Full-automatic double-workbench plate wiping machine

A technology of double worktables and wiping machine is applied in the direction of cleaning method using tools, cleaning flexible items, cleaning method and utensils, etc., can solve the problems of prolonging production time, low production efficiency, increasing production cost, etc. The effect of working efficiency and saving the interval time of plate changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

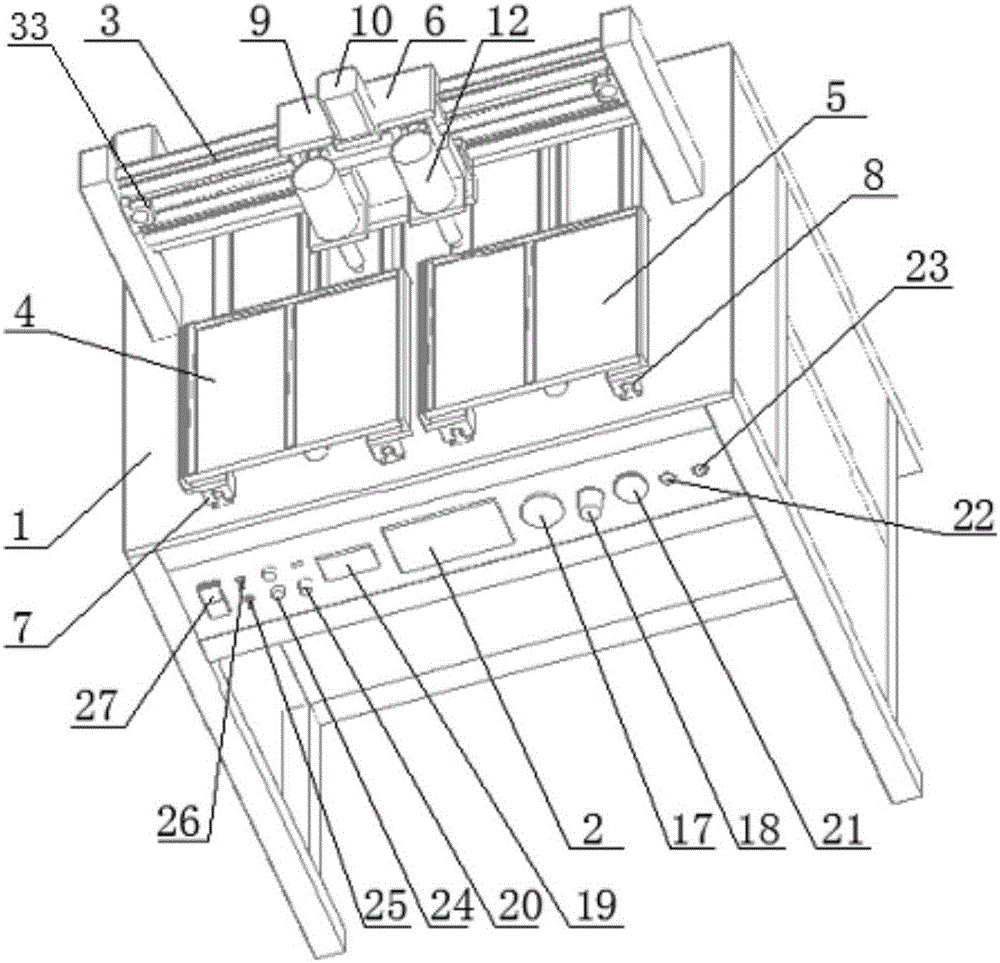

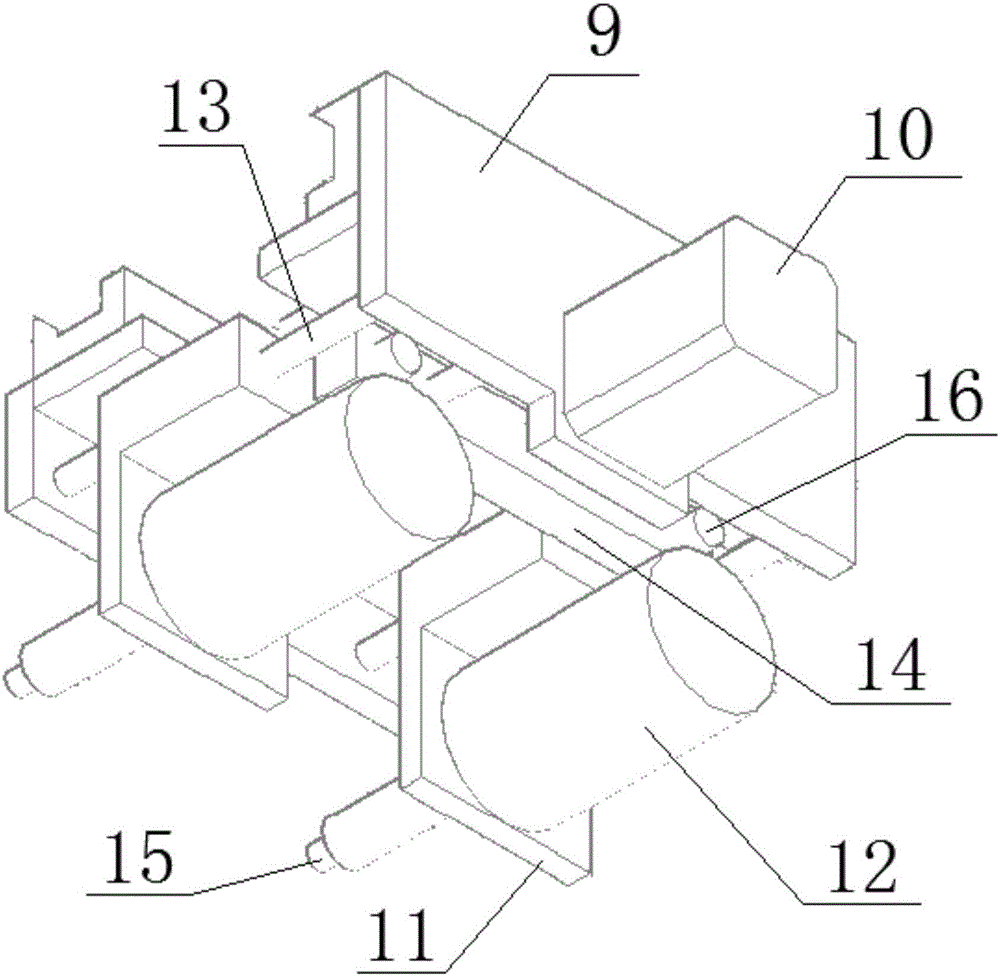

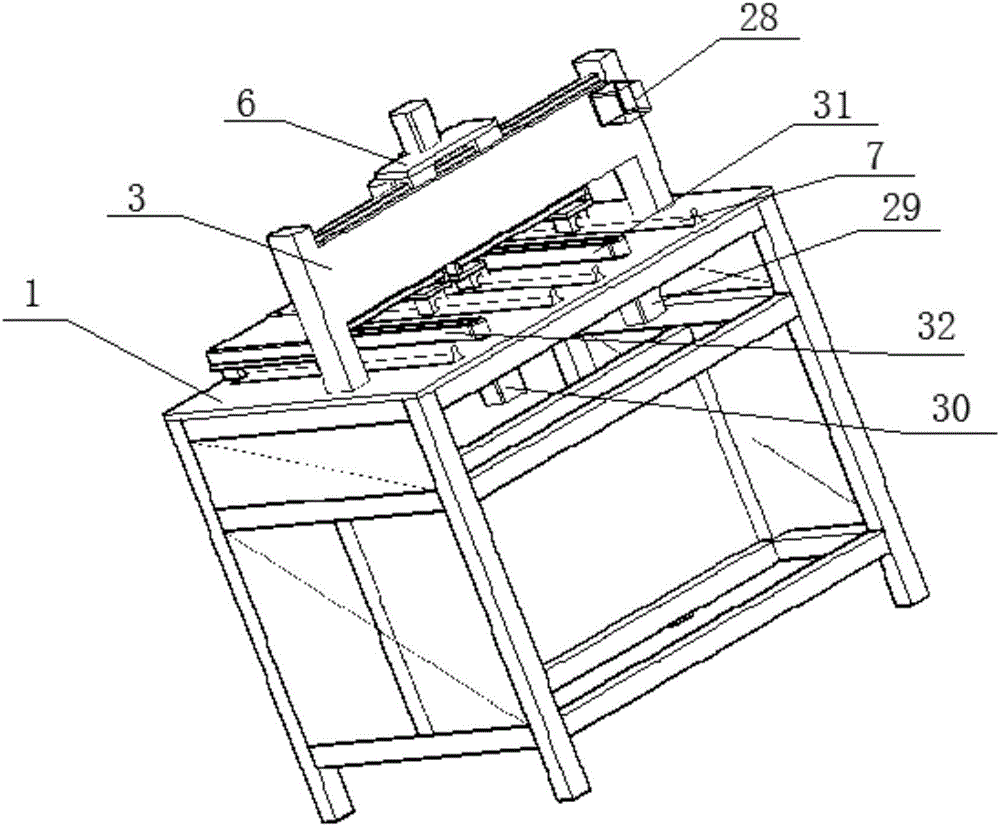

[0028] Such as figure 1 and image 3As shown, a full-automatic double-table wiping machine includes a machine platform 1, a motion controller 2, a truss 3, a first workbench 4, a second workbench 5 and a wiper device 6, and the motion controller 2 Placed in the machine platform 1, the truss 3 is fixed laterally on the upper end of the machine platform 1, the wiper device 6 is placed on the truss 3, and the back of the truss 3 is provided with a first synchronous The motor 28, the first synchronous motor 28 drives the wiper device 6 to move along the truss 3 through the first synchronous pulley 33, and the first workbench 4 and the second workbench 5 are vertically arranged side by side on the On the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com