A method for making an individualized intestinal fistula stent and its applicable mold

A manufacturing method and a technique for intestinal fistula, which are applied in the field of individualized intestinal fistula stent manufacturing and applicable mold fields, can solve the problems of limited specifications and models, affecting the use effect, and the stent cannot be matched at the intestinal fistula, achieving simple operation, Reasonable design and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

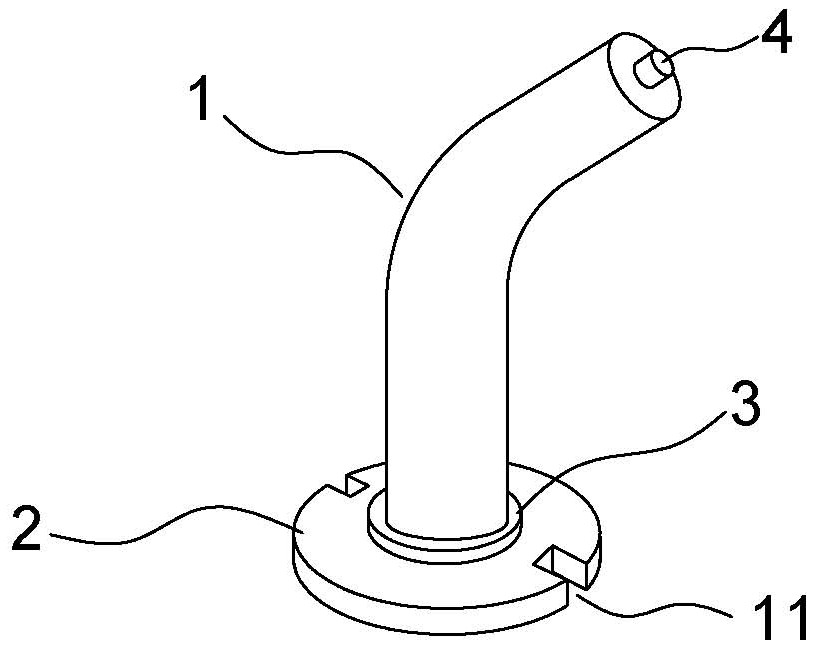

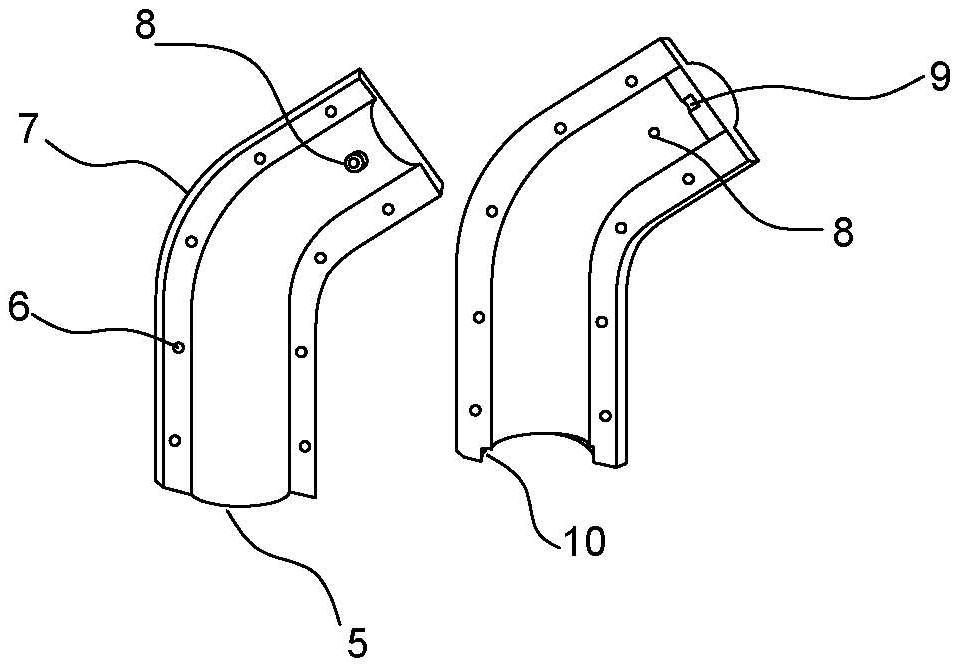

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A method for manufacturing an individualized intestinal fistula stent, comprising the following steps:

[0024] 1) Perform diatrizoate meglumine angiography on patients with intestinal fistula, and use high-resolution CT to perform three-dimensional reconstruction of the angiographic image, understand the anatomical structure around the fistula, and obtain the size of the distal and proximal intestines;

[0025] 2) Use graphic design software such as 3D max software or solidwork software to design molds and convert them into .STL files; the .STL files can be recognized by 3D printers and metal powder printers;

[0026] 3) Use 3D printing or metal powder printing to make molds; among them, polylactic acid, polyurethane or polycaprolactone can be used for 3D printing; or, iron powder, titanium powder or aluminum powder can be used for metal powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com