Liquid silicone injection molding system and method for producing liquid silicone molded products

A liquid silicone, injection molding technology, applied in the field of control systems, can solve the problems of single process flow, inoperability, and difficulty in unifying control computer operation standards, and achieve the effect of simple operation, simple control, and resume production process technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

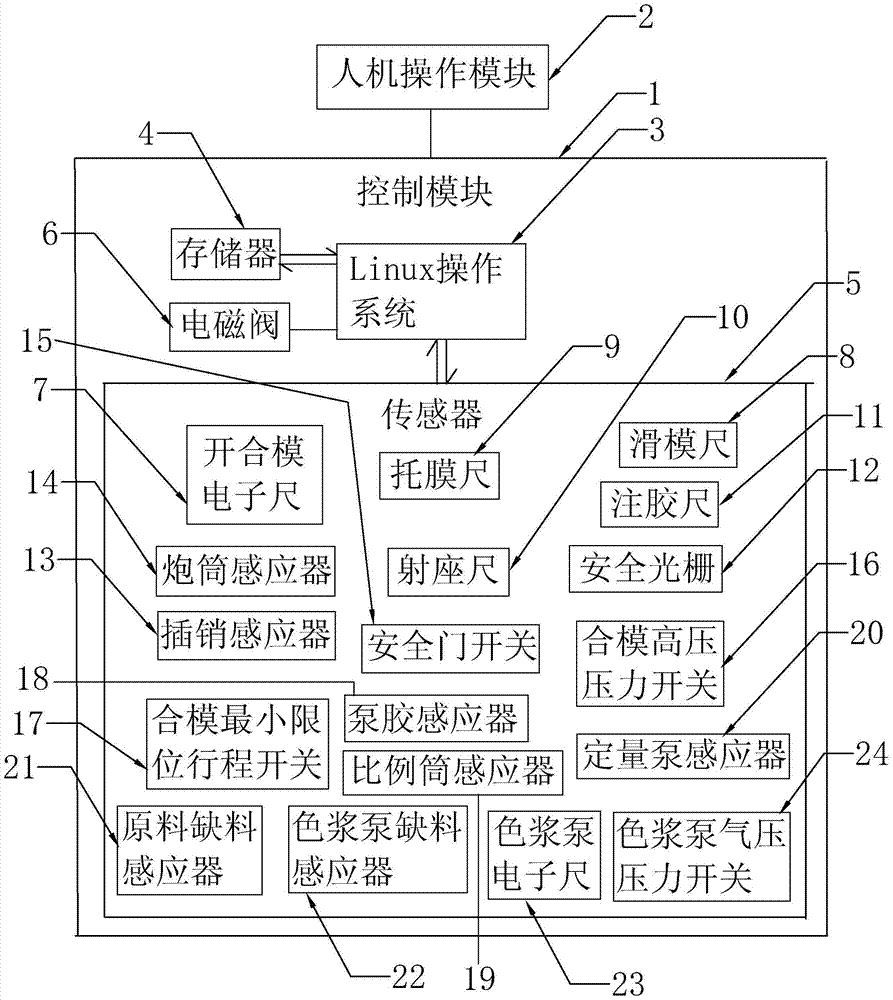

[0031] Such as figure 1 As shown, the liquid silicone injection molding control system of the present invention includes a control module 1 and a man-machine operation module 2, and the control module 1 is electrically connected to the man-machine operation module 2; wherein the control module 1 serves as the core The module is used to control the mold opening and closing operation, sliding mold operation, pin positioning operation, air blowing operation, film holding operation, feeding operation, glue pumping operation, injection base operation and glue injection operation of liquid silicone injection molding equipment; The internal core program is based on the secondary development of the underlying program system of Taiwan Baoyuan Computer, which is suitable for horizontal liquid silicone rubber programming machines, vertical single-slide liquid silicone rubber injection molding machines, and vertical double-slide liquid silicone rubber injection molding machines. machine, ...

Embodiment 2

[0040] The only difference between this embodiment and Embodiment 1 is that in the production method of the liquid silicone injection molded product, an action interlocking step is added, which is specifically:

[0041] The mold opening and closing operation, sliding mold adjustment operation, pin positioning operation, air blowing operation, film holding operation, material feeding operation, glue pumping operation, injection seat operation and glue injection operation are all controlled by internal relays, only all actions are OFF The interlocked internal relay can only be ON when in the state, and the internal relay is OFF when any action is executed; only when the internal relay is in the ON state can the output action be executed, and the action will be self-maintained for continuous output after output, while the internal The relay is in the OFF state, and other actions cannot be output, realizing the interlock function.

[0042] This step can more effectively ensure tha...

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that in the production method of the liquid silicone injection molded product, an automatic mold adjustment step is added, which is specifically:

[0045] Firstly, the horizontal liquid silicone rubber programmer executes the rough mold clamping action with the mold adjustment parameters of small pressure and speed. After the data of the electronic scale is no longer small, perform a rough return to zero action, so that the mold clamping scale obtains a value close to the thickness of the mold. First align the zero position; then the horizontal liquid silicone rubber programmer executes the mold opening action to move a certain distance, and then executes the mold closing action, and performs the mold closing high pressure action to make the horizontal liquid silicone rubber programmer lock the mold After the mold is locked, the control module resets the position of the mold clamping ruler to zero to obtain the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com