A color paste pump for liquid silicone injection

A technology of liquid silica gel and color paste, which is applied in the field of color paste pumps, and can solve the problems of difficult removal of feeding amount, low precision, and low feeding accuracy of color paste pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

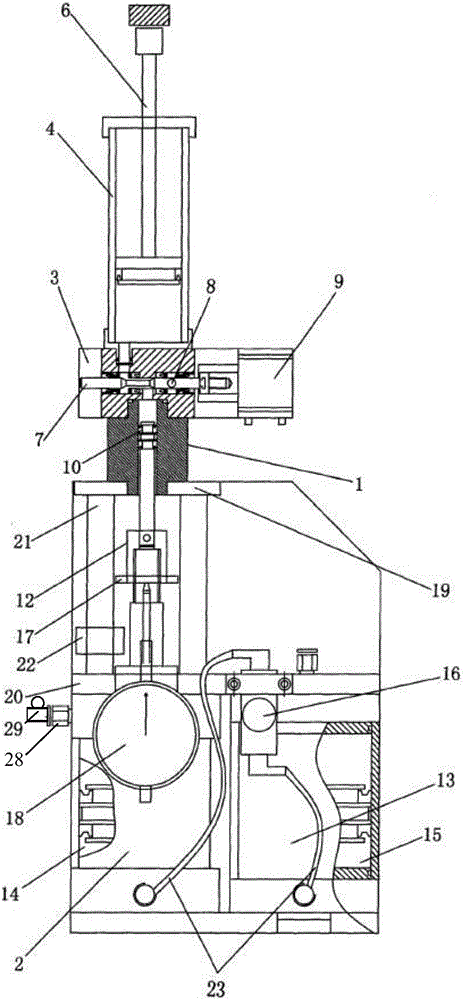

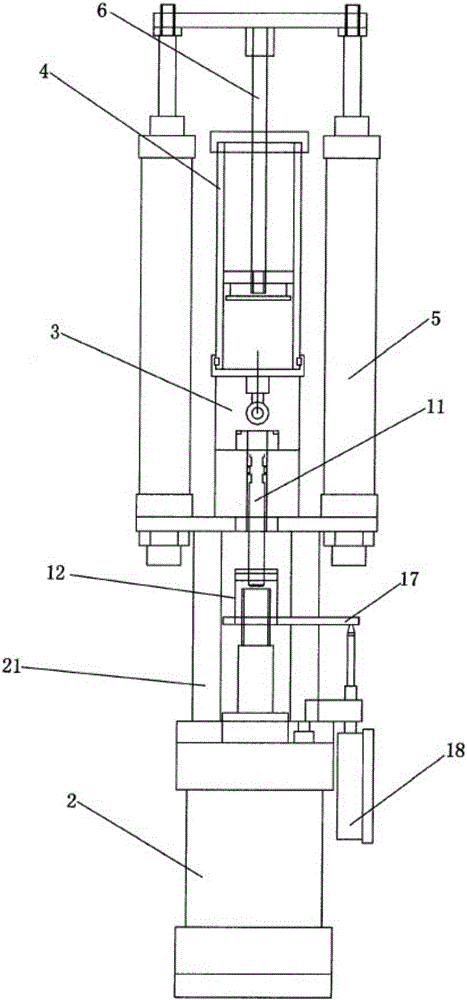

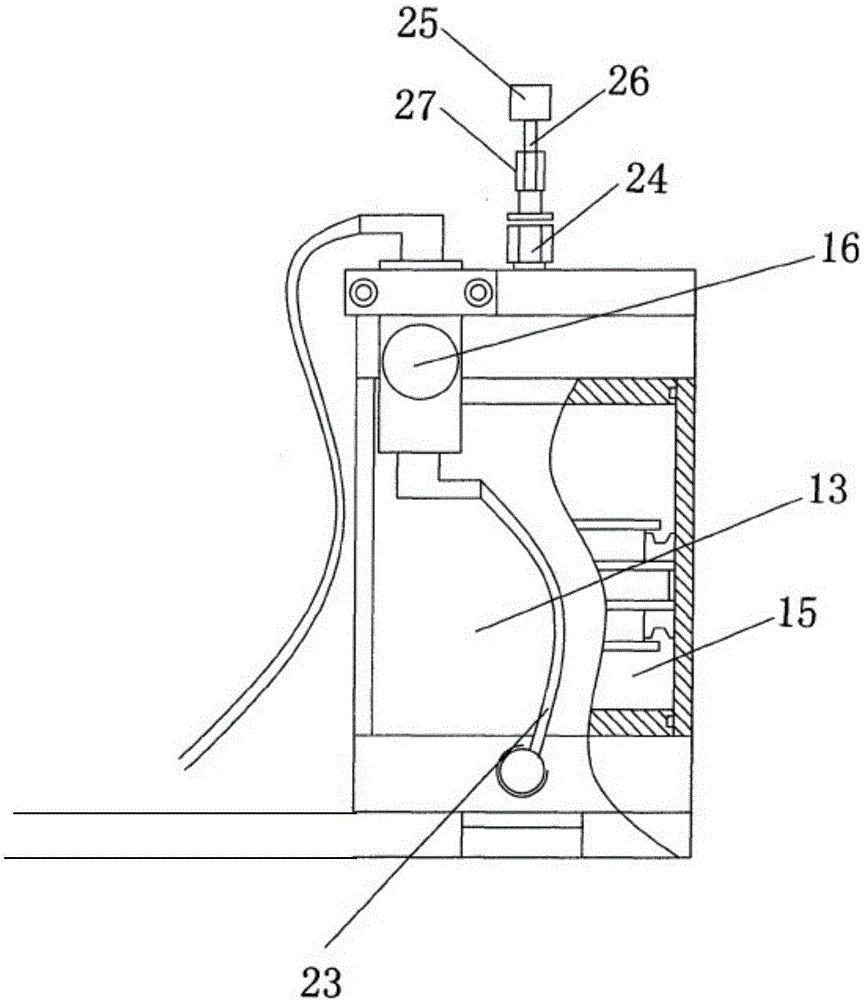

[0018] Such as figure 1 , figure 2 , image 3 As shown, a colorant pump for liquid silicone injection includes a pump body 1, a color material storage device, a cylinder 2, and a switching valve 3. The lower part of the pump body 1 is connected to the cylinder 2, and the switching valve 3 is set Between the pump body 1 and the color material storage device, the color material storage device includes a color paste cup 4 inserted on the switching valve 3, and a charging cylinder 5 is arranged in the center of the cavity of the color paste cup 4 as a The moving push rod 6, the switching valve 3 includes the steering valve needle 7 provided inside the switching valve body, the color paste outlet 8 is arranged on the steering valve needle 7, and the steering valve needle 7 passes through the The movement of the reversing cylinder 9 controls the output of the color paste outlet 8. The pump body 1 further includes a piston rod 11 provided with a sealing ring 10. The piston rod 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com