Anisotropic conductive solder paste and its preparation method and integrated preparation device

An anisotropic and silver soldering technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of high preparation process requirements, affecting anisotropic conductivity, low reliability, etc., to simplify the connection process, Realize the effect of highly reliable connection and expand the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An anisotropic conductive welding, the preparation method is: 1 g of alicyclic epoxy resin A and 0.2 g of phenoxy resin B are uniformly mixed in the solvent, adding 0.8 g of tin silver soldering from 2 to 8 um. Ball, tin silver solder ball is a nickel powder powder having a 0.2 g of medium particle diameter of 2 um, and 0.1 g of modified BF3 complex and 0.05 g of glutaric anhydride were added, and finally 0.02 g of silane was added. The coupling agent A151 vinyl triethoxysilane and 0.02 g of the antifoam polysiloxane solution are mixed uniform, and the vacuum is deprived, which is to be anisotropic conductive welding.

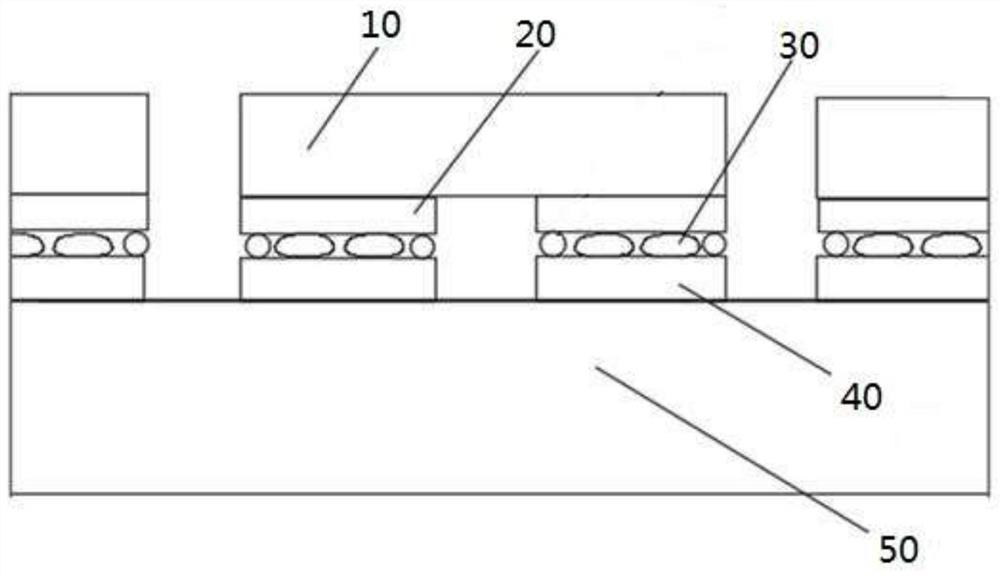

[0046] The anisotropic conductive welding is uniformly applied to the experimental substrate, and there is 180 um * 100 um square pad on the experimental substrate, the pad spacing is 50 um, and the LED chip is connected to the substrate, such as by using a hot pressing process. figure 1 Indicated.

Embodiment 2

[0051] An anisotropic conductive welding, the preparation method is: 1 g of alicyclic epoxy resin A and 0.2 g of acrylic resin C are mixed in a solvent, add 0.5 g of tin silver solder balls of 2 to 8 um. The volume fraction of tin silver solder ball is a nickel powder powder of 0.2 g of the median particle diameter of 2 um. After dispersion is uniform, 0.1 g of modified BF3 complex and 0.05 g of glutaidine, and finally add 0.02 g of silane coupling. The agent A151 vinyl triethoxysilane and 0.02 g of the antifoam polysiloxane solution were mixed uniform, and the vacuum deprivation was obtained, i.e., anisotropic conductive welding.

[0052] The anisotropic conductive welding is uniformly applied to the experimental substrate, and there is a square pad on the experimental substrate, the pad spacing is 50 um, and the LED chip is connected to the substrate with a heat pressing process.

Embodiment 3

[0057] An anisotropic conductive welding, the preparation method is: 1 g of alicyclic epoxy resin A and 0.2 g of acrylic resin C are mixed in a solvent, add 0.5 g of tin silver solder balls of 2 to 8 um. The volume fraction of tin silver solder ball is a nickel powder powder of 0.2 g of the median particle diameter of 2 um. After dispersion is uniform, 0.1 g of modified BF3 complex and 0.05 g of glutaidine, and finally add 0.02 g of silane coupling. The agent A151 vinyl triethoxysilane and 0.02 g of the antifoam polysiloxane solution were mixed uniform, and the vacuum deprivation was obtained, i.e., anisotropic conductive welding.

[0058] The anisotropic conductive welding is uniformly applied to the experimental substrate, and there is a square pad on the experimental substrate, the pad spacing is 50 um, and the LED chip is connected to the substrate with a heat pressing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com