Novel grinding tool assembling structure

An assembly structure and a new type of technology, applied in the direction of manufacturing tools, devices for fixing grinding wheels, grinding machine parts, etc., can solve the problems of high cost, laborious, time-consuming, etc., to reduce manufacturing costs, shorten processing cycles, and facilitate installation and the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

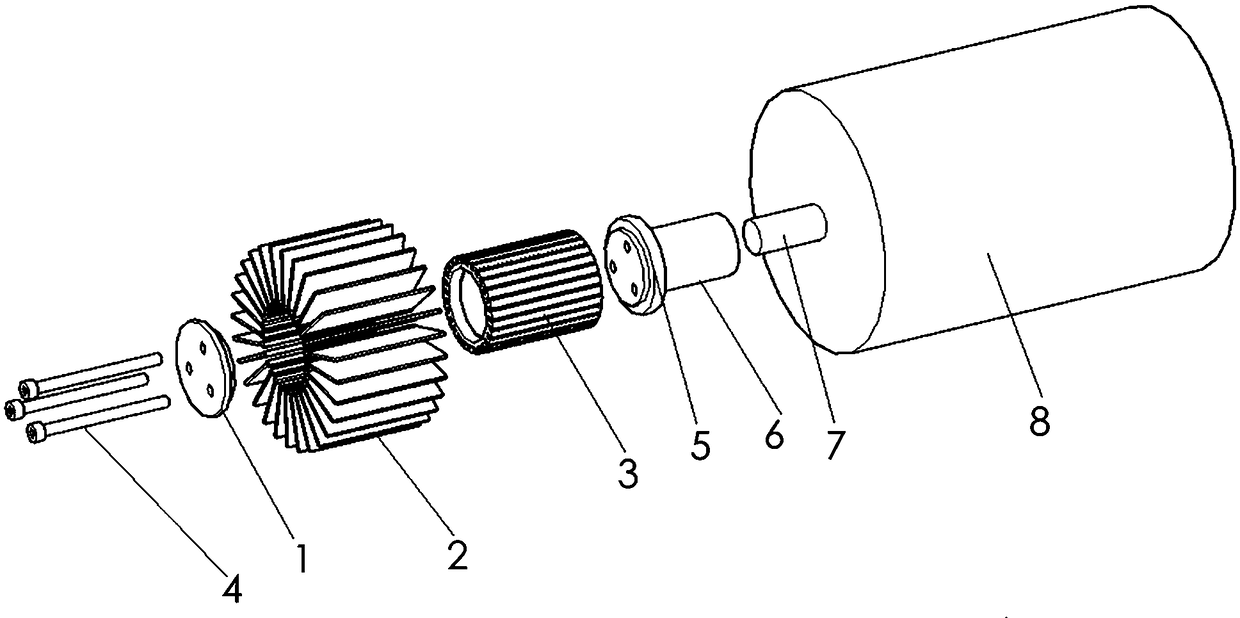

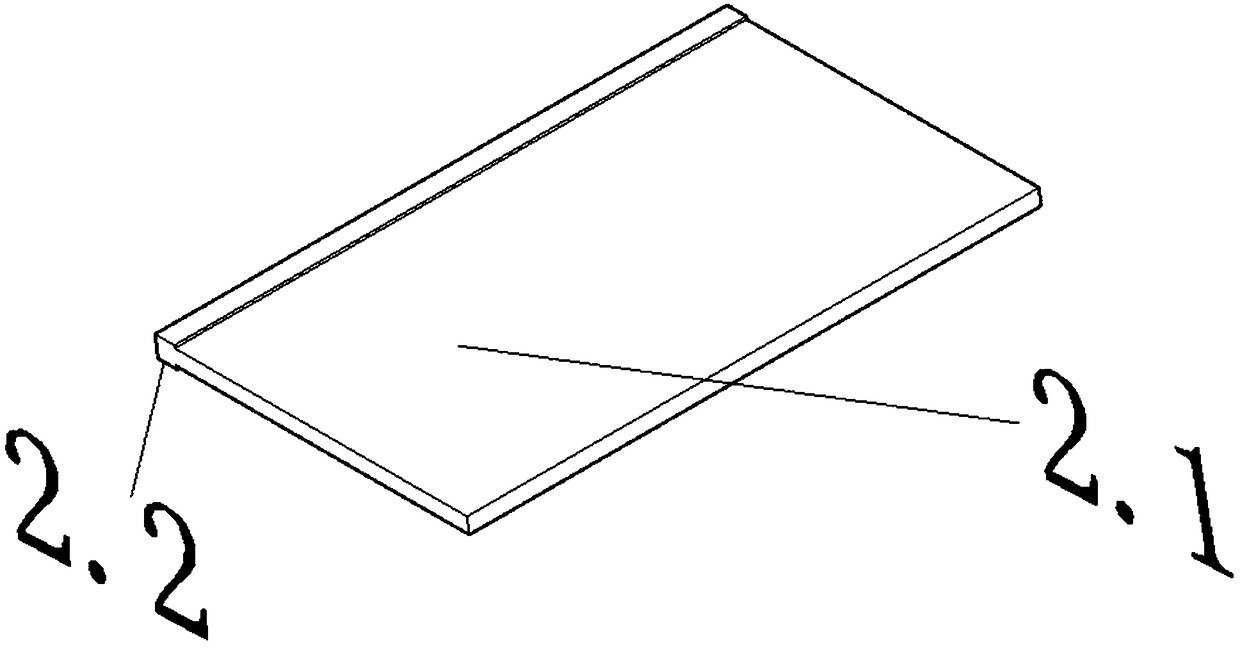

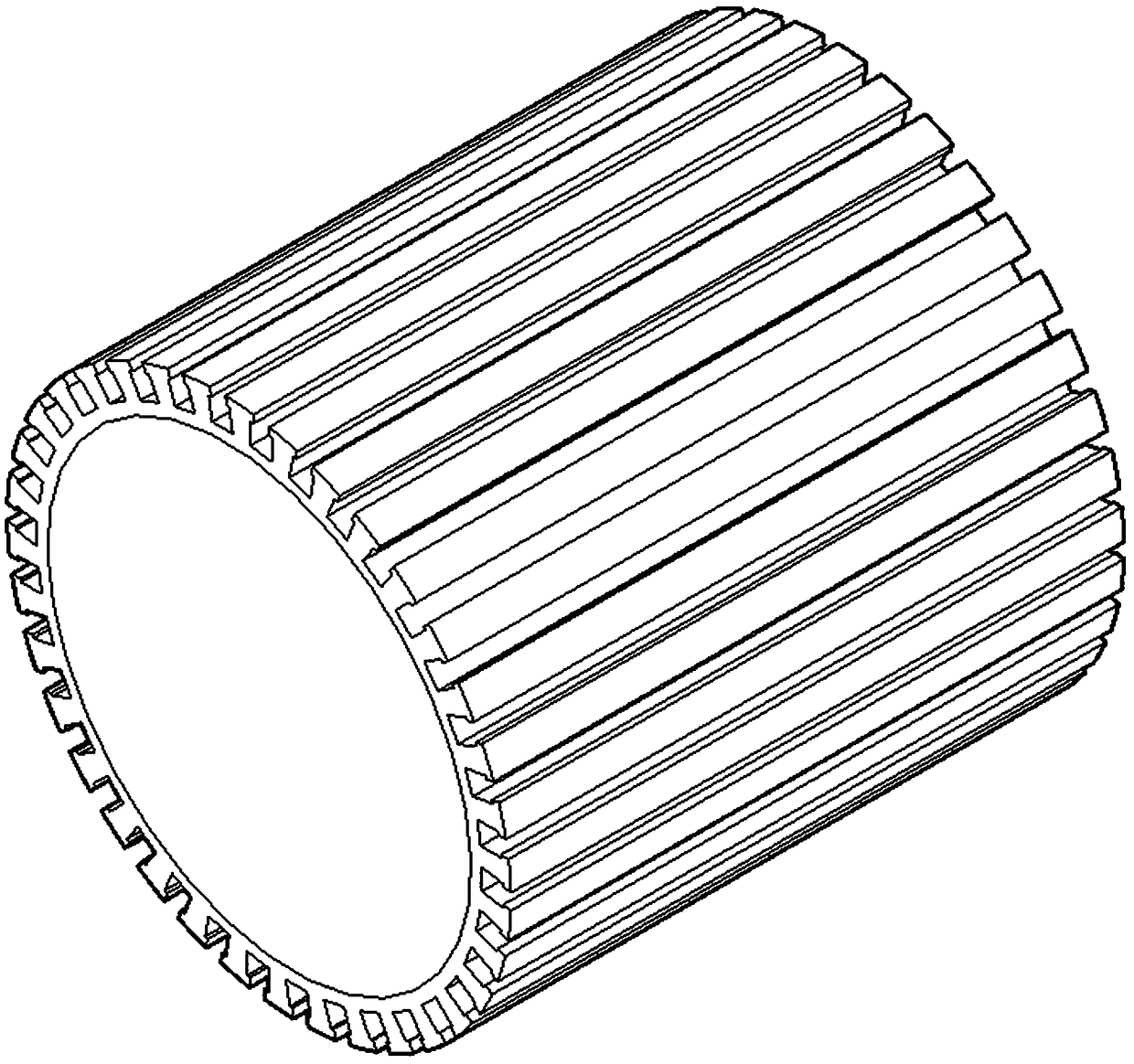

[0056] The invention proposes a new type of assembly structure for abrasive tools, which solves the disadvantages of time-consuming, laborious and high cost of the existing assembly structure of abrasive tools, and detachably fixes the grinding core to the The adapter connected to the motor makes the connection more stable, has the advantages of short processing cycle, easy installation and replacement, such as Figure 1~Figure 4 As shown, the following arrangement structure is adopted in particular: comprising a grinding tool and a motor 8 connected with the grinding tool, the grinding tool includes a grinding core 3, one end of the grinding core 3 is connected with the motor 8 through an adapter, and the grinding core The other end of 3 is provided with an end cap 1, which is connected to the adapter through at least one connecting piece 4, and a detachable abrasive material device (grinding brush) 2 is detachably provided on the outer periphery of the grinding core 3.

[00...

Embodiment 2

[0059] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as Figure 1~4 As shown, the following arrangement is adopted in particular: the adapter includes a flange head 5 and an adapter section 6, the flange head 5 is matched with the grinding core 3, and the adapter section 6 is sleeved on the output of the motor 8 on axis 7.

[0060] As a preferred arrangement, the adapter includes a flange head 5 and a connecting section 6, the flange head 5 is interference fit or threaded with the grinding core 3, the adapter section 6 is sleeved on the output shaft 7 of the motor 8, and Interference fit or thread fit is used between the adapter section 6 and the output shaft 7, but not limited thereto; when the motor 8 is working, the output shaft 7 drives the adapter to rotate, and the adapter further drives the abrasive tool to rotate.

Embodiment 3

[0062] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as Figure 1~4 As shown, the following arrangement method is adopted in particular: there are three connecting pieces (4), and the three connecting pieces 4 pass through the end cover 1 in an equilateral triangle shape to connect with the adapter piece.

[0063] As a preferred arrangement, when the connecting piece 4 is set, three connecting pieces 4 are preferably provided, and the three connecting pieces can be triangular, preferably isosceles triangular, passing through the end cover 1 and the inner cavity of the grinding core 3 To connect with the adapter piece, it is also possible to connect the three connecting pieces 4 in the shape of an equilateral triangle through the end cover 1 and the inner cavity of the grinding core 3 to connect with the adapter piece, but it is not limited thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com