High speed dynamic state on-line mixing device applicable to large-scale mixing

A mixing device and large-scale technology, applied in the direction of mixers, mixers with rotating stirring devices, engine components, etc., can solve the problems of material liquid leakage, low mixing efficiency, accelerated wear, etc., to reduce wear and material consumption, Strong mixing and uniform performance, the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

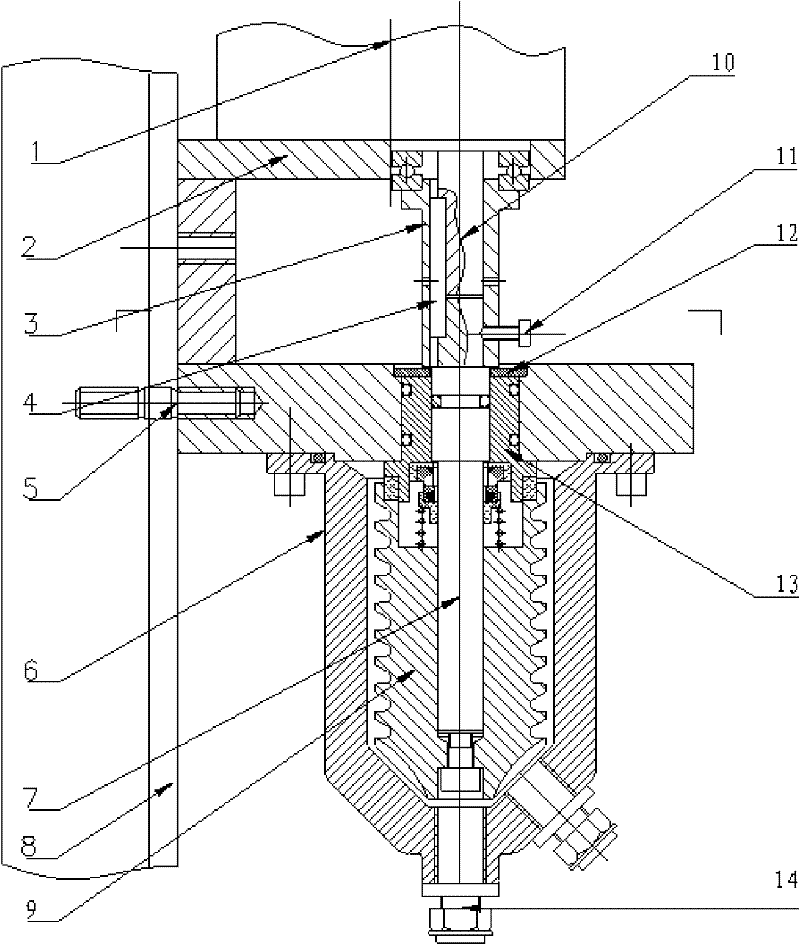

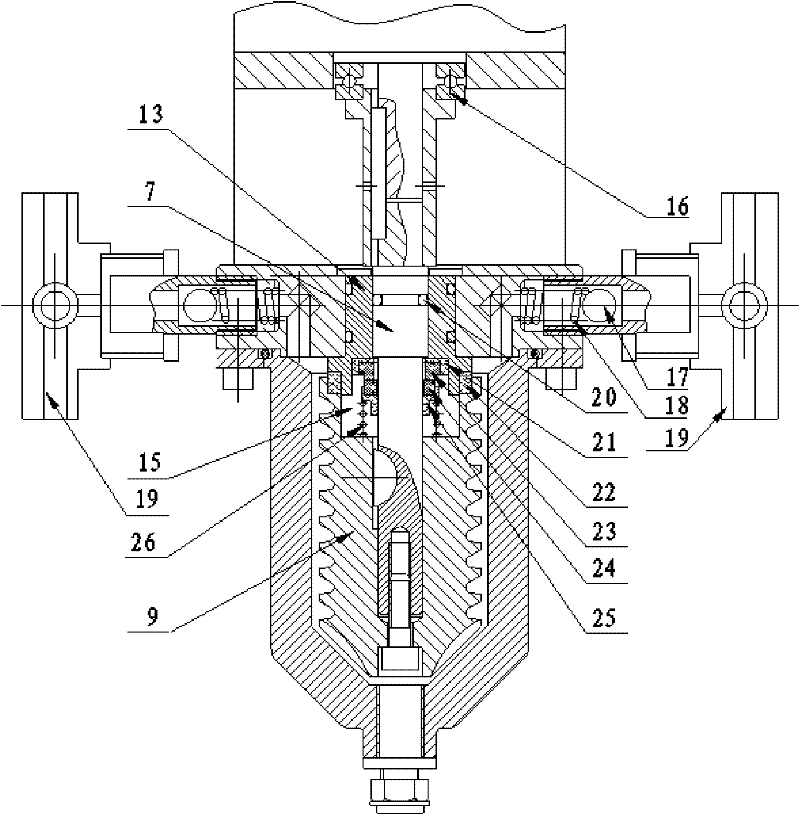

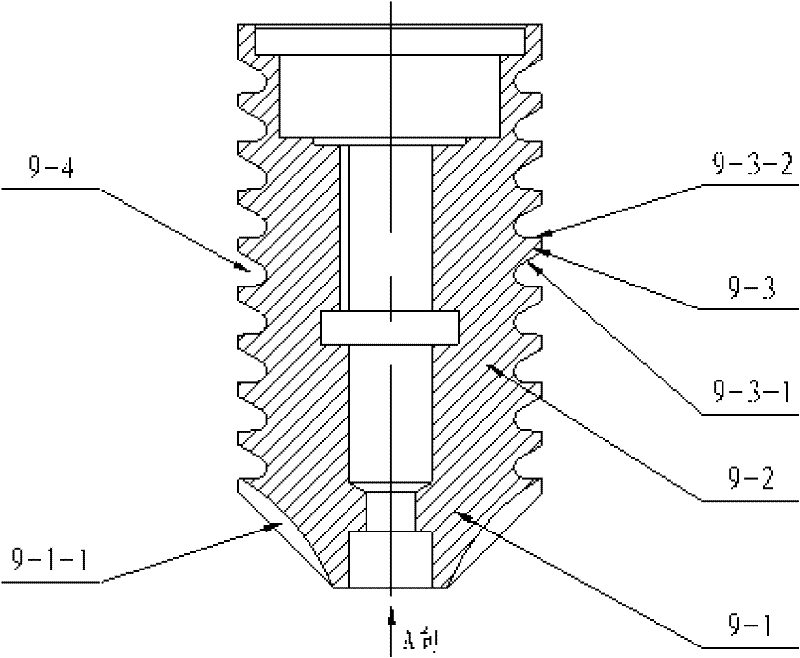

[0020] see Figure 1 ~ Figure 4 , a high-speed dynamic online mixing device suitable for large-scale mixing in the present invention includes a mixing tank 6 and a stirring mechanism sealed to it; the mixing tank 6 is provided with a feed liquid inlet and an outlet, and the stirring mechanism includes a motor 1 and a rotating shaft 7 , support 8, stirring piece 9. Its characteristics are: the connecting seat 2 is connected to the bracket 8 through the stud bolt 5, the motor 1 is fixed on the connecting seat 2, the flat key 4 is the connecting part between the motor shaft 10 and the rotating shaft 7, and the flat key 4 is a cuboid, through The screw is fixed on the key sleeve 3, and the rotating shaft 7 is further fixed with a top screw 11. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com