A peel-off method for pi flexible substrates based on a silk-mesh-like substrate layer, flexible substrates and OLEDs

A flexible substrate and substrate layer technology, applied in the direction of organic semiconductor devices, electric solid devices, semiconductor devices, etc., can solve problems such as complex operation process, inability to contact skin, damage to flexible OLED, etc., and achieve simple operation process without affecting integrity , The effect of reducing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of the substrate film in the step (1) is sol-gel technology, dip coating method, CVD, PVD, liquid phase deposition method, electroevaporation, sputtering, silk screen printing and the like.

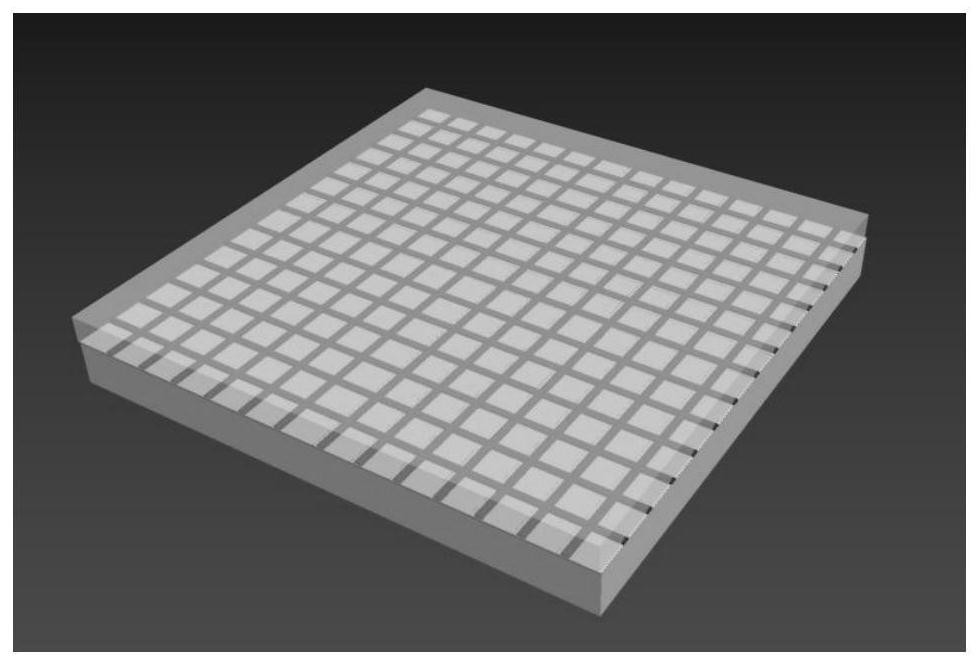

[0077] In the step (1), the screen pattern of the screen-like substrate layer is any pattern such as a square grid, a rhombus grid, a circle grid, a straight line grid, a curved grid, a circuit pattern, and a calligraphy and painting pattern.

[0078] In the step (1), the thickness of the wire mesh substrate layer is controlled within 10nm to 900um. The screen size is defined by line width and area ratio (screen area / substrate area), the line width is controlled from 1nm to 100um, and the area ratio is 0.01% to 99%.

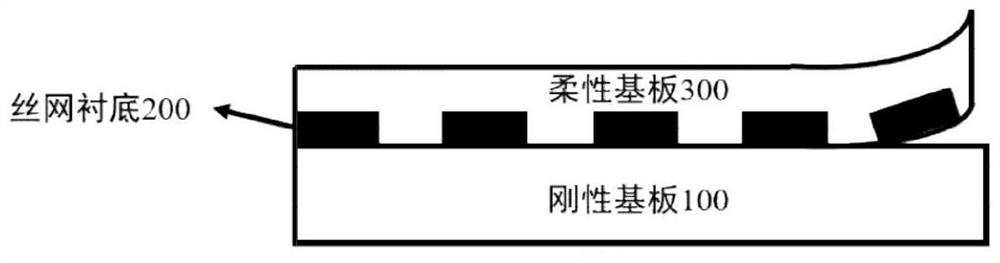

[0079] In the step (2), a polyimide thin film PI flexible substrate is prepared on the screen-like substrate layer by means of spin coating, scraping coating and casting.

[0080] The step (3) prepares an organic optoelectronic device and packa...

Embodiment 1

[0086] Embodiment 1: A PI (polyimide) flexible substrate peeling process based on silicon nitride mesh substrate layer technology.

[0087] Step (1): preparing a silicon nitride wire mesh substrate layer on the glass substrate;

[0088] The substrate material in step (1) is a glass substrate, which can also be replaced with one of ceramics and metal.

[0089] The material for depositing the screen-like substrate layer in step (1) is silicon nitride.

[0090]The thickness of the silicon nitride wire mesh substrate layer in step (1) is 230nm-290nm.

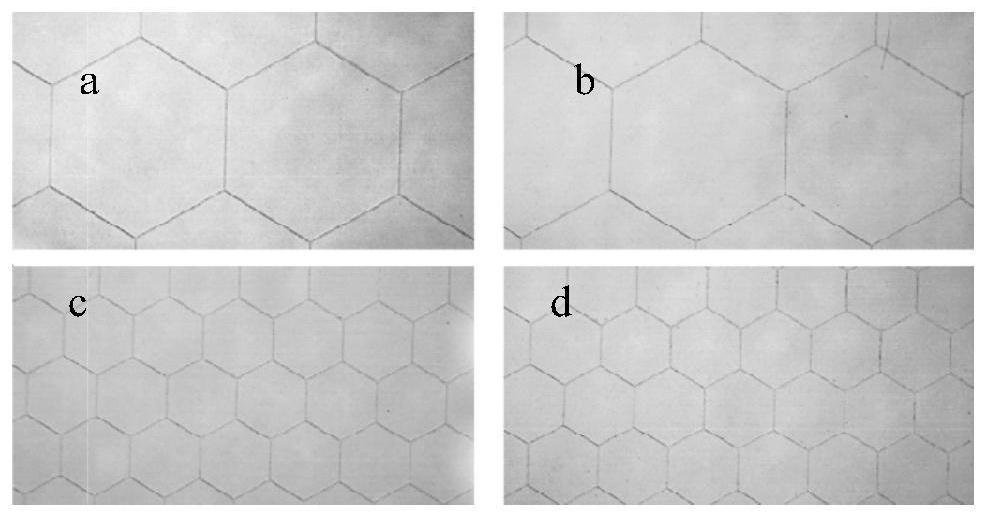

[0091] The pattern of the screen-like substrate layer in step (1) is selected as a hexagonal grid, and the line width of the screen is 200 μm-5 μm, 200 μm-10 μm, 500 μm-5 μm, and 500 μm-10 μm. . The area ratios were 0.494%, 0.975%, 0.0199%, and 0.0386%, respectively.

[0092] The screen-like substrate structure in step (1) is prepared by first photolithography and then deposition process:

[0093] Carry out pretreatment on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com