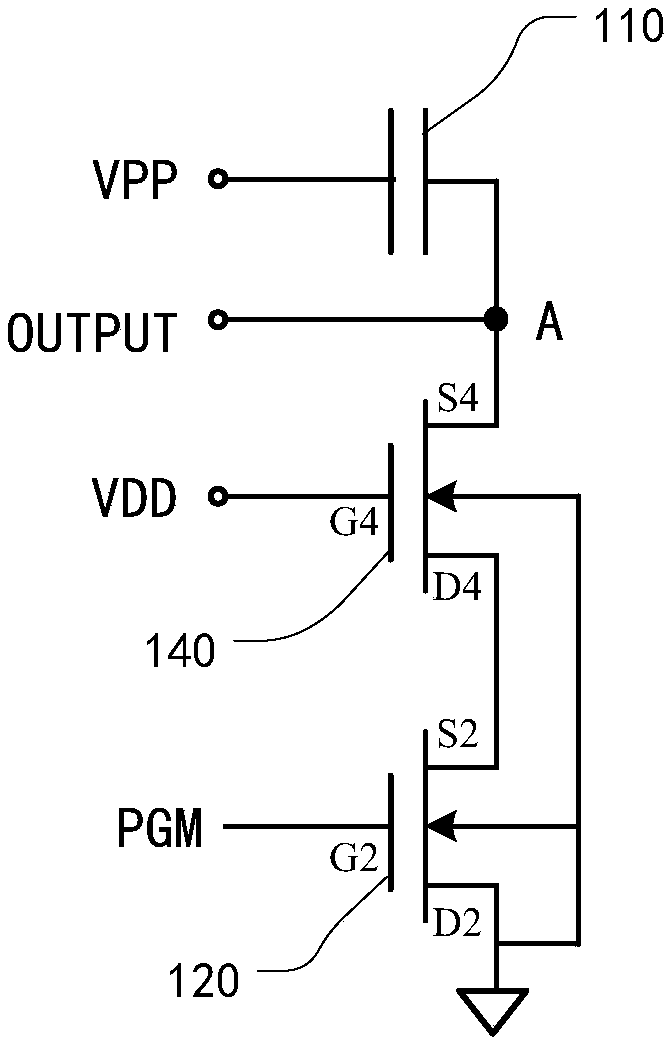

One-Time Programmable Non-Volatile Fuse Memory Unit

The present invention provides an OTP non-volatile fuse storage unit comprising an accumulation type MOS transistor varactor, the gate of which is connected to a programming voltage, and the source and drain of which are connected together to form a first connection point; and a selection transistor , the gate of which is connected to the control signal, the source is connected to the first connection point, and the drain is grounded; wherein, when the selection transistor is turned on under the control of the control signal, a programming voltage greater than the threshold voltage is applied to The gate of the accumulator MOS transistor varactor is maintained for a predetermined period of time to change at least one physical characteristic of the accumulator MOS transistor varactor, so that the logic level output by the first connection point is changed. The OTP non-volatile fuse storage unit of the present invention can realize OTP through the fuse principle, and does not need additional masks, can meet the requirements of different manufacturing processes of CMOS technology, and provide diversified OTP solutions.

Owner:CHANGXIN MEMORY TECH INC

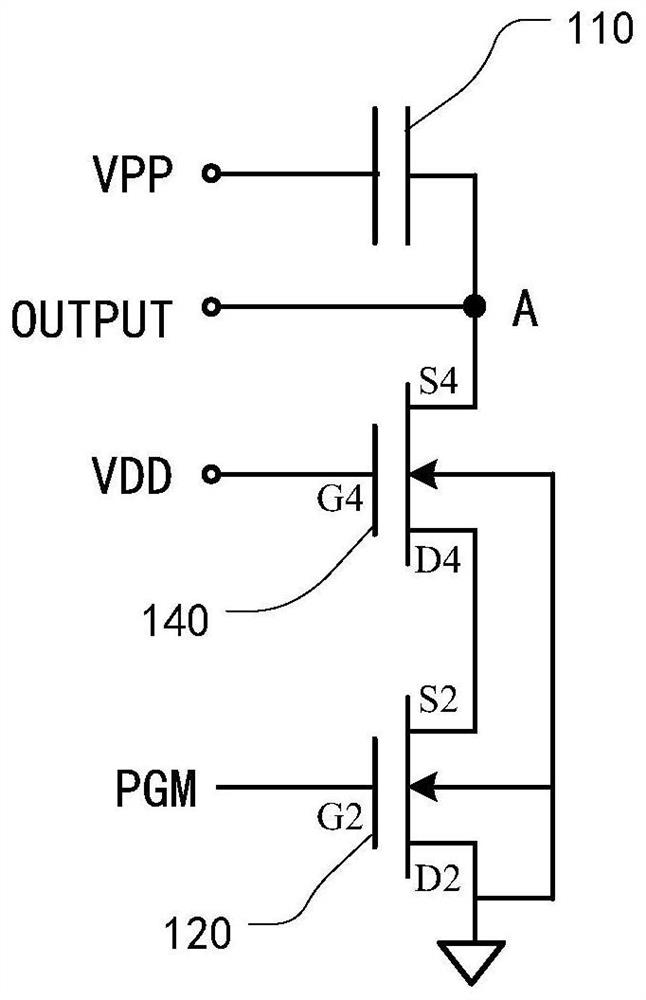

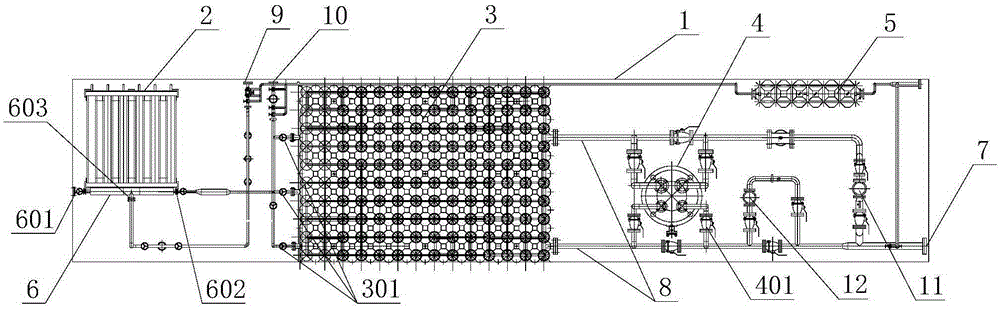

LNG vaporizing, pressure-regulating and metering prizing tool and operation method thereof

ActiveCN104197184AImprove work efficiencyExtended service lifePressure vesselsContainer discharging from pressure vesselsControl engineeringInlet valve

The invention discloses an LNG vaporizing, pressure-regulating and metering prizing tool which comprises a base; an unloading pressurizing device, an air-heated vaporizer, an electric-heating heater and an air-heated EAG heater are arranged along the length direction of the base in sequence; a first main pipe is horizontally arranged on one side of the unloading pressurizing device; a first air inlet and a first air outlet are formed in two ends of the first main pipe; a second air outlet is formed in the middle of the first main pipe; a second air outlet branch is connected with a natural gas outlet by the air-heated EAG heater; the first air outlet is connected with a first air outlet branch in a conduction manner by a pipeline; the first air outlet branch extends from the second air outlet; the air-heated vaporizer comprises at least one air outlet which is connected to the natural gas outlet by the electric-heating heater; liquid inlet valves are arranged on connection parts of first to third liquid inlets of the air-heated vaporizer and the pipeline. The invention also provides an operation method of the LNG vaporizing, pressure-regulating and metering prizing tool; the working efficient is improved, requirements of different processes can be met, and the service life is long.

Owner:江苏大昌燃气设备有限公司

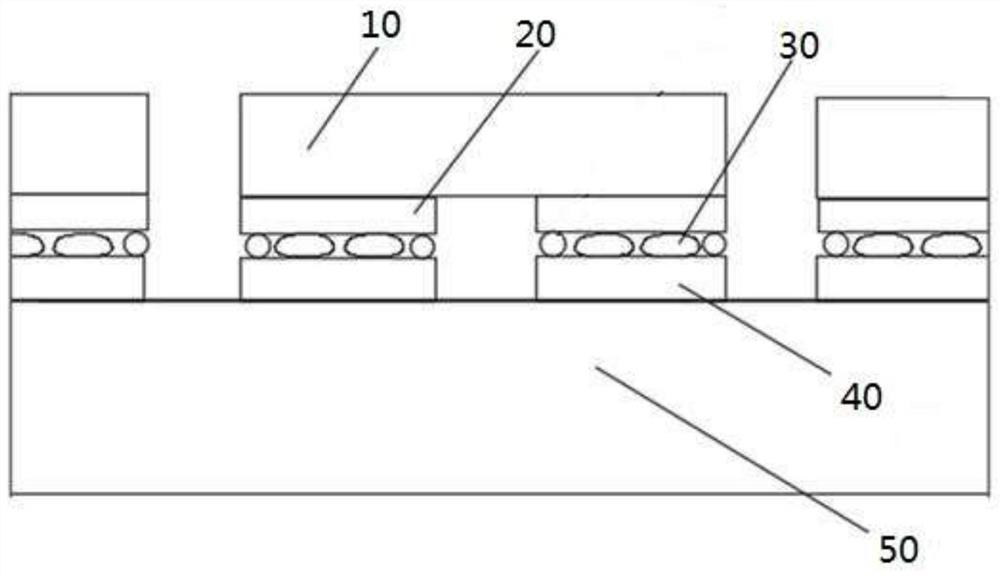

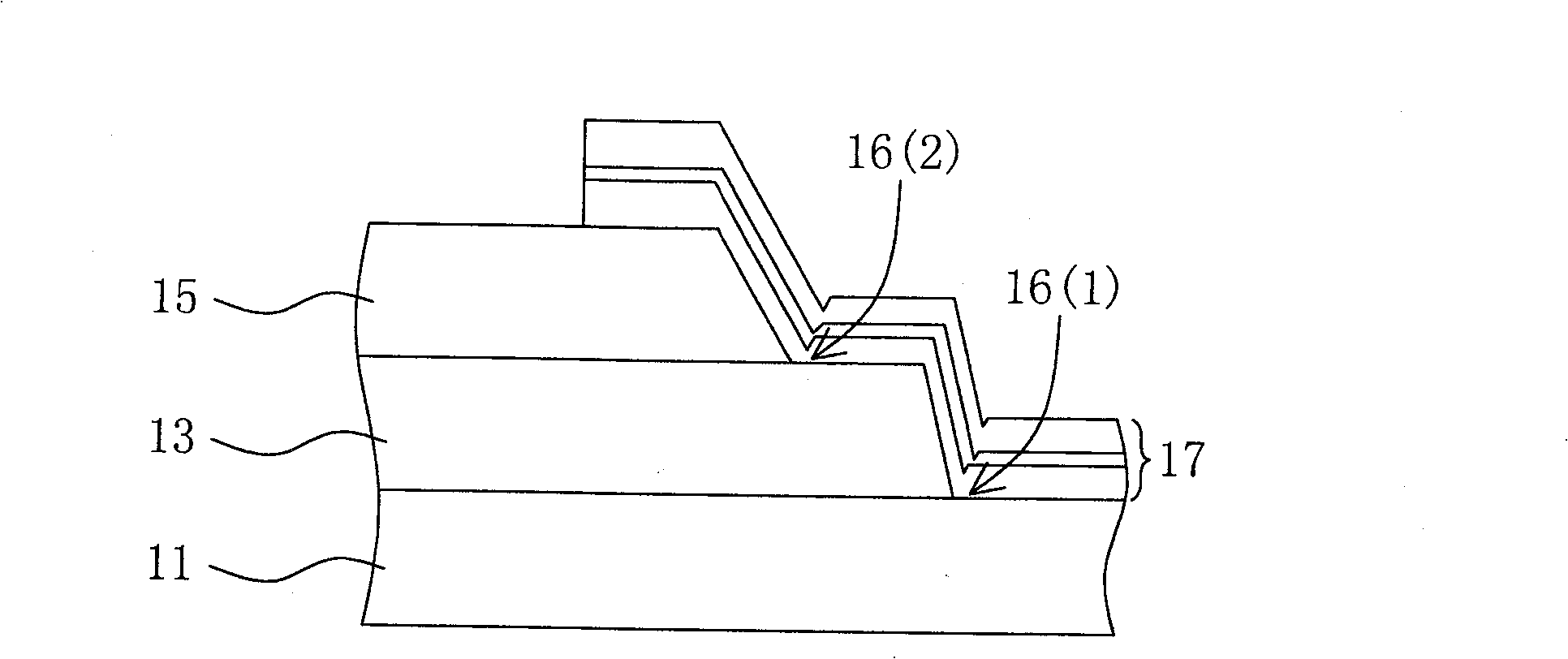

Wafer structure and forming method thereof

ActiveCN100541751CImproved stacking capabilitiesImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

Owner:ADVANCED SEMICON ENG INC

Double-acting combined type cylinder moving hydraulic oil cylinder suitable for minitype hydraulic machine

InactiveCN109058220AAchieve normal workImplement backhaulFluid-pressure actuatorsCylinder blockPiston rod

The invention belongs to the related technical field of hydraulic transmission and control and discloses a double-acting combined type cylinder moving hydraulic oil cylinder suitable for a minitype hydraulic machine. The hydraulic oil cylinder comprises a cylinder body, a plunger piston, a piston rod and a piston, wherein one end of the cylinder body is formed with a working cavity, one end of theplunger piston is provided with a blind hole, the other end of the plunger piston is provided with a first oil hole communicating with the blind hole, the plunger piston is further provided with a second oil hole and a third oil hole, the second oil hole and the third oil hole are arranged around the blind hole, the second oil hole runs through the plunger piston, the third oil hole runs throughthe hole wall of the blind hole, one end of the piston rod is fixedly connected to the cylinder body, the other end of the piston rod is connected to the piston, the piston is arranged inside the blind hole, the end, away from the first oil hole, of the plunger piston is arranged inside the working cavity, and the hydraulic oil cylinder realizes pressure and speed classification by controlling oilinlet and outlet states of the first oil hole, the second oil hole and the third oil hole. The double-acting combined type cylinder moving hydraulic oil cylinder suitable for the minitype hydraulic machine can realize the pressure and speed classification and is high in practicability and simple in structure.

Owner:HUAZHONG UNIV OF SCI & TECH

A one-time programmable non-volatile fuse memory cell

ActiveCN109903802AMeet the needs of different processesEasy to understand implementationRead-only memoriesCMOSControl signal

The invention provides: an OTP non-volatile fuse memory cell, which comprises a cumulative MOS transistor varactor, of which the grid electrode is connected to a programming voltage, and the source electrode and the drain electrode are connected together to form a first connection point; a selection transistor, wherein The grid electrode of the selection transistor is connected to the control signal, the source electrode of the selection transistor is connected to the first connection point, and the drain electrode of the selection transistor is grounded; When the selection transistor is controlled by the control signal to be turned on, a programming voltage greater than a threshold voltage is applied to the gate of the cumulative MOS transistor varactor and maintained for a predeterminedperiod of time to change at least one physical characteristic of the cumulative MOS transistor varactor, thereby changing a logic level output by the first connection point. According to the OTP nonvolatile fuse memory cell, the OTP can be achieved through the fuse principle, no extra mask is needed, the requirements of different manufacturing processes of the CMOS technology can be met, and diversified OTP solutions are provided.

Owner:CHANGXIN MEMORY TECH INC

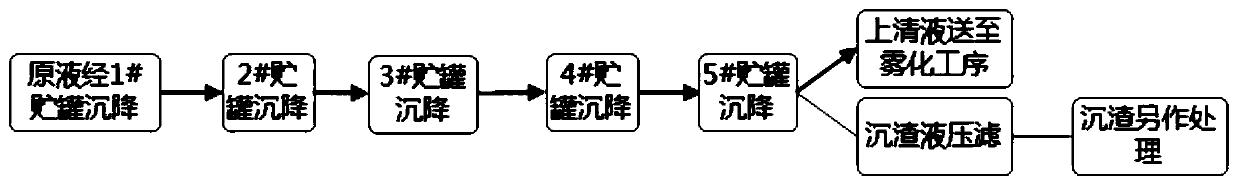

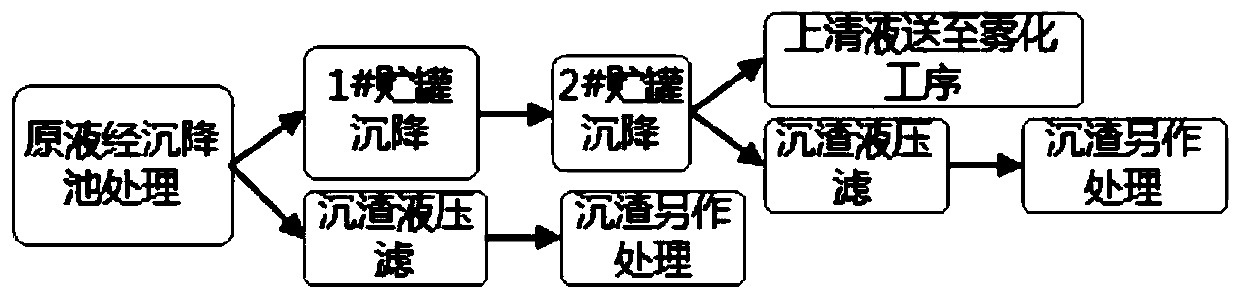

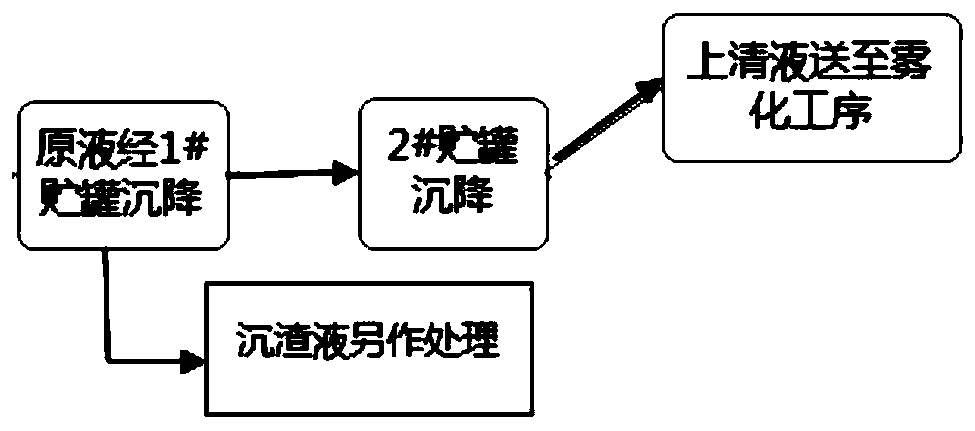

Cyclic sedimentation method and device, and method for producing dry organic fertilizer powder

PendingCN110467505AHigh removal rateSmall footprintCalcareous fertilisersBioloigcal waste fertilisersEngineeringColloid

The invention discloses a cyclic sedimentation method. The cyclic sedimentation method comprises the following steps: step 1, subjecting a stock solution to primary standing in a first storage tank, and transferring a liquid supernatant in the first storage tank into a second storage tank for secondary standing; and 2, transferring a stock solution containing sediments and colloids and located atthe lower layer of the second storage tank into the first storage tank for standing, and transferring the liquid supernatant of the first storage tank into the second storage tank for standing, wherein a liquid supernatant in the second storage tank is a desired raw material. According to the cyclic sedimentation method in the invention, an occupied area is reduced; cost is reduced; multiple timesof sedimentation treatment can be realized to meet requirements according to the conditions of raw material components or requirements of processes on raw material indexes; and no equipment cost needs to be increased.

Owner:GUANGXI JINSUI ECOLOGICAL TECH CO LTD

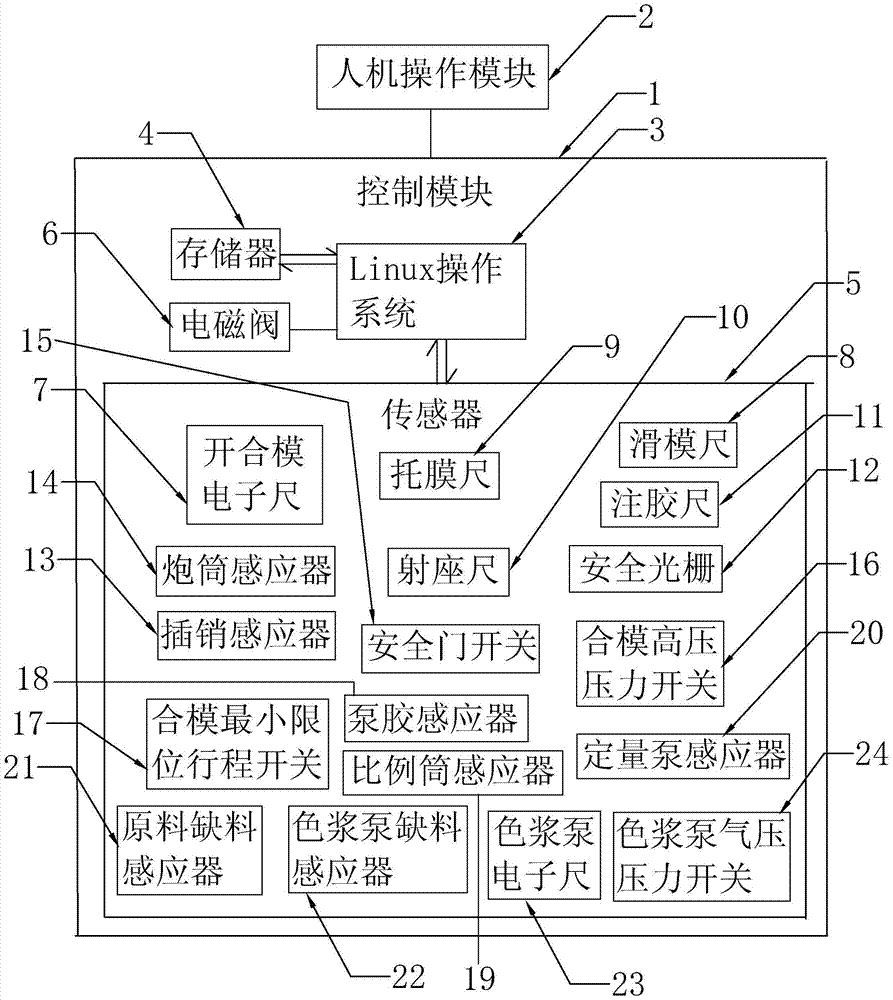

Liquid silicone injection molding system and method for producing liquid silicone molded products

The invention discloses a liquid silica gel injection molding control system. The system comprises a control module and a man-machine operation module. The control module is electrically connected to the man-machine operation module. The invention also discloses a method for producing a liquid silica gel molded product. The method comprises the following steps of building a production flow process by control program pre-written by the man-machine operation module, storing the production flow process in a memory of the control module, inputting control parameters into the man-machine operation module, according to production demand, calling the production flow process stored in the memory, by the control module, transmitting an instruction for starting a liquid silica gel injection molding device, and carrying out corresponding processes by the liquid silica gel injection molding device according to the written production flow process and set motion control parameters to produce the corresponding liquid silica gel molded product. The system has the characteristics of good functions and good compatibility.

Owner:GUANGZHOU TIANYUAN SILICONE MACHINE TECH

A lng gasification pressure regulating metering skid and its operation method

ActiveCN104197184BImprove work efficiencyExtended service lifePressure vesselsContainer discharging from pressure vesselsThermodynamicsInlet valve

The invention discloses an LNG gasification and pressure regulating metering skid, which includes a base, and the base is sequentially and horizontally provided with an unloading supercharger, an air-temperature gasifier, an electric heater and an air-temperature EAG heater. ; One side of the unloading supercharger is horizontally provided with a first main pipe and the first main pipe is provided with a first inlet and a first air outlet located at both ends thereof, and a second air outlet located in the middle; the second air outlet branch The natural gas outlet is connected to the natural gas outlet through the air-temperature EAG heater; the first gas outlet is connected to the first gas outlet branch extending from the second gas outlet through a pipeline, and the air-temperature gasifier includes at least one gas outlet and the gas outlet passes through The electric heater is connected to the natural gas outlet, and the first to third liquid inlets of the air-temperature vaporizer are respectively provided with a liquid inlet valve at the connection with the pipeline; and the operation of the LNG gasification pressure regulation metering skid is provided. The method can improve work efficiency, meet the requirements of different processes, and have a long service life.

Owner:江苏大昌燃气设备有限公司

A feedback throttling device

ActiveCN110500430BEffective controlEffectively fixedOperating means/releasing devices for valvesFlanged jointsControl engineeringStructural engineering

The invention relates to the field of chemical equipment, in particular to a feedback throttling device. The feedback throttling device comprises a valve body. The left side of the valve body is connected with a left outer flange. A right outer flange is connected to the right side of the valve body. A left inclined hole which gradually decreases from left to right is formed in the left outer flange. The left inclined hole is communicated with an inlet formed in the valve body. An inclined hole which gradually decreases from left to right is formed in the right outer flange. The inclined holeis communicated with an outlet formed in the valve body. According to the feedback throttling device, the flow rate and the flow of fluid in a pipeline can be uniformly controlled through effective self-feedback adjustment, so that the accuracy of raw material proportioning is ensured; and meanwhile, a pipeline fixing device is additionally arranged, so that the pipeline and the valve can be effectively fixed together, the phenomena of pipeline falling, valve leakage and the like can be effectively prevented, and meanwhile, the flow of the valve can be conveniently controlled so as to meet therequirements of different processes.

Owner:中玺新材料(安徽)有限公司

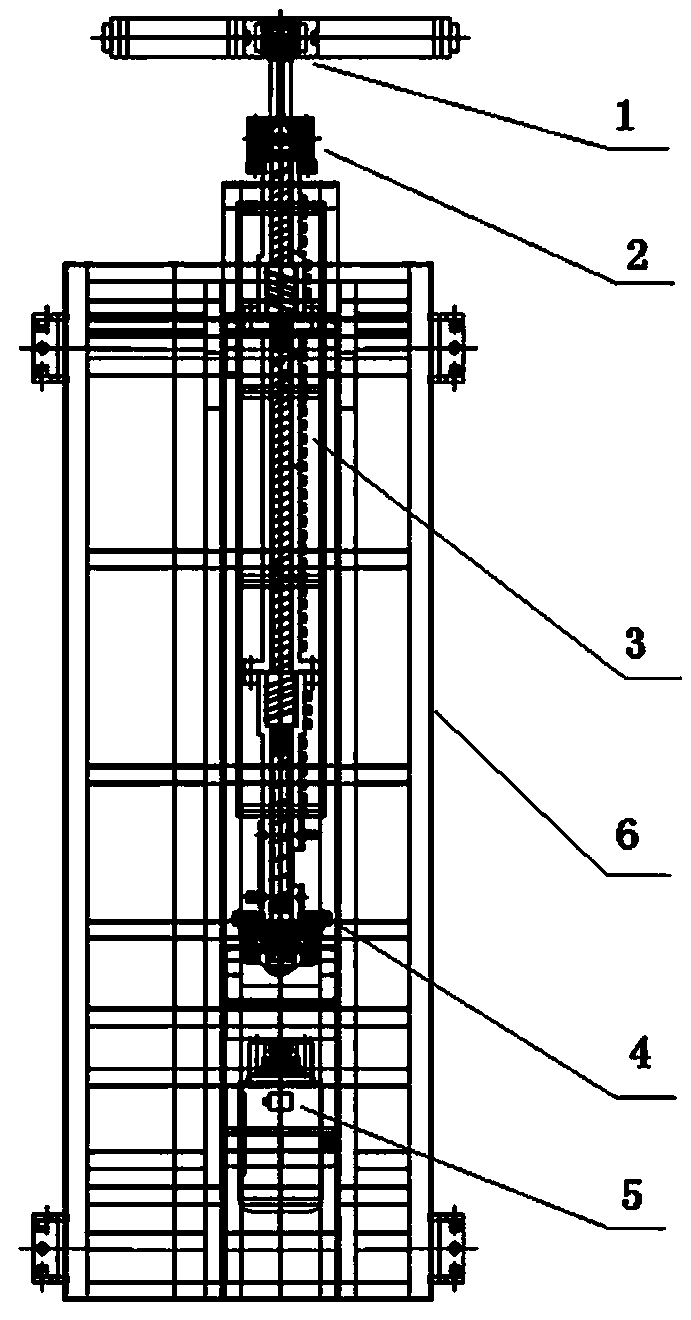

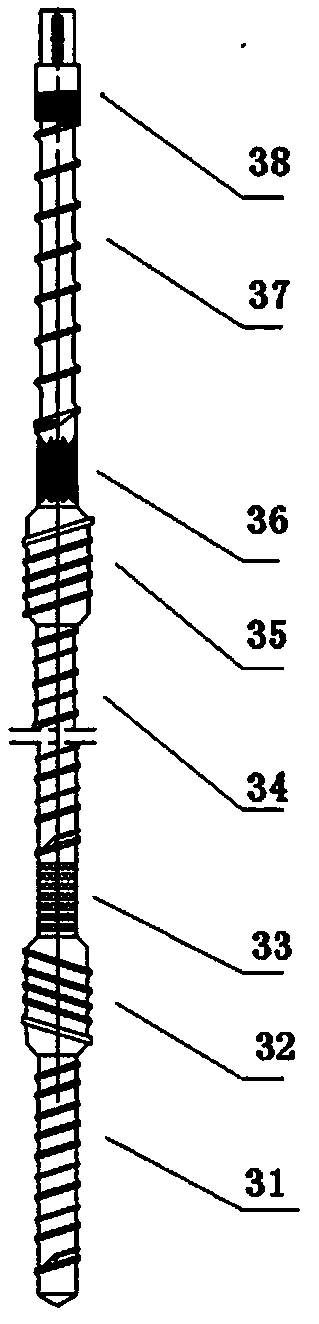

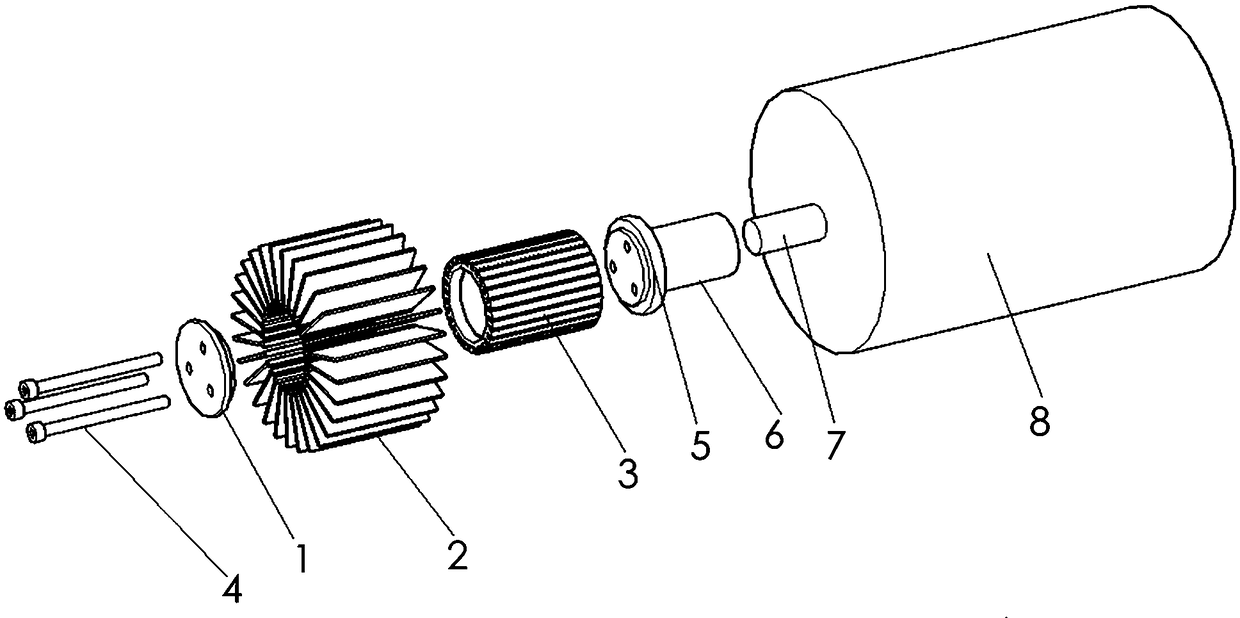

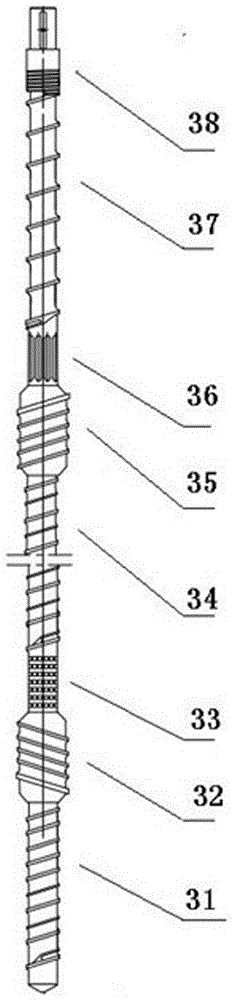

Hot reflux high-speed smelting and spiral pushing device

InactiveCN103934941AMeet the needs of different processesHigh speedCoatingsReduction driveElectric machinery

The invention relates to high-molecular leather release paper producing equipment, and in particular to a hot reflux high-speed smelting and spiral pushing device. The device is characterized by comprising a rack, wherein a pushing mechanism and a flow reducing spray head are connected in the rack; the pushing mechanism comprises a motor, a screw mechanism and a pressurizing filter mechanism; the motor is connected with the tail end of the screw mechanism through a speed reducer; the top end of the screw mechanism is connected with the flow reducing spray head through the pressurizing filter mechanism. By means of the device disclosed by the invention, various high-molecular materials can be mixed in the state of high-speed melting and uniformly sprayed on the front side of a base paper.

Owner:青岛鼎立强包装机械有限公司

Turnbuckle screw assembly device for binding containers

InactiveCN103909408AOptimize resource allocationEasy to controlMetal working apparatusAutomatic controlMan-hour

The invention discloses a turnbuckle screw assembly device for binding containers. The turnbuckle screw assembly device for binding containers comprises an assembly table; a positioning plate is mounted on the assembly table; an automatic greasing mechanism is mounted on the positioning plate; a guide rail is arranged below the assembly table; an assembly trolley is mounted on the guide rail; a rotating shaft is mounted above the assembly trolley; the head of the rotating shaft is provided with an automatic clamp; a cylinder, a control cabinet, a switch for controlling the cylinder to operate and a limit switch for controlling travel of a cylinder shaft are further arranged on the assembly table; a motor is further mounted on the assembly trolley and connected with a drive mechanism. The turnbuckle screw assembly device for binding containers has the advantages that a counter is disposed in the control cabinet, man-hour, capacity and the like can be counted, and resource allocation is optimized accordingly; automatic control and manual control are switched through an operating button, switching is more convenient, spring force of a spring on the automatic clamp is adjusted through a bolt, control is easier, and requirements of different techniques are met.

Owner:江苏鼎宇机械科技有限公司

Control method of grain conveying system

InactiveCN109230355AImprove efficiencyControl deliveryControl devices for conveyorsEmbedded systemTransmitter

The invention discloses a control method of a grain conveying system. The system is provided with a controller, and a plurality of belt conveyors are arranged in the conveying system. Signal receiversare arranged on the plurality of belt conveyors. Signal transmitters are arranged on devices in front and rear processes of the conveying system. The controller is connected to the signal receivers and the signal transmitters by signals. The signal transmitters are arranged on the devices in front and rear processes of the signal receiver conveying system of the belt conveyor. The controller controls forward and reverse rotation of a motor output shaft of the belt conveyor according to received signals, thereby sending different grains to different positions or placing the grain on the belt conveyor for different time to meet needs of different processes.

Owner:ANHUI SUNMIRO AGRI TECH

Novel grinding tool assembling structure

PendingCN109397087AStructural solutionSolve laboriouslyGrinding wheel securing apparatusElectric machineryEngineering

The invention discloses a novel grinding tool assembling structure which comprises a grinding tool and a motor (8) connected with the grinding tool. The grinding tool comprises a grinding core (3); one end of the grinding core (3) is connected with the motor (8) through an adapter piece; an end cover (1) is arranged at the other end of the grinding core (3) and is connected with the adapter piecethrough at least one connecting piece (4); and a detachable grinding material device (2) is detachably arranged on the periphery of the grinding core (3). The problems of time and labor waste and highcost of an existing grinding tool assembling structure are solved, the grinding core can be detachably fixed onto the adapter piece connected with the motor through three connecting pieces arranged in a triangular shape so as to be connected stably, and the novel grinding tool assembling structure has the advantages of short processing period, and convenience in installation and replacement.

Owner:四会市冠源机械科技有限公司

A thermal reflow high-speed smelting screw pushing device

InactiveCN103934941BMeet the needs of different processesHigh speedCoatingsReduction driveElectric machinery

The present invention relates to a production equipment of polymer leather release paper, especially a heat reflow high-speed smelting screw pushing device, which is characterized in that it includes a frame, and the inside of the frame is connected with a pushing mechanism and a flow reducing nozzle. The pushing mechanism includes a motor, a screw mechanism and a pressurized filter mechanism. The motor is connected to the tail end of the screw mechanism through a reducer; the top end of the screw mechanism is connected to the flow reducing nozzle through a pressurized filter mechanism. The invention can mix various polymer materials in a state of high-speed melting, and spray them evenly on the front side of the base paper.

Owner:青岛鼎立强包装机械有限公司

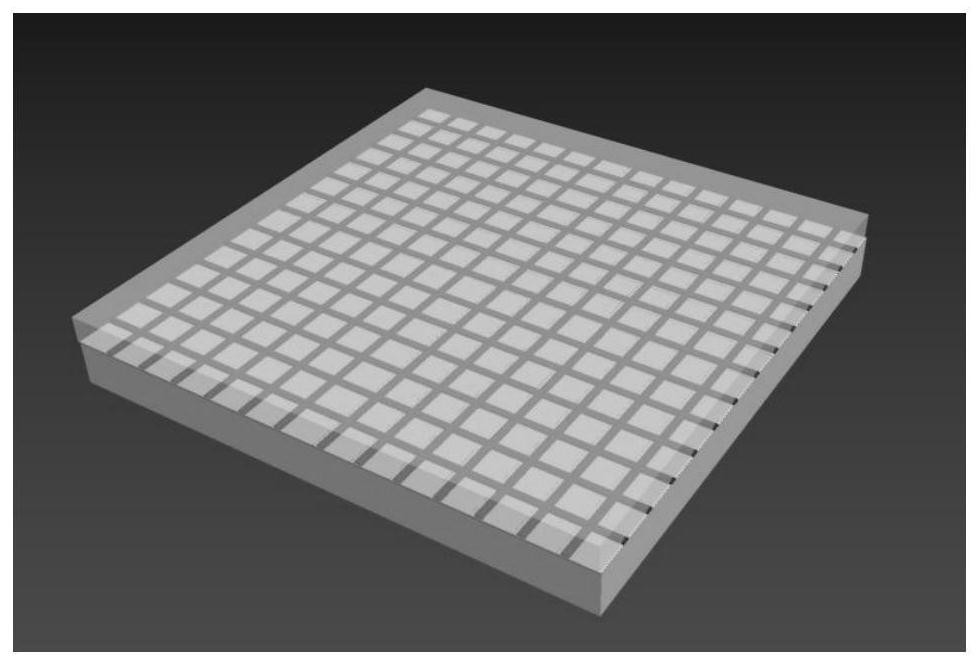

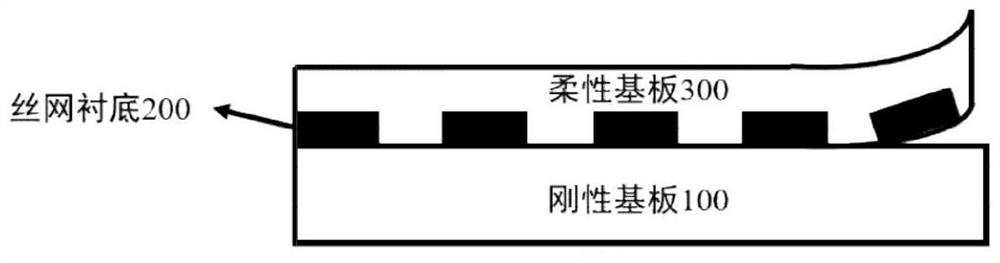

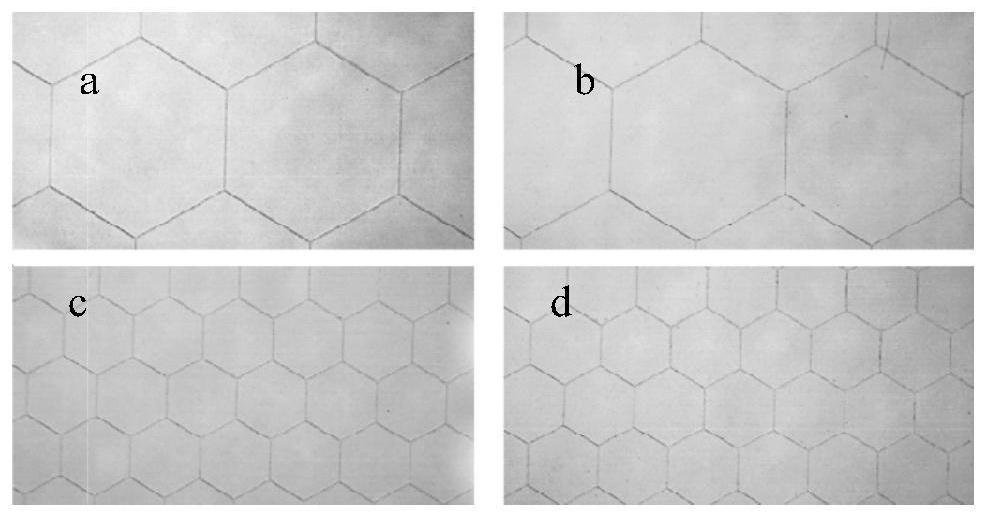

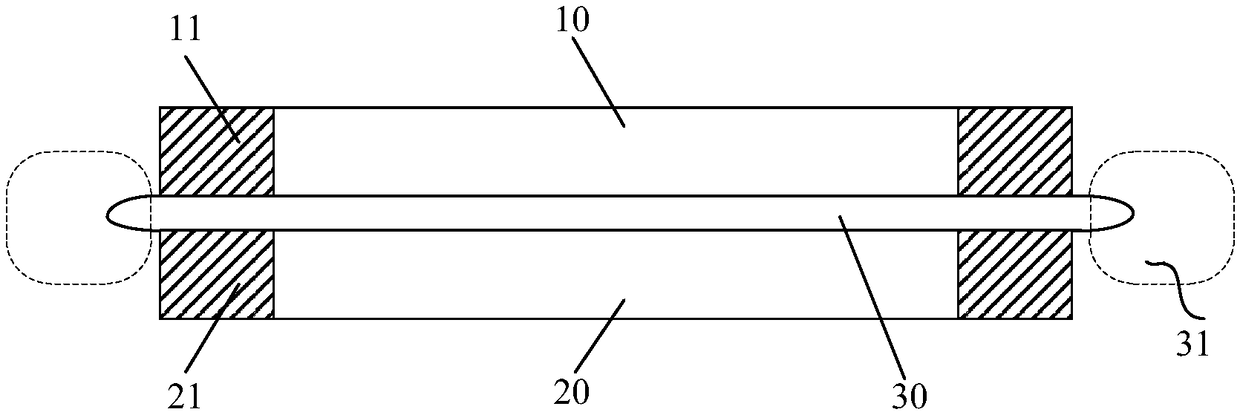

A peel-off method for pi flexible substrates based on a silk-mesh-like substrate layer, flexible substrates and OLEDs

ActiveCN112968144BIntegrity is not affectedSmall peeling forceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringStructural engineering

Owner:HUAZHONG UNIV OF SCI & TECH

Etching electrode and edge etching device

ActiveCN108470670AAdjust the occlusion areaMeet the needs of different processesElectric discharge tubesPhysicsElectrode

The invention relates to an etching electrode and an edge etching device; the etching electrode comprises the following parts: an electrode body including a pedestal and a projection electrode arranged on the pedestal, wherein the projection electrode top is the electrode surface, and an annular groove is formed between the pedestal and the projection electrode; at least one shield ring embedded inside and outside the electrode body in an encircling manner, and the at least one shield ring is located in the annular groove; a drive unit connected with the shield ring and used for controlling each shield ring to move up and down in the direction vertical to the electrode surface, wherein in rising, the shield ring moves to the electrode surface direction, and in descending, the shield ring moves to the pedestal direction.

Owner:淮安西德工业设计有限公司

A fully automatic double-table wiping machine

ActiveCN106180021BQuality improvementFinish quicklyFlexible article cleaningCleaning using toolsWorking pressureMotion controller

The invention relates to a fully automatic dual-workbench board wiping machine, which includes a machine platform, a motion controller, a truss, a first workbench, a second workbench and a board wiping device. The motion controller is placed inside the machine platform. , the truss is transversely fixed on the upper end of the machine platform, the wiping device is placed on the truss, the wiping device can move along the truss, the first workbench and the second workbench The first workbench and the second workbench can be longitudinally moved to the bottom of the truss; the first workbench, the second workbench and the wiping device are all composed of Controlled by a programmable motion controller, the wiper device provides downward adjustable working pressure through a needle cylinder. Compared with the existing technology, the present invention can perform board wiping operations on two workbenches and complete the COB board wiping work quickly, stably and with high quality.

Owner:深圳市拓普微科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com